Design aspects in such an element as suspension not only have a significant impact on driving comfort, but also determine the handling characteristics of the LADA Granta. The main suspension criteria that determine the owner’s choice are reliability and maintenance costs.

The LADA Granta model, popular today, belongs to the new generation of cars. When designing, the designers paid special attention to the chassis; in fact, the suspension itself was well designed.

Front suspension "Lada Grants"

It has an independent suspension with wishbones and a stabilizer bar. Damping of vibrations is carried out by hydraulic shock absorbers. The main structural element is the stand. It includes a swivel bearing, shock absorber and spring. The latter uses coils of variable diameter. The spring itself is made of a metal rod with a circular cross-section. It can have variable and constant hardness.

The pillar support has also been improved. Suspension creaking on the Lada Granta appears much less frequently than on Kalinas and Priors. To reduce roll, the design includes a stabilizer bar. It is made of spring steel. The stabilizer is installed with its ends to the lower suspension arms. Its middle part is fixed to the body.

Product description

Set of rear compression stroke buffers with boots and cups for VAZ 2110, 2170, Kalina, Granta

To confirm quality, each batch of products is subjected to a whole range of tests, which includes:

- determination of the elastic characteristics of products at temperatures of plus 23˚С and minus 40˚С;

- durability tests under cyclic compression at temperatures of plus 23˚С and minus 40˚С;

- determination of relative residual deformation after durability testing under cyclic compression;

- water absorption tests;

- impact brittleness testing by dropping a 20 kg load from a height of 1 meter at a temperature of minus 40˚C.

Rear suspension

Unlike the front, it has undergone virtually no changes. Here, just like on the first Soviet G8s, a semi-independent beam is used. It is attached to the body on hinges (fortunately, there are no “crabs” in the design). A helical spring with constant stiffness is used as an elastic element. To dampen vibrations and prevent swinging, two shock absorbers are used.

- High reliability. The design does not have additional levers, which, in addition, can bend when falling into a large hole.

- Energy intensity. The Lada Granta absorbs all bumps perfectly, especially if oil shock absorbers are installed at the rear.

- Cheap maintenance. Due to its simple design, this pendant can be rebuilt even with your own hands. And the cost of new rubber-metal elements is unlikely to empty the pockets of even the most stingy car owner.

The main difference between the “Grant” suspension is the wheel alignment angles.

Algorithm for self-replacement of rear struts of Lada Granta

A common reason for replacing a rear shock absorber is oil leakage from the cylinder, depressurization, loss of integrity, or seal defects. Less common spring sagging. Tools: open-end wrenches “17, 19”, a set of new struts, WD fluid – 40.

- We fix the front wheels with wheel chocks and engage first gear;

- We fold the back row of seats for ease of maintenance;

- We pry off the rubber plug of the rear glass and remove it;

- Unscrew the upper shock absorber fixing nut;

- Jack up the rear wheel and remove it;

- We hang the side of the car at such a height that the beam has free movement;

- Unscrew the lower fastening, remove the eye from the seat;

- Remove the shock absorber assembly;

- Using a crab puller, compress the spring and remove the boot.

Replacing the Lada Grant strut with a new one, assembling the parts in the reverse order. When moving the rod in the upper position, it will be difficult to get into the hole; an assistant may be needed.

Replacing support bearings without removing the strut

- Jack up the car and remove the wheel;

- Using a crab puller, compress the spring several turns;

- In the engine compartment, unscrew the three nuts securing the support bowl to the glass;

- Unscrew the steering tip and unscrew the nut;

- Lower the shock absorber assembly down;

- We remove the support bowl and replace the Granta strut bearing.

The repair is completed by reassembling in the reverse order.

Grant strut spacer. For what. What is the price

In order to increase the service life of the glasses in the engine compartment and to prevent an increase in the angle of inclination of the pillars, the structure is reinforced with a metal beam. The ends are attached to support bowls and connected to each other by a metal pipe. This is the simplest design. Modernized versions have a different layout. But this is not for everyone.

The strut of the rear struts of the Grant is carried out by analogy with the front ones. The cost of the budget option is from 850 – 900 rubles. More complex designs from 1500 rubles. Everyone determines their effectiveness independently.

Repair, pumping of racks or replacement with new ones. Is there any reason

The difference in cost between replacement and partial repair is only 30 - 35%. If you have a very limited budget, then give Grant shock absorbers for pumping. If you have sufficient funds, buy new ones.

Reupholstering does not always give a positive result; sometimes the service life is several thousand kilometers.

Oil or gas-oil as a filler for racks

As in the previous case, start from the allocated budget for repairs. Obviously, the oil type is the cheapest, the least quality, with the shortest service life. Combined option: gas-oil - the most popular type of shock absorber filler. It has proven itself well on rough terrain, road potholes, bends, and ice. The cost of the kit is 17% more expensive than the oil equivalent.

Gas: high performance characteristics, long service life, versatility in use, wide range for any modification of the car. At the same time, the exorbitant cost is the main stumbling block for many owners, for whom the amount is unaffordable. Obviously, gas-oil ones are the optimal solution for most owners.

Source

Shock absorber

This element is a damping device. The shock absorber serves to reduce the range of vibrations of the car body. In other words, the element prevents spontaneous rocking. The work of the shock absorber is based on hydraulic resistance. Inside it there is a liquid of a certain viscosity. It moves through a special valve. Thus, the device absorbs sharp impacts while preserving vulnerable suspension parts. Therefore, the shock absorber is one of the most important components in the chassis. On our roads, this element lasts about 60-80 thousand kilometers. But this period may be shorter, even with careful driving. It is enough just to damage the protective boot, and all the dirt will accumulate in the rod seal.

Also note that the damping element changes in pairs. That is, in the event of a breakdown of the rear left shock absorber, the rear right shock absorber also changes. As for the front struts, they are more durable. Often they are replaced already assembled with a spring, since they fail no earlier than after 150-200 thousand kilometers.

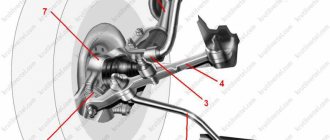

Removing the front shock absorber strut and disassembling it Lada Granta

- Driver for socket attachment

- Torx wrench attachment E12

- Torx wrench attachment E14

- Attachment for Torx E8 wrench

- Large flat screwdriver

- Large hammer

- 17 mm straight box spanner

- 22 mm straight box spanner

- 6 mm hex key

- Ratchet wrench

- 13 mm head

- 19 mm head

- Adjustable stop or puller for pressing out the ball pin

- Chisel or marker

- Spring tie - 2 pcs.

- Worm clamp

Parts and consumables:

Remove and disassemble the shock absorber strut when it is necessary to replace the upper support, bearing, spring, telescopic strut. The telescopic stand is non-removable and cannot be repaired. Carry out the work on a lift, but you can get by on a flat platform. There are two options for removing the shock absorber strut. The first allows you to avoid subsequent adjustment of the steering wheel alignment angles, the second method requires less work, but after it requires adjustment of the steering wheel alignment angles. Replace the telescopic stand using the second option.

Removing the shock absorber strut without the need for subsequent adjustment of the steering wheel angles

In the first option, remove the strut together with the steering knuckle, without loosening the nuts of the upper (adjusting) and lower bolts securing the strut to the steering knuckle. At the same time, disconnect the tie rod end from the shock absorber strut swing arm.

1. Disconnect the ball joint from the steering knuckle as described in this article.

2. Remove the outer CV joint from the wheel hub, and also remove the pad guide with the caliper and cylinder.

3. Tie the clamp to the brake hose bracket, making sure there is no tension on the hose.

4. If the strut is to be disassembled, use a 13 mm socket to unscrew the three nuts securing the strut's upper support to the body.

5. Remove the shock absorber strut along with the knuckle.

6. Using a 22 mm spanner, loosen the rod nut while holding the rod from turning with a 6 mm hex key.

Removing the shock absorber strut with the need for subsequent adjustment of the steering wheel angles

To remove the shock absorber strut using the second method, disconnect the tie rod end from the shock absorber strut swing arm.

1. Unscrew the nut securing the ball joint of the tie rod end.

2. Place the adjustable stop under the pin, tighten it and, hitting the swing arm with a hammer, press the pin out of the lever or use a puller to press out the ball pin.

3. Using a 22 mm spanner, loosen the rod nut, holding the rod from turning with a 6 mm hex key, and with a 13 mm socket, unscrew the three nuts securing the upper support of the strut to the body (see point 6 above).

4. If the car is equipped with an ABS system, use the E-8 head to unscrew the sensor mounting bolt.

5. Remove the sensor from its mounting location.

6. Remove the brake hose coupling and sensor wire from the shock absorber strut holder.

7. Use a chisel or marker to mark the location of the adjusting bolt relative to the rack.

With this method, after assembly, the deviation of the wheel camber angle from the original value will be insignificant.

8. Using a 19 mm socket, unscrew the nuts of the bolts securing the strut to the steering knuckle, holding the bolt from turning with a 17 mm wrench.

9. Remove the bolts and take out the shock absorber strut.

The eccentric top bolt is needed to adjust the camber, so do not lose the washer from it, it often sticks to the strut. This bolt must then be put in its place, so do not mix it up. Wheel alignment will have to be done in any case, so remembering the rotation of the eccentric along the axis is pointless.

10. Remove the upper support support plate.

Cause of malfunction

The main cause of element malfunction is a violation of the boot seal. Once it starts to crack, dirt and dust will get inside. They act on the ball like an abrasive. As a result, play appears and the support begins to break on its own. Is it possible to repair it? The Lada Granta suspension is designed in such a way that the ball joints cannot be restored and must be replaced entirely with new ones.

Wheel bearing

This element serves for uniform rotation of the car wheels. There are 4 such bearings on the Grant. On average, their resource is 100 thousand kilometers. What are the signs of a problem? The main symptom is a characteristic hum when moving. It may get worse as the car turns. The hum can occur on either side of the car, depending on which bearing has fallen apart. The entire assembly is replaced with a new one, and it doesn’t matter whether the Lada Granta’s rear suspension or the front one. It is pressed out using a puller with special paws. Pressing takes place in a vice. It is important to maintain alignment when pressing. If a bearing is installed crookedly, it will be subjected to high loads and may fall apart after just a thousand kilometers.

The car suspension is designed to level the movement on any type of road surface and provide comfort for the driver and passengers. The presence of vibration for a long time negatively affects all components and assemblies of the car - bolted and screw connections are weakened. Serious consequences include bent door hinges, sagging doors, and loose closure of the hood and trunk.

The chassis of the Lada Granta has become more modern and modernized. Especially in comparison with previous AvtoVAZ models - two generations of Samara and first generation Kalina. The car has rear and front suspensions, which differ significantly from each other.

The rear suspension of the Grant is the same for the sedan and liftback. In fact, this is the same beam with springs and shock absorbers that is installed on Kalina, Samara and Samara 2. Instead of a stabilizer, a beam is used, which means the structure is dependent.

Silent blocks

By 100 thousand, the silent blocks of the cross member and lower arms fail. Signs of a malfunction are a dull knock from the front suspension of the Lada Granta. Motorists recommend replacing these elements with polyurethane ones.

They are characterized by higher strength and good service life. At the factory, rubber silent blocks are installed that do not withstand the impacts of our roads. To replace, we need to press out the old element. First, the bead is cut off from it, and then knocked out using a mandrel or chisel. Pressing is done using a vice. It is important to maintain alignment and not mix up the installation side. For easier pressing, it is recommended to use lubricant.

The silent blocks of the anti-roll bar also fail. These bushings are also replaced with polyurethane ones.

Features of the Granta front suspension

The front suspension is independent, which means that when one of the front wheels falls into a hole, the second one maintains its position. So that when driving on a flat road, both wheels are in the same plane and rotate evenly and parallel to each other, a stabilizer is installed between them. On the front part of the Granta suspension system, the mounting bearing is installed between the shock absorber spring and the body support. As a result, the weight of the machine is completely concentrated on it and keeps it in a compressed position. With this design, the backlash is reduced to zero - extraneous noise disappears.

Weak points of the suspension

In wet weather it is not always possible to see a defect in the shock absorber strut

If you carry out independent repairs, for example, replacing a ball joint, then you must carefully tighten the fastening bolts. There are no through holes in the steering knuckle to which the support is attached: the bolt is screwed into the knuckle itself. Excessive tightening force may cause the bolt to break. A knock in the front suspension may also occur for this reason.

For reliable and long-term operation of the suspension, it is necessary to comply with the speed limit of the machine stated in its technical passport. Also, regular maintenance will help eliminate the appearance of noise, knocking and deviation from straight-line movement.

Rear suspension features

The rear suspension of the Grant is the same for the sedan and liftback. In fact, this is the same beam with springs and shock absorbers that is installed on Kalina, Samara and Samara 2. Instead of a stabilizer, a beam is used, which means the structure is dependent. Structurally, the rear part of the suspension system remains unchanged. Looking under the bottom, you can see the usual picture - a beam fixed in a semi-rigid position. It is attached to the body using hinges.

Support struts (springs with shock absorbers) are attached to the levers on the right and left. Despite the outdated design, a semi-rigid beam with racks has a number of undeniable advantages:

- even the maximum load actually has no effect on its behavior, which confirms the high level of energy intensity;

- maintenance, even according to regulations, should be carried out once every 100,000 km, but this period increases for the entire period of operation;

- Parts can be replaced in a garage even by beginners.

The rear suspension of the Granta has a feature that distinguishes it from the Priora - a negative camber of the rear wheels of 1° is created at the rear. This was done to improve the vehicle's directional stability, but given the design features of the suspension system, this solution is not capable of significantly changing anything.

Basic faults

To recognize faults in the chassis of the Lada Granta, it is not necessary to seek help from specialists. Problems can be easily identified on your own. The main suspension faults are presented in the table:

When the car is moving, a knocking sound is heard from the suspension

Most of the problems described can be easily diagnosed without the need to visit specialized service stations. You can do the repairs yourself, but after all the manipulations you definitely need to do a wheel alignment.

Tuning the suspension of the Lada Granta sedan and liftback

The suspension system is modified in a variety of ways, some are trying to radically remake the suspension.

Installation of wishbones

Instead of standard levers, a rigid and durable unit - a triangular lever - can be installed on the Granta's front suspension. It is installed for the following reasons:

- increasing the rigidity of the unit;

- lifting the base up to 3 cm;

- castor adjustment at any time in the range from 1° to 4° in negative values.

Analogues of the front / rear pillars of the VAZ-2190. Price

| Name / article | Price, rub.) |

| Pilenga SHP2791O / left | from 1400 |

| Pilenga SHP2790O / right | from 1400 |

| SS20 (СС20) SS20194 (front set) | from 3100 |

| Demfi | from 1400 |

| Elastomag | from 1400 |

| HOLA SH21-270G | from 1700 – 1800 |

| HOLA SH21-270 | —/— |

| HOLA SH22-270G | —/— |

| HOLA SH22-270 | —/— |

| HOLA SH40-270G | —/— |

| HOLA SH40-270 | —/— |

| Sachs 316763 rear set | from 2500 |

| Trialli AH01510 rear | from 1500 |

| Boge 30N87A rear kit | from 2500 |

*prices as of September 19, 2018.

Owner reviews of the Granta suspension

The opinions of motorists are largely similar. They note a number of advantages of the suspension system:

- for Russian roads it has a strong and reliable design;

- at very low temperatures it does not freeze and works out all the irregularities;

- capable of “swallowing” even deep holes without much damage;

- The car does not pull to the side at high speed when driving on the highway.

There are also disadvantages:

- the suspension is not soft and smooth;

- Unlike Logan, with which the Grant is often compared, the chassis is clearly stiffer.

In general, this is the same suspension system from the “nine” with minor changes, but for the Russian automotive industry this is a big step forward. Especially when you consider that the condition of the vehicle depends entirely on your driving style.

The unpretentiousness, simplicity and reliability of the chassis are the pride of Granta. There is one minus: the suspension with negative caster of the front wheels, front anti-roll bar and negative camber of the rear wheels is installed exclusively in modifications above the basic one - “Norma”, “Lux”. For owners of the “Standard” configuration, a suspension option borrowed from Kalina is provided.

Features of design solutions in the front suspension

The front suspension in the LADA Granta is based on the following aspects:

- independent design with hydraulic shock absorbers;

- a pair of wishbones;

- anti-roll bar;

- the levers are equipped with auxiliary braces;

- the spring, combined with the shock absorber into a single strut, has a conical profile and coils of variable cross-section.

The shock absorber strut is connected to the steering knuckle by a lower bracket. The design feature is that during a turn with a fist, the shock absorber and spring rotate. The scheme is very simple. This solution made it possible to preserve the technological hole in the shock absorber body, which helps to increase its service life.

The pillar supports have undergone some modifications, which made it possible to get rid of unpleasant squeaks and increase the strength characteristics of the structure.

The transverse stabilizer is based on spring steel. Its middle part is fixed to the body, both end sections are fixed to the mounting points of the transverse arms.

The modernized front suspension of the domestic Lada Granta differs from its counterpart in other representatives of the model range due to the increased steering angle of the wheels. The value of the so-called cluster reached 2° 45`. The undeniable advantage of this solution is the improvement of directional stability, especially when driving at high speeds. The other side of the coin is the slightly increased required force that should be applied to the steering wheel during a turn. If you believe the reviews of the owners, this moment is almost imperceptible.

This is due to the modernization of the steering control unit, namely:

- integration into the unit of an amplifier with an increased compensating effect;

- use of a short-throw steering rack.

This approach resulted in improved handling and resulted in a reduction in the number of steering wheel rotations. And the steering wheel itself now has more information and sensitivity.

Based on reviews from LADA Granta owners, one can judge that the designers have adopted a design solution that is strange for the modern era of automotive manufacturing - this is when a standard suspension is used and there is no power steering in the steering mechanism. Can this solution be interpreted as a way to reduce the cost of the design?

Overview of the main shock absorber manufacturers

By default, hydraulic ones from SAAZ (Skopovsky Automobile Plant) are installed from the factory. They are not particularly distinguished by their quality, but with moderate use they can last up to 60,000 km.

- Kayaba : Japanese, characterized by high quality, reliability, and long service life. When purchasing, be careful, as some of the products are made in China.

- ASOMI: domestic manufacturer for GAZ, VAZ, LADA models. One year warranty from the date of installation. Judge the quality for yourself.

- SS (SS): also a domestic manufacturer of racks for VAZs. Quality guarantee for two years, according to the owners' reviews, they are not bad, a little harsh.

In general, all shock absorbers are divided into three categories:

The differences in the categories are insignificant and unnoticeable for the average driver. The kit comes with a warranty card and operating instructions.

What is the rear suspension like?

Unlike the front suspension, the rear suspension of the Lada Granta chassis is practically devoid of innovations. As before, its basic element is a rigid torsion beam, as the diagram shows. It is attached to the body by means of hinges, and its swinging arms are equipped with support posts. The last components are shock-absorbing struts with spring elements.

If you believe the reviews, then this rear suspension allowed the car to acquire serious advantages over its competitors:

- high energy intensity (it is noted that the degree of loading is not capable of having a significant negative impact on the behavior of the car);

- increased reliability (due to the simplicity of the design aspects of the suspension, its elements may need repairs no more than every 100 thousand km);

- a simple design solution, which makes it possible to carry out repairs with the simplest tools and the owner’s basic experience.

Among the minor changes that affected this model and distinguish it from the Priora, there is a negative camber of the stern wheels (-1°). A slight positive toe-in (0.1°) should also be highlighted. These solutions are aimed at ensuring increased directional stability.

Innovations in the suspension system

Despite the different types of front suspension designs used (differences depend on the configuration), the developers took measures aimed at improving the performance indicators displayed by the front suspension. So the basic version of the Lada Granta served to create a modification with a more comfortable design of both elements - the front suspension and, accordingly, the rear suspension. Modernization includes:

1. Front suspension:

- the presence of a spring with an oversized coil diameter;

- gas-filled shock absorbers;

- reinforced longitudinal brace structures;

- increase in the diameter of the transverse stabilizer bar by a significant 2 mm.

2. Rear suspension:

- reinforced springs;

- gas-filled versions of shock absorbers.

An addition to the factory tuning was improved sound insulation. Due to these upgrades, the car began to confidently hold onto the road at increased speeds - up to 150 km per hour. Now sharp maneuvers in turns and bad surfaces are not a problem for him.