The front suspension arms of the VAZ 2107 are subject to significant loads when driving, and given our roads, their premature failure is not surprising. To take care of your safety, you need to regularly check the condition of the suspension and have it repaired in a timely manner. In this article I want to touch on how to replace the upper front suspension arm of a VAZ 2107 (this, in principle, also applies to models 2101 - 2106).

Reasons for replacement

This is a fairly rare repair as the upper arm is subject to less stress than the lower arm, but it does happen. The reason for replacing a part may be:

Trying to solve the problem by soldering and straightening is simply not recommended if you value your life. Firstly, it is dangerous to drive a car with a faulty suspension part, even if in your opinion it is not critical. Secondly, the price for the upper arm of the VAZ front suspension is low (about 200 rubles), so it is better to replace it.

Tool for work

You will need a good jack. It is preferable, of course, to use a hydraulic one, as it is much more convenient to work with. But if there is none, then use the one that is in your arsenal. You also need car supports and wheel chocks. With their help, you will prevent the car from rolling and falling. The upper silent blocks of the VAZ-2107 are being replaced after removing the lever. But to press out the hinge you will need a special puller. Its cost is slightly less than that of a set of hinges, but it will be useful in the future, during the next suspension repair. And of course, you need a standard set of tools - open-end wrenches, spanners, and socket wrenches.

Replacing the upper arm

- jack the car;

- remove the wheel;

- unscrew the protection;

- unscrew the bumper mounting bolt;

- We unscrew the nut and squeeze out the ball joint bolt with a puller (you don’t have to touch the bolt, but unscrew the ball joint itself);

- unscrew the lever axis;

- remove the upper arm;

- fix the lever in a vice and remove the silent blocks with an extractor;

- We install removed or new silent blocks onto a new one.

We assemble in reverse order.

Check the condition of the silent blocks and ball joint in advance; it is better to replace them immediately. Check the size of the old and new parts. It happens that after such a replacement the upper arm touches the spring, since the new one has a difference in size (false). I purchased it during repairs, after assembly the spring clings to the part. After starting, all the springs died.

Price list

- Special offers

- KAMAZ spare parts

- Spare parts KAMAZ-5490

- Spare parts MAZ, YaMZ

- ZIL spare parts

- Spare parts ZMZ, for GAZ vehicles

- Spare parts for Volzhanki cars

- Spare parts for Gazelists

- Spare parts for trucks Lawns

- Spare parts for GAZ-71 caterpillar

- Spare parts UAZ, UMZ

- Spare parts KrAZ, BelAZ

- Spare parts URAL

- Spare parts BUSES

- AMAZ spare parts

- IKARUS spare parts

- KAVZ spare parts

- LAZ spare parts

- LIAZ spare parts

- NEFAZ spare parts

- PAZ spare parts

- Other buses

- Tractors, computer equipment, attachments

- Tractors and walk-behind tractors

- Municipal vehicles

- Attachments and trailed equipment

- Spare parts for TRACTORS and SPECIAL EQUIPMENT

Notes

It is better to replace the self-locking nuts of the upper ball joint and axle with new ones.

If your VAZ 2107 has an upper arm kickback and it is loose, then it’s time to change the silent blocks or change the axle due to wear due to poor tightening.

If the VAZ 2107 upper arm bolt does not come out, treat it with a WD wheel, then turn it with a wrench and lightly tap it.

Shoulder replacement video:

The most loaded element of the VAZ 2107 car is the front suspension. In fact, it takes on almost all the mechanical loads that arise during movement. For this reason, it is important to pay close attention to this unit, carry out timely repairs and, if possible, modify it by installing more durable and functional elements.

What are silent blocks needed for?

All cars that are called classics have wheels. Consequently, it is more complex when compared with MacPherson, which is used on front-wheel drive cars. From this we can conclude that the front silent blocks of the VAZ-2107 should be replaced as often as possible in order to avoid problems with control. The appearance of rubber-metal hinges resembles a glass. It is made of metal inside and treated with rubber on top.

Suspension arms are precisely the elements into which silent blocks are mounted. There are a total of four levers on the front of the VAZ-2107 - two on the left side, and the same number on the right. They are attached to the body using rubber-metal hinges. It was, of course, possible to use ball bearings for this purpose, but their service life would be much lower. And they would not be able to smooth out the impacts when driving on uneven roads.

Purpose and design of the front suspension

suspension is usually called a system of mechanisms that provide an elastic connection between the frame and the wheels of the car. The main purpose of the unit is to reduce the intensity of vibrations, shocks and jolts that occur during movement. The machine constantly experiences dynamic loads, especially when driving on poor-quality roads and when transporting goods, i.e. in extreme conditions.

It's at the front where the suspension most often experiences bumps and undulations. By right, this is the busiest part of the entire machine. On the G7, the front suspension is made better and more reliable than the rear - the manufacturer, of course, took into account the high load on the unit, but this is not the only reason. On rear-wheel drive vehicles, the front suspension has fewer parts than the rear, making it cheaper to install.

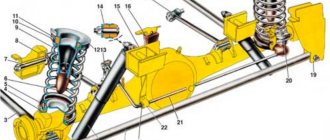

The front suspension diagram of the VAZ 2107 includes important parts, without which the smooth movement of the car would be impossible.

- Anti-roll bar or anti-roll bar.

Front beam

The purpose of the front beam is to stabilize the car when cornering. As you know, during maneuvers a centrifugal force arises, which can lead to the vehicle tipping over. To prevent this from happening, the designers developed a transverse stability beam.

The main purpose of the part is to rotate the opposite wheels of the VAZ 2107 using an elastic torsion element. The stabilizer is secured with rotating rubber clamps and bushings directly to the body. The bar is connected to the suspension elements using double wishbones and shock absorbers, or bones, as they are also called.

Levers

The front levers are the driving elements of the VAZ 2107 chassis. They provide a flexible connection and transmission of vibrations to the body.

The levers are directly connected to the wheels and body. It is customary to distinguish between both suspension arms of the “seven”, since they are replaced and repaired in different ways:

- the upper arms are screwed on and are easier to remove;

- The lower arms are bolted to a cross member connected to the side member, they are also connected by a ball joint and a spring - replacing them is a little more difficult.

Front shock absorber strut

VAZ 2107 owners learned about the existence of racks when the VAZ 2108 model appeared. From that time on, the manufacturer began to gradually install new mechanisms on the “seven”. In addition, the racks were chosen by specialists who modernize a classic car.

The strut is part of a damping system, the work of which is to dampen vertical vibrations of the body that is subject to certain impacts. The stability of the car on the road depends on the technical condition of the strut.

The front shock absorber strut consists of several separate elements:

- glass or top thrust cup with bearing. It takes the load from the shock absorber and distributes it throughout the body. This is the strongest point of the strut, on which the top of the shock absorber rests. Glass is quite difficult to repair, it consists of a special thrust bearing, nuts and washers;

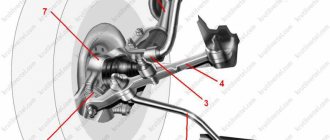

Spherical bearing

A ball joint is an element of the front suspension that provides a fairly rigid attachment of the lower arms to the vehicle hub. Thanks to these loops, the car on the road can ensure smooth movement and necessary maneuvers. In addition, thanks to these parts, the driver can easily control the wheels.

The ball joint consists of a pin with a ball, a thread and a housing with a recess. The finger, which is an important part of the element, has a protective cover. Regular inspection of the balls by the driver helps to avoid breakages: as soon as a crack is discovered on this protective element, it is necessary to urgently inspect the zipper.

I remember the first time in my life I changed ball valves. It happened unexpectedly: I went to the village to visit a friend. Exciting fishing was expected. On the way to the lake I had to brake sharply and turn the steering wheel. A creaking sound was heard, then a bang, and the car began to be pulled to the left. “The ball flew,” said Tolya (my friend) with the air of an expert. Indeed, when the car was lifted, it turned out that the “center” had jumped out of its socket - what a force the blow must have been! Apparently, the ball had been subjected to heavy loads before: it often traveled along a dirt road and did not spare the “seven”, sometimes crossing the field, stones and holes. Tolya went on foot to look for new loops. The broken part was replaced on site, and the second one was installed later in my garage. Fishing was unsuccessful.

Hub

The hub is located at the center of the front suspension structure and is a rounded piece connected to a shaft. It has a bearing, the model and strength of which depend on the design work.

Therefore, the hub consists of a housing, metal wheel studs, bearings and sensors (not installed on all models).

The steering knuckle is an important part of the hub because it integrates the entire front suspension with it. The element is fixed with hinges to the hub, steering tips and strut.

Removing the lower arm

If it is not possible to change the silent blocks using the method described above, or the lever is destroyed, you need to completely disassemble the mechanism. To do this you will need:

- Spring puller.

- Keys for "10" and "19".

- Gas canister (if there is a need to press out the old silent block).

Removing the top one turns out to be somewhat simpler, since this element does not affect the camber angles of the wheels. But when dismantling the lower arm, pay attention to the plates that are located between the body and the axle. It is with their help that the camber angle of the wheels is set. And in addition to purchasing a repair kit, you will also need to adjust the wheel angles.

In order not to disturb the settings, be sure to install these metal washers in the order in which they were installed. They cannot be swapped. When removing the lower arm, you will need to do the following:

- Compress the spring with a special puller.

- Remove the three bolts that secure the ball joint.

- Remove the two nuts that secure the shock absorber to the arm.

- In the engine compartment, unscrew the nut from the shock absorber rod, after which the entire thing must be removed from the VAZ 2107.

- Disconnect the lateral stability link bracket.

- Now you can remove the lever by unscrewing the two nuts that secure the axle to the body.

Now all that's left to do is the repairs are moving to the completion stage. Using a gas canister, you warm up the places where the silent blocks are pressed. Unfortunately, this is the only way to change the hinges, which even a puller cannot remove. You should not do this procedure indoors, as the rubber will immediately begin to burn and smoke will fill the entire space. Carry out such removal of silent blocks only in the open air, or in a well-ventilated area.

Removing silent blocks VAZ 2107: suspension repair

4 — Ratings: 32

A silent block is a machine part that is needed to reduce the noise of the suspension. It is also an intermediary between the frame element (subframe, spring, shock absorber, lever, etc.) and the rigid body structure.

Silent blocks connect the suspension parts, which eliminates vibrations and rattling in the joints of the parts. During driving, the silent block accounts for the bulk of the shock loads received by the suspension, so its function is to restrain significant deformation, which occurs simultaneously in different directions and planes. In addition, it serves to ensure angular, radial and axial compliance.

Materials used to make hinges:

- Metal.

- Rubber.

- Polyurethane.

In a VAZ-2107 car, the hinges are on the suspension both front and rear. This location is determined to ensure the reliability of the fastening. In the latter place, silent blocks are damaged more often due to the colossal load placed on them.

Due to the enormous loads placed on these parts, the manufacturer initially guarantees a very long service life, namely replacement no earlier than after 100 thousand kilometers. But due to the quality of the road surface in our country, all specialists recommend checking silent blocks no later than after 50 thousand kilometers or if there is a suspicion of their malfunction.

List of signs of failure of silent blocks on the VAZ-2107:

- the car pulls to the side while driving;

- the car rocks when turning;

- When driving over bumps in the suspension, a distinct metallic ringing will be heard.

If you suspect the presence of this kind of problem, it is necessary to carry out an inspection, and for this you should go to the pit and inspect a possible breakdown. If cracks, tears are found in the rubber part, or it protrudes from under the washer, these are the first signs of urgent replacement. If the silent blocks on a VAZ-2107 break, the levers become slightly crooked, and if they are completely worn out, the metal parts can break the hinge seats, which will lead to great difficulties in eliminating this problem.

Replacing faulty silent blocks on a VAZ-2107 is quite possible without contacting specialized service station workers.

Front suspension malfunctions

Problems with the VAZ 2107 suspension arise due to bad roads. First of all, the ball joints suffer, so the struts and other elements of the shock absorption system fail.

Quite often, owners of the “seven” complain of a shock when driving at a speed of 20-40 km/h. Then, as they accelerate, the dull sound disappears. The noise zone is the front suspension.

First of all, it is recommended to put the car on a lift and check how the ball, shock absorbers and silent blocks work. The wheel bearings may be worn.

Experienced owners of the VAZ 2107 claim that the low-speed shock that disappears during acceleration is associated with the shock absorbers. They receive a vertical blow from below when the machine moves slightly. At high speed the car levels out and the shocks disappear.

Below are detailed instructions on what to do if a driver notices a collision.

- Inspect the glove box, instrument panel components, and other parts of the cabin that may be impacted. It is also worth checking the engine protection and some parts under the hood - maybe something is loose.

- If everything is in order, you need to move on to checking the suspension.

- The first thing you need to check is the condition of the silent blocks - be sure to check the rubber bushings on both levers. The bushings knock, as a rule, when starting from a stop or during sudden braking. The problem is eliminated by tightening the bolts and nuts or replacing the elements.

- Perform diagnostics on the suspension strut support bearing. Many people do this: they open the hood, put one hand on the support bearing, and rock the car with the other. If the element is triggered, you will immediately feel shocks and impacts.

Video: what is knocking in the front suspension

The car is pulled to the side

If the car begins to pull sideways, it can cause the steering knuckle or suspension arm to become deformed. On old VAZ 2107 cars, it is possible that the rack spring will lose its elasticity.

Basically, if a car pulls to one side, it is due to brake pads, play in the steering, and other non-suspension-related causes. Therefore, it is recommended to proceed to the elimination method and only then check the suspension.

Noise when turning

The hum when cornering is associated with wear on the wheel bearing. The nature of the noise is as follows: observed from the side, appears up to a speed of 40 km/h and then disappears.

Here's how to check a wheel bearing for play.

- Place the front wheel on a jack.

- Grasp the top and bottom of the wheel with your hands and begin to swing it away from/towards you.

Signs of malfunction of levers and silent blocks

One of the signs of a malfunction is noise in the suspension when driving, especially on a bad road. Among other things, it occurs when silent blocks (rubber-metal hinges of levers) are severely worn. Also, if the silent blocks are worn out or the VAZ 2107 lever is deformed, it becomes impossible to set the alignment angles of the front wheels. The same problem occurs when the axes of the front arms are deformed.

If the levers are deformed, the car may pull to the side when driving on a flat road. An extremely unpleasant phenomenon - self-excited vibrations of the front wheels - is often a consequence of wear of the silent blocks.

Elimination of any of the listed malfunctions of the levers and silent blocks requires the removal of the suspension arms.

Tools

For repair you will need:

- jack;

- wheel wrench;

- keys 13, 17, 19, two keys 22;

- upper arm;

- ball puller;

- silent block remover (you can do without it).

Replacing the upper suspension arm of a VAZ 2107

The upper suspension arm of the VAZ 2107, as well as the lower one, is replaced in case of mechanical damage, as well as to replace worn silent blocks.

The sequence for disassembling and removing the upper arm is as follows:

- Remove the wheel from the side to be repaired.

- Disconnect the upper ball joint from the lever; to do this, use a thirteen key to unscrew the three nuts of the ball joint housing bolts (see Replacing ball joints on a VAZ 2107).

- After the ball joint is disconnected, slightly lift the lever up and use a 22mm wrench to unscrew the self-locking nut of the bolt securing the lever to the car body, hold the bolt from turning with a second 22mm wrench.

- Remove the bolt and lever. In order to remove the bolt (it is long), you may need to unscrew the front part of the plastic fender liner. The bolt may rest against the fender liner.

After the lever is removed from the car, it is necessary to remove two silent blocks:

- Clamp the lever in a vice and install the puller. When tightening the puller bolt, first press one, then the other silent block out of its place.

- Replace the lever or make some other repair and use the same puller to install new or old silent blocks in place.

Install the upper suspension arm of the VAZ 2107 in the reverse order of removal

Having installed the lever, install its fastening bolt, tighten, but do not completely tighten the self-locking fastening nut, then load the suspension by placing a spacer under the lower arm and lowering the car on a jack, screw the ball joint housing to the upper arm and without unloading the suspension, tighten the nut of the lever fastening bolt .

If the ball joint was disconnected by pressing out the pin, then it is recommended to replace the self-locking nut securing the pin, as well as the nut securing the lever axis, with new ones. At this point, the repair work of removing and replacing the upper arm is completed.

After replacing the lever and/or silent blocks, it is necessary to re-adjust the wheel camber/toe angles.

Suspension upgrade

The standard suspension of the "seven" is considered soft and imperfect. That's why many people decide to do tuning and modifications. This helps significantly improve handling and overall comfort, as well as extending the life of springs, balls, bushings and other components.

Reinforced springs

Springs are the main element that ensures a smooth ride, directional stability and good handling. When they are weakened or lowered, the suspension cannot compensate for the load, so failure of its elements and other problems occur.

Owners of the “Seven” who often drive on bad roads or drive with a loaded trunk should definitely think about upgrading the standard springs. In addition, there are two main signs by which you can judge that the elements need to be replaced.

- After a visual inspection, the springs were found damaged.

- The vehicle's ground clearance has decreased significantly because the springs have dropped over time or due to excessive load.

Spacers are the first thing that comes to mind for VAZ 2107 owners. But this is not an entirely correct conclusion. Yes, they will restore the stiffness of the springs, but will negatively affect the service life of the elements. Soon cracks will appear on the springs reinforced in this way.

Therefore, the only correct solution would be to replace conventional springs with reinforced or modified ones from the VAZ 2104. In this case, the shock absorbers must be replaced with more powerful ones, otherwise the reinforced springs will easily damage the standard system.

Before you begin the replacement procedure, you need to equip yourself with the following tools.

- Lift up.

- A set of various keys, including a wheel wrench.

- Scrap.

- Bruscom.

- Wire hook.

Now more about the replacement.

- Place the car on a jack and remove the wheels.

- Disassemble conventional struts or shock absorbers.

- Loosen the shoulder clamps.

- Place a block under the car and lift the lower arm with a jack.

- Unscrew the stabilizer bar mount.

Then you need to release both springs from the seals and check the condition of the latter. If they are in good condition, install them onto the new spring using electrical tape. Install reinforced springs in place of the standard ones.

Air suspension

The “Seven” has great potential in terms of modernizing the front suspension. And many car owners decide to install an air suspension with an electric compressor, hoses and a control unit.

This is a real electronic assistant that allows you to change the ground clearance depending on driving conditions. Thanks to this innovation, the car's stability at high speeds increases, long trips become comfortable, the car overcomes bumps more smoothly, in a word, it looks like a foreign car.

The system modernization goes like this.

- VAZ 2107 is installed on a pit.

- The battery is de-energized.

- The wheels are removed from the car.

- The front suspension was completely disassembled and air suspension elements were installed in its place.

- The control unit, compressor and receiver are located under the hood. Then the elements are connected to each other by pipes and hoses.

Video: air suspension on a VAZ, is it worth it or not?

Electromagnetic suspension

Another upgrade option involves the use of an electromagnetic suspension. This is a set of mechanisms and components that act as a link between the road and the body. By using this suspension setup, a smooth ride, high stability, safety and comfort are guaranteed. The car will not “lower” even during long stops, and thanks to the built-in springs, the suspension will remain operational even in the absence of commands from the on-board network.

Today the most famous manufacturers of electromagnetic suspensions are Delphi, SKF, Bose.

The front suspension of the VAZ 2107 requires timely maintenance and inspection of the main components. Remember that road safety depends on this.

Hospitality! Upper arms: a ball joint is installed on them, in addition, thanks to them, it also holds the spring (Located inside, between the lower arm and the body, but the upper arm also plays an important role, if you remove this, the springs will fly out of their place after the first impact ), all classic levers are used in the front suspension, if we are talking about PP- “Front-wheel drive”, then they have a suspension design, then the rear one, the one that has been radically changed in the front, there are already telescopic struts, thanks to which the car is better It stays on the road and the spring and shock absorber eliminate unevenness as much as possible, because they are very, very close to each other (the shock absorber is located inside the spring).

Note! To replace the upper control arm you need to remove the wheel, ball joint, and to remove the ball you will need a puller and a lot of time, so immediately be patient, pick a day and get to work you will need to do. : Also, horn keys, caps, connecting rods with heads would be nice, and you will also need a balloon and a jack to hang the front of the car!

Summary:

Where is the upper arm? Below is a photo in which the arrow indicates the upper lever. Today we are disassembling this lever, unlike the lower one, it is not difficult to replace it, because everything is done to a minimum, that is, we unscrew the three small nuts that attach the ball joint and then unscrew the large nut, the bolts of the upper arm and after that it will be necessary to remove it, and if the lower one changes, then it will be a hemorrhoid, firstly, it is inconvenient to crawl the nuts, secondly, the spring must be tightened with ties and thirdly, the upper ball will need to be unscrewed before anything becomes possible, because that the upper lever will interfere and by unscrewing the ball and pressing on it with a special puller, the upper lever can be easily tilted back, that's how many more actions need to be done, so drive carefully, most often it is not possible to turn the lower lever (usually when you get into a deep hole , if you drove the car for more than a year, q so most likely they got into such a situation and since the lever is at the bottom and the car falls into the hole, all the weight falls on it, in other words, the car falls on the lever, which means it is deformed and must be replaced).

When should you change your shoulder? It should be replaced only in case of deformation, if it was accompanied by a crack and similar defects, there are those who change the levers when the bushings break, but some of these bushings themselves are changed in the old levers and put everything in place, without special tools these bushings cannot be replaced, they press hard, and new ones go even worse, therefore, in order not to bother, motorists immediately buy a new lever assembly, the price of which is 200-400 rubles, you can find it for 100 rubles for disassembly in normal conditions.

How to replace the upper arm on a VAZ 2101-VAZ 2107?

Note! Before you start replacing the arm, you can stock up on special offers of a ball joint puller, but just look at the fact that the puller is really intended for ball joints, otherwise some sellers sell a puller for steering rods, for example, and say that it is fantastic, but this is where difficulties and wasted time begin, so don’t listen to the sellers, but read what is written on the box, what is it, since the upper arm will be removed, the upper spheres will also go to take from half, using a puller and remove them completely if the balls have already arrived unusable and require replacement, then this is the best time to use it, then sit on the front suspension, that is, do not change the ball better!

1. Lift the wheel, then remove it, remove the upper ball joint, if you are not going to remove it, but just decided to replace the lever, you will need to unscrew not three nuts, but also the healthy nut that secures the ball joint, you will find how to do everything in the article entitled: “Replacing a ball joint with a classic one,” read points 1 and 2 and everything will immediately become clear to you.

2. That’s it, since the ball is removed or separated from the upper lever, you can proceed to removing it, to do this you will have to unscrew the nut of the bolt that secures the lever, over time it turns sour and it is very difficult to unscrew it, the most important thing is to make sure that the edges do not fall off the nuts , otherwise there will be very big problems and the lever will have to be removed from the car much longer.

3. After unscrewing the nut, unscrew the bolt and remove the lever, replace the damaged lever with a good one, and also insert the bolt and tighten the nut that secures it. Before inserting the bolt, it is recommended to lubricate it with graphite grease, so that in the future, when removing the upper lever again the nut is quite easy to unscrew and, by the way, you need to tighten this nut, like the healthy nut of the ball joint pin, it’s very, very difficult, it’s better not to mess with the suspension, if these nuts are turned out, the wheel just fell to the side and if the car also starts moving, nothing good it won't work out.

Note! If your upper control arm is in good condition and you only removed it to replace the silent blocks inside it, take a closer look at the video below, which explains the entire principle of replacing them!

Features of replacing silent blocks on different models

VAZs 2108-21099 and 2113-2115 use strut mounting brackets. Therefore, it is easier to replace silent blocks. Unscrew the nuts securing the brackets and remove them.

Next, pressing and pressing is carried out using a vice using a piece of pipe and an extension.

In models 2110-2112, the spacer is attached to the cross beam. Therefore, replacing silent blocks is usually carried out without removing the beam from the car. And a puller is used to carry out all work.

READ ON THE TOPIC: Typical malfunctions of the VAZ 2110 and other cars in the series.

Definitely, when replacing silent blocks on any VAZ model, you will have to suffer a little. Here, in addition to dexterity and flexibility of thinking (in the technical aspect), you also need strong nerves.

Therefore, it is no wonder that many car owners entrust such work to car services. And not everyone has a garage with the necessary tools and equipment.