I want to say right away that I will not describe in detail all the repair procedures for this device, but I will give the main ones that VAZ 2107 owners quite often have to perform. I’ll start with the necessary tools that will be needed to repair and disassemble the generator on the “classic”:

- Wrench size 19 - the ring one is more convenient

- Socket heads for 8 and 10

- Extension

- Hammer

Now below I will describe in more detail the disassembly procedure, and I will also analyze the dismantling of each part separately.

Complete disassembly into parts

First, unscrew the 4 nuts that are located on the back cover of the device, and in the bottom photo they are very clearly visible:

Then we try to unscrew the pulley mounting nut with a 19mm wrench. Usually, it is very tightly tightened and it is quite problematic to do this with the generator removed, unless you clamp it in a vice. But there is a way out of the situation - you can press on the bolts from the reverse side, where we unscrewed the nuts, so that they rest against the impeller blades, thereby fixing it in a stationary state. Next, you can try to unscrew this nut, holding the generator stationary.

Now we take a hammer and, with light tapping, try to separate the generator into two parts, as is clearly demonstrated in the photo below:

As a result, it should look something like this:

As you can see for yourself, there will be a rotor on one part, and a stator (winding) on the other.

Removing the VAZ 2107 generator

First of all, you should disconnect the battery terminals. To make work easier and improve access to the generator, it is better to remove the battery from the car. The further order of work is as follows:

- disconnect the generator connector;

- remove the insulating cover from the terminal, unscrew the fastening nut using a 10mm wrench;

- disconnect the terminal;

- loosen the generator by unscrewing the nut and remove the belt;

- remove the adjusting bar by unscrewing the fastening nut;

- unscrew the lower fastening nut and remove the bushing with the bolt;

- get the generator.

Removing and Replacing the Rotor

It is very easy to remove; first we remove the pulley, removing it from the shaft:

Then remove the key:

And now you can easily remove the rotor of the VAZ 2107 generator, since it is easily released from the housing:

Now you can move on.

↑ How to assemble a generator

The misalignment of the holes in the legs of the generator covers should be no more than 0.4 mm. Therefore, during assembly it is necessary to insert a special gauge into these holes. It is a stepped cylindrical mandrel having a diameter of 12 mm on one side and 22 mm on the other.

The conical spring washer of the pulley with its convex side should be in contact with the nut. Tighten the pulley nut to a torque of 38.4–88 N·m (3.9–9.0 kgf·m).

When assembling a generator 37.3701 manufactured before 1996 (with a dismountable regulator-brush holder assembly), in order to avoid breakage of the brushes, before installing the regulator with the brush holder in place, it is necessary not to completely insert the brush holder into the regulator, but only partially push it in and insert it into the generator in this form. After installing the brush holder in place in the generator cover, lightly press the adjuster and slide it into the generator.

Removing the winding (stator)

To do this, you need to unscrew the three nuts from the inside with a head, as shown in the picture:

And after this, the stator can be removed without any problems, since it is disconnected from the diode bridge:

If it needs to be replaced and you need to remove it completely, then of course you will need to disconnect the plug with the wiring, which is visible in the top photo.

Assembling a VAZ 2107 generator

Before assembling the generator, it is necessary to clean the parts from contamination. It is better to wash metal parts with gasoline, and wash windings and other complex parts with air from a compressor.

The new bearing is pressed onto the rotor using a mandrel. You can use a head or tube with a diameter that matches the size of the inner ring of the bearing.

Before installing the rear and front covers, it is necessary to check the condition of the bearing seats. They must not be damaged or scratched.

If there are cracks in the cover, they must be replaced with new ones. Bolts and nuts of poor quality must also be replaced.

The sequence of assembling the generator corresponds to the procedure for disassembling it.

After installing and connecting the generator, it is necessary to tighten the belt with the necessary force. If it is overtightened, the bearings will fail; if it is loose, the generator will slip under load and will not produce the required charging current.

If there is a problem with the bearings or the belt is dirty

If the device slipping in the VAZ-2107 is caused by the slow rotation of the pulley, which depends on the serviceability of the bearings, it’s time to start repairing the latter. To do this, you will again need to use the instructions on how to remove the generator and how to disassemble it. If you are not confident in your abilities, you should not experiment; it is better to contact a service station.

Another possible breakdown is contamination on the belt. It is difficult to completely clean the part from dirt and dust, so experts recommend replacing the old belt with a new one.

Step-by-step video instructions on how to properly disassemble the VAZ-2107 generator are shown below:

About installing an additional diode

Installing an additional diode is quite rare. Why is this being done? In order to slightly increase the voltage of the on-board network. The need for this increase arose due to new laws. As you know, in 2015, changes were made to the traffic rules, forcing drivers to constantly drive with their running lights on. And owners of classic VAZ models are forced to constantly drive with their low beams on. In such a situation, both battery charging and on-board voltage drop significantly. To somehow solve this problem, craftsmen install additional diodes, which are located between the voltage regulator terminals and the common output wires for the additional diode, as shown in the figure below.

An additional diode is placed between the terminals of the voltage regulator (number 1) and the common wire for additional diodes (number 2)

For installation, KD202D diodes are usually used, which can be found in any radio parts store.

The KD202D diode is very popular among owners of “Sevens”

If the above diode is not available, you can choose any other one. The main thing is that the direct forward current is at least 5 amperes, and the maximum permissible reverse voltage is not lower than 20 volts.

So, in order to change the diode bridge on a VAZ 2107, you do not need to go to the nearest service center and pay a mechanic 800 rubles. Everything can be done on your own, and in a fairly short time. To remove and disassemble the generator, 20 minutes is enough for an experienced car enthusiast. It will take a beginner more time, but in the end he will cope with the task. All you need to do is follow the recommendations given above exactly.

Causes of malfunction

If the voltage generator does not work, first you need to understand the main reasons. As a rule, the need to diagnose a malfunction first arises if the device does not charge the battery or the so-called tablet does not work.

So, for what reasons the device does not work:

- Brushes. In practice, brushes are one of the main problems on a VAZ 2107 carburetor or injector engine. Brushes are essentially consumables. In fact, from time to time a malfunction in the form of worn brushes forces car owners to resort to disassembly, modification or replacement. Worn brushes will prevent you from using your car.

- The windings have burned out.

- Problems with the housing of the voltage generator on the VAZ 2107 injector or carburetor. As a rule, we are talking about mechanical damage.

- The need to modify, disassemble and replace the voltage generator on a VAZ 2107 injector or carburetor arises due to bearing wear. If the bearings squeak or make noise, they need to be replaced (video author - Avtoelektika HF).

Generator bearing and belt diagnostics

To check, the generator does not need to be removed. The test is carried out using a tester. You can use a cheap Chinese tester. The two probes of the measuring device need to be connected to the battery terminals and the voltage checked.

Analysis of voltage values makes it possible to judge the health of the generator set. What voltage the generator device produces can be found in the manual.

Signs of device malfunction:

- The charging indicator light is constantly on or flashes when the engine is running;

- the battery either does not discharge completely or receives an increased charge;

- The headlights do not shine well enough when the engine is running, poor performance of other electricity consumers;

- the headlights are too bright, the electrolyte in the battery boils;

- heats up at high voltage;

- increased noise during engine operation from the generator side.

If the brushes are less than 0.5 cm long, that is, they do not correspond to the required size, they need to be replaced. The condition of the brushes is checked to see how the brushes move in the grooves. After replacing the brushes, the generator restores its operation after a few minutes when the slip rings and brushes grind in.

The three-level regulator should be checked along with the brush holders. If the regulator is working properly, the voltage should be 14.7 V. If the voltage is less than 13 V, the regulator must be replaced with a new one, since it maintains the required voltage for devices in the on-board network.

Problems are possible not only with the cheeks, but also with the diode bridge.

Signs of a diode bridge malfunction:

- There is no charging at all;

- charging significantly exceeds the permissible values.

While the generator is running, with or without noise, it is rarely noticed. But as soon as it stops producing current, its absence is immediately noticed

The battery charging light comes on and the search for a fault begins. But it was enough to just listen to the sounds that the generator makes, and the trouble could have been avoided.

Replacing the VAZ 2114 generator bearing may be required as early as 60-80 thousand km

It all depends on how much the owner pays attention to such little things as the tension of the generator drive belt. First of all, this is what affects the resource of the generator

For prevention, let's check the degree of belt tension.

An ordinary eight-cylinder engine, which costs 2114, does not require special maintenance skills. On the tenth family, the belt is tensioned through a tension roller, but in 2114 there is none of this, and the belt itself no longer drives any mechanisms or assemblies.

Signs and causes of diode bridge failure

As mentioned above, a generator equipped with a diode bridge is the most important component of a car. If the alternator fails for some reason, the battery will stop charging. And this is the only sign of a faulty diode bridge. Without additional recharge, the battery will work for a few hours at most, after which the car will be completely immobilized. A diode bridge fails when one or more diodes burn out in it. Here are the reasons why this happens:

moisture has entered the generator. Most often, this is condensation that forms on the internal surfaces of the generator in the autumn-spring period, when relatively warm weather alternates with frosts;

The diode has simply exhausted its resource. Like any other part, the diode has its own service life

The manufacturer of 2D219B diodes claims that the service life of their products is about 10 years, but after this period no one guarantees anything to the car owner; The diode burned out due to the negligence of the car owner. This usually happens when a novice car enthusiast tries to “light” his car from another car and at the same time confuses the battery poles

After such an error, the entire diode bridge and part of the generator usually burn out.

How to find the reason for the battery not charging

The first sign of a lack of charging is the warning light on the instrument panel coming on or if the voltmeter needle is not in the green zone when the engine is running. You can more accurately check the voltage on the battery using a multimeter.

When the engine is running, the voltage on the battery should be – 13.9±0.3 V. If the battery is not charging, the voltage will be approximately 12 V.

Warning: to avoid damage to the ECU and regulator relay, do not remove the battery terminals while the engine is running.

Increased or decreased voltage of the on-board network harms the battery. In the first case, the electrolyte boils away, in the second, it is discharged, which leads to failure of the battery.

To find the problem and fix it, you will need the following tools and devices:

- control lamp 12 V;

- multimeter;

- knife;

- flat screwdriver;

- pliers;

- sandpaper.

BEARINGS

The generator on a VAZ 2114 car consists of the following main parts:

- A housing consisting of two aluminum covers (front and back);

- Stator (winding located inside the housing);

- A rotor rotating inside the stator;

- Diode bridge;

- Voltage regulator.

The armature (rotor) rotates in two bearings, which are installed: one in the front cover and one pressed onto the rotor. Both bearings are press-fit and therefore are not that easy to replace.

There are usually two main problems with a generator:

- Charging disappears;

- Noise occurs: whistling, grinding or humming.

If there is a whistling noise under the hood, a worn alternator bearing is often to blame. Due to such a malfunction, charging is not lost, but you still shouldn’t drive with noise, since as a result the generator will jam because the rotor will stop rotating.

Before changing or starting repairs, you need to buy the necessary spare parts. And before purchasing, you need to find out what bearings are on the VAZ 2114 generator. A bearing of brand 180202 (a foreign analogue of 6202-2RS) is installed on the rear of the rotor, and 180302 (an analogue of 6302-2RS) is installed on the front cover. The cost of Russian parts is low - in the range of 50-80 rubles per piece, imported spare parts are noticeably more expensive - from 200-250 rubles. Bearings are often sold as a set, that is, in pairs. Imported analogues are of much higher quality, so when choosing parts it is better to buy brand 6202-2RS and 6302-2RS.

Bearing 6302-2RS

Common battery problems:

- short circuit of battery electrodes/plates;

- mechanical or chemical damage to the battery plates;

- violation of the tightness of battery cans - cracks in the battery case as a result of impacts or improper installation;

- chemical oxidation of the battery terminals. The main causes of these malfunctions are:

- gross violations of operating rules;

- expiration of the product's service life;

- various manufacturing defects.

It is very useful for a motorist to know the main causes of generator malfunctions , how to eliminate them, as well as preventive measures to prevent breakdowns.

All generators are divided into alternating and direct current generators. Modern passenger vehicles are equipped with alternating current generators with a built-in diode bridge (rectifier). The latter is necessary to convert current into direct current, on which the vehicle's electrical consumers operate. The rectifier, as a rule, is located in the cover or housing of the generator and is integral with the latter.

All electrical appliances of the car are designed for a strictly defined operating voltage range. As a rule, operating voltages are in the range of 13.8–14.7 V. Due to the fact that the generator is “tied” with a belt to the engine crankshaft, it will work differently . It is for smoothing and regulating the output current that the relay-voltage regulator is designed, playing the role of a stabilizer and preventing both surges and dips in the operating voltage. Modern generators are equipped with built-in integrated voltage regulators, colloquially referred to as “chocolate” or “tablet”.

It is already clear that any generator is a rather complex unit, extremely important for any car.

Design and operating principle

The voltage regulator can be of several types: contact, electronic and three-level. The contact relay of the regulator can be missed, since it has not been used on VAZ cars for a long time. Today, the most popular is the electronic type voltage regulator. Its design includes a winding consisting of 1300 turns of wire. During operation, it magnetizes the metal core.

The factory resistance value for this relay is 17 ohms. If, when checking with a special device, the resistance level is lower or higher, this means that a short circuit occurs inside the relay.

The main component of the device responsible for voltage stabilization are resistors. During operation, switching occurs in them. Their device is designed in such a way as to withstand voltage drops of up to 80 Ohms.

The exception is the three-level regulator. It is installed separately from the electronic relay, instead of the generator brushes. In order to secure and connect this device to the VAZ 2107, you need to drill a small hole in the generator casing. The wires coming from the device must be inserted into this hole and connected in such a way that the three-level regulator and its control unit, located on the body ground, receive power from one source.

Three-level launch vehicle

Many may have the following question: “why is this device called “three-level”?” The answer is simple: when it operates, there are three standard operating modes: minimum (13.72 V), average (14.26 V), and maximum (14.75 V).

The three-level type differs from the electronic one in its purpose. On the VAZ 2107, there is such a problem as: during frosts, the battery does not hold a charge, and the generator does not charge it. So, in order to eliminate this problem, use a regulator of this type.

Checking the general performance of the generator with a light bulb

To carry out the procedure you will need:

- a light bulb with two wires (a small three-volt one will do; you can also use a regular 220-volt one);

- two wires approximately 50 centimeters long;

- car battery.

The electrical circuit for testing is assembled like this:

- a wire is pulled from the negative terminal of the battery and connected to the body (ground) of the generator;

- one wire from the light bulb is also connected to ground;

- the second wire is connected to the thread coming out of the generator and marked B+ on the body;

- The positive terminal of the battery is connected via a wire to a plug on the generator housing, marked with the letter D.

1 - battery, 2 - light bulb, 3 - generator

The check itself occurs as follows. After assembling the circuit, you need to start rotating the generator rotor. When rotated, it begins to generate and supply current to the light bulb, and it lights up. You can rotate it manually. However, those who doubt that manual rotation of the rotor can start the generator can do this using a drill or screwdriver.

When the light is on, it means everything is working properly. The absence of combustion indicates a malfunction, but what exactly it is cannot be said right away - further diagnostics are required.

It should be borne in mind that this method cannot check the performance of diode bridges, the absence of short circuits on the housing or in the winding. The technique only allows you to verify whether current is generated or not.

Preparing to test the relay for functionality

Checking the relay will not take much time if all the preparatory work is done correctly.

Before you begin diagnosing the device, you need to determine the purpose of the pins of the part being tested. To do this, use the documentation supplied with the device; it contains all the diagrams and operating features, and the characteristics of the device.

There are common cases when the operating diagram is depicted on the relay body itself. Contacts are represented by dots; they are connected by an inductor, the switching elements are straight lines with a dotted line. The power supply pins are shown schematically as a rectangle.

If the relay is built into the circuit, you need to visually inspect the state of the bus and power traces on the board itself. To check the relay with a tester, you can use both digital and analog instruments. No preliminary preparation or setup of testers is required.

The functionality test is carried out in several stages:

- winding;

- normally closed position;

- normally open state.

Then you can proceed directly to diagnosing the relay.

What generators can be installed on the “seven”

The design of the VAZ 2107 allows the installation of not only the G-221A generator. Therefore, if necessary, the driver can install a more efficient device, but in this case some changes will have to be made to the electrical circuit of the car. The question arises: why should a motorcyclist even change his “original” generator?

The G-221A was the optimal device for equipping cars at the beginning of mass production. However, a lot of time has passed since the 1980s, and today almost every motorist uses modern electronic devices:

- sound systems;

- navigation systems;

- additional lighting devices (tuning), etc.

Accordingly, the G-221A generator cannot cope with heavy loads, so drivers begin to look for more powerful units.

At least three more powerful units can be installed on the “seven”:

- G-222 (generator from Lada Niva);

- G-2108 (generator “eight”);

- G-2107-3701010 (Car injection model with carburetor).

It is important that the last two models do not require changes in the design of either the generator housing or its mountings. If you are installing a Niva generator, you will have to make some changes.

Video: principle of operation of the generator

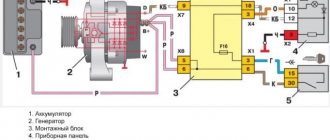

Connection diagram G-221A

As an electronic device, the generator must be used correctly. Accordingly, its connection diagram should not cause misunderstandings. It is worth noting that the “seven” drivers can easily connect all the generator terminals on their own, because the circuit is accessible and understandable to everyone.

Many car owners wonder where to connect which wire when replacing the generator. The fact is that the device has several connectors and wires, and when replacing it is easy to forget which wire goes where:

- The orange one is useless for wiring, you can leave it as is or connect it directly to the gray one to start automatically;

- a thick gray wire goes to the brushes from the voltage regulator;

- the gray thin wire goes to the relay;

- yellow wire - coordinate indicator lamp on the control panel.

Repair instructions for the unit of the seventh VAZ model

To solve the problem of overcharging, replacing a pulley, regulator or diode bridge, repairs are performed:

- First, the nut that secures the pulley itself is unscrewed; at this moment you need to hold the rotor so that it does not turn.

- The pulley must be moved to the side, the impeller is removed and the key with washers is removed. After dismantling the pulley, the regulator relay is disconnected; to do this, unscrew the fixing bolts in advance and also disconnect the block. The regulator is removed with the brush mechanism.

- After removing the regulator, unscrew the nuts securing the device cover. The cover is moved to the side, after which the sleeve is dismantled.

- Now you need to check the performance of the bearing. If you see that when you turn it, a gap appears, then change the element by unscrewing it with an 8-mm wrench. Of course, to replace it, you need to remove all the screws and fixing nuts.

- The next step will be to dismantle the rotor. As practice shows, performing this procedure without the use of auxiliary tools can be problematic. Therefore, immediately take two small bars and fix them at the edge of the back cover. Using a special drift (preferably made of soft metal), you need to knock out the rotor. If the cover is damaged during dismantling, you can try to process it using a grindstone.

- Check the rear bearing in the same way. If you need to replace the device, remove it from the rotor. It will be more convenient to use a puller for this.

- The next step will be to dismantle the diode bridge. To remove the diode bridge, it is necessary to unscrew the nuts securing the bridge block, as well as the terminals on the winding. Next, you can remove the stator mounting screws and dismantle the device. You need to carefully diagnose the integrity of the winding. If there is damage on it, for example, broken wiring or signs of burning, the winding is changed and rewound.

- Next, you need to remove another nut, after which the bridge can be removed without any problems.

- Use a screwdriver to unscrew the bolt securing the capacitor and pull out the element.

How to replace the charging relay?

- Important! First, as always, we turn off the ground, remove the negative wire from the battery terminal, then remove the yellow wire going from the generator to the relay, then use a Phillips screwdriver to unscrew it;

- Then we take it out together with the brushes:

- Now we need to carry out diagnostics. To do this, we test the voltage on the brushes with a voltmeter, and we power the relay itself from the battery, “simulating” the rectified current of the generator. At the same time, we apply (+) to terminal “B”, to the yellow wire, and connect (-) to the other terminal, “ground”. We are familiar with the signs of trouble. If you don’t have a tester, you can take a 1-3 W, 12 V light bulb.

- When installing a new relay, you need to press it firmly during installation, since new, unworn brushes provide more resistance.

If after taking these measures there is no effect, you need to look for the cause in the generator, we’ll talk about this next time. At the same time, remember that if you are removing a generator, then either you have decent knowledge in electrical engineering, or you have someone to give it to. There is no third option, especially if you have an injector.

In conclusion, let me tell you about several other reasons for the lack of charging or imitation, and also give advice:

- If you have a VAZ 2107 injector, then it is strictly not recommended to reset the battery terminal for various “checks” while the engine is running, and especially to allow strangers near the hood for this purpose. This is very harmful to electronic “brains”.

- It is advisable for those who like to “light up” to be able to say a firm “no” if you have a VAZ 2107 injector.

- On the instrument panel, the connectors are not soldered to the board, but riveted. Therefore, in some cars in the cold, while the interior is cold, there is no contact with the charging lamp. It lights up, simulating a lack of current from the generator. After the interior has warmed up, contact is restored and the lamp goes out.

- The next reason for those who like to go to the car wash in the cold. When water gets into the relay and brush assembly and freezes there, there is no charging. The solution is to heat it with any powerful hairdryer.

Sources:

https://7-vaz.ru/remont/propala-zaryadka-vaz-2107.html https://znatokvaz.ru/elektrooborudovanie/remont-generatora-vaz-2107 https://21074.ru/elektrooborudovanie/net- zarjadki-na-vaz-2107-ishhem-prichinu/ https://bumper.guru/klassicheskie-modeli-vaz/generator/remont-generatora-vaz-2107.html https://7vaz.ru/remont/zarjadka-inzhektor .html

Let's start the renovation

There may be several reasons for the battery not charging. The instructions below are quite universal and are suitable for any case.

Troubleshooting algorithm:

- First of all, we check the serviceability of the belt and its tension. If it is damaged or loose, charging will be less than normal and will ultimately lead to battery failure. The belt is also partly responsible for the operation of the cooling pump, so a damaged belt can cause other problems as well.

The problem can be determined by the sign when, when the engine is running, the voltage in the power circuit is within the normal range, but immediately after connecting the load it disappears. Another sign of a weak belt may be a whistling sound. It may appear immediately after starting the engine or when large current consumers, such as lights, are turned on.

This needs to be corrected, since a poorly tensioned belt slips during operation of the mechanism, which accelerates its wear. It must be tightened to a deflection level of 12 - 17 millimeters with a pressure of 10 kgf, or replaced with a new one;

This is interesting: How to save fuel?

- In order not to waste time and not draw false conclusions, you need to check the voltage on the battery with the engine stopped and running. The normal supply voltage of the machine when the engine is running should be 13.6 - 14.1 volts. A voltage below this will indicate a weak belt (point 1), a faulty regulator relay, or a failed diode bridge.

- If everything is fine with the belt, remove the charging relay and check the wear of the brushes. They should be longer than 5 millimeters, this can be seen visually, but to be sure, check with a ruler. If they malfunction, replace the VAZ 2022 charging relay.

You can check the relay by applying a battery voltage of up to 12 volts to it and connecting a multimeter to the brushes. There should be tension. Next, you need to apply a voltage of 16 - 18 volts to the relay. There should be nothing on the brushes;

- The next reason for low voltage is a break in one or more diodes. Revealed when removing and disassembling the generator.

It’s worse when a diode breakdown occurs, then there is no voltage drop, but this has a detrimental effect on the battery. An alternating voltage enters the machine's power circuit, which leads to boiling of the battery, destruction of the plates and a decrease in its service life.

- If the VAZ 2107 battery charging does not light up, or rather, the indicator light on the instrument panel does not light up, despite the fact that the voltage gauge shows normal voltage and despite all this there is no charging, then the problem lies in the contact at the terminals. To fix this, you need to disconnect the wire and clean it with sandpaper or a file and check the integrity of the wire from the battery to the generator.

- Another reason why the battery charge lamp does not light up at all is a break in the armature winding. It can only be determined after disassembling the generator and measuring the winding for an open circuit using a tester or a multimeter.

Below is a charging diagram for the VAZ 2107 battery: