The front suspension is the weak point of any car. Many owners of domestic cars are interested in how to replace the front suspension of a VAZ 2106 with their own hands. There is nothing difficult about this if you follow the instructions and use a good set of tools.

The quality of roads in our country has always not been of high quality, and it especially deteriorates after winter. After the snow melts, numerous potholes and cracks are found in the asphalt. As you know, the VAZ 2106 suspension is designed to soften vibrations transmitted from potholes on the road to the vehicle body. Over time, the chassis wears out and requires repairs, which you can do yourself.

Replacing shock absorbers

Having found out that the shock absorbers of your “six” have served their purpose and need to be replaced, you need to know in what sequence to carry out this procedure. It is also worth considering that dampers are replaced in pairs, i.e. if the right element on one axis fails, then the left one must also be replaced. Of course, if a shock absorber breaks down with a short mileage (up to 1 thousand km), then only that can be replaced. As for the repair of the products in question, almost no one does this at home due to the complexity or impossibility of carrying out the work due to the lack of necessary equipment. In addition, shock absorber designs are not collapsible at all.

Which ones to choose

You have to think about choosing damping devices for the front and rear suspension not only when they break down. Some owners of the VAZ 2106 and other classic Zhiguli cars are not satisfied with the soft suspension. For better vehicle stability, it is recommended to install shock absorbers from VAZ 21214 (SAAZ) on the front end. Often original products are replaced with imported analogues precisely because of excessive softness.

Table: analogues of front shock absorbers VAZ 2106

| Manufacturer | vendor code | price, rub. |

| KYB | (oil) | 700 |

| KYB | (gas) | 1300 |

| Fenox | A11001C3 | 700 |

| SS20 | SS20177 | 1500 |

Kayaba shock absorbers are one of the most common when installed on classic Zhiguli

cars. To improve the performance of the rear suspension, instead of standard shock absorbers, elements from the VAZ 2121 are installed. As in the case of the front end, there are foreign analogues for the rear.

Table: analogues of the rear shock absorbers of the “six”

| Manufacturer | vendor code | price, rub. |

| KYB | 343098 | 1400 |

| KYB | 443123 | 950 |

| Fenox | A12175C3 | 700 |

| QML | SA-1029 | 500 |

How to replace the front shock absorber

To dismantle the front shock absorbers, you need to prepare keys for 6, 13 and 17. The process itself consists of the following steps:

- Open the hood and unscrew the shock absorber rod fastening with a 17 key, holding the axle from turning with a 6 key.

- Remove the nut, washer and rubber elements from the rod.

- We go down under the front end and use a 13 key to unscrew the lower fastening.

- We remove the damper from the car by removing it with the bracket through the hole in the lower arm.

- We hold the bolt from turning with one wrench, unscrew the nut with the other and remove the fastener along with the bracket.

- We install the new shock absorber in the reverse order, replacing the rubber cushions.

Video: replacing front shock absorbers on a VAZ “classic”

How to replace a rear shock absorber

To remove the rear damper you will need the following tools and materials:

- 19mm wrench and head with ratchet and wrench;

- hammer;

- WD-40 or any other penetrating lubricant.

We dismantle the elements in the following sequence:

- We place the car on the inspection hole and tighten the handbrake.

- Using two 19mm wrenches, unscrew the lower damper mount.

- Remove the bolt from the sleeve and eye.

- Remove the spacer sleeve from the bracket.

- We move the shock absorber to the side, remove the bolt and remove the bushing from it.

- Using a key of the same size, unscrew the top fastening.

- We remove the washer and the shock absorber itself with rubber bushings from the axle.

- Installation is carried out in reverse order.

How to bleed shock absorbers

The shock absorbers must be bled before installation. This is done in order to bring them into working condition, since during transportation and storage in warehouses they are in a horizontal position. If the shock absorber is not pumped before installation, the piston group of the device may fail during vehicle operation. The pumping procedure is mainly carried out on two-pipe dampers and is done as follows:

- We turn the new element over with the stem down and gently compress it. We hold it in this position for a few seconds.

- We turn the device over and hold it in this position for a few more seconds, after which we extend the rod.

- We repeat the procedure several times.

The dampers of the front and rear suspension of the VAZ 2106 rarely fail. However, driving a car on poor quality roads significantly reduces their service life. Finding faulty shock absorbers and carrying out repairs will not require much effort and time. To do this, you will need a minimum of tools, as well as familiarization and following step-by-step instructions.

Tools and materials

To carry out the entire scope of work, a limited number of tools and materials will be required. First of all, you need to acquire:

- shock absorbers;

- key at 6, 17, 13, 19;

- locksmith tool.

This is quite enough

to do all the work efficiently. Before starting it, you should think about installing the car on an observation deck or lift. This is the only way to easily reach the element being replaced. The car must be on wheels, and the distance from its bottom to the ground should be approximately 50 cm.

Front suspension

The front end of the VAZ “six” has a more complex suspension design, since the front wheels are steerable and it is on this part of the car that heavy loads fall. The front suspension of the car is an independent double wishbone with coil springs, hydraulic shock absorbers and a stabilizer bar.

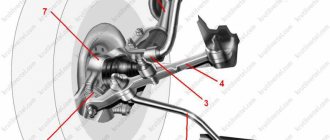

Front suspension diagram of VAZ 2106: 1 - hub bearings; 2 — hub cap; 3 - nut; 4 — steering knuckle axle; 5 - cuff; 6 — hub; 7 — brake disc; 8 — protective cover of the upper ball pin; 9 — upper ball pin; 10 — bearing (liner) of the upper support; 11 — upper lever; 12 — compression stroke buffer; 13 — spring insulating gasket; 14 — shock absorber; 15 — shock absorber mounting pad; 16 — axis of the upper arm; 17 — rubber bushing of the hinge; 18 — outer bushing of the hinge; 19 — adjusting washers; 20 — suspension cross member; 21 — stabilizer bar cushion; 22 — stabilizer bar; 23 — axis of the lower arm; 24 - lower arm; 25 — clip for attaching the stabilizer bar; 26 - spring; 27 — rubber bushing of the shock absorber spring; 28 — lower spring support cup; 29 — steering knuckle; 30 — lower ball pin race insert; 31 — lower support bearing; 32 - lower ball pin

Cross member

The front beam is the strength element of the volumetric structure. The material used to manufacture the product is steel. The cross member is located in the engine compartment below. The power unit is fixed to it through the cushions, as well as the lower arms of the shock absorption system.

The cross member is the power element to which the engine and lower suspension arms are attached

Levers

The front suspension consists of four levers - two upper and two lower. The lower elements are fixed to the crossbar using an axle. Between the beam and the axle there are washers and shims that change the camber and angle of the front wheel steering axis. The upper arm axle is a bolt that goes through the mudguard post. Rubber-metal products are installed in the holes of the levers - silent blocks, through which the suspension elements in question can move. Using ball joints, the steering knuckle (trunnion) is mounted to the levers. The wheel hub with the brake disc is fixed on it using tapered roller bearings. The hub is tightened on the axle with a nut, and on the right the fastener has a left-hand thread, and on the left it has a right-hand thread.

The front suspension arms connect and hold the elements of the shock-absorbing system

Shock absorbers

Shock absorbers ensure a smooth ride of the car, i.e., eliminating bouncing on uneven surfaces. Damper devices of almost identical design are installed at the front and rear. The difference lies in the size, mounting methods and whether the front shock absorber has a buffer. The front dampers are mounted with their lower part to the lower arm, and mounted on the top on the support cup.

The shock absorber in the suspension design ensures a smooth ride of the car

Table: parameters of the “six” shock absorbers

| vendor code | Rod diameter, mm | Case diameter, mm | Body height (excluding stem), mm | Rod stroke, mm |

| 2101–2905402 2101–2905402–022101–2905402–04 (front) | 12 | 41 | 217 | 108 |

| 2101–2915402–02 2101–2915402–04 (rear) | 12,5 | 41 | 306 | 183 |

Springs

The “six” is equipped with cylindrical springs, the upper part of which rests against the rack through the gasket and support cup, and the lower part rests against the recess of the lower arm. The purpose of the elastic elements is to provide the necessary vehicle clearance and smooth out shocks while driving on uneven roads.

Springs are an elastic element that provides ground clearance and smoothes out shocks when driving over uneven surfaces.

Stabilizer

The stabilizer is a part that reduces body roll when cornering. It is made of special steel. In the middle, the product is fixed to the front side members through rubber elements, and at the edges - to the lower arms.

To reduce roll when cornering, the suspension uses a transverse stabilizer

Spherical bearing

The ball joints of the front suspension are a hinge, thanks to which the car is able to maneuver and move smoothly. In addition, these elements make it easy to control the front wheels. The support consists of a housing with a ball pin and a protective element in the form of a rubber boot.

The front suspension contains 4 ball joints that connect the arms and the steering knuckle to each other

Polyurethane or regular?

On sale you can find two types of elements - polyurethane and rubber-based. The question is: which ones are better to use on the VAZ 2107? Rubber ones have many disadvantages:

- Even the new ones squeak.

- They have a relatively small resource.

- Under the influence of an aggressive environment they quickly become unusable.

But they also have a big advantage - a fairly low price. Depending on the “appetites” of the seller, you can purchase a set for 500-700 rubles. But polyurethane ones have higher characteristics. They are practically not exposed to aggressive environments, have a long service life (at least twice as long), but there is one drawback - the price. It is within one and a half thousand. Look at how you are used to using your car.

Which ones should you install on your VAZ 2107? The question is not easy, you need to weigh everything to answer it. And most importantly, assess your financial capabilities.

You also need to pay attention to your driving style. If aggressive, then polyurethane will be more suitable for the job.

But if you drive quietly and the suspension is not subjected to significant loads, then you can install regular rubber ones. But we need to make a reservation again - it all depends on your capabilities and preferences. Polyurethane ones are many times better than rubber ones on the VAZ 2107 and similar models. And they are free from the main drawback of rubber joints - they do not creak.

Diagnostics of rubber-metal joints

To check the condition of silent blocks, you need to use a pit or overpass. Without such amenities, it will be problematic to drive the seven, so there should be a pit in every garage. therefore, it can be repaired by hand without any problems. But you need to determine whether the VAZ-2107 silent blocks need to be replaced; the price of one is approximately 50 rubles. For a set of 8 silent blocks you will pay 400 rubles.

Carefully inspect the suspension on the lever, evaluate the appearance of the rubber-metal hinge. If the rubber has obvious damage - it has begun to become cracked, or there are any cuts at all, then all elements must be replaced. When carrying out repairs, try to do as much work as possible. Therefore, you not only change all eight silent blocks, but also, after assessing the condition of the balls, replace them if necessary. It is also worth looking at the condition and tightening the nut if necessary.

Do-it-yourself replacement of VAZ-2106 silent blocks video instructions

Silent blocks are used in the construction of cars of all models. They are rubber inserts between suspension parts; they are used to absorb vibration and, accordingly, to prolong the uninterrupted operation of the machine’s chassis. The silent blocks themselves are subjected to very high loads, which leads to their frequent failure.

In this article we will talk in detail about how to replace silent blocks on a VAZ-2106 car, we will provide step-by-step instructions and useful recommendations, thanks to which you can perform this rather complex procedure with your own hands, without involving car service specialists.

Tools and accessories needed to replace silent blocks

First of all, you will need to prepare all the necessary tools. Without them, it will be quite difficult to get to the silent blocks in a VAZ-2106 car and dismantle failed parts. So, for high-quality and convenient repairs you will need:

- special tools for dismantling ball joints, the upper arm, removing and installing a new hinge made of metal and rubber, as well as for unpressing the far steering tips;

- open-end, ring and miter wrenches for 13, 22 and 24 millimeters;

- jack;

- set of mounts;

- a thin and sharp chisel that will allow you to carefully dismantle the lower silent blocks without removing the lever;

- hammer.

Additionally, you will need to prepare the new suspension components that will be installed on the vehicle. Today it is best to buy polyurethane silent blocks, which differ from ordinary ones in their service life increased several times.

But if your goal is to carry out repairs at minimal cost, then you can get by with traditional rubber parts.

Step-by-step instructions for replacing upper control arm silent blocks

If the entire tool is already ready for use, we begin to replace the rubber-metal hinges, which is performed according to the following scheme:

- jack up the car and remove the wheel from the side on which the work will be done;

- unscrew the nuts holding the silent block and the steering tip;

- Unscrew the fastening nut of the ball joint;

- using a special puller, press out the bipod support pin;

- remove the nut holding the upper arm;

- we take out the lever, carefully clamp it in a vice and change the silent blocks using a special device;

- We install the lever in the reverse order. After this, all that remains is to mount the wheel and remove the jack. The same work is performed on the other side.

It is much easier to replace the silent blocks of the lower arm:

- after removing the nut holding the lever itself, we take a special device and press out the rubber-metal hinge;

- We carry out preparatory work. During this process, it is necessary to remove dirt and carefully lubricate the seat for the new silent block, as well as the lever axis and threads. This, firstly, will greatly facilitate subsequent procedures, and secondly, it will ensure stronger fixation of the part;

- press in a new silent block;

- install the steering ends and insert the cotter pins that secure these parts;

- tighten the nuts of the upper and lower arm.

The procedure for replacing silent blocks must be carried out under load. It is best to first seat your acquaintances or friends in the car, and also place a load weighing 40 or more kilograms in the trunk.

The nuts of the upper and lower arms must be tightened until they stop only after the new silent blocks have been installed. Otherwise, serious problems with the operation of the car suspension may arise.

Expert advice

- The condition of all silent blocks can be assessed independently. During a visual inspection, you will notice rubber peeling or cracks and an increase in play. This is a signal to replace parts. Their service life is designed for 100 thousand kilometers, but given the state of our roads, it is approximately halved.

- Replacement of silent blocks of VAZ and other rear-wheel drive cars is carried out simultaneously on the left and right sides of the car.

- When replacing parts, it is better to use pullers, since unnecessary impacts on rods and levers can negatively affect their condition, especially in places of welded joints. The pin and bolt on which the old part was located must be cleaned and lubricated with oil.

- It is better to install expensive but high-quality polyurethane silent blocks. They have a much larger resource.

- If the part cannot be pressed out, it must be sawed using a hacksaw.

- If you have no experience in car repairs, it is hardly worth taking on the replacement yourself, even though you know how to change silent blocks. It is better to entrust this matter to service station specialists.

Correctly performed replacement of silent blocks on VAZ 2107 vehicles will extend its service life and make travel safer and more comfortable. The tires wear out less and the car makes less noise. The operation of replacing silent blocks can be done with your own hands if you have some experience in car repair work.

replacing the front door pillar of a VAZ 2106.

| VAZ 2106 front door pillar replacement |

| Making a new stand and all the accompanying patching and strengthening. |

| Tags: |

| Replacement of VAZ2101 front pillar with trim and strengthening of windshield frame |

| Click to view | Windshield pillars What's inside!LOP ULA STAND LET'S SEE WHAT'S INSIDE Life channel!—- … |

| Tags: |

| Zhiguli Repair of the windshield pillar “Zhiga” (5 hours) |

| The windshield pillars on the VAZ 2106 were torn off. Repair of the windshield pillars of the VAZ Life channel!—- … |

| Tags: |

| The windshield pillars of a VAZ 2106 were torn off |

| Click to view | Today I decided to replace the glass. |

| Tags: |

| how to replace a VAZ classic glass |

| Lada sedan-buckle jean - replacement of door pillar repair inserts. VAZ-21 06. |

| Tags: |

| Lada sedan-aubergine-replacement of door pillar repair inserts.VAZ-2106. |

| Click to view | how to replace the front suspension spring of a VAZ without ties and is it even possible? VKontakte group... |

| Tags: |

| replacing the front glass of a vaz classic |

| Click to view | Top 5 Zhiguli modifications in my opinion. The top is based on personal experience. Drive2 blog-Drive2 ... |

| Tags: |

| Replacing the front spring without a puller or zip ties. |

| Click to view | The video shows the process of replacing the lower arm on a VAZ 2106 car. All videos on repairing VAZ 2101-2107 ... |

| Tags: |

| TOP 5 UPDATES FOR ZHIGULI, WHAT YOU NEED TO DO WITH A CLASSIC |

| vaz #lubrication for doors #poorly closed two and Cleaning and lubrication, maintenance and adjustment of locks... |

| Tags: |

| Replacing the lower arm of a VAZ 2106 |

| The car was redone after a previous repair. We changed the threshold, amplifier, threshold connector, lower middle... |

| Tags: |

| The doors of VAZ 2104, 2105, 2106, 2107, NIVA do not close well. Part 1 |

| Click to view | Reanimation of VAZ 2101. Part 4. I cook the sills and spar. The beginning of the repair can be seen here: Reanimation... |

| Tags: |

| VAZ 2107 Replacement of threshold left Ch 2. +repair of bottom, amplifier, connector, B-pillar, fender, arch |

| one of the reasons why it is not possible to set the wheel camber of the front suspension of a VAZ classic. groups... |

| Tags: |

| Reanimation of VAZ 2101. Part 4. I cook the sills and spar. |

| Tools for car repairs with your own hands Discounts on tools in Chinese stores... |

| Tags: |

| The camber is not set, one of the reasons. |

| smoothly even, normal)) for the search engine Rikhovka ZAZ VAZ spotter slipway Merc Ford pfp dfp ford benz… |

| Tags: |

| How to eliminate play in VAZ door hinges and adjust the door |

| Click to view | Korch a year later... The car was built as a weekend sports equipment for... |

| Tags: |

| door pillar hood. doors. gaps. |

| Click to view | Video from 2006. Drag repair: who will change the front shock absorber on a VAZ-2105 faster? |

| Tags: |

| Additional Front Shock Absorbers for 2101-07 (cross cramp) 4 series |

| Replacement of VAZ2109 rack. |

| Tags: |

| Repair with partial replacement of the front door pillar of a VAZ 2109 |

| Click to view | Replacing the rack for a VAZ 2109. |

| Tags: |

| Replacing the front shock absorbers of a VAZ classic |

| Click to view | I do welding, straightening and painting of cars! Subscribe to my channel! It only gets more interesting! |

| Tags: |

| Replacing the front door pillar on a VAZ 2109 |

| Click to view | The racks are rusty and need to be replaced. |

| Tags: |

| Replacing the front strut on a VAZ 2109 |

| Click to view | Replacement of thresholds on Lada VAZ Kassika Do-it-yourself repairs. |

| Tags: |

| repair of the front pillar and doorways of the VAZ 2106 part 2 |

| Click to view | Replacement of the front and middle pillars, complete painting of the car with acrylic enamel Duxon ○ VAZ 21099○ Cut out the whole… |

| Tags: |

| Zhiguli 2106. Replacement of the front pillar. |

| How to replace the silent blocks of the lower arms on a VAZ classic car without the help of a puller. groups... |

| Tags: |

| Replacing the threshold of a VAZ classic 2101-07 (body repair) |

| Click to view | When removing doors on a Zhiguli, owners very often encounter this problem - the fasteners do not unscrew... |

| Tags: |

| Replacing the A-pillar and B-pillar Painting VAZ 099 |

| We improve your Lada. |

| Tags: |

| How to replace the silent blocks of the lower arms of a VAZ without a puller. |

| Video about massage. |

| Tags: |

| How to remove the door on a Zhiguli (classic) VAZ. Useful thing” rel=”spf-prefetch |

| Click to view | Description missing |

| Tags: |

| REPLACING REAR SHOCK ABSORBERS FOR VAZ 2106 (CLASSICS)” rel=”spf-prefetch |

| Click to view | Description missing |

| Tags: |

| Strengthening the roof rigidity of the VAZ 2101-07. (part 1)” rel=”spf-prefetch |

| Click to view | Description missing |

| Tags: |

| 2106. Welding window frame cracks.” rel=”spf-prefetch |

Replacing silent blocks in the upper control arm of a classic with your own hands.

So, let's begin! In rear-wheel drive VAZs, the silent blocks in the upper arm can be changed without even driving into a hole and without removing the arm from the ball (provided that you have a remover for silent blocks). But first you need to determine whether the bushings of the silent blocks are stuck to the bolt securing the lever to the body. To do this, jack up the car and remove the wheel.

Arrows point to bolt and nut

We loosen the nut securing the upper arm with a 22mm wrench and try to turn the bolt. If it spins and the bushings stay in place, then you're in luck! But if this bolt rotates with great effort and the bushings rotate with them, then as they say: “Houston, we have problems!” Next we will consider both cases.

If the silent blocks are not stuck.

Further actions depend on whether you have a puller for silent blocks. If there is one, then you don’t have to remove the lever completely, but just unscrew the nut 22 to the end, take out the bolt and turn the lever towards yourself (for the convenience of further repairs).

We turn the lever for convenience.

Next, take a puller and press out the silent blocks.

Removing the silent block using a puller

And with his help we press in new silent blocks. Before pressing, the mounting hole must be cleaned and preferably lubricated with lithol. In the upper arms, silent blocks are pressed into place up to the ribs, as shown in the photo below.

The new silent should be pressed in exactly like this.

But what to do if you don’t have a silent block remover? Then you will have to completely remove the lever. We take out not only the bolt securing the upper arm to the body, but also take out the ball from the hub (this is faster than unscrewing 3 bolts securing the ball to the arm). Detailed removal of the ball joint is written here.

We removed the lever, put the lever ear on a pipe or on a yew tree (as in the photo), the main thing is that the silent block does not rest against anything, and knock it out with a hammer.

To press in new ones, we need a mandrel (old bearing, piece of pipe, nut head). The inner diameter of the mandrel must be equal to the diameter of the skirt of the new silent block. And we begin pressing in new parts using this mandrel, having previously lubricated the seat with lithol. Reassemble in reverse order.

Important: we pull the bolt securing the lever to the body only under the load on this wheel! Those. The car should not be on a jack, but on all wheels!

If the silent blocks are stuck to the bolt.

This is a very difficult case, since you will have to spend a long time trying to get the bolt that secures the front upper arm to the body.

For those who want to save themselves a lot of time and are ready to fork out a little, I advise you to buy a new bolt, this lever from disassembly and just cut off the old bolt with a grinder.

Well, if you have time and nerves, then we take a gas burner in our hands and burn out the silent block. Follow fire safety precautions! After all the rubber has burned out, you can begin to knock out the bolt. Get ready to do this for a very long time. After you remove the bolt, knock out the remaining clip of the burnt silent tape from the lever and follow the instructions written above.

Sequence of work

First you need to remove all the fastening elements of the shock absorber. First you need to loosen the nut and remove it, and then remove all the other elements. We are talking about special pillows, as well as a spring pressure washer. Now you can lift the car, if of course the work is done on a lift.

The bracket is in any case attached to the system lever. In order to separate them you only need to unscrew a couple of nuts.

After this, the spring washers should be removed. Now access to the old shock absorber is completely open. It is removed through a special mounting hole in the lever. The pillow must also be removed. The car's shock absorber is tightly fixed to the bracket. To remove it, you will have to perform a number of manipulations.

In fact, it all comes down to unscrewing one single fastening nut. When it is removed, you can easily and simply pull out the mounting bolt and, accordingly, remove the shock absorber itself.

In principle, all work related to removing the old shock absorber has been completed, which means that installation of a new one can begin. It is installed in reverse order. A new shock absorber with a rubber-to-metal hinge is installed.

Sources

- https://avtovx.ru/podveska-stoiki-amortizatory/zadnjaja-podveska-vaz-2106-217/

- https://smotri-dtp.ru/voprosy-i-otvety/chertezhi-kronshtejnov-dopolnitelnogo-zadnego-amortizatora-vaz-2106.html

- https://motorchina-online.ru/novosti/kreplenie-amortizatora-vaz-2106.html

- https://workoutcrew.ru/verhnee-kreplenie-zadnih-amortizatorov-vaz-2106/

- https://avto-mekhanik.ru/hodovaya-chast/remont-verhnego-krepleniya-zadnego-amortizatora-vaz-2106.html

[collapse]

Replacing the front suspension springs of a VAZ 2106

When the integrity of the spring is compromised, damage and cracks appear, you need to urgently replace it. You can replace the front suspension springs of a VAZ 2106 car with your own hands; we will tell you in more detail below.

Consequences of faulty springs:

– The smoothness of the ride deteriorates. – There is a clear distortion of the front part of the body – A significant (noticeable) difference in height between the front and rear. – Clear traces of coils hitting each other.

We will need the following tool:

– Keys to “22″ and “13″. – Two jacks (screw and hydraulic). - Bolonnik. – Metal brush. - Hammer.

Replacing the front suspension springs of a VAZ 2106 with your own hands

1. While the car is “on wheels,” tear off the wheel mounting bolts with a bologna.

2. Jack up the car with a screw jack on the side where you are going to remove the suspension spring.

3. Next, you need to hang the wheel and completely remove it from the car.

After this, remove the shock absorber, this is done as follows:

4. To do this, use the key at “6, 13, 17 and 19”.

5. The rod must be kept from turning with a key.

6. Next, loosen the tightening of the nut and remove it.

7. Also remove the cushion washer, spring washer and upper shock absorber mounting pad.

8. Unscrew the two fastening nuts of the bracket to the lever and remove the spring washers.

9. Remove the shock absorber from the bottom using the mounting hole in the arm.

10. Loosen the mounting nuts that secure the lower arm to the axle, but do not rush to remove them. We take a second jack, preferably a hydraulic one.

11. Place it under the lower control arm, then raise it slightly to load the suspension and level the lower control arm.

12. Remove the stabilizer bar.

13. Unscrew the nuts of the stabilizer bracket and remove the bracket with the rubber cushion.

14. Unscrew the nut that holds the pin in the ear of the steering knuckle, but now you can remove the lower ball joint.

15. Lower the jack and knock out the support pin with a hammer; to do this, hit the lower ear of the steering knuckle several times.

16. With the lower ball joint removed, reinstall the jack under the lower control arm, but there is now no need to load the suspension.

17. After this, you can unscrew the ball joint pin nut completely, slowly, and carefully lower the lower arm down. Help yourself with a mounting spatula by moving the stabilizer to the side so that it does not catch the bracket mounting studs.

18. Now completely unload the suspension and move the jack to the side.

19. Prepare a strong rope or wire, with its help you need to pull the upper arm as high as possible in order to provide yourself with access to the front suspension spring.

20. Take a pry bar and use it to pry the lower end of the spring, then carefully remove it from the lower arm support cup.

21. Remove the suspension spring, remove the spring gasket from the upper support cup.

Now that nothing is in the way, the front suspension spring can be replaced.

How to install a spring correctly

1. Take a new spring, attach a gasket to it (use regular electrical tape for this) and install it in place.

2. Install the mounting blade into the hole for the shock absorber and, holding the spring with it, fix the lower coil. By looking at the surface of the lower arm, you can see a helical surface indicating the correct position of the spring. Helping yourself with mounting, you need to adjust the correct position of the spring in relation to the screw surface.

3. Having set the correct position of the lower coil, install the jack under the lever and create a load on the spring, then use a mounting blade to finally seat the spring on the screw surface.

4. Increase the load on the spring and, using a mounting tool, install the stabilizer bar into a position between the two mounting studs of the stabilizer bracket.

Assembly is carried out in reverse order. Let us remind you that the previous article was about replacing the VAZ 2106 clutch with your own hands.

Security measures

When performing repair work, do not forget about basic safety measures:

- Before hanging on a jack, the car is placed on the handbrake, and wheel chocks are placed under the wheels;

- In parallel with the jack, a safety support is installed under the body of the suspended car;

- When working with a hammer, for example, pressing a ball joint out of a bipod, use safety glasses;

- Wear gloves to protect your hands from damage if the wrench may slip off the nut.

Almost every owner of a domestic car, especially a classic rear-wheel drive model, sooner or later faces problems large and small. Some units and parts fail and have to be replaced. Some repair work is performed at numerous car service stations, while some can be done yourself in your garage. Such work includes replacing the silent blocks of the front and rear levers that have become unusable.

Replacing silent blocks on a VAZ 2106 car

The design of silent blocks looks like a rubber insert that is pressed inside two connected metal bushings. The part in question must be replaced in case of critical wear or damage. They are connecting elements of fastenings of various components and mechanisms from the car suspension to the transmission. The silent block absorbs harmful vibrations and dampens them. Since it can withstand enormous loads, it is not at all surprising why its failure is a fairly common event.

If during the next maintenance of your vehicle it was discovered that the silent block filler was squeezed out and a web of cracks formed, then it is necessary to replace this unit in order to avoid subsequent problems. Malfunctions of the upper and lower control arms have a significant impact on vehicle control. In addition, the tread of the front tires begins to wear very badly.

Silent blocks resource, ways to check them

The service life of silent blocks depends on the operating conditions of the vehicle. If the car is used on roads with good coverage, then the joints can move up to 100 thousand km.

But constant travel on roads with poor road surfaces (potholes, potholes, etc.), of which we have a lot, significantly reduces the service life of the product, and its replacement may be required after 40-50 thousand km.

The main signs of severe wear of rubber-metal joints are deterioration in car handling, vibrations on the steering wheel, knocking from the wheel arches while driving over uneven surfaces.

Checking the condition of silent blocks is not difficult. First, you should simply inspect them, or rather, the visible parts of the rubber elements.

If it is clear that the rubber layer has “come apart” and cracks are visible on it, then such a hinge no longer fully performs its functions.

Additionally, you can use the mount to swing the suspension elements in which the silent blocks are installed. A large amplitude of vibration of the unit and knocking in it indicate critical wear of the hinge and the need for its replacement.

Lower arm of the front suspension VAZ 2107

The VAZ 2107, popularly known simply as the “Seven,” is the latest rear-wheel drive representative from the model range of the popular domestic manufacturer. Unlike front-wheel drive cars, the front suspension here has fewer parts, so diagnosing and repairing it is much easier and you can handle everything yourself, without involving expensive specialists.

The “Seven” has an independent front suspension, the main parts of which are two levers: upper and lower. The lower arm connects the hub or steering knuckle to the car body. Due to the front suspension arms, the wheels are held in a vertical position, and the lateral forces that arise while the vehicle is moving are dampened.

Lower arm housing

The lower arm is fixed to the suspension cross member, which is mounted on the front side members. A ball joint is attached to it, and a spring also rests on the lower edge. All this makes it difficult to replace this suspension element, but even a novice car enthusiast can cope with such a task with his own hands. It is enough to determine the cause of the breakdown, and then act in accordance with the developed rules and recommendations of specialists.

Spherical bearing

A ball joint is securely fixed directly to the lower arm. This is a hinge element that connects the lever and the hub.

The ball joint absorbs all the impacts that occur when the wheel hits uneven roads, so special attention is paid to its strength

Serviceable ball joints limit the swing of the wheel in the vertical direction, but at the same time allow it to move freely in the horizontal plane. When a ball joint breaks, the wheel turns spontaneously, and if this happens while driving, it can lead to an accident.

This element is a hinge, the main part of which is a ball rod, on one side there is a ball, on the other there is a thread. The rod is securely pressed into the eye with a plastic liner, after which the entire structure is covered with a boot to prevent moisture and dust from entering the friction points. Modern manufacturers usually use transparent boots, which allows you to assess the condition of the hinge without removing this element.

Since the ball joint is a very important and responsible part of the suspension, if it needs to be replaced, you need to purchase only high-quality products. Some of the most reliable and popular manufacturers of ball joints are the following brands: “TRACK”, “KEDR”, “BELMAG”, LEMFORDER (German company)

In addition, any major manufacturer offers reinforced versions of such parts; they are also called sports: “Track-sport”, “Cedar-trial-sport”, etc.

Silent block

The silent block is a part that allows the lever to rotate on an axis. It consists of two metal bushings, between which there is a rubber insert.

Modern industry offers silent blocks made of rubber and polyurethane. Nowadays, basically everyone is switching to polyurethane silent blocks, since they have a longer service life, but their cost is several times higher than their rubber counterparts.

Replacing rubber silent blocks on a VAZ 2107 with polyurethane ones allows you to:

- reduce deformations occurring in the suspension;

- improve car handling;

- remove the squeezing that is typical of rubber products;

- reduce noise and vibrations that occur while driving.

Axle bolt

The axis of the lower arm is rigidly connected with two bolts to a beam fixed to the front side members. On the axis, the mobility of the lower arm is ensured by the presence of silent blocks.

Removing the upper arm of the VAZ front suspension is necessary in three cases:

- Replacing the lever.

- Replacing silent blocks.

- Replacing the lever axis.

The procedure for removing the lever is as follows:

- Place the car on a lift or inspection hole.

- Remove the wheel using a wheel wrench and a jack (the latter is only needed in a pit).

- Remove the bolt securing the front bumper bracket.

- Disconnect the upper ball joint by unscrewing the self-locking nut and mounting bolts.

- Unscrew the self-locking nut of the lever axle, holding the axle with a wrench.

- Remove the axle.

- Remove the upper arm.

Replacement of the rear wheel bearing of VAZ-2101, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic

In this article we will look at how to change the rear wheel bearing of a VAZ-2101, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic and how to check the rear wheel bearing of a VAZ.

It was time to change this bearing a long time ago, but for some reason I only got around to it now. On the highway the car still behaves normally, but on the off-road the rear of the car began to wobble, and it began to creak when cornering.

The easiest way to check the rear wheel bearing is to press the outside of the wheel with your foot to wiggle it (you will hear a distinct thump). The wheel will simply dangle.

One thing can be said, if you drive carefully, these spare parts will last a long time, if you don’t drive carefully, you will gouge everything, even those spare parts that cost 100 rubles more. The most important thing to understand is that careful driving extends the life of any part and the car as a whole. The bearing must be well filled with grease. Now let's start removing the wheel and see how to change the rear wheel bearing of a VAZ-2101, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic. Changing the rear bearing is very easy, not like the front wheel bearing.

1. We begin to remove the wheel. We tear off the bolts when the wheel is on the ground, it’s more convenient. And there is no need to put it on the handbrake, since you will have to remove the brake drum.

2. When you lift the car with a jack, be on the safe side. The picture shows that the car rested against the jack and the safety stump. If the jack falls out, the box will rest against a stump. Even if the box bends, it’s okay, but you will remain alive.

We remove the drum.

Unscrew the nut.

We knock out the bearing (the blows should fall on the inner race, since the outer race is very thin and will crumble).

6. All that remains is to hammer in the new bearing. In order for the bearing to seat well, lubricate the walls of the cage with oil. Align the wheel bearing as level as possible. And carefully hammer the bearing evenly, the main thing is that it does not warp. If the bearing is installed level, it will easily go into place. Install the retaining ring and screw it back on.

If you hit the hub, the inner part of the bearing race will come out, this cannot be allowed. Therefore, we score with light blows using a pipe. All that remains is to tighten the nut so that nothing dangles. The bearing must be tightened, the tighter the better. Tighten tightly and loosen a little, and seal.

8. All that remains is to install the wheel. The wheel will no longer dangle. 2 years should be enough.

Replacing the rear wheel bearing of a VAZ-2101, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107, Classic can be done with your own hands, it is not difficult.

Body reinforcement

Today, many motorists are wondering about strengthening the body. All the advantages of this operation can be explained using the example of a cardboard box from any model of household appliance. It is easy to tear it with your hands, but if you strengthen it at the corners with tape, the box turns into a durable thing that is not so easily dented.

VAZ 2106 body strengthening

The car will be more prepared for extreme and emergency situations if it is strengthened. Despite the fact that the frame of this car is quite rigid and durable, some of its areas are so vulnerable that they are easily deformed.

Front and lower struts

Installing the lower brace

Installing front struts is one of the common methods of strengthening. This tuning has a lot of advantages:

- Ease of implementation;

- Low cost of work;

- A significant increase in the rigidity of the car frame in the front part.

Selecting spacers for your “six” will also not present any difficulty. There are various models of these components available on the market. There are so many of them for every taste and color that it’s dizzying. It will be easy for each owner of a VAZ 2106 to choose front struts that are suitable in terms of parameters and price characteristics.

Even an inexperienced owner can strengthen the “six” with front struts. The geometry of the car is simple, various elements are installed in several ways, without much complexity.

In addition to the usual front struts for reinforcement, there are also lower struts. Their installation will have a positive effect on the body, the handling characteristics of the “six” will increase, and road stability will improve. But the lower struts are quite difficult to install compared to the front ones, and not every car owner is capable of this.

Bottom and its reinforcement

Body modification for VAZ 2106 photo

We offer an option for strengthening the bottom of the VAZ 2106. It is suitable for beginners who are not “friendly” with welding. The process can be carried out in normal garage conditions. The method is not only simple, but also cheap. The price of consumables will not take much money out of the family budget.

We prepare the following materials and equipment:

- Pieces of galvanized steel (about 2 square meters);

- Bitumen-based mastic (2 cans are enough);

- Fastening elements (bolts, screws);

- Grinder and drill;

- New spars.

Here's what to do:

- Disassemble the interior, remove the Shumka;

- Scrape the mastic from the bottom to make it easier to assess the condition of the floor;

- Cut off rotten and too rusty parts of the floor with a grinder;

- Using the same grinder, polish the metal floor;

- Cover the floor inside and outside with pieces of tin;

- Apply with mastic (it is better to use two layers with breaks for drying);

- Treat the galvanized surface with mastic. Fix the pieces prepared for installation from the outside with self-tapping screws (cut off their protruding ends in the interior);

- In the interior, put galvanized sheeting, also heavily coated with mastic, but fasten it with bolts.

Reworking the body of a VAZ 2106 instructions

- Prepare the side members by drilling 6 holes on the mating tabs (3 on one side and 3 on the other);

- Place the spar to the floor, press it from below with a jack and mark the locations of the holes in the floor;

- Remove the side member and drill holes in the floor;

- Treat the element with mastic, as well as the bottom section in this place;

- Place and secure firmly with bolts.

That's it. The protruding ends of the bolts can also be cut off. The sheet of iron supplied must also be covered with mastic on top, trying to push it into the cracks (if any remain). The cost of this tuning will not exceed 1000 rubles, but the effect will be just right. A floor reinforced in this way will last longer than one that has been overcooked.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

If you still have any questions, you can ask them using the feedback form, or write us an email at