Hello, dear visitors, site VAZ2110-REMONT.RU. This time we will show you and tell you how to tighten the rack on a VAZ 2110. Why do you need to tighten it? It's all because of our roads. In general, a steering rack should last 14-15 years, but as we all know, with our operating conditions, the service life of the rack is reduced by five. So, common malfunctions of the VAZ 2110 steering rack are play and knocking in the steering rack. In order to avoid wasting money immediately when problems occur, rebuild the steering rack or replace it altogether. You can first try to adjust, or rather tighten.

Read more How to tighten the rack of a VAZ 2110? →

I think everyone understands that with roads like ours, the chassis often requires repairs. Quite often after winter, when the snow has melted and the holes are not yet visible due to puddles, shock absorbers and support bearings often get damaged. Because of such situations, it is necessary to repair this component of the VAZ 2110 chassis. It is better to carry out repairs in a timely manner, since in the first stages it will result in you spending less money than if you cause a breakdown and it will lead to a more disastrous result.

This article will provide information so that you can replace the VAZ 2110 support bearings with your own hands. Moreover, we will do this in such a way that we do not have to adjust the wheel alignment. That is, we will not touch the camber bolts. Continue reading Replacing the support bearing →

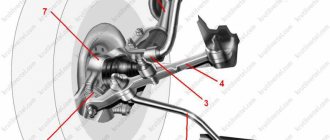

In this publication I want to tell you how to replace the anti-roll bar. And how to replace its parts. You can easily carry out this type of repair in the garage with your own hands. Stabilizer mounts 4: in two places it is attached to the car body and two more are where its struts are attached to the lever

Well, let's begin:

Let's immediately take care of the attachment points with the lever. Unscrew the nuts.

The first thing I immediately want to write about is that do not delay repairing the ball joint! There were situations when the front wheel lay completely on the road while the car was moving due to wear on the ball. I think there is no need to describe what will happen to the car if this happens at high speed. In addition, from the article you will learn how to replace the ball joint on a VAZ 2110 with your own hands, thereby saving money.

Such a car part as the steering tip is classified as a car chassis. And naturally, like other parts of the VAZ chassis, it often fails on our roads. This type of repair, like replacing ball joints, is quite common on the VAZ 2110. It is difficult to detect a breakage of the steering tip in a timely manner. Basically, everyone notices a problem when problems such as a knocking sound in the front end, the car does not listen well to the steering wheel and the steering becomes loose.

If you are not sure that the cause of the problem lies precisely in the steering tips, then lift the wheel with a jack and shake it in different directions. If it's a worn tip, you'll notice free play and play. To replace steering tips on a VAZ 2110, you don’t need a lot of tools and skills. For convenience, here is a list of the tools you will need: Continue reading Replacing tie rod ends →

Every motorist understands how important the front suspension of the VAZ 2110 plays. But this unit may have certain problems, characteristic malfunctions, which almost everyone who has more or less little experience in car repair can know and fix. Therefore, today we will talk specifically about the front suspension of the “tens”.

Removing and installing the lever and extension VAZ 2110, VAZ 2111, VAZ 2112

front suspension, service manual

We remove the lever from the VAZ 2112 car to replace the silent blocks of the lever and the extension or the lever itself. We remove the extension to replace its silent blocks or when completely disassembling the front suspension.

We carry out the work on an inspection ditch or a lift.

Remove the engine mudguard (see Removing the engine mudguard for a VAZ 2111).

Remove the ball joint or disconnect it from the lever (see Removing the ball joint).

Holding the extension with a 24mm spanner, use a spanner of the same size to unscrew the extension nut.

Using two 17mm wrenches, unscrew the nut of the bolt securing the stabilizer bar of the VAZ 2112 to the lever.

Use a soft metal drift to knock out and remove the bolt.

Using two 19mm wrenches, unscrew the nut of the bolt securing the lever to the body of the VAZ 2110.

We remove (or knock out) the bolt and remove the lever from the bracket.

Remove the washer and lever from the stretcher.

On the stretcher behind the large washer there are washers for adjusting the pitch angle of the VAZ 2111 turning axis (in our case there are three of them).

To remove the brace from the cross member of the front suspension of the VAZ 2110, use two 24mm wrenches to unscrew the nut...

...remove the washer and remove the extension from the silent block of the VAZ 2112.

At the front end of the stretcher, washers for adjusting the angle of the longitudinal inclination of the steering axis can also be installed (in our case there are two of them).

To replace the silent block of the VAZ 2110 lever, press it out in a vice with suitable pipe sections.

We wet the new silent block with soapy water and press it into the lever.

We knock down the silent block of the extension with a chisel.

Having removed one, we similarly dismantle the second.

We pre-press the new silent block in a vice...

...and finally press it, striking a punch with a diameter of 8 mm through three windows in the rubber layer.

We carry out the assembly in the reverse order, and tighten the threaded connections of all rubber-to-metal hinges in the “vehicle on wheels” position.

Front suspension of VAZ 2110, VAZ 2111, VAZ 2112

- – Front suspension design

- – Wheel alignment angles

- - Spherical bearing

- – Lever and suspension extension

- – Disassembly and assembly of the rack

- – Anti-roll bar

- – Silent crossbar blocks

- – Front suspension cross member

- – Replacing the wheel bearing

Chassis components of VAZ 2110, VAZ 2111, VAZ 2112

Maintenance and repair of the running gear of the fret 2111. Operating instructions for the running gear components of the fret 2110. Checking the rear and front suspension of the fret 2112.

The duration of repair of the VAZ 2110 chassis is affected by the volume of work performed. On average, repairs to a VAZ 2110 chassis are carried out within a day. In the event of a critical condition of the chassis, as well as the need to perform welding and plumbing work, repairs may take two days.

However, before this, our Moscow car services provide free suspension diagnostics. After its completion, a list of urgent and optional work is compiled.

The main causes of malfunctions are also stated and the price of spare parts that will be used during the repair of the VAZ 2110 chassis is indicated. They can be ordered at an affordable price at the car service warehouse.

| Types of work on the chassis: | Price |

| Replacing the lever | from 1200 rub. |

| Replacing the shock absorber | from 800 rub. |

| Spring replacement | from 800 rub. |

| Replacing the ball joint | from 850 rub. |

| Replacing the silent block of the lever | from 250 rub. |

| Replacing the steering tip | from 550 rub. |

| Replacing the steering rod | from 750 rub. |

| CV joint replacement | from 1300 rub. |

| Replacing stabilizer struts | from 600 rub. |

| Replacing stabilizer bushings | from 400 rub. |

| Replacing the subframe | from 4000 rub. |

| Chassis diagnostics | for free |

When restoring a running VAZ 2110, it is recommended to combine mandatory and additional work. This will reduce the cost of repairs. For example, when urgently replacing the front springs, the support bearings are also changed. Thus, the client saves on costs for separate replacement of support bearings

How to upgrade wipers

In most cases, the windshield cleaning area will be improved. In principle, there is nothing complicated here. But first you can change the wipers if they do not cope with their function

It is worth drawing your attention to the fact that from the driver's side the visibility should be 100%, especially on the left. Dirt appears right on the left pillar side, which the wipers cannot cope with.

One of the outputs is to adjust the position of the device. In our case, it is necessary to slightly raise the driver's wiper, that is, change its initial position. But not everyone will like this method, and the result is not 100%, since some of the dirt still remains. In this case, a slightly different modification to the VAZ-2110 wipers will be required.

Sometimes the cause is a windshield that does not allow the glass to be cleaned evenly. In this case, for a more noticeable result, you need to bend the frill leash. You can direct the hook under the brush; near it we need to bend the leash a little. There's already a factory bend there that we need to make a little bigger. In addition, you need to bend the end of the wiper spoiler slightly upward. This is done so that it does not catch the brush. After this, it is advisable to check if everything worked out for you. That, perhaps, is all that needs to be done on the VAZ-2110. Modifications to the wipers, of course, are different, but they are done quite quickly and simply, so you will succeed

Now let’s move on to something no less important – the car’s heater, which warms us up in the cold. There is a lot you can do here, but let's talk about the most important thing.

View gallery

A little about the generator and its improvement

The battery must be recharged while the vehicle is moving. At this time, all devices are powered by a generator. The voltage should be within 14 Volts. So, if you have too many electrical appliances and the voltage drops to about 11-12 Volts, then there is one way on how you can increase the power of the device by about 10%. Such a modification of the VAZ-2110 generator involves the installation of one diode. First of all, we need to disconnect the battery terminal, and then disconnect the wire marked “D”. Next, you need to remove the clamps from the back cover of the generator. After that you will see the voltage regulator. We need to thread the wires from the pre-prepared diode through the holes in the generator cover.

View gallery

After this we connect the wires. To do this, the “mother” is connected to the PH, and the “father” is connected to the standard wire. After that, we need to close the back cover and screw everything into place. This completes the modification of the VAZ-2110 generator. The voltage should rise to approximately 13 Volts, which is closer to normal. By the way, it is advisable to use a diode with a breakdown of no more than 20 V and a current of 5 Amps. As for the voltage drop, it should be within 0.6-0.7 Volts.

VAZ 2110 suspension repair

The simple, understandable and reliable suspension 2110 does not require any special or costly measures for maintenance and repair. Chassis repair involves, first of all, eliminating the consequences of driving on our less than ideal road surfaces. In this regard, the top ten also compares favorably with more recent and much more expensive foreign cars in the budget segment. If you have a lift or, in extreme cases, an inspection hole, any part of the front suspension can be easily replaced or repaired with your own hands using basic tools. There are some peculiarities in the repair of front struts, support bearings and stabilizer bars, but they are present in every car.

Steering rack repair requires special attention. Its dismantling is simple, but the reassembly process itself can cause some difficulties, since there is a need for some pullers and calibrated samples. But it is enough to disassemble it yourself once, and in the future its maintenance will not cause problems. When repairing a steering rack, it is imperative to use the correct repair kits. And full. They can be sold either as a simple set of seals and a bushing, or as a complete repair kit with a bearing, corrugations, the same bushings and seals, as well as retaining rings. Considering that you will have to spend a good half day replacing a repair kit, it is better to replace the complete set.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at

Main nodes

Let's talk about its device. The most important element of the front suspension is its strut (hydraulic telescopic) - indispensable in the matter of shock absorption, that is, ensuring a comfortable ride, without much shaking (as far as possible) over bumps and potholes on our roads. It is thanks to the rack, or rather its steering knuckle with an upper bolt equipped with an eccentric washer and a belt, that makes it possible to change the camber of the wheel.

Telescopic strut of the front suspension of VAZ 2110

The following are installed on the rack:

- Special spring;

- Buffer limiting the compression stroke, made of polyurethane;

- Upper support. Its structure is as follows: it is attached to a stand, to which the mudguard is attached with self-locking nuts. Therefore, if you make repairs yourself, do not miss this moment - you cannot use ordinary nuts;

- A bearing that makes it possible to rotate the stand together with the wheels;

- A shock absorber in which a spring and a plunger are installed for better performance.

The ball joint combines the lower parts: the steering knuckle and the lever. The longitudinal braces, lower arms, and supports that the crossbar has are connected to each other by rubber-metal hinges. With the help of special washers, it becomes possible to adjust the longitudinal inclination of the turning axis. An angular contact, non-adjustable bearing secures the wheel hubs.

Ball joint VAZ 2110

The cross member is the rod to which the lower arms are connected. It is attached to the body in the middle, helped by rubber cushions. This, in a nutshell, is the front suspension design. Now let’s look at possible malfunctions, which in some cases can be fixed with your own hands, in others it is better to contact specialists.

Cross member VAZ 2110

Replacing stabilizer struts

If there are loud knocking sounds in the front suspension, and dull knocks are heard when turning, then perhaps it’s time to change the bushings and stabilizer links. On a VAZ 2110 you can replace it yourself. Before repairs, you should diagnose the malfunction of the stabilizer struts.

A VAZ 2110 car is lifted from the front. Wheels must be hung freely. Climb under the car and pull the stabilizer itself with your hand. If there is play and a knock is heard, then the bushings and stabilizer struts need to be replaced.

Replacing stabilizer struts on a VAZ 2110 yourself is a simple repair of the front suspension, but it should be carried out with full responsibility. To replace the stabilizer struts on a VAZ 2110, the car is driven onto an inspection pit or overpass. Before carrying out repairs, the vehicle is set to the parking brake. It is necessary to install stops under the rear wheels to prevent the vehicle from accidentally rolling away.

To carry out repairs, the following is required:

- a set of keys;

- hammer and spacer made of soft metal;

- WD-40 penetrating fluid (ordinary brake fluid is suitable as an alternative);

- metal brush.

Work order:

1. Clean all threaded connections with a wire brush. Spray them with WD-40 or wet them with brake fluid. This will help loosen the nuts and bolts. After waiting a few minutes, he begins to dismantle the anti-roll bar. 2. Using two 17mm wrenches, unscrew the fastening of the “ten” stabilizer strut on the lower arm. Carefully knock out the fastening bolt using a hammer and a soft spacer. It serves to protect the threads on the bolt. If a bolt is damaged, you will need to look for a replacement. 3. Remove the stand from the bar. 4. Having coated the rubber bushings with plenty of soapy water, we put a new strut on the anti-roll bar. 5. Attach the stabilizer link to the lever. 6. Following steps 2-5, we replace the stabilizer link on the other side of the car.

As a rule, when replacing stabilizer struts on a VAZ 2110, the stabilizer bushings are replaced. To make replacement easier, you need to raise the front of the car. In garage repairs, jacks and stands are used. The stabilizer bushings are changed after dismantling the stabilizer link (see paragraph 3).

Sequence for replacing bushings:

1. Using a 13 mm wrench and WD-40, unscrew the bracket fastening. 2. Remove the old stabilizer bushings. You can cut them with a regular knife. 3. Having generously moistened the bushings with soapy water, put them on the stabilizer. 4. Screw the stabilizer to the car body. 5. We continue replacing the stabilizer link from step 4 of the instructions stated above.

The final tightening of threaded connections is carried out with the car lowered on its wheels. After replacing the stabilizer struts, there is no need to visit a service station and do a wheel alignment. Replacing stabilizer struts on a VAZ 2110 does not affect the wheel alignment angles.

Stabilizer links are called “eggs” in automotive slang. The stabilizer struts received this name because of their appearance. The auto parts store offers “eggs” from various manufacturers. It's difficult to recommend anything specific.

The service life of stabilizer struts and bushings depends on the road surface and manufacturer. On the spare parts market there are reinforced stabilizer struts for the VAZ 2110. Replacing conventional ones with reinforced ones will lead to a more rigid steering and reduce the roll of the car.

Stabilizer struts have to be replaced quite often; if a VAZ 2110 car owner can change them himself, he will save enough money and enjoy doing the repairs himself.

Front wheel hub

This part of the front suspension of the VAZ-2110 is located on the steering knuckle, connected to the strut and ball joint. It contains a cylindrical bearing in which the CV joint tip rotates. Using two bolts located on the steering knuckle, the wheel camber angle is adjusted.

When making repairs, be sure to remember how these elements were installed relative to each other. Otherwise, you risk accelerating the wear of your car's tires. At the bottom of the fist there is a hole for the ball joint pin. The hub itself has four threaded holes for fastening the wheel and two for screwing in the guide pins.

Steering

The steering is rack-and-pinion type, with a movable tip hinge attached to the racks. The principle of operation is very similar to the previously mentioned ball joint. Even the design is largely similar, except for the fact that the steering end is attached to the main rod. This is done using two nuts and a long sleeve with internal thread. They are necessary for precise adjustment of wheel toe angles. If this adjustment is not carried out, excessive tire tread wear will occur. In addition, it is possible that the car will pull to the side when driving even in a straight line. For this reason, it is extremely important to promptly adjust the camber and toe angles of the front wheels. Otherwise, you will have to purchase new tires for your car.

Main components

The front suspension of the VAZ-2110 includes the following elements:

- Shock absorber strut with welded steering knuckle.

- The ball joint that connects the lower control arm to the wheel hub.

- A support bearing is a device mounted on the body. With its help, the stand rotates around its axis.

- Hub - with the help of this mechanism, the CV joint rotates and motion is transmitted to the wheel. Installed on the steering knuckle.

- The levers fix the suspension elements and do not allow them to move in the longitudinal direction.

Each suspension element has its own characteristics; when it fails, characteristic signs will appear. It is by them that you can determine the breakdown.

Support bearing

This element allows for a movable connection between the shock absorber rod and the car body. After all, do not forget that the shock-absorbing strut serves as a rotating mechanism. Consequently, it must rotate freely along its axis, having movable supports at the bottom and top. A support bearing is a simple hinge. Its operating principle is similar to any other bearing. But the VAZ 2110 suspension (front) will not be able to function normally without it. Pay attention to the condition of this item. The fact is that if it fails, anything can happen. For example, a knocking or grinding noise may occur. And if the bearing jams, it will be impossible to turn the steering wheel at all. Therefore, try to replace it in a timely manner. Yes, it cannot be repaired; only the installation of a new element is required.

We will replace

— Overhaul of the engine - overhaul of the removed engine - removal and installation - oil in the hydraulic booster - oil in the engine VAZ 2110-2111-2112, Lada Priora, Largus - engine valves - brake piston ring pads - gearbox mechanical repair - steering knuckle assembly - sump - engine crankcase - Spark wheel bearing - exhaust pipe Alexander Kalyuzhin, 2022. - cylinder head gaskets VAZ 2110-2111-2112, Lada Priora, Largus - valve cover gaskets - rear or front springs - radiator VAZ 2110-2111-2112, Lada Priora, Largus - camshaft - steering rack mechanism - steering tip left or right - steering rod right or left - lower front suspension arm right or left - rear hub - starter VAZ 2110-2111-2112, Lada Priora, Largus - front hub with knuckle and brake disc assembly - clutch - fuel pump - fuel filter - ball joint VAZ 2110-2111-2112, Lada Priora, Largus - ball joint with rivets - Daewoo internal CV joint - CV joint, Spark external - CV joint, external boot - cabin filter, oil Alexander Kalyuzhin, 2022.

Possible breakdowns

If you hear a knock in the front suspension while driving, the main reasons may be:

- Faults in the rack;

- The bolts have become loose, the stretch marks or cushions with which the cross member is equipped may have worn out;

- The attachment to the body has become loose;

- The rubber parts have collapsed, and the knocking has a distinct “metallic” sound;

- A “limp” or even a broken spring knocks;

- Wear of hinges;

- Knocking due to wheel imbalance.

In principle, in any of the listed cases, repairing the VAZ 2110 front suspension, done by yourself, can help, during which you need to replace a worn part or (in the latter case, the reasons why a knock is heard) - balance the wheel.

Vehicle pull to the side

The car pulls to the side when driving straight. The reasons for this malfunction may include:

- Each spring has its own compression ratio. In this case, the spring that has lost its elasticity must be replaced;

- Tires have different pressures. We check and correct;

- The rubber element near one of the strut supports was destroyed. At the same time, a characteristic knocking sound is also heard while driving. The problem is solved by replacing this element;

- The wheel alignment angles are incorrect. Increased tire wear may be associated with this malfunction. If you can’t handle it yourself, it’s better to entrust this task to specialists.

Shock absorbers

The easiest way to find out that one of them is out of order is to press on the hood above the suspicious wheel. A working shock absorber will allow a maximum of 2 rocking up and down. If the body collapses and remains in this position or oscillates like a ball on a string, the shock absorber is damaged on this side.

- The fastener on the element rod is unscrewed;

- All existing washers plus the rubber upper cushion are dismantled;

- The bracket from below, which combines the shock absorber and lower arm, is unscrewed;

- The broken element is pulled out through the existing technological hole, the mounting bracket is removed from it, and a complete shock absorber is installed;

- We assemble the auto-constructor in the reverse order. And remember: like all paired parts, shock absorbers change along the axis on both sides, even if only one is covered. Otherwise, your ride will be very uncomfortable, and car control will deteriorate greatly.

We have listed the main failing components and briefly explained the procedure for replacing them. However, if you are not confident in your mechanical abilities, it is better not to attempt to repair the VAZ 2110 front suspension yourself, but to trust the specialists. It is worth doing the same if it was not possible to accurately determine the origin of the knocking in the suspension.

Front suspension arm

The design includes such an element as the front suspension arm of the VAZ-2110. It connects the hub through the ball joint and the car body. The lever has rubber-metal bushings - silent blocks. With their help, the suspension element moves in a vertical plane when moving. In fact, there is almost nothing to break in this mechanism - it is very strong and reliable. The “weakest link” is the silent block.

Over time, under the influence of loads, high temperatures, and liquids, the rubber is destroyed, which leads to deterioration in the performance of the suspension. When silent blocks break, extraneous sounds appear and play in the suspension increases. There is practically nothing left to break. The lever itself can only collapse, but this happens only after a serious accident. When hitting curbs or potholes, it is impossible to bend or break the lever.

Spherical bearing

The VAZ 2110 front suspension arm is attached to the hub using a ball joint. If you have consulted the reference literature, you may know that this node is practically invulnerable. It is difficult to break it and put it in bad shape. Unfortunately, the support still breaks. And its resource largely depends on the following factors:

- Driving style.

- Quality of the road surface.

- Original quality of the product.

Very often, it is because of a ball failure that a knocking sound appears from the front suspension of the VAZ 2110. Moreover, it can be observed both when the car is moving and when passengers are boarding and disembarking. And it doesn’t matter how fast you move or which direction you turn. But knocking in the suspension is not uncommon. And if it appeared due to a ball joint, then repairs will not be very expensive.

Why does the car pull to the side?

Sometimes drivers notice how, when driving in a straight line, the car begins to pull to the side. There are several reasons for this phenomenon:

- Each spring has its own specific compression ratio. If it loses elasticity, the element must be replaced;

- Tires may have different pressures. Check this first;

- A rubber component on one of the strut supports has collapsed. In such a situation, a characteristic knock may appear. The situation can be corrected by simply replacing the element;

- The wheels are set at the wrong angle. A common cause of tire wear. It is better to trust such a problem to a specialist, since it is difficult to repair the front suspension on a VAZ 2110 with your own hands in case of such a malfunction.

Second in line: silent block

To check its functionality, the silent block is pryed off with a pry bar and oscillating movements are carried out. If there is the slightest play, the part must be replaced.

- The old silent tape is removed from the car and pressed out using a vice;

- The new one is moistened in water with dissolved soap and placed in its place. It is inserted into the socket by pressing;

- In order for the silent block to sit well in place, careful blows are applied to the drift;

- Please note: all threaded connections are tightened after the car is placed on the wheels.

Why does the car pull to the side?

Sometimes drivers notice how, when driving in a straight line, the car begins to pull to the side. There are several reasons for this phenomenon:

- Each spring has its own specific compression ratio. If it loses elasticity, the element must be replaced;

- Tires may have different pressures. Check this first;

- A rubber component on one of the strut supports has collapsed. In such a situation, a characteristic knock may appear. The situation can be corrected by simply replacing the element;

- The wheels are set at the wrong angle. A common cause of tire wear. It is better to trust such a problem to a specialist, since it is difficult to repair the front suspension on a VAZ 2110 with your own hands in case of such a malfunction.

Typical faults

The front suspension is characterized by certain breakdowns, which are determined by two phenomena:

They should be considered separately, since the reasons for their appearance are different.

Knocks

If you start to hear knocking noises coming from the front suspension, this could be caused by several reasons:

- The rack has certain faults;

- The ties on the cross member, the cushions are worn out or the bolts are loose;

- The attachment to the body was not strong enough;

- The springs have failed;

- The hinges are worn out;

- The rubber part of the suspension has broken its integrity. The knock should be clear, like the impact of metal on metal;

- Wheel alignment is out of balance.

If you do not hear a knock, but a noise, then the causes of front suspension problems may be as follows:

- The bolts that secure the stabilizer bar to the body have become loose;

- The rubber components in the strut support have collapsed;

- The rubber pads of the coupler or rod are worn out;

- The suspension spring has broken or violated its geometry;

- The wheels are unbalanced;

- The compression stroke buffer has collapsed.

Increased tire wear

If you are not a fan of fast acceleration, harsh braking, or do not overload the car, then the reasons for increased wear may be:

- The wheel alignment angles are incorrect;

- The hinges are worn out;

- Wheel balance is off.

Examination

- Experts recommend paying special attention to the protective covers of the joints, monitoring their condition, and also checking the front suspension for mechanical damage.

- Make sure that neither the front suspension arm of the VAZ 2110 nor any other element has cracks or other visible damage. Pay attention to checking the connection points of the elements.

- If the components are deformed, the angle of the wheels will most likely be disrupted and they will no longer be able to be adjusted.

- Check ball joints, hinges, upper stack mounts, cushions. If there are breaks in the rubber elements, they must be replaced.

- Measure the distance between the lower arm and the brake disc. This way you can check the condition of the suspension joint. If the distance is more than 0.8 millimeters, the hinge must be replaced with a new one.

- If the buffer shows signs of destruction, it should be replaced immediately.

- The spring is replaced if it has failed or sagged.

- Ball joints are replaced when they are worn or deformed. Other hinges must be replaced if they or the stabilizer bar struts are worn out.

- All rubber elements change under conditions of deformation or failure.

- If the fastening of the upper strut mount to the body is loose, simply try to tighten the fastening. Most likely, no major intervention will be required.

Main front suspension components

The main element of the front suspension is a hydraulic telescopic strut, which is simply irreplaceable in the matter of shock absorption and ensuring a comfortable ride on the car. The car won’t shake much, and going through every hole won’t turn your trip into a nightmare.

To change the wheel camber, there is a strut in the front suspension. To be more precise, the steering knuckle and the upper bolt, which has an eccentric washer and a belt, are responsible for this process.

Mounted on the rack:

- Special springs;

- Buffer to limit the compression stroke. On the VAZ 2110 this element is made of polyurethane;

- Upper support. It is attached to the rack, to which, in turn, the mudguard is attached. Please note that only self-locking nuts are used for fixing. Therefore, ordinary nuts will not work for repairs;

- Bearing to ensure rotation of the stand together with the wheels;

- Shock absorbers with spring and plunger.

The ball joint serves to combine the steering knuckle and the lever, that is, the lower part of the suspension. Rubber-metal hinges combine the lower arms, longitudinal braces, and cross member supports.

By the way, the cross member of the front suspension of the VAZ 2110 is a bar to which the lower arms are connected. In the center it is attached to the body using a rubber cushion.

This is a brief diagram of the front suspension of the VAZ 2110, your instruction manual will help you get to know it better. Many motorists underestimate the importance of this literature, which the manufacturer attaches to each of its cars. But in fact, the necessary, useful and important information about each component, unit and system of the machine is presented in detail and in all colors. Including the front suspension, of course.

The part is installed quite simply

Having opened the hood, you need to unscrew the nuts from the bolts of the strut stops, install a brace on the bolts and screw the nuts into place. When driving at low speeds when maneuvering, the effect of the stretch will be almost imperceptible. But as the speed increases, changes are immediately felt. The car becomes more “obedient”, roll is significantly reduced when cornering - you get the feeling that the car has become more reliable.

To install the front strut extension, the car must be placed on a level area without slopes. The brace should fit freely onto the studs of the upper posts. If small discrepancies (a few millimeters) are detected, you can try to “pull” the body in the right direction. If the discrepancy is much greater, then an adjustable stretch will help you better.

Many car owners install an additional fourth engine mount. It allows you to limit the maximum movement of the engine when hitting an obstacle and a sharp start. Some car owners also believe that the additional support prevents the gears from disengaging themselves.

Shock absorber

The basis of the entire structure is the shock absorber strut. It houses the front suspension spring. The operation of the entire mechanism is most efficient if these elements are in good condition. In particular, there must be sufficient oil inside the rack. And the spring should not be “sagging”. If the car is used in harsh conditions for a long time, the length of the spring decreases gradually. Despite its apparent rigidity and strength, the coils become closer to each other. Even half a centimeter of drawdown will make itself felt - the entire suspension will begin to work ineffectively. This is one of the elements that makes up the front suspension of the VAZ 2110. You can even repair it yourself. As for the shock absorber itself, try to keep it clean. In particular, it is imperative to change the boot if cuts or cracks suddenly appear on it. Even a small amount of dust will make itself felt very soon. The seal will certainly collapse and the oil will begin to come out.

Vulnerable point - rubber bands

There are quite a lot of them on the suspension, and they quickly wear out from negative road conditions. First of all, these are anthers, also called sheaths. They are rubber stockings that protect the balls from dirt, water and dust. If they are torn or cracked, without replacement you will soon be in danger of breaking the hinge - and this is a completely different amount of work and a lot of money spent.

The next item is rubber bushings, which absorb hard impacts, preventing vibration from being transmitted to the car body. They are on both the control rods and the shock absorber lugs.

Replacing all rubber bands is quick, cheap and affordable even for a novice car enthusiast. Thanks to it, much more difficult repairs can be avoided.

Main front suspension components

The main element of the front suspension is considered to be a hydraulic telescopic strut, which is simply irreplaceable in the matter of shock absorption and ensuring a comfortable ride on the car. The car won’t shake much, and going through every hole won’t turn your trip into a nightmare.

To change the wheel camber, there is a strut in the front suspension. To be more precise, the steering knuckle and the upper bolt, which has an eccentric washer and a belt, are responsible for this process.

Mounted on the rack:

- Special springs;

- Buffer to limit the compression stroke. On the VAZ 2110 this element is made of polyurethane;

- Upper support. It is attached to the rack, to which, in turn, the mudguard is attached. Please note that only self-locking nuts are used for fixing. Therefore, ordinary nuts will not work for repairs;

- Bearing to ensure rotation of the stand together with the wheels;

- Shock absorbers with spring and plunger.

By the way, the cross member of the front suspension of the VAZ 2110 is a bar to which the lower arms are connected. In the center it is attached to the body using a rubber cushion.

This is a brief diagram of the front suspension of the VAZ 2110, your instruction manual will help you get to know it better. Many motorists underestimate the importance of this literature, which the manufacturer attaches to each of its cars. But in fact, the necessary, useful and important information about each component, unit and system of the machine is presented in detail and in all colors. Including the front suspension, of course.

Purpose

The wheels are attached to the front suspension; the unit provides shock absorption for the “front” of the car, is responsible for stability while driving, wheel adjustment, camber, and toe-in.

The front suspension design of the VAZ 2110 is quite complex, but any of you can figure it out. The main thing here is to arm yourself with an instruction manual, as well as understand the essence of the main angles.