The VAZ-2107 car is the latest model produced by AvtoVAZ using the so-called classic layout, when the car was driven by the rear wheels.

And since the majority of our car enthusiasts prefer rear-wheel drive cars, the 2107 is still a popular car among the people.

The chassis of any car includes two main suspension components: front and rear wheels.

If we take into account the front suspension of the VAZ-2107, then it is more reliable than that of the VAZ-2108.

This is explained by the fact that the “Seven” has fewer front suspension components than the “Eight” due to the drive to the rear wheels.

But at the same time, due to the same drive, the rear suspension is more complex, which means there is a greater likelihood of a malfunction.

Suspension structure

The front suspension of the VAZ 2107 is “independent”. It consists of two levers and a coil spring, shock absorbers with a telescopic structure, as well as an anti-roll bar.

The lower arms are bolted to a beam that connects to the front spar. There are shims between the beam and the lower arm; they help adjust the camber of the front wheels.

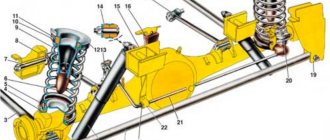

The upper arms are attached to the body with a bolt. The hub is secured using a ball joint. The front suspension spring is in the mudguard strut cup, and its lower edge rests against the lower arm support cup. You can see all this clearly in the diagram below.

The anti-roll bar serves to prevent the car from skidding. It is attached at the front through rubber bands to the side member, and at the rear to the lower suspension arms.

REPLACING SHOCK ABSORBERS

The shock absorber is a non-separable paired part. That is, if one of them fails, then both change.

In order to replace the shock absorber, you need to carry out the following steps:

- Unscrew the fastening nut on the rod;

- Remove the washers along with the upper cushion made of rubber;

- We unscrew the bracket with which the shock absorber is connected to the lower arm;

- The broken shock absorber can be removed through the slot in the lever housing;

- The bracket is removed from the shock absorber and a new shock absorber is installed in the reverse order.

Front suspension diagram

This diagram will help you clearly understand the suspension structure.

1) rubber wheel bearings; 2) hub protection; 3) nut; 4) part of the base with a steering knuckle; 5) cuff; 6), 7) location of the hub and brake disc; protection for the upper ball pin; 9) place of attachment of the upper ball pin; 10) liner for the upper support; 11) lever (upper); 12) the so-called “chipper”; 13) fastening the spring gasket; 14) shock-absorbing element; 15) a pad for attaching a shock-absorbing part; 16) base of levers (upper); 17) rubber hinge bushing; 18) hinged bushing located outside; 19) washers for adjustment; 20) cross member for axle suspension; 21) cushion on the stabilizer bar; 22) place of attachment of the rod; 23) base of the lever (lower); 24) lever located below; 25) clip for attaching the stabilizer rod; 26) spring; 27) rubber bushing for the shock absorber spring; 28) spring support bowl (lower); 29) place for the steering knuckle; 30) location of the ball pin race liner (lower); 31) support bearing (lower); 32) fastening for the lower ball pin.

As you noticed, the scheme is not complicated.

Chassis of VAZ 2107

The chassis of the VAZ 2107 consists of two suspensions: on the front and rear axles. That is, each axis of the machine has its own set of mechanisms. An independent suspension is mounted on the front axle, and a dependent suspension is mounted on the rear axle, since the car is equipped with rear-wheel drive.

The operation of these components is designed to ensure a smooth and soft ride of the car . In addition, it is the suspension that is responsible for the integrity of the body while driving on uneven roads. Therefore, the performance of any element is very important - after all, the slightest inaccuracy in the function of any part can lead to serious damage.

Front suspension

The front suspension on the “seven” is completely independent. It includes:

- upper position lever;

- lower position lever;

- stabilizer unit responsible for the stability of the machine;

- small auxiliary parts.

Roughly speaking, it is the lever elements and the stabilizer that are the connecting passage between the wheel and the body shell. Each of the wheels of the front pair is mounted on a hub, which rotates easily and without friction on bearings. To ensure that the hub is held securely, a cap is placed on the outside of the wheel. However, this equipment allows the wheel to rotate only in two directions - forward and backward. Therefore, the front suspension necessarily includes both a ball joint and a steering knuckle, which help the wheel turn to the sides.

The ball joint in the design of the VAZ 2107 is responsible not only for turning, but also for minimizing vibration from the road. It is the ball that takes on all the impacts from the wheel falling into a hole or when hitting a road obstacle.

To prevent ground clearance from decreasing while driving, the suspension is equipped with a shock absorber. To adapt the “Seven” to Russian roads, the shock absorber is additionally equipped with a spring. The spring “winds” around the shock absorber, creating a single whole with it. The mechanism is installed strictly vertically to ensure maximum ground clearance in all driving conditions. This mechanism perfectly withstands all road troubles, while the body does not experience strong vibrations and shocks.

The front part of the chassis also includes a cross member. It is this part that connects all the suspension elements and brings them to work with the steering column.

How to check the chassis on the "seven"

Self-checking the chassis of a VAZ is a relatively simple and quick procedure. No special tools are required, but you need to drive the car onto an overpass or pit.

Checking the chassis involves a visual inspection, so you will need to take care of good quality lighting. During the inspection, it is necessary to carefully examine all suspension components, paying special attention to:

- the condition of all rubber elements - they should not be dry or cracked;

- the condition of the shock absorbers - there should be no traces of oil leakage;

- integrity of springs and levers;

- presence/absence of play in ball joints.

This check is quite enough to find the problematic part in the chassis of the car.

Video: chassis diagnostics

The chassis of the VAZ 2107 has a fairly simple structure. An important fact can be considered the ability to independently identify chassis faults and ease of diagnosis.

The latest luxury version of the VAZ “classic” is still popular among our fellow citizens. The VAZ 2107 is easy to maintain, and many operations to restore the chassis can be done with your own hands. The front and rear suspension of the car are quite reliable, and spare parts for the car can be purchased at any store or market.

Maintenance and repair of the machine will not be a difficult task if the owner knows the material well. The front suspension of the car consists of the following elements:

- upper and lower lever;

- ball joints;

- pivot pin;

- hub with bearing;

- shock absorber;

- coil spring.

The rear suspension design includes:

- set of four longitudinal rods;

- rear axle with gearbox and hubs;

- lateral Panhard rod;

- shock absorbers;

- springs.

Many years of experience in operating the model shows that it is possible to tune it by installing gas-filled shock absorbers with improved characteristics.

REPLACING A BROKEN SPRING

To replace the spring (which also cannot be repaired), you need to remove the shock absorber and disconnect it from the roll bar. After this, you need to loosen the screws of the lower arm, after that it is jacked up, then using a special puller we remove the ball pin.

Now you can slowly release the jack, as a result of which the spring weakens and is easily removed from the cup.

Attention! A new spring can be placed in the support bowl only by first tightening it with a special tie.

After this, the lower arm is pressed in the same way, then its ball joint fits into the steering knuckle. Then you can release the spring from the tie. A diagram of spring compression using a tie is shown.

In conclusion, it must be said that a novice motorist is quite capable of monitoring the serviceability of the suspension, the main thing is that he has an overpass or a pit at his disposal.

Basic front suspension faults

In the chassis of the VAZ 2107 model, some components bear significant loads, which leads to their failure. Most often the following parts break:

- ball joints especially the lower ones;

- silent blocks;

- lateral stability link bushings;

- shock absorber sealing elements.

Repair for such breakdowns usually comes down to replacing worn parts. In the process of restoring performance, you can tune the front suspension. In order to reduce the cost of repairing your own car, you can dismantle and replace parts yourself. If you plan to tune the car, then when purchasing parts you need to select spare parts with the appropriate characteristics.

Rear suspension diagnostics

The chassis of the VAZ 2107 model is subject to significant wear during intensive use on roads with poor-quality surfaces. Before repairing a particular vehicle malfunction, it is necessary to carry out diagnostics. The following parts are most likely to fail:

- rubber bushings of transverse and longitudinal rods;

- development of shock absorbers in valve mechanisms;

- destruction of fasteners on the body or bridge.

Restoring the performance of the rear suspension of the VAZ 2107 can be done with your own hands without the involvement of specialists. When tuning a car, you should not get carried away with fashion trends such as increasing or decreasing ground clearance, this can have a negative impact on its handling.

The most loaded element of the VAZ 2107 car is the front suspension. Indeed, it takes on almost all mechanical loads that arise during movement. For this reason, it is important to pay careful attention to this unit, carry out timely repairs and modify it, whenever possible installing more durable and functional elements.

Polyurethane or regular?

On sale you can find two types of elements - polyurethane and rubber-based. The question is: which ones are better to use on the VAZ 2107? Rubber ones have many disadvantages:

- Even the new ones squeak.

- They have a relatively small resource.

- Under the influence of an aggressive environment they quickly become unusable.

But they also have a big advantage - a fairly low price. Depending on the “appetites” of the seller, you can purchase a set for 500-700 rubles. But polyurethane ones have higher characteristics. They are practically not exposed to aggressive environments, have a long service life (at least twice as long), but there is one drawback - the price. It is within one and a half thousand. Look at how you are used to using your car.

Which ones should you install on your VAZ 2107? The question is not easy, you need to weigh everything to answer it. And most importantly, assess your financial capabilities.

You also need to pay attention to your driving style. If aggressive, then polyurethane will be more suitable for the job.

But if you drive quietly and the suspension is not subjected to significant loads, then you can install regular rubber ones. But we need to make a reservation again - it all depends on your capabilities and preferences. Polyurethane ones are many times better than rubber ones on the VAZ 2107 and similar models. And they are free from the main drawback of rubber joints - they do not creak.

Front suspension malfunctions

Problems with the VAZ 2107 suspension occur due to bad roads. The first thing that suffers is the ball joints, then the struts and other elements of the shock-absorbing system fail.

Quite often, owners of the “Seven” complain about a knocking sound when driving at a speed of 20–40 km/h. Then, as you accelerate, the dull sound disappears. The area of noise is the front suspension.

First of all, it is recommended to put the car on a lift and check how the balls, shock absorbers, and silent blocks work. It is possible that the wheel bearings are worn out.

Experienced owners of the VAZ 2107 claim that knocking at low speeds, which disappears as they accelerate, is associated with the shock absorbers. They receive a vertical blow from below when the machine's movement is weak. At high speed the car levels out and the knocking noises disappear.

Detailed instructions for the actions of a driver who notices a knock are given below.

- Inspect the glove compartment, elements of the instrument panel and other interior parts that may be knocking. It is also worth checking the engine protection and some parts under the hood - maybe something is loose.

- If everything is in order, you need to move on to checking the suspension.

- The first step is to check the condition of the silent blocks - the rubber bushings on both levers must be checked. Bushings knock, as a rule, when starting from a stop or sharp braking. The problem is eliminated by tightening the bolts and nuts or replacing the elements.

- Diagnose the support bearing of the shock absorber strut. Many people do this: they open the hood, put one hand on the support bearing, and rock the car with the other. If the element is exhausted, shocks and knocks will be immediately felt.

Video: what is knocking in the front suspension

The car is pulled to the side

If the car begins to pull to the side, the steering knuckle or suspension arm may be deformed. On old VAZ 2107 cars, loss of elasticity of the strut spring is possible.

Basically, if the car pulls to the side, this is due to brake pads, steering play and other third-party reasons not related to the suspension. Therefore, it is recommended to use the method of elimination, and only then test the suspension.

Noise when turning

The hum when turning occurs due to wear on the wheel bearing. The nature of the noise is as follows: it is observed on one side, appears up to a speed of 40 km/h, and then disappears.

Here's how to check a wheel bearing for play.

- Place the front wheel on a jack.

- Grasp the top and bottom of the wheel with your hands and begin to swing it away from/towards you.

REPLACING BALL JOINTS

The work scheme (like all others) begins with cleaning the parts from dried dirt. You need to make it a rule to clean all the elements at the bottom of the machine before starting diagnostics and repairs. The most convenient way to do this is to first use a stream of water from the nozzle of a portable car wash, and then dry it with compressed air.

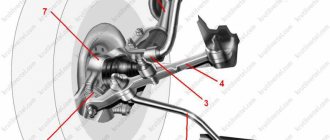

To replace the ball joints, first remove the wheels of the VAZ 2107.

The jack for loading the lower part of the suspension rests on the lower arm, simulating a “load” on the suspension.

Then:

- Unscrew the ball pin nut (for example, the top one).

- A special pressing tool is used to separate the steering knuckle and the support pin;

- Unscrew the ball joint and remove it in its protective case.

- A new support is installed and assembly occurs in the reverse order.

The lower support is also replaced. After this, the car is jacked up on the other side and the ball joints on the other side of the suspension are replaced.

After this, it is necessary to adjust the wheel alignment; this must be done at a service station on a special stand.

Silent blocks.

Let us recall that the silent block is a connecting element in the suspension of the VAZ 2107, and any other “classic”, which has an elastic liner made of polyurethane or rubber in order to soften the shocks of the suspension and vibrations. These parts take on large shock loads.

The figure shows the mounting diagram for the silent block of the lower arm.

Because of this, silent blocks are susceptible to wear, as a result of which the alignment is disrupted. It is advisable to change silent blocks every 50-100 thousand km. Mileage.

Suspension upgrade

The standard suspension of the “seven” is considered soft and imperfect. That's why many people decide to do tuning and modifications. This helps to significantly improve handling and overall comfort, as well as increase the service life of springs, balls, bushings and other elements.

Reinforced springs

Springs are the main element responsible for a smooth ride, directional stability and good handling. When they weaken or sag, the suspension is not able to compensate for the load, so breakdowns of its elements and other troubles occur.

Owners of the “Seven”, who often drive on bad roads or drive with a loaded trunk, should definitely think about upgrading the standard springs. In addition, there are two main signs by which you can judge that elements need to be replaced.

- Upon visual inspection, it was discovered that the springs were damaged.

- The car's ground clearance has noticeably decreased, as the springs sagged over time or due to excessive load.

Spacers are the first thing that comes to mind for VAZ 2107 owners. But this conclusion is not entirely correct. Yes, they will restore the stiffness of the springs, but will have a negative impact on the service life of the elements. Soon cracks will be found on springs reinforced in this way.

Therefore, the only correct solution would be to replace conventional springs with reinforced ones or modified ones from the VAZ 2104. At the same time, it is necessary to change the shock absorbers to more powerful ones, otherwise the reinforced springs will easily damage the standard system.

Before you begin the replacement procedure, you need to arm yourself with the following tools.

- By lift.

- A set of various keys, including a cylinder key.

- With a tire iron.

- Bar.

- Wire hook.

Now more about the replacement.

- Place the car on a jack and remove the wheels.

- Remove struts or conventional shock absorbers.

- Loosen the upper arm clamps.

- Place a block under the car and jack up the lower arm.

- Unscrew the stabilizer beam fastening.

Then you need to free both springs from the gaskets and check the condition of the latter. If they are in good condition, install the new spring using electrical tape. Install reinforced springs in place of the standard ones.

Air suspension

The “Seven” has great potential in terms of modernizing the front suspension. And many car owners decide to install an air suspension with an electric compressor, hoses and a control unit.

This is a real electronic assistant that makes it possible to change the ground clearance depending on driving conditions. Thanks to this innovation, the stability of the car at high speeds increases, trips over long distances become comfortable, the car goes over bumps more smoothly, in a word, it becomes like a foreign car.

The system modernization goes like this.

- VAZ 2107 is installed on a pit.

- The battery is de-energized.

- The wheels are removed from the car.

- The front suspension is completely disassembled and air suspension elements are installed in its place.

- Under the hood there is a control unit, compressor and receiver. Then the elements are connected to each other by pipes and hoses.

Video: air suspension on a VAZ, is it worth it or not?

Electromagnetic suspension

Another modernization option involves the use of an electromagnetic suspension. It is a set of mechanisms and components that serve as a connecting link between the road and the body. Thanks to the use of this type of tuning suspension, a smooth ride, high stability, safety and comfort are ensured. The car will not “sag” even during long-term parking, and thanks to the built-in springs, the suspension will remain operational even in the absence of commands from the on-board network.

Today, the most famous manufacturers of electromagnetic suspensions are Delphi, SKF, Bose.

The front suspension of the VAZ 2107 requires timely maintenance and control of the main components. Remember that road safety depends on this.