Replacing silent blocks on a VAZ-2110 with your own hands

Over time, under the influence of loads and the influence of an aggressive external environment, they become unusable and require replacement. Let's look at how to replace silent blocks on a VAZ-2110 car on your own, without contacting a car service.

Where are the silent blocks located on the VAZ-2110

The main task of silent blocks is to soften shock loads that are transmitted to the car body from the suspension, engine or gearbox.

In a VAZ-2110 car, such hinges are installed in:

- elastic shock absorber mounting points;

- jet rod fastening elements;

- upper arms (popularly called “sabers”);

- elements of fastening of the stabilizer cross member;

- support beams for mounting the engine and gearbox;

- rear suspension rod elements.

Most often, the front suspension silent blocks and stretch bands (popularly called “daisies”) require replacement, since they experience the greatest loads here.

Signs of wear

During operation, silent compounds are exposed to reagents used on winter roads, dirt and large temperature changes. The rubber-metal hinge loses its elasticity over time, cracks and wears out.

Theoretically, the resource of silent blocks is 100,000 kilometers. However, they have to be changed (they cannot be repaired) much more often, every 50,000 kilometers.

How can you open a VAZ-2110 without a key?

Some of the signs that silent blocks need to be replaced are:

- the appearance of extraneous creaks and knocks in the area of the vehicle’s chassis;

- play of levers and wheels;

- uneven tire wear;

- loss of stability of the car on the road, difficulties in controlling it (the car seems to become “wobbly”);

- Upon visual inspection of silent blocks cleared of dirt, cracks and damage to the rubber are detected.

An indirect sign is considered to be a violation of the camber/toe of the car's wheels, if it is known that it was previously adjusted.

Polyurethane or rubber, which is better?

It is better to replace standard rubber bushings with polyurethane ones, then they will last much longer. Polyurethane hinges improve the car's behavior on the track and reduce unwanted deformations in the connections of suspension elements.

Polyurethane hinges are better than rubber ones at absorbing suspension shocks, vibrations and reducing noise when the car is moving. Their only drawback is their relatively high cost, but the increased service life of the products offsets this difference in price.

Replacing silent blocks

The general principles for replacing rubber-metal hinges are the same for all elements. First of all, they need to be freed from all fastenings. If it is possible to remove the part with the silent block, then replacing them will be much more convenient.

Then you need to press out the silent itself. This is often quite difficult to do. It is better to press out and install new silent blocks using a special squeezing device.

If there is none, then the easiest way is to cut off one of the hinge shoulders and knock out its remains with a drift. It’s time to use the old “old-fashioned” method - burn out the rubber element.

Before installation, be sure to lubricate the surface of the part with liquid soap or soap solution; you can chamfer one of the collars.

Do I need to do a wheel alignment after this?

Of course, after replacing the vehicle's engine or gearbox mounts, after repairing a non-adjustable rear axle (for example, a torsion beam), or replacing stabilizer struts, such wheel adjustment will not be necessary. But if the hinges of the front axle, adjustable steering rack or rear rack have been replaced, then such an adjustment is necessary, since previous adjustments were made taking into account the wear of the silent blocks.

What are the consequences of untimely replacement of these hinges? If these joints wear out too much, the car loses its controllability: it is pulled off the road at speed or “thrown” from side to side. This is fraught with emergency situations. Over time, the hinge seats may collapse, which will require the replacement of more expensive parts.

Polyurethane silent blocks, what is the advantage

The service life of the hinge is influenced by a number of other circumstances. For example, the rubber used in the silent block design is very badly affected by petroleum products and chemicals used to treat the road surface in winter. Temperature changes also have an extremely negative effect on the part - in the summer the rubber softens, and in the winter it begins to freeze and becomes too hard. Under conditions of severe mechanical loads, rubber begins to wear out, “age”, lose elasticity, delaminate, and fail.

Replacing lower arm joints

Replacing the lower front suspension arm on VAZ 2107 cars.

When you finish with the upper one, you can proceed to the lower one. His fastening is done a little differently. And the replacement of VAZ-2106 silent blocks is carried out without removing the suspension arm. You just need to unscrew the nut, which, by the way, needs to be replaced with a new one during assembly. And remove the washer. That's all, now use the hollow bolt of the puller to press out the hinge. The second one is extracted using the same exact technology.

Installation of new hinges is done by pressing. To do this, a silent block is inserted into the hole by hand. Then, using a stand, carefully strike with a hammer. You don’t need to hit with all your might, a sharp but weak blow is enough. But this is if there is no puller, and if there is one, then the task is simplified many times - place it on the hinge and slowly, avoiding distortions, screw in the bolt. After pressing, check that there is no gap. When finished, screw in a new nut, not forgetting the washer. That's all, the replacement of the VAZ-2106 silent blocks is completed, you can put the upper arm in place.

The silent block is an important part of the suspension, which ensures the mobility of the elements relative to each other, and also eliminates friction from metal parts. If so, it needs to be changed. On all VAZ classic models (2101, 2102, 2103, 2104, 2105, 2106 and 2107), the silent blocks of the front levers change in the same way. The procedure for replacing the silent block of the VAZ upper arm is as follows: 1. Jack up the car and remove the front wheel.2. Unscrew the nut on the axis of the upper arm (you need a 24mm wrench).

3. Using the same 24mm wrench, unscrew the nut on the upper ball joint, then use a puller to unpress the support pin (instead of a puller, you can use two 13mm wrenches to unscrew the support).

4. Tighten the steering tip nut and unpress it.

5. Unscrew the nut of the upper arm axle, and then remove the axle. On VAZ 2104, 2105 or 2107 cars, this will also require unscrewing the vertically located bolt that secures the bumper.

6. Holding the lever in a vice, press out and replace the silent blocks of the upper lever using a special tool.

7. Lubricate the axis of the upper lever, then put the lever in place. Do not tighten the axle nut completely.

8. Assemble the support in the reverse order, tighten the wheel, lower the car, and then tighten the axle nut completely. After this, you can begin replacing the silent block of the lower arm: 1. Unscrew the nuts of the lower arm axle (you need a 22mm wrench).

2. Using a puller, squeeze out the silent block

Please note that the tie rod end may need to be removed to install the puller. 3

Remove the silent block, lubricate the axle with oil, and then insert a new silent block

3. Remove the silent block, lubricate the axle with oil, and then insert a new silent block.

4

Insert a stop bracket between the arm and the nut that secures the lower arm axle to the beam. 5. Press in the silent block, then install and pin the steering ends.

6. Assembly is carried out in reverse order.

Car silent blocks require monitoring and timely replacement. The service life of the silent block is up to 100,000 km

mileage, but Russian conditions dictate their own rules, it has to be done

every 50,000 km

.

Broken silent blocks of the front suspension arms on VAZ-2110 vehicles are indicated by a characteristic knocking or grinding sound that is heard when the car is moving. The car not only begins to rattle, but also loses stability on the road and becomes more difficult to control. It happens that when a car undergoes a wheel alignment, it is discovered that the silent blocks are faulty.

It is quite possible to change the silent blocks of a VAZ 2110 with your own hands. Of course, you will have to get dirty and spend several hours of your time to repair the car. The same procedure for replacing a set of silent blocks at a service station will cost 1100-1400 rubles

. You can decide whether to take on the work yourself or entrust it to others after viewing this photo report.

It is worth noting that the photo instructions are based on the experience of car enthusiasts and contain tips for drivers with a minimum set of necessary tools. In the repair instructions you can find another solution to this problem.

How to press in a silent block at home video

The silent blocks of the front levers perform a very important function - they dampen vibrations. These parts fail quite often, because they are subject to incredible loads, and they, in turn, must withstand all deformations. How to replace them if they break?

What is the purpose of the suspension arm silent block?

These parts consist of two metal bushings (internal and external), and between them there is a rubber insert, which is most often made of polyurethane, so sometimes you can come across such a thing as a “polyurethane silent block”. It is this insert that plays the most important role. The silent block of the suspension arm connects its elements; in addition, such parts are widely used for mounting the gearbox, shock absorbers, and even the engine.

It is quite difficult to underestimate their role in the car, so it is necessary to monitor their condition. In general, manufacturers usually provide a guarantee for as much as one hundred thousand kilometers, but given the “wonderful” condition of our roads, you should not be guided by this figure; it is better to carry out a visual inspection at least after 50 thousand. Moreover, you can assess the condition of the rear silent blocks of the front control arms yourself at home.

How to check the silent blocks of the front control arms?

The rubber must not peel off or bulge from under the washers; its surface must be smooth, without cracks; large play is also unacceptable, since the result of these malfunctions may be the destruction of the hinge seats, in which case it will be necessary to replace the entire suspension arm, not individual parts. You can tell that the front lower control arm silent block has failed by the uneven wear of the tires. It is quite possible that the car will also be thrown from side to side at speed, and this already poses an immediate danger to all road users.

Replacing the rear silent block of the front lever certainly requires attention and accuracy; it would be nice to have some skills in this area. But, in principle, if there are no special problems with the mechanics, then it is quite possible to carry out the operation yourself and not contact expensive service stations. Of course, you should start by diagnosing the problem; to do this, you need to jack up both suspensions one by one and remove the wheels. If defects are found on their surface, then the next step is straight to a specialized store for new parts.

The biggest difficulty may arise with how to press the silent block into the lever, but this issue can be completely resolved.

Replacing the front arm silent block - how to do it correctly?

Now, in order, about how the replacement process goes. First of all, you need to jack up your “iron horse” and remove the wheel. Next, you need to find the bolt on the front arm that secures the front silent block and unscrew it. We also unscrew the fastening nut of the rear silent block. Now we pull the stand along with the lever towards us; Having pulled it out, unscrew the bolts securing the lever to the ball joint and dismantle it. Next, you can proceed directly to the replacement; to do this, press out the rear silent block of the front lever using a small sledgehammer.

In order to press in a new part, you can also use a special device for replacing silent blocks, however, this does not mean that you need to immediately run to the store and purchase it, since in this case a hammer or sledgehammer will again be a faithful assistant. We assemble the lever in strict reverse order. Next, we install all the dismantled elements of the car in their places, but keep in mind that the front silent block can only be tightened with the car removed from the jack. And finally, don’t forget to restore the wheel alignment.

Feet and shoes stink: what to do at home?

Withdrawal from binge drinking. How to stop binge drinking at home, what medications

Knitting a vest and jacket with knitting needles. Diagrams and description (step by step)

Volunteers. How to join the militia?

Elena in the Box (1993) watch online or download movie via

Replacing the suspension arm

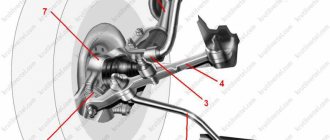

Front suspension design for VAZ 2110

Replacing the suspension arm on a VAZ 2110 is necessary when cracks, chips, wear and tear of rubber are detected. To do this, you need to place the car on a flat surface (it should have its wheels on the ground), and place shoes under the rear wheels. Loosen the bolts of the front wheels, and only now place the front of the car on supports. Remove the wheels and then the crankcase protection of your VAZ 2110.

When unscrewing the nuts holding the suspension arm, and then the ball joint, you should hold the bolts from turning on the reverse side. As you remove the washers from the guy wire, count them and mark which one comes next. When installing a new lever, they must be placed in the same order. Typically, a complete replacement of the lever is carried out if the hinges are damaged. Before tightening all connections, it is better to lower the VAZ 2110 to the ground.

https://youtube.com/watch?v=5oZihfXdmRE

Hi all! It's time for me to replace the front control arm bushings. When I was about to do this, I was sweating just at the thought. They are HEALTHY! How to press them in. It was decided this way: if there is a strong problem, then I will take the beam to a service station and let them press it there. Got it. To remove the beam, I placed the car in a pit. I unscrewed the nuts from the levers (using a two-meter pipe and “some kind of mother”) and all the fastenings to the body. Stripped off.

Set of tools: - sharp knife; - hammer; - Silicone Grease; — soap (without rope); - a 12 pin, about 20 cm long, with nuts; - two wrenches; — corner No. 45 with a hole along the hairpin; — front washer from the same silent; - two-inch coupling (or a piece of suitable pipe).

Pressing out old rubber bands We secure the beam in a good vice.

After thoroughly spraying with silicone, we cut off the extra “ears” from the silent tape. Without silicone it is very difficult to cut rubber, there is a lot of friction.

Having cut off the “ears,” we protrude the rubber from the metal and spray more silicone there. After that, with a couple of blows of the hammer, everything pops out with a whistle.

Installing a new silent Installation requires: a stud, nuts, an angle and a washer. We smear everything that rubs with soaked soap.

Tighten the nuts on the stud. The silent begins to sink into the beam.

Let's stop here for a moment. When twisting, the silent every now and then tries to slide away from the axis of the hole to the side. The rubber band starts to go in on one side, but the other doesn’t go in at all. It's warped, in short. The corner helped a lot here (see photo). When a distortion is detected (in the initial phase), press the corner in the direction opposite to the distortion. Editing rules

So the whole skirt went into the beam.

The corner is already in the way for further pressing. We disassemble the entire coupler and insert the coupling like this:

Let's move on. Result:

There you go! One silencer takes 15-20 minutes with a smoke break.

How to recognize steering rack faults

Any mechanism does not last forever, including this part. Most often, a malfunction of the steering rack is indicated by a knock that can be heard when turning. But there are other signs. To accurately determine the cause of the knocking noise, which lies in the steering rack, you must:

- take the steering shaft with your hand where it connects to the rack and move it up and down (if there is a knock, then the steering rack needle bearing in the steering rack needs to be replaced or simply lubricated);

- hold the joint of the steering rods with your hand and check the play of the bushing, as well as the steering gear.

Often the cause of knocking is poor adjustment of the fasteners and then nothing, everything works without dismantling. But if knocking is still observed in the rack itself, then you need to do the following:

- purchase a new steering rack;

- restore it to a service station;

- carry out independent repairs.

Attention: All three options have their advantages, but the most profitable from an economic point of view is, of course, the third method. It will allow you not to spend money on expensive parts and auto mechanic services. But this method will require certain initial knowledge about the mechanisms of the car, dexterity and patience.

Preparation for work on replacing silent blocks

Rear suspension of the VAZ 2110 do-it-yourself tuning and repair (photo)

To press in new silent blocks you will need a special puller.

Before you begin the process of replacing suspension parts with your own hands, you need to prepare a place and a set of tools. A garage with a spacious inspection pit is ideal as a place. As for tools, to replace you will need:

- Set of wrenches and sockets with ratchet.

- Special puller for pressing out silent blocks. You can either buy this specific tool or ask your garage mechanic friends to borrow it while you work.

- VD-40 or analogues.

- Soap solution.

The necessary puller is quite easy to make from a pipe of a suitable size, a long bolt and a washer.

If you cannot get a puller, you can use available equipment. This can be done by a tube of suitable diameter with washers and a vice.

Replacement process

If replacing rubber suspension parts is new to the car owner, it may immediately seem like a very time-consuming and complicated procedure. Often, at the inspection stage, inexperienced VAZ-2110 owners decide that they won’t be able to do anything on their own. In fact, the replacement process is quite simple. If you do this once, changing any silent blocks in the future will be easy and simple.

The only problem may be pressing the new silent block into place, since the new parts may be poorly processed or too rigid. This is especially true for parts made of polyurethane.

Rubber silent block.

Polyurethane silent blocks.

Replacement occurs according to the following algorithm:

- First you need to raise the front wheel using a jack.

It is advisable to use a hydraulic jack, and place wheel chocks under the rear wheels on both sides. It is advisable to duplicate the jack with a support. This way the car will definitely not jump off and crush its owner. We remove the wheel. - Next you need to unscrew and remove the wheel.

- At this moment, you can also check the silent blocks that are located in the levers. If they are loose, then you need to replace them too.

- The front support is knocked out.

Before doing this, unscrew the nut that holds it in place. The blow should be accurate, but not strong. Unscrew the saber nut. - After this, you can remove the upper arm.

To do this you need to unscrew the bolt. Having removed the saber, we get free access to the silent block itself. - After these procedures, you can knock out the silent blocks themselves.

A chisel and hammer are used for this. As a rule, they come out easily, but in rare cases you need to use WD-40. It will be easier to knock out the parts if you trim them. - Now you need to install the new part.

To do this you will need a pressing tool. In order for this process to go smoothly, it is recommended to clean the socket from rust and lubricate it and the part with a soapy solution. Before pressing, generously lubricate the parts with soapy water.

Examination

The main thing is not to confuse which side you need to press in the silent block!

After the work is completed, there should be no play, otherwise the suspension will cause many problems in the future. Then everything is put together in reverse order.

The process of replacing silent blocks yourself can be mastered within a few hours. In the future, this will save the VAZ-2110 owner a lot of money.

Choosing which ones to buy

It is impossible to say unequivocally which front struts are best to choose for the VAZ 2110. Some choose factory ones because they are not rigid enough for them, others prefer analogues for their softer and more comfortable behavior.

Some people even want to install a sports version of the struts on their “top ten”, since they are the stiffest and the springs are the thickest.

Sports

Focus on what you want to get out of driving. But from the point of view of manufacturers, Samara CC20 devices have proven themselves to be excellent. If necessary, you can figure out how to pump up such racks.

The choice is between oil and gas (gas-oil, actually). The former are more affordable from a financial point of view, but they do not have such a wide temperature range, which is why the shock absorbers become stiffer in winter.

Gas analogues have a more complex design, a high price, but an excellent “tenacity” indicator.

Among the manufacturers, in addition to CC20, the following manufacturing companies can be distinguished:

- KONI

- Sachs

- Kayaba

- Monroe

- Brillstein.

All of them have approximately the same devices, so there should be no problems with selecting suitable parts.

Reasons for replacement and self-installation of VAZ 2110 silent blocks

Experienced car owners, of course, know that it is the silent blocks on the VAZ 2110 that affect the wheel alignment angles. And for new car enthusiasts, this may be news, but it encourages the idea that the condition of these parts needs to be monitored.

Set of silent blocks and bushings. Article 17-21-004

When should you change?

Usually, the driver will probably guess that the silent block has failed. If a replacement is needed, discomfort while driving will tell you about it. You can feel distinct “iron” impacts and noises in the suspension. But that's not all.

If urgent measures are not taken, the VAZ 2110’s fastenings and connections will break and play will appear. The wheel alignment angles will also suffer, which obviously will not lead to any good.

Worn silent block

There are some symptoms to look out for that these rubber parts are worn out:

- When driving, the tires on the wheels squeak. Not necessarily much. There shouldn't even be a slight squeak;

- A knocking sound is heard in the wheel area. The point here is the poor rotation of the collapsing silent blocks;

- As the silent block wears out, it first becomes covered with cracks and then completely falls apart. Here only the deaf can no longer hear the knocks.

You can find out the overall and geometric dimensions of the VAZ 2110 body in this material: https://vazweb.ru/desyatka/kuzov/geometricheskie-razmery-kuzova.html

DIY replacement

Even in an ordinary garage, high-quality replacement of silent blocks is possible. To do this, you only need to have a puller, which you can make yourself, having a simple drawing. Or you can borrow it from your motorist friends.

Silent block remover

Such a device will become an assistant when removing and then further installing new silent blocks. It consists of two tubes and washers. The length of the puller legs is about 20 cm.

Some, having adapted, make do with a mandrel.

Front suspension

For the front suspension, silent blocks are provided: front beam, upper, lower arm.

Replacement for parts of the front upper arm of the VAZ 2110 occurs as follows:

- You need to jack up and secure the car;

- Remove the front wheel;

- Unscrew and knock out the support. To do this, hit the bipod with a hammer, turning the wheel out;

- Once the support is knocked out, it becomes possible to remove the upper front control arm. To do this, unscrew a long bolt from the side. At the same time they look at the axial play. If it is palpable, replacement may be warranted;

- Removing the silent tape is quite simple using a chisel and a hammer. The main thing is to accurately calculate the impact in order to avoid damage to other parts. Sometimes very “stubborn” silent blocks have to be drilled out and only then knocked out;

- You can press in a new silent block by pressing it into the socket using a smaller bushing until it sits securely there.

Replacing the silent blocks of the front lower control arms of a VAZ 2110 is a more difficult task; to complete it, you will need:

- Remove the stabilizer so that the lever can be moved;

- Unscrew the nuts holding the silents;

- Remove the rubber bushings (same as in the case of the upper arm);

- Press in new ones, and then be sure to fix them in the loaded state of the VAZ 2110.

You can read more about the front beam malfunctions in this material: https://vazweb.ru/desyatka/podveska/perednyaya-balka.html

Tools, accessories, consumables, pro tips

The work itself of replacing silent blocks is not difficult, but special tools may be needed to press out the hinges.

In total for work you will need:

- actually, new silent blocks

- spanners and open-end wrenches of the required size (heads and ratchet)

- puller for silent block

- lubricant (soap solution)

- jack

- vice

- hammer, small chisel.

The hinge fits very tightly into place, and to dismantle it, most likely, you will need a special puller. A necessary condition for high-quality replacement of hinges is their correct selection. Before you go to the store, you need to find out which silent blocks are most often installed on the BA2110, their serial number, size parameters, etc. Let us repeat, the hinge fits very tightly, and a discrepancy in size of just a few millimeters will result in the new silent block simply not being pressed in.

For this work, special pullers are used, with the help of which it is easy to remove the old part and press in the new one. Sometimes it happens that to replace the silent block you have to remove a suspension element, for example, a lever. In this case, the puller can be successfully replaced with a conventional bench vice. True, in this case it will be quite difficult to remove the silent block. Then you can simply burn it out with a blowtorch or over an open fire. Sometimes craftsmen cope with it using a sledgehammer and a metal punch.

Before installing a new part in place, it must be lubricated with soap or a soap solution. This will make installation very easy. You cannot use lubricants made from petroleum products - grease, litom, oil, etc., as they have a negative effect on the rubber. This does not apply to polyurethane hinges, which are practically unaffected by petroleum products. To make installation even easier, a small chamfer can be removed from the rubber surface of the part from the end. The main thing is not to overdo it and not to cut off too much.

Why do the rear beam silent blocks fail?

During operation, the rubber part peels off from the metal bushing.

The rubber of the parts itself, which is cast with metal bushings, must withstand enormous loads, but time destroys the rubber.

In addition, if the parts are installed skewed, or the quality of the ohms turns out to be low, which often happens, then the silent blocks can quickly fail. In addition, the following factors affect the durability of parts:

- The main factor that affects the service life of obviously high-quality silent blocks is driving style. If you do not pay attention to holes and other irregularities, then they will be the first to suffer in the suspension.

- Wheel alignment also affects the life of the hinges. If this is not done periodically, the wheel alignment angles will change, which will lead to incorrect operation of the suspension.

- Rubber is not very durable, especially if oil and other technical liquids get on its surface. In these cases, the surface of the silent compounds becomes covered with cracks, which can lead to ruptures.

In order to avoid problems and expensive suspension repairs, it is recommended to inspect the condition of the silent blocks at least once every six months. This will help to identify and eliminate problems in a timely manner.

What to consider when replacing

The silent blocks of the VAZ-2108 and VAZ-2110 visually seem exactly the same, but in fact their mounting dimensions are different.

There are several secrets and recommendations, taking into account which you can achieve more durable operation of the rear suspension hinges:

- You should not try to install silent blocks from the “nine” on a VAZ-2110. Although they are almost identical in appearance, the “nine” spare part is a couple of millimeters smaller. Therefore, setting this element to “ten” is unacceptable. But the opposite can be done by applying a little more effort when pressing.

- Scheduled replacement of rubber suspension joints should be carried out no less than after 40–50,000 km.

- If one silent block fails, it is better to change the others that are located next to it. This will save the owner from repeated repairs, the need for which may arise after several thousand km.

High-quality repair of the rear suspension on a VAZ-2110 depends on the skills of the car owner. At the same time, it is quite simple. It is enough to do it yourself once to acquire the necessary skills. In order for everything to work out right the first time, it is recommended to involve more experienced colleagues in the work for the first time.

Repairing the suspension yourself, or contacting a specialized service station is everyone’s personal choice. If you decide to entrust the work to specialists, it is better to control the entire process yourself, so that next time you can do everything yourself.

Selecting New Items

To replace and ensure reliable operation of the car, you need to purchase excellent silent blocks. It’s easy to choose them if you know certain aspects:

- For the VAZ 2110 model, elements with catalog number 2110 2914054 are suitable. They have the required external diameter corresponding to this specific VAZ model;

- Do not try to purchase a silent block from a 9 and install it on your 10. Nothing will come of similar events, no matter what anyone says;

- Make sure of the quality of the products. Low-grade silent blocks have flooded the market, but their service life leaves much to be desired. Excellent parts made from quality materials that can withstand extreme loads and temperatures.

How to replace the silent blocks of the lower control arms on a VAZ 2110 (2112) with your own hands?

For the softness and comfort of driving a car, not only properly inflated wheels or comfortable seats are responsible, the serviceability of the suspension is important, the parts of which must work as a single whole. A disruption in the operation of at least one of the above components will entail a general imbalance and disruption of ride comfort as a whole. One of the most important elements of a car’s suspension is rubber and rubber-metal seals, they are called silent blocks. Thanks to these seemingly inconspicuous and unnecessary rubber or polyurethane rollers, the suspension parts are connected. While the connection is rigid, softness between the parts is maintained, which allows the motorist to drive quietly and comfortably, “without knocking or rattling iron.”

On the pages of VAZ Repair we have already talked about how to replace silent blocks in the article: Replacing silent blocks on a VAZ 2109, this time you will learn how to replace silent blocks on lower control arms on a VAZ 2110 at home.

A few words about the signs of silent block failure If you notice:

- Creaking of rubber when driving over uneven surfaces;

- Knocking while driving over uneven surfaces;

- Backlash in connections when checking the chassis;

- Deterioration or cracks in silent blocks;

- Uneven tire wear disrupts wheel alignment.

It is necessary to take immediate action and replace faulty silent blocks.

To work you will need:

New lower control arm silent blocks - rubber or polyurethane; Set of keys, hammer; Soap solution; Liquid WD-40; Lift or inspection hole;

Axial play, what is it and how to eliminate it

This is a fairly common “disease” of the lower arm of domestic cars, and the VAZ 2110 is no exception. Backlash occurs when the bracket on the body to which the lever is attached has loosened for some reason, and a gap has appeared between the lever and the bushing, which is why the silent block begins to move inside the lever.

Axial play has a very negative effect on the operation of the front suspension, so, of course, it should not exist. If there is a backlash, it can be eliminated in several ways. First, you can try to slightly compress the bracket on the body. It will be very difficult to do this, because it is undesirable to hit the body with a hammer, and in order to use pliers or a clamp, you will need a fair amount of physical strength, and it will be inconvenient to work under the car with these tools.

It is much easier to eliminate axial play by placing several washers between the bracket and the silent block. Although according to the rules it is necessary to replace the entire lower arm along with the silent block.

Replacing silent blocks "tens"

The replacement of VAZ 2110 silent blocks can be entrusted to specialists by contacting a car maintenance station. Or replace it yourself. In order to assess your strengths and capabilities, it is recommended to read this article to the end and watch video reports on replacing silent blocks on a VAZ 2110. The videos can be easily found on specialized websites on the Internet.

Let's consider the steps of replacing silent blocks of the front suspension with your own hands. It is better to entrust the replacement of silent blocks on a VAZ 2110 in the rear beam to car repair specialists. It is very difficult to carry out a high-quality replacement on your own. To replace the front silent blocks of a VAZ 2110 you will need the following tools and accessories:

- socket and ring wrenches for 17, 19 and 24;

- hammer;

- vice;

- device for pressing silent blocks;

- chisel;

- metal brush;

- WD-40 product.

The front suspension of the VAZ 2110 uses:

- Rear front lever silent block – 2 pcs.;

- silent blocks for fastening the guy wires – 4 pcs.

The latter consist of two parts: internal and external. It is better to replace the silent blocks of the VAZ 2110 in an inspection pit or overpass. It's more convenient and safer.

To make it easier to remove the lever when replacing silent blocks, it is necessary to remove the mudguard. If the engine compartment is protected, then remove the engine protection. To make it easier to unscrew threaded connections, you should first spray them with WD-40. If it is not available, you can use regular brake fluid. Generously lubricate the mounting points of the bolts and nuts and wait a few minutes. The liquid will eat away the rust and help prevent the threads on the bolts from being stripped.

Let's consider the procedure for replacing the front silent blocks of a VAZ 2110:

- Unscrew the ball joint. Separate it with the lever.

- Unscrew the nut that holds the extension.

- Using two 17mm wrenches, unscrew the bolt securing the stabilizer link.

- Carefully knock out the fastening bolt. It is better to do this with a soft metal hammer or, using a wooden spacer, knock it out with a regular hammer.

- We release the mounting of the lever on the body. To do this, you need a key for 19.

- We take out the fastening bolt. If he doesn't go, you should knock him out.

- For convenience, it is recommended to remove the lever along with the stretcher. To do this, unscrew the crab that attaches the guy to the car body.

- The lever is removed, we proceed to replacing the silent blocks. First we change the silent blocks of the extension. We dismantle them using a chisel, knocking them off the lever. We clean the place where the silent block is attached from rust. Using a vice, we press in new silent blocks one by one on each side. Using a vice it is not always possible to completely seat the silent block. You can “finish off” it with 2-3 precise blows of a hammer or sledgehammer.

- The next step is to replace the rear silent block of the front lever. If it is broken, then removing it will not be difficult. It is enough to pull out the metal sleeve and remove the rubber with a screwdriver or chisel. Otherwise, you will have to use a device for pressing out silent blocks. If it is not there, then you can use the old-fashioned method and burn out the rubber using fire. Then clean the eyes from dirt and rust. It is better to press silent blocks using a special device. Before doing this, you should generously moisten the silent block and the eyelet with soapy water. This will make the pressing process easier.

- After replacing all the silent blocks, we assemble the front suspension parts in the reverse order. Full tightening of threaded connections should only be carried out with the vehicle mounted on the wheels.

When purchasing silent blocks, you should pay attention to the manufacturer. It is recommended to use two brands. These are “Balakovo” and “SEVI”

The price of these spare parts is practically the same. The quality of these silent blocks is quite high

These are "Balakovo" and "SEVI". The price of these spare parts is practically the same. The quality of these silent blocks is quite high.

The process of replacing silent blocks is not easy. The cost of this service is quite high, but by following the instructions exactly, you can replace the silent blocks yourself and save a lot of money.

Disassembly

Using the example of the Opel Zafia B, a method for replacing the silent blocks of the rear beam without completely removing the beam will be described.

Loosen the nut securing the silent block to the bracket. Unscrew the nuts securing the bracket to the car body. Remove the fastening bolt and the silent itself. Don't forget to mark where the silent block was located relative to the bracket! Operations No. 1-3 should be performed on the second side as well. Raise the rear of the car with a jack and secure it on stands. The beam should lower slightly, after which you will have room to press out. Assemble the puller as shown in the photo and video. The essence of pressing out is to create the necessary force by holding the bolt on one side and tightening the nut on the other side to remove the silent block from the seat. In the video, the master drills the outer ring of the rubber damper, thereby weakening the internal tension

But note that the outer ring has a thickening that allows you to carefully drill a hole. In the case of most products, you will not be able to do this trick.

Pressing and assembly

Clean the seat in the beam thoroughly. It is best to use a metal drill brush, but a regular brush with metal fibers will also work. Before pressing, generously lubricate the seat with engine oil or other grease. Since the rubber damper is in a metal frame, technical fluids will not harm it and will not affect its service life in any way. On the pressing side, we recommend removing a small chamfer on the outer ring - this way the part will fit better into the mounting hole.

The same puller is suitable for pressing. As a mandrel for pressing, you can use the clip from under the old silent block. If you do not have suitable mandrels, then you can cut a square 3-4 mm thick as a stop. In this case, at the end of pressing, the rubber damper will rest against the thrust plate. To press the part flush, you will need to put something under the plate.

If necessary, the alignment can be corrected by carefully hitting the mandrel from the protruding side with a hammer.

When installing the bracket to lift and guide the beam, you will need to guide the beam into position manually or using a jack. It may be enough to lower the body. In any case, you need to navigate the place and the current situation. Initially, all the bolts and nuts only need to be tightened, then the bracket mounting bolts must be tightened. After which you can lower the car onto the wheels and tighten the bolt securing the silent block

The bolt should only tighten when the car is standing under its own weight on the ground - this is very important!

Replacing silent blocks with complete removal of the beam

Below in the video you can see the process of replacing silent blocks with complete removal of the rear beam. The disadvantage of this method is that you need to disconnect the brake hose, since its length is not enough to completely lower the beam. Of course, after replacement, you will need to refill the brake fluid and bleed the brakes, which is quite difficult to do alone.