Hi all! Any problems associated with the braking system of vehicles are potentially very dangerous. Therefore, every motorist should know why the brake caliper jams, what can provoke such a situation, how to diagnose and eliminate it. On your own or with the help of specialists, decide for yourself.

Our regular readers remember that we have previously talked about situations when the caliper knocks. Now let's consider a slightly different situation. Moreover, it is even more dangerous and unpredictable in terms of possible consequences if nothing is done after noticing the symptoms.

Let's start with the theory. The caliper on a car is part of the brake system. It is used in the design to press automobile brake pads when the corresponding pedal is pressed against the brake disc. As you understand, the node is extremely important.

But sometimes it can jam and creak because of this.

Reasons for caliper failure

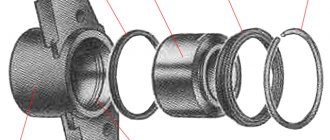

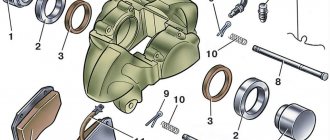

The design of the caliper is quite simple: it is a cylinder with a piston, a movable bracket that moves on guides, a bleeder fitting and protective boots. However, even in such a seemingly simple component of the brake system, problems often arise. Let's look at the reasons that lead to brake caliper failure:

- Tearing of the anthers is the first and most important cause of brake caliper failure. Despite the fact that the piston is made of relatively corrosion-resistant steel, when water gets in it gradually begins to rust. And due to the fact that the piston is fitted to the cylinder with a very small tolerance, even surface corrosion can cause serious impairment of its mobility. The caliper boots (both on the piston itself and on the guides) are most often damaged due to unqualified intervention in the system, for example, when replacing the pads by a non-specialist.

- Late replacement of brake fluid. All modern brake fluids are hygroscopic (except for silicone DOT-5), that is, they accumulate water in their volume. The presence of water leads to corrosion on metal surfaces and accelerated wear of seals. And in this case, visually, the entire caliper may be seriously damaged from the inside due to exposure to brake fluid enriched with water.

It is recommended to change the brake fluid at least once every three years, regardless of the vehicle's mileage. This is the average service life until a critical amount of water accumulates in its volume. In regions with a humid climate, it is better to replace more often: once every two years.

- Critical wear of discs and pads. The more the pads and discs wear, the further the caliper piston has to extend to create braking force. This is fraught with spontaneous tearing of the anthers, the appearance of a leak, and even jamming of the caliper.

We have listed the main reasons why a caliper may fail. The best way to avoid problems is to monitor the brake system: replace worn or damaged parts in a timely manner and periodically lubricate the guides. If you do not deprive this unit of attention, then it is quite capable of working until the end of the car’s service life without replacement or repair.

About diagnostics and scheduled maintenance

To prevent this kind of repair work from turning into a kind of regular ritual, it is necessary to regularly diagnose the entire brake system and monitor the cleanliness of each individual part.

Timely diagnosis

allows you to avoid not only jamming of the caliper, but also premature, uneven wear of the brake pad and overheating of the brake discs. All this makes it possible to maintain the serviceability of the brakes and be calm on the road.

Once a year, it is best to carry out a detailed check of the caliper piston and boot.

– it must be without any damage. The surface of the caliper, its piston and other parts should be free of rust and serious contamination.

For prevention, you can treat the surface of the caliper with WD-40 once every 6 months.

The information presented here is a list of actions to take in cases where the brake caliper is stuck and the braking system begins to lose its original effectiveness.

Signs of caliper malfunctions

There are several main signs of a caliper failure. Let's look at the most common of them.

- Brake fluid leak. Monitor the brake fluid level in the expansion tank, and also periodically pay attention to the calipers. If possible, inspect not only their outer surface, visible from the wheel rim, but also the inner surface. Oily stains, even without obvious leaks, are the first warning sign. Carefully inspect the engine compartment from the side of the “fogged” caliper. If there are no other sources of oily traces visible, be sure to seek help from specialists.

Liquid can flow either through the gap between the piston and the caliper cylinder, or at the connection point of the line or through the bleeder fitting. Therefore, in some cases, repairs come down to just replacing a fitting or brake hose, which is much cheaper than a complete overhaul.

- The car spontaneously pulls to the side after pressing the brake pedal. If the suspension is in good working order, the wheels are inflated equally, and there are no irregularities in the wheel alignment angles, then this behavior of the car indicates a large difference in braking forces on one axle. And in most cases, the cause is a stuck caliper.

- The grinding of the pads on the discs after releasing the brake pedal is the main sign of a faulty caliper guide. After creating the force, under the influence of the rotating discs, in a working brake system, the pads should return to their original position. This occurs both by pressing the piston back into the caliper and by moving the caliper on the guides. As practice has shown, it is the bracket that rusts and loses mobility more often. Although the caliper, especially with a damaged boot, can also jam.

- Overheating of brake discs for no reason. If, after driving with relatively infrequent braking (for example, on the highway), the discs become too hot to touch, especially with the appearance of the characteristic smell of burning pads, the problem is almost always a jamming caliper.

Are you suspicious that your brake caliper has failed? Contact us for help! "Auto-Master" (gate No. 5) will repair a caliper of any design with a guarantee of its proper operation. Sign up with us using the form below or by calling +7 (905) 378-74-22.

Also read on our website about which timing belt is best to choose.

Issues discussed in the material:

- How do brakes work?

- What are the main causes of front brakes sticking?

- What other faults can cause the front brakes to jam?

Caliper repair methods

Caliper malfunctions can be different. However, we can highlight the most common cases, as well as recommendations for eliminating them.

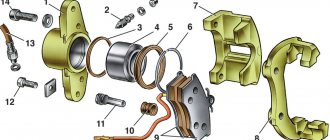

Brake pads jam in caliper

This is noticeable when, with the caliper removed, the pads do not move freely. Usually the reason is rust on the stationary caliper pads, which prevents the pads from moving.

To eliminate the problem, you should arm yourself with sandpaper, a metal brush and a file (but only a small one). Then you need to clean off the corrosion from the metal, and then lubricate the surface with a high-temperature type lubricant. However, there should be no wear on the caliper - pits from corrosion. If they are present, cleaning will not help - the pad will not be pressed tightly enough or will not move away from the surface of the brake disc quickly enough.

Sometimes such a defect can be eliminated with a file (subject to insignificant wear), but usually you have to buy a new part of the caliper (fixed).

Something else useful for you:

Video: Passat front caliper rebuild

Corrosion on the caliper piston

It can be triggered either by a defective boot or a long downtime of the machine.

To eliminate the problem, it is recommended to remove and disassemble the caliper. Remove the rust-damaged piston from it and polish it with a special paste or fine rust. After this, thoroughly wash the piston seat with WD-40 and reassemble the caliper. Installing new cuffs won't hurt either. But the best option would be to buy a new piston or caliper assembly.

The caliper guides are jammed

It is necessary to achieve free movement along the guides. To do this, you will need to dismantle the pads, then reassemble the brake caliper and try to move it along the guides. If sliding is difficult, it is recommended to take measures - inspect the guide for bends or breaks, lubricate them, clean them, etc. It is necessary to achieve free movement.

Piston jams in caliper

To check, you need to release the bleeder fitting after the pads jam. In the event of a malfunction, jamming is not observed after that. And with the caliper removed, it is extremely difficult to press the piston back.

For prevention, you can periodically move the piston all the way inside the caliper using a screw, and then push it out with the pedal. But not entirely, so that it does not fall out.

Volga gas car 31105

Comments 21

If they don't move, they're jammed!

As the brakes warmed up, they began to pull to the side when braking - uneven braking. Different pad wear on both sides. In general, unscrew it and it will become clear.

May jerk when braking

How does the steering gear feel?

yes, he seems to feel normal,

depending on how it jams, if in the open position, then the most obvious sign is that when braking sharply, the car is pulled in the other direction, if it jams in the closed position, then vice versa, when the pedal is already released, the car is already pulled in the direction of the problem

How the brakes work

The serviceability and correct operation of the car's braking system determines whether you can drive it normally or not. The law prohibits driving a car with broken or jammed brakes, even if it is a minor problem. This is still unsafe for both you and other road users.

To understand possible malfunctions and understand why the front brakes jam, you need to have an idea of the principle of their operation. The braking system in modern cars consists of brake discs or drum pads, which mechanically, if necessary, slow down the speed of the car. The system works like this: the brake pedal is pressed, the piston in the main brake cylinder moves, “adjusting” the brake fluid, which, in turn, passing through the lines, affects the brake cylinders of the wheels. They press pads equipped with a friction mixture against the discs or drums. This leads to braking.

In addition, the brake system is equipped with an expansion tank for brake fluid and a vacuum booster, thanks to which you only need to press lightly on the pedal. There are quite a few car models equipped with a special electronic system (ABS) that prevents the wheels from locking during braking.

We recommend

Other reasons why front brakes stick

The front wheels do not always jam the same way; this can manifest itself in different ways. Both front wheels can “stick” at once, and you simply won’t be able to move. It happens that they seem to be spinning, but with great difficulty, making a creaking sound. This is a dangerous situation, especially if you ignore the problem and continue driving. Only one front wheel can jam, while the other spins freely. Let's look at the possible reasons.

- The brake pedal is poorly adjusted or has no free play at all

.

There must be sufficient clearance between the master cylinder piston and the pusher for the pedal to move normally. This is adjustable.

Brake pad tension spring is faulty

.

This does not mean that it is cracked or completely torn, perhaps just stretched. There is such a thing as metal fatigue, and a weakened spring will no longer function normally; it is better to replace it.

Another reason why the front brakes stick is that the vacuum booster is not in order.

.

It can jam for several reasons. The diaphragm may be swollen, or the protective cap or lid seal may be pinched.

Pay attention to the amplifier adjusting bolt. It shouldn't be too tight. It is important that it protrudes slightly above the surface of the master cylinder.

There is something wrong with the brake pad friction lining.

.

The problems can be different: the gasket wears out, breaks, or becomes too thin. This usually leads to damage to the pad itself, so in this case both it and the lining have to be replaced. Important: if you are changing a worn gasket, then the pair to it should also be replaced; they must be the same in thickness, otherwise the car will be pulled off the line of movement to the side.

The reason that the front brakes are sticking may be a stuck piston in the wheel brake cylinder.

.

This kind of trouble can happen in any car, so you need to be able to deal with it. The reasons for this situation are different: low-quality brake fluid, uneven position of the cylinder body in the caliper, rust and corrosion on the working surfaces of the piston. Disassemble the problematic cylinder, clean all components, rinse with brake fluid, reassemble the system and bleed. Fill with good quality brake fluid.

The cuffs on the wheel cylinder have lost their shape or are swollen

- This is also one of the reasons why the front brakes jam.

The cuffs of the master cylinder or wheel cylinders swell from fluids such as oil, gasoline and others that have entered the brake system. This jams the cylinders, which results in a problem with the brakes. But you just have to replace the cuff, and everything will work out. It is recommended to at least occasionally check the condition of the cuffs, and when disassembling the car (no matter for what reasons), replace them, even if these elements appear to be completely intact.

Oxidation spots on the guides

.

They need to be cleaned, lubricated, and you will no longer have to think about why the front brakes are sticking.

The compensation hole on the brake master cylinder is dirty

.

This is a labor-intensive process, a large and messy piece of work, but no spare parts will be needed, meaning repair costs will be minimal. It is necessary to clean the hole and bleed the brake hydraulics.

The pistons of the master cylinder and wheel brake cylinders are stuck

.

In this case, only experienced car owners who have already disassembled and reassembled various systems of their car more than once will be able to figure out why the front brakes are jamming. It is better to entrust the diagnostics to specialists: they will find the cause of the malfunction and immediately begin repairs.

Save the brakes: everything about caliper maintenance

They don’t brake, they jam, they get hot... At some point, the brakes, which previously pleased with the precise operation, begin to throw up unpleasant surprises. This is due to the fact that most motorists begin to deal with this unit only when problems arise, although this should be done much more often, our expert today is convinced. For obvious reasons, he asked not to give his first and last name, but he promised to clearly demonstrate what brake maintenance is in his understanding.

The main enemy is corrosion

– Let's not forget that brakes, in principle, work in very harsh conditions. During active braking, the discs can heat up to 600 degrees! The rest of the caliper parts get less, but they also constantly experience heating/cooling, and besides, disc brakes are exposed to water, dirt, salt, sand...

It is clear that the caliper working cylinder is initially protected by a boot plus an O-ring (cuff). But over time, corrosion may appear on both the cylinder itself and the piston. Yes, one of the reasons is water and dirt that enter through a damaged boot (we don’t check the rubber bands often). But due to constant heating/cooling, condensation may occur, and the protruding edges of the cylinder and piston may also begin to corrode. Like here - do you see this “fungus”? In general, for one reason or another, corrosion occurs and the surface of the cylinder is damaged.

At first, the piston begins to move with noticeable effort; over time, this problem progresses, which affects the quality of operation of the entire system. You press the brake pedal, but it’s tight, you press harder, but “there are no brakes,” or they work normally every other time. The cylinder here is in very good condition, so in this case I will limit myself to running rust remover in there, then apply a special lubricant, and everything will be fine. But it is not always possible to resolve the issue this way, with little bloodshed.

Replacement or restoration?

If the problem starts, the piston generally gets stuck in the cylinder, and here you won’t get away with replacing the repair kit, which essentially consists only of rubber bands (boots and cuffs) - you need to somehow restore the surface of the cylinder, change the piston. The solution to the problem depends on the design features of the caliper, the car model, and the neglect of the issue. At a minimum, you will have to get (buy or grind) a new piston; at maximum, you will have to restore or buy a used or new caliper.

The last option is the most expensive. As a rule, people prefer to look for a used one or turn to workshops to repair or restore their parts - this turns out to be much cheaper. This is understandable: a new original or good licensed caliper for an inexpensive mass-produced model like the Opel Astra H will cost 3-4 million rubles, a used one will cost about 0.5 million, but will still require a rebuild and installation of a repair kit, so restoration is all it will still be cheaper.

By restoring a caliper, you get a new part. Pistons, guides, boots and cuffs are changed, and only the body remains old, which has been thoroughly cleaned (as a rule, they prefer to sandblast) and a new protective coating has been applied.

There are nuances...

Everything can look beautiful: pads, discs, and calipers - but the brakes “stick”! You start to figure it out and you find the reason.

If the mechanic at the station, when replacing the pads, did not carry out a complete cleaning procedure (on both sides!) of these “guides,” then it turns out that the pad simply jams in a certain position and does not brake. In order for the pad to press against the disc, you need to create additional force on the pedal - much higher than what was initially required.

I use a screwdriver so confidently now, because I have to change the disks anyway. Why? They are warped and hit when braking. And I suspect why.

There is an interesting point with some cars: the right disk is different from the left, and accordingly they have different numbers. Whoever knows this orders one right disk and one left one. Well, those who don’t know, choose any of them and order two identical (right or left) disks.

These discs are ventilated, the air channels in them are located at a certain angle. If we place the right disk on the left (and vice versa), then there will be no cooling provided, and overheating can easily occur during hard braking. And then they start saying: bad parts...

Now let’s take new disks, clean them of grease with a special agent - and everything will be beautiful! There are no special nuances when installing a disk on the hub; the main thing is that the mating plane is smooth and clean.

The main thing is lubrication!

Why do the caliper guides turn sour? As with cylinders, torn boots allow water and dirt to get inside. And also because the old lubricant develops its properties, or instead of a special high-temperature lubricant, a regular one, for example graphite, was used. In a good way, you need to service the brakes at least once every six months: disassemble them, clean the guides and re-lubricate them - don’t wait until the pads run out.

How does a brake caliper work?

In ideal condition, the brake caliper should operate as follows:

- The driver inside the car presses the brake pedal;

- At this moment, pressure is built up inside the brake line and it is transmitted to the piston group of all calipers;

- The calipers, under the influence of pressure, bring the brake pads to the disc mounted directly on the rotating wheel;

- Due to the frictional force that arises, the rotation of the disk, and at the same time the wheel, slows down.

Important: for proper operation of the brake system, the pads must be positioned strictly parallel to the brake disc.

Because friction occurs when a vehicle brakes, it also generates heat, which warms the brake pads, fluid, and calipers. Accordingly, a working brake caliper must consist of a material whose properties do not change when heated. Also, the caliper material must be strong to withstand heavy loads.

A little history

The first to create such a model of brakes (disc type) was Frederick Lanchester (Great Britain). It was in its design that a caliper was used that pressed the pads. However, technology at that time did not allow the creation of reliable disc brake systems.

Disc brakes were revived in aviation, and in the 50s they began to be installed on cars - first on sports models, and then on production ones. The first car with serial front disc brakes was the Chrysler Crown Imperial (in 1949).

The importance of this component is difficult to overestimate, because the brake disc and pads are passive components, while the caliper plays an active role. Due to this, the pads are pressed. Therefore, the brake caliper is the most important component.

Why does the brake caliper squeak and jam?

A signal that there are problems with a car caliper is a squeaking sound. It may indicate that the caliper is worn out and needs to be replaced, or that a part needs diagnostic maintenance. The squeaking sound when calipers operate most often occurs for one of the following reasons:

- The pads are not installed correctly. If the pads are not parallel to the brake discs (or are not in the right place, for example, due to an error during repair), this can lead to squeaking;

- Worn brake discs, which are also directly involved in the braking process;

- There is no lubricant or the lubricant selected is incorrect. Often, drivers (and private services) save on grease for calipers, which is absolutely not allowed. The fact is that it is necessary to select for the caliper not only a lubricant with the ability to cool and prevent friction. Also, the caliper lubricant must be resistant to external influences, especially in winter, when there is a lot of dirt and salt on the road.

The situation is critical when the brake caliper not only creaks, but jams during operation. In other words, the driver presses the brake pedal, and when it is released, the caliper does not remove the pads from the brake discs, which leads to uncontrolled braking of the car, excessive wear and overheating of parts in the brake mechanism.

Driving from the adjacent area to the intersection

It is the creaking that indicates that the element is seriously worn out. In the near future, the unit must be replaced without fail, which the car literally and figuratively screams about. It is extremely difficult not to hear such a creak. But for some reason, thousands of motorists still stubbornly ignore it. As a result, they pay a rather high price. Sometimes even to the point of road accidents resulting from brake failure while driving. To prevent this, you need to understand the issue and understand the essence of what is happening.

The first step is to look at the possible causes. In fact, there are several potential problems to look for. Some of them arise due to the fault of the motorist, others are caused by the natural process of wear and tear.

What to do if the caliper creaks or jams

If the brake caliper creaks or jams, and the part is in good condition, you can try to fix the problems yourself. To do this, it is recommended to perform the following set of actions:

- The first step is to unscrew the brake caliper; to do this, you need to put the car on a jack and remove the wheel. It is worth noting that in some car models the caliper can be unscrewed counterclockwise;

- Having removed the caliper, unscrew the piston using a wrench, then it must be pulled out of the cylinder;

- The removed parts must be carefully inspected for chips, rust, corrosion and various damages. If rust is found, it needs to be cleaned well. When the calipers are heavily worn, problems may arise with cleaning the rust with improvised means; in such a situation, the part will need to be sanded;

- After cleaning the caliper from rust, drain the liquid from it, remove the sealing ring and clean everything thoroughly, special attention should be paid to the place where the ring is attached;

- Next, all the parts need to be dried, filled with liquid, and the caliper put back together.

Important: When reassembling the caliper, pay special attention to the boot so as not to accidentally damage it. If there are cracks on the boot, be sure to replace it.

How to turn an inoperative brake cylinder piston into a functional one?

1) At the very beginning of the operation, you will need to remove the wheel from the car.

Note! By the way, when you remove the wheel from the car, try to spin it while it is in the air; if it slows down, then some piston has actually become unusable!

2) After your wheel is removed, immediately remove the caliper from the car after it in order to get out the brake piston that is not working. (For information on how to remove the brake caliper on front-wheel drive cars, see the article: “Replacing the brake caliper on a VAZ 2109”, and for information on how to remove this caliper on a classic, see “this article”)

3) Now, when the caliper is removed from the car, you will need to find a vice, or a very strong compressor, in order to remove the piston from the brake cylinder, so if you have a vice, then go to it and clamp the piston itself and behind the caliper after Once you clamp the piston, pull it, and thereby the piston will be removed from its installation location.

Note! If you don’t have a vice, then pick up a compressor or something else where air can come out under pressure and thereby insert the hose from the compressor into the small hole in the caliper, namely where you connect the brake hose itself and then turn on the compressor and the piston will fly out of its installation location!

4) Next, take the removed piston in your hands and inspect it, if you find traces of rust on it as shown by the arrow in the photo below, then they will have to be removed using some kind of chemical or something else (A good example of cleaning the piston from rust, shown in one of the videos below), and after the rust has been removed, also inspect the brake caliper itself and finally reassemble all previously removed parts in the reverse order of removal and at the very end check their functionality.

Note! Still, a new piston is not too expensive in the store for our domestic cars, so if you have the opportunity, then it’s better to replace it with a new one and throw away the old one, because who knows after how long it will start to rot again, maybe it won’t even last for a week will last and thus you will again have to disassemble the entire brake system, and by the way, if the boot on it is torn, then you will definitely need to replace such a piston with a new one, since dirt has already got into the inner part and it is unlikely to be able to get it out, yes Moreover, there will still be lubricant there, so as they say, decide for yourself to repair the piston or replace it with a new one!

Additional video: If you want to know how to remove the piston from the brake cylinder on front-wheel drive cars using the VAZ 2109 as an example, then watch the video below, which explains all this in detail:

Source