The engine control unit (ECU) is the brain center of the entire car; it consists of a large number of complex connections. With the help of this device, the functions of all elements of the power unit are controlled and coordinated.

Control devices installed on various car models are made of high quality materials; high technologies are used in their manufacture to ensure high-quality assembly of electronic circuits.

But even the highest quality ECUs are susceptible to breakdowns and often require urgent repairs.

Purpose of the electronic control unit

The ECU uses signals sent by sensors installed on the power unit to adjust the composition and amount of fuel entering the engine. During its operation, the engine operating mode is set and the fuel mixtures are accurately dosed.

As a result of the functioning of the controller, engine operation is stable both when cold and after warming up. It is impossible to start the engine if there is a breakdown in the ECU or if its control signals are missing.

Powerful transistors included in the control unit control the operation of the following actuators of the engine and fuel system:

- injection system ignition coils;

- idle speed valve;

- electric injectors;

- fuel tank ventilation valve;

- electromagnetic coils - solenoids;

- turbocharging;

- intake-exhaust system;

- exhaust gas recirculation;

- cooling system.

The electronic device is an integral part of the vehicle’s on-board equipment; it is in constant information communication with the following important systems:

- Anti-lock system.

- Automatic transmission.

- Stabilizing system.

- Car security system.

- Cruise control.

- Climate control.

More information about the ECU design

The electronic control unit, otherwise called the controller, or popularly the “brains” of the engine, is quite complex. Externally, it is a relatively small unit with a metal body, but all the most interesting things are hidden inside. The control unit includes the following elements:

- The processor part, otherwise called a microcomputer;

- Elements that generate signals, otherwise input and output shapers;

- Power supply;

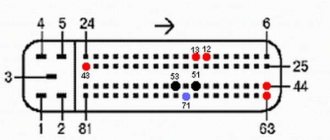

- Multi-pole plug connector.

As the reader probably knows, the ECU works in tandem with many sensors. Here are some examples: throttle position sensor, mass air flow sensor, knock sensor. Almost all of these sensors are covered in separate materials in the “Useful Tips” section on Avto.pro – we recommend that you familiarize yourself with them. And we will continue analyzing the ECU.

Operating principle of the engine control unit

When using this device, the most important parameters are optimized:

- fuel consumption;

- engine oil consumption;

- power characteristics;

- torque, which affects the acceleration of the car;

- the amount of toxic components present in the exhaust gases.

Sensors send information to the controller in the form of digital signals. The control and functional calculation modules included in the software analyze sensor signals and correct the operation of actuators. The output signals during the adjustment process can even bring the diesel engine to a complete stop.

When making significant changes in the design of the power unit (tuning), it is possible to reprogram the electronic engine control unit.

All control units are integrated into a common system using a special bus.

Types of blocks and their location

It is the use of such fully electronic control units that has significantly improved the usability of a car with an automatic transmission. The design of the automatic transmission electronic control unit consists of memory blocks in which the logic of action under certain engine operating conditions and vehicle speed is recorded. The control unit is also responsible for diagnosing, adjusting the operation of the box and storing errors. The presence of such an electronic control unit can significantly simplify the diagnosis of errors in the operation of an automatic transmission, which allows you to quickly eliminate gearbox breakdowns.

Electronic control unit closed

Like any other complex element, the gearbox control unit can fail and break. It should be noted that due to its structural complexity, repairing an automatic transmission ECU is very difficult. In some cases, it is necessary to completely replace it, which leads to significant costs for the car owner. Only a professional specialist can determine the exact breakdown and the cost of its elimination when performing transmission diagnostics.

The electronic transmission control unit can be located either directly inside the transmission or outside the gearbox housing. Each of these options for the location of control units has both its advantages and disadvantages.

Internal layout

If the control unit is located inside the gearbox, the number of wires that go from the control brain to directly the sensors in various transmission elements is significantly reduced. However, there are also disadvantages to this arrangement of the electronic unit. First of all, this is exposure to high temperatures. During operation, the gearbox heats up significantly, and exposure to high temperatures can lead to failure of microcircuits and memory cards. In addition, repair work becomes significantly more complicated, since if problems arise with the electronic control unit, you have to unwind the gearbox, which greatly complicates troubleshooting the operation of this element.

A classic example of the location of a block inside an automatic transmission

External location

When the control unit is located outside the transmission housing, it is necessary to lay a large number of wires from the control unit to the sensors inside the transmission. However, in this case, it is possible to install the control unit in any location, which allows you to protect it from moisture and high temperatures. This extends its service life and simplifies repair work, since access to this mechanism is significantly simplified.

Signs of ECU failure

Situations often arise when car owners are faced with the need to repair the engine control unit. Carrying out this type of work with your own hands is possible if you have certain qualifications.

Malfunctions in the operation of the control device occur due to broken contacts with sensors that monitor the functioning of the engine’s operating systems:

- Anti-lock braking system (car braking control).

- Ignition unit.

- Injector controller.

- Throttle position.

- Engine temperature.

Mechanical damage, water getting on the microcircuit parts, and failed attempts to repair the device with your own hands also lead to breakdown of the electronic control unit.

Loss of contact with the sensors occurs due to a lack of electricity, which indicates an internal malfunction that requires mandatory repair. Signs of lack of contact may include the following:

- no data is received from the scanner;

- messages contain incorrect parameters;

- the check indicator light does not light up when the ignition is turned on;

- lack of information about unstable engine operation.

Timely detection of defects and repair of electronic engine control units will prevent a stop in the operation of vehicle systems, components, and assemblies.

Posts 1 to 15 of 22

#1 Topic from _Denis_ 09-11-2015 11:48:28 (09-11-2015 11:48:53 edited by _Denis_)

- _Denis_

- Jedi Knight

- More details

- KapaceB

- Jedi Master

- More details

- Pueblo

- Jedi Apprentice

- More details

- _Denis_

- Jedi Knight

- More details

- Pueblo

- Jedi Apprentice

- More details

- _Denis_

- Jedi Knight

- More details

- Pueblo

- Jedi Apprentice

- More details

- _Denis_

- Jedi Knight

- More details

- nitro

- Jedi Knight

- More details

- PASSERBY 2

- Jedi Knight

- More details

- _Denis_

- Jedi Knight

- More details

- PASSERBY 2

- Jedi Knight

- More details

- _Denis_

- Jedi Knight

- More details

- Young

- Jedi Master

- More details

- _Denis_

- Jedi Knight

- More details

Topic: Where can I check the ECU for serviceability?

The scanner does not see the ECU, the car is a Kia Sportage-1, I removed the brains, opened them for moisture, there is a little, but I don’t think it’s critical. Is it possible to somehow test the removed brains for functionality and where?

#2 Reply from KapaceB 09-11-2015 11:50:38

Re: Where can I check the ECU for serviceability?

The scanner does not see the ECU, the car is a Kia Sportage-1, I removed the brains, opened them for moisture, there is a little, but I don’t think it’s critical. Is it possible to somehow test the removed brains for functionality and where?

on another Kia Sportage 1. and stop climbing on shit

#3 Reply from Pueblo 09-11-2015 11:50:47

Re: Where can I check the ECU for serviceability?

Is it possible to somehow test the removed brains for functionality and where?

As an option, hook them up to the same machine.

#4 Reply from _Denis_ 09-11-2015 12:05:32

Re: Where can I check the ECU for serviceability?

on another Kia Sportage 1. and stop climbing on shit

yes, as an option, of the two cars that I know it won’t fit, one has an automatic transmission, the other has an immobilizer, but I don’t have one

#5 Reply from Pueblo 09-11-2015 13:15:18

Re: Where can I check the ECU for serviceability?

The steering wheel seems to have its own block. At least I have a separate one.

#6 Reply from _Denis_ 09-11-2015 13:24:03

Re: Where can I check the ECU for serviceability?

The steering wheel seems to have its own block. At least I have a separate one.

I’ll also help you on the Internet Timokh, there are so many options offered here

#7 Reply from Pueblo 09-11-2015 13:33:05

Re: Where can I check the ECU for serviceability?

there are so many options here

Be a man, buy new 91 rubles and wait 20 days.

#8 Reply from _Denis_ 09-11-2015 13:36:22

Re: Where can I check the ECU for serviceability?

Be a man, buy new 91 rubles and wait 20 days.

scribe, not not ready, already looked used, 4000

#9 Reply from nitro 09-11-2015 15:23:25

Re: Where can I check the ECU for serviceability?

maybe it's the scanner)

#10 Reply from PASSERBY 2 09-11-2015 15:46:55 (09-11-2015 15:48:32 edited by PASSERBY 2)

Re: Where can I check the ECU for serviceability?

No, this is not a scribe, a scribe is when they screw up the ECU after who, who knows what scanner, who knows how, tried to connect and did not connect. This time.

regarding moisture, there is a little, but I think it’s not critical

You're wrong. This two.

#11 Reply from _Denis_ 09-11-2015 16:04:45 (09-11-2015 16:05:56 edited)

Re: Where can I check the ECU for serviceability?

The scanner is working properly, when connected to the connector it shows a network connection, but it doesn’t want to continue “no connection with the ECU”

Damn, everything is regrettable, I looked on the Internet, there are options that are not the ECU, I even start with the usual power supply to the ECU

#12 Reply from PASSERBY 2 09-11-2015 18:16:36

Re: Where can I check the ECU for serviceability?

Whether power is supplied to the ECU can be seen by certain signs when the ignition is turned on. But it's better to go to a diagnostician.

#13 Reply from _Denis_ 09-11-2015 19:43:31

Re: Where can I check the ECU for serviceability?

everything is correct, it seems like a person has been found, what will he say tomorrow

#14 Reply from Young 09-11-2015 19:45:00

Re: Where can I check the ECU for serviceability?

You can also open the ecu and look at the power/signals from the pins of the legs, but this is not for average minds)))

#15 Reply from _Denis_ 09-11-2015 19:50:53 (10-11-2015 14:22:57 edited)

Description of the main reasons for ECU failure

The list of most likely causes includes the following factors:

- Microcracks in the circuits and body of the device caused by mechanical stress (shocks, strong vibrations).

- A sharp increase in temperature leading to overheating of the motor control unit.

- Destruction of ECU elements due to corrosion.

- Penetration of moisture into the controller housing due to its depressurization.

- Incompetent repair actions.

- Applying the “lighting up” effect while the engine is running in order to help the neighboring car.

- Changing the position of the terminal connections while connecting the battery.

- The power bus is not connected when the starter is turned on.

The efficiency of the ECU fully depends on the listed factors, many of which can cause significant harm to the control device.

To prevent permanent breakdowns, it is necessary to carry out regular diagnostics of the electronic engine control. In order to save on expensive repairs and complete replacement of electronic control system elements, the inspection is carried out at least once a year.

Diagnostics of the controller in a garage

Malfunctions that have occurred in the engine control unit are indicated by the following malfunctions in the vehicle:

- problems starting the engine;

- engine tripping;

- the appearance of thick smoke;

- decreased response to the gas pedal;

- interruptions in connection with the ECU;

- loss of control over turning the engine fan on and off;

- malfunctions of the ignition coils;

- failure of fuses;

- sensors do not send signals.

Thanks to the self-diagnosis system built into the ECU, you can check and determine the extent of the breakdown yourself. To carry out diagnostic activities, you need to connect to the device using a laptop with an installed program designed to work with diagnostic data. Instead of a laptop, you can use special testers and oscilloscopes.

The data obtained during the measurement process is compared with standard indicators.

Trouble the engine: a simple way to check the ignition coil control keys

Troubles the engine

- this is a very common problem with injection cars, one of the reasons for this is this.

But how can you determine that the control unit has actually failed and not some other system? This can be understood by a number of the very first signs that may appear in such a situation:

1. Presence of obvious physical damage. For example, burnt contacts or conductors.

2. Inoperative control signals for the ignition system or fuel pump, idle mechanism and other mechanisms that are controlled by the unit.

3. Lack of indicators from various system monitoring sensors.

4. Lack of communication with the diagnostic device.

Identifying faults that have arisen in engine control

The causes of engine control unit breakdowns are divided into two main types: faulty conductor or firmware failure. The firmware can only be restored with the help of specialists at the service center. You can check the electrical parameters yourself using a special measuring device - a multimeter.

To search for a breakdown in the wire, you need to familiarize yourself with the diagram of the control device. Having studied the location of conductors, resistors and power, it is time to “check” the electrical circuit in the place where an error in the readings of the electronic unit is detected. In the absence of such information, it is necessary to check the wires throughout the entire circuit.

How the processor part works

The basis of the processor part of the ECU is a single-chip microcomputer (microelectronic computer). In fact, this is the very “brain” of the electronic engine control unit. By modern standards, a microcomputer is designed quite simply. The fact is that its key elements are included in a structure that fits on one crystal (chip). An important point in describing a microcomputer is its capacity. Bit capacity refers to the number of bits of information that the microprocessor will operate with. There are microcomputers 8-

,

16-

and

32-bit

. The devices themselves include:

- Central process;

- Read-only memory (abbr. ROM);

- Analog-to-digital converter (abbr. ADC);

- Random access memory (abbr. RAM);

- Input and output ports;

- Clock generator;

- Timers, otherwise called counters.

A parallel can be drawn between a modern computer and the processor part of the ECU. In fact, the ECU combines a number of components that go separately from each other in the system unit of personal computers and laptops, but are combined by the motherboard

There are interesting features here, but we will not consider them - it is important for a car enthusiast to understand that the circuit diagrams of modern electronic computers are very similar to each other

The central processor of the computer selects commands and data from memory and performs various operations on this data. In addition, it controls signals passing through the internal address and data bus. Read-only storage is where programs and data are stored. The information is in the form of constants. The program itself is written in the form of microcomputer machine codes. The data are calibration tables of constants involved in the calculation process. Data from tables can also be selected as control parameters. Interestingly, data in ROM is stored indefinitely

. Random access memory takes on the task of storing data that may change. For example, intermediate results of calculations or values received from sensors. RAM can store information for a limited period of time - it is erased after the power is turned off.

The tandem central processor - ROM - RAM is key

for ECU. To put it simply, it is this tandem that selects data and parameters, calculates them, remembers them and issues commands. This tandem can also include the so-called non-volatile RAM. They are powered directly from the battery. Such memory can record data and store it for a very long time. As long as the battery does not lose stored energy due to self-discharge, non-volatile RAM will continue to store data.

An important element of the ECU is the analog-to-digital converter. The fact is that single-chip microcomputers can only work with digital signals. The ADC converts the analog signal into digital code

. Input and output ports, as you might guess from their names, are used to receive and read input signals and transmit output signals and information. A timer is a device that serves both to measure time intervals and count the number of events. The clock generator is designed to synchronize the operation of the entire system by generating clock pulses. The accuracy of measuring time intervals will depend on the accuracy of the generator.

Algorithm of actions to restore ECU operation

To repair the engine ECU, the following operations are needed:

- Find the location of the breakdown.

- Re-measure the resistance.

- Find the conductor attachment points.

- Attach a wire with the required resistance in parallel using a soldering iron; it is recommended to leave the old wire in place.

After the measures taken, the system should work stably. If ECU errors recur, you must contact a service center.

The service life, safety and reliability of the vehicle depend on the timely repair of the engine control unit.

Procedure

The only thing you will need is a multimeter and a wiring diagram for the unit. The first one will have to be purchased (it is not included in the package of cars of all brands), and the latter must be included in the documents supplied with the car. You will have to study the diagram carefully. If the ECU does not produce random data, but points to a specific block, find it on the diagram and begin to “ring” it.

If accurate data is not available, the entire system will have to be checked. Having found a breakdown, measure the resistance again and determine where exactly the wire is attached. Parallel to the old one, without removing it, solder a new one with the same parameters. If this is the problem, it should work. If it doesn’t help, the block or some part of it may have fallen off. In this case, sighing heavily, stomp to the service station.

Self-repair of the “brain” of the car - the engine control unit

The electronic engine control unit is the “brains” of the vehicle. With its help, the main processes that ensure the normal operation of the power unit are carried out and controlled. You can learn more about how to diagnose and repair an engine control unit at home from this material.

Practical advice

To avoid such difficulties, you should take care of the engine control unit in advance. Remember: electronics are delicate things, and they are susceptible to dust, temperature changes, and moisture. If you value your four-wheeled horse, learn the block diagram like a multiplication table, and call him at the slightest problem. It doesn’t show fuel consumption - you can live without these indicators (some people manage to estimate it by mileage). However, the failure of this sensor may foreshadow more severe problems to come.

If you already know how to check the engine control unit, do not be lazy to use your skills. Preventive measures can prevent major problems and significant costs.

A modern automatic transmission is a high-tech unit that is largely controlled by electronic systems. Numerous sensors receive information about certain parameters of the transmission and transmit data to the central transmission control unit. The automatic brain analyzes all the data and sends commands to change gears or change transmission operating parameters.

Content :

ECU diagnostics

Before you repair the engine control unit in your car, you need to be sure that the occurrence of breakdowns is related to its operation. According to many of our compatriots, repairs of electronic engine control units should be carried out by specialists. But do not forget that almost all ECUs are equipped with a self-diagnosis system, which allows you to easily determine system malfunctions.

Motor control unit repair

To diagnose the ECU yourself, you will need to connect to the device; for this you will need a special tester or computer. If you are using a laptop, then you should install the appropriate software used for testing on it in advance. Many domestic VAZs, as well as foreign cars, are equipped with a Bosch engine control unit; using this device as an example, you will look at the verification procedure. For diagnostics, you will need the KWP-D utility (you can use any other one, we took this one as an example). In addition to the program, prepare an adapter that must support the KWP2000 protocol.

- The diagnostic procedure begins with connecting the adapter - one of its outputs must be connected to the port of the unit, and the other to the computer.

- Turn on the ignition and launch the utility. A message will appear on the computer screen indicating that the error checking procedure has begun.

- Next, you can see a table that shows the main parameters of the car’s functioning. Pay attention to the DTC category; all errors that exist in the operation of the machine’s motor are noted here. If there are any, then in the “Codes” section you can decipher these errors.

It is also necessary to pay attention to other sections. For example, the UACC indicator is responsible for the functionality of the battery - ideally its parameters should correspond to 14-14.5 V. If the voltage level is lower, it is necessary to diagnose the wiring. The THR parameter is responsible for the performance of the throttle; if the device is working normally, then it should be 0%. The QT parameter is responsible for the volume of fuel consumption; at idle speed this figure should correspond to 0.6-0.9 liters per hour (the author of the video is the AlexBrooy channel).

How to check the ECU for performance

p, blockquote 48,0,0,0,0 —>

The first stage of performance testing is monitoring all supply voltages.

p, blockquote 49,0,0,0,0 —>

The second stage is computer diagnostics. If the diagnostic device communicates with the engine, this is already a sign that the ECU is working.

p, blockquote 50,0,0,0,0 —>

Computer diagnostics may display a message that the unit is blocked by the immobilizer, then you need to bind the keys.

p, blockquote 51,0,0,0,0 —>

In some cases, to determine the malfunction, it is necessary to disassemble the computer, that is, remove the sealant and remove the cover, gaining access to the board. On it you can find burnt conductive paths, faulty transistors, diodes and other elements.

p, blockquote 52,0,0,1,0 —> adsp-pro-3 —>

The most reliable way to check is to “toss” a known good ECU. But it must either be immobilized or you will have to re-tie the keys and immobilizer.

p, blockquote 53,0,0,0,0 —>

Sometimes a set of ECU + immobilizer + key chip is sold at disassembly sites. In this case there is no problem. Connect the ECU and the immobilizer to the circuit, install the chip at the end of the pump coil on the ignition switch, and then start the engine.

p, blockquote 54,0,0,0,0 —>

Typical unit malfunctions

Repair of vehicle control units must be carried out if a malfunction is detected.

Before removing and disconnecting the faulty ECU, let's look at the main causes of breakdowns:

- Repair of the engine ECU can be carried out in case of mechanical damage. The “brains” of the car can be subject to vibrations and shocks, which can result in cracks forming on the device body and circuit board.

- The cause of a car ECU malfunction can also be temperature changes, which contributes to overheating of the device.

- Corrosion and exposure to aggressive environments on the device.

- Moisture - if it gets into the housing, it may require replacing the vehicle's ECU. Often it is not possible to make repairs after moisture gets inside the structure. The reason for moisture getting into the device may be depressurization of the housing elements.

- As experts note, quite often the need for repairs arises as a result of interference in the work of the “brains” of inexperienced repairmen.

- Lighting the battery from a car with the engine running.

- Replacing the engine control unit may be necessary if the “+” and “-” terminals were reversed when connecting the battery.

- Another reason is that the starter is turned on when the power bus is not connected (video author - Ramil Abdullin).

We will also consider the signs of a malfunction of the car ECU, which will help determine the breakdown of the device:

- The engine does not start, smokes, detonation is possible.

- Mistakes during engine operation.

- Dips, when you press the gas pedal, the car may not respond.

- There is no connection with the “brains”.

- The engine control system malfunction indicator light is on. This may be the Check Engine light, but some cars use a separate unit performance indicator.

- The cooling system fan turns on randomly.

- Safety elements regularly burn out.

- Controllers and sensors stop sending signals.

This is interesting: We personally repair rotten car sills

Visual inspection of the power supply

One of the most common and common reasons is a faulty cable. Try replacing it and if the PC still does not turn on, you will have to disassemble the power supply and look at its insides.

To do this, you will need to completely disconnect the power supply from the case and remove its frame. You can do it with a simple screwdriver by unscrewing a few screws. First of all, check the capacitors: they should not be swollen or deformed. Of course, they can be soldered to new ones of the same or higher rating (in no case should you be soldered to a lower rating!), but this does not guarantee that after repair the unit will be working

Also pay attention to the cooler and check its bearing. If the PSU makes strange sounds during tests, this is the first sign of a worn bearing.

However, the cooler can be replaced very easily.

DIY troubleshooting instructions

Before removing the control unit and disassembling it, inspect the device connector; it may be damaged.

The repair procedure is described using the example of a BMW ECU:

- Using a screwdriver, you need to bend the petals on the cover of the device, and then simply remove it.

- After this, on the back side of the structure, unscrew the bolts securing the housing.

- Having disassembled the case, you can see a diagram of the device with soldered pins.

- As practice shows, one of the most common causes of brain failure is cold soldering of radio component contacts. In other words, all the contacts are soldered, but around them there may be a small crack in the solder itself. That is, there seems to be soldering, but in fact there is none. For diagnosis you will need a magnifying glass. If during inspection you notice poorly soldered leads, you will need a soldering iron.

- Next, you need to pay attention to diagnosing transistors and microcircuits; these components may have burnout. If there is burnout, these components will need to be replaced.

- If there are no burns or damage on the device board, then you will have to look for failed device components. Namely, we are talking about Darlington transistors. This component is a composite transistor, which in turn consists of two transistors. If you have any doubts about its performance, this board element also needs to be replaced.

- The last thing you should pay attention to is the quartz resonator, which is also mounted on the scarf. As a result of vibration, this element may fail, which, in turn, may lead to failure of the fixed frequency generator device.

Common ECU malfunctions and their causes

The electronic control system can fail for various reasons. One way or another, the car owner in this case will be faced with the need to carry out diagnostics in order to accurately determine the malfunction of the unit, since in most cases these devices cannot be repaired. As practice shows, even specialists usually do not undertake to repair the device, but simply replace it with a new one. But in any case, before you say goodbye to the ECU, you need to carefully understand the reasons why it failed.

Russian-made electronic engine control system controller

According to many electricians with whom we consulted when writing this material, the main reason for unit failure is voltage surges in the on-board network . Overvoltage usually occurs as a result of a short circuit in one or more solenoids.

Diagnostics and repair of the engine control unit: full range of services in Moscow

Problems with the electronic engine control unit (ECU) in modern car brands arise quite often. Therefore, repair of the engine control unit remains a priority service in the service station market. The “electronic heart” or “brain center” of the car is equipped with a factory database that ensures the uninterrupted operation of all systems and mechanisms of the vehicle: from ignition to engine cooling.

Correct, technically feasible operation of the electronic engine control unit within the framework of the factory specifications contributes to the high-quality performance by the vehicle of all functions provided by the manufacturer.

The ECU plays an important role in vehicle diagnostics: sensors signaling the status of controlled on-board modules provide all the necessary information on the car’s peripheral systems.

The owner of the vehicle will immediately know that there are problems with the ECU. Unauthorized switching on and switching off of the air conditioning system, malfunctions in these panel instruments, or even the inability to start the engine - all this is a hint that your car needs repair of the engine control units (ECU).

Procedure

The only thing you will need is a multimeter and a wiring diagram for the unit. The first one will have to be purchased (it is not included in the package of cars of all brands), and the latter must be included in the documents supplied with the car. You will have to study the diagram carefully. If the ECU does not produce random data, but points to a specific block, find it on the diagram and begin to “ring” it.

If accurate data is not available, the entire system will have to be checked. Having found a breakdown, measure the resistance again and determine where exactly the wire is attached. Parallel to the old one, without removing it, solder a new one with the same parameters. If this is the problem, it should work. If it doesn’t help, the block or some part of it may have fallen off. In this case, sighing heavily, stomp to the service station.

When is car engine control unit repair necessary?

Repair of the engine control unit, the price of which depends on the type of breakdown, will be needed in the following cases:

- short circuit in the electronic system of the car, during surges and interruptions in the current supply, emergency current supply to the solenoid network;

- mechanical damage to the car as a result of impacts, road accidents, exposure to climatic factors, increased vibration during maneuvering and excessive physical exertion;

- occurrence of corrosion processes;

- block overheating, etc.

Algorithm for diagnosing the engine control unit with subsequent repair

Before deciding what type of manipulation the ECU needs (repair of the engine fan control unit or complete replacement), a thorough diagnosis should be carried out.

At the slightest suspicion of a technical “inadequacy” of the ECU, there is a strong desire to repair it yourself - but this cannot be done: at best, you will not change anything, at worst, you will significantly aggravate the problem. According to experts, the ECU (as the “intelligent” center of the machine) is the most complex implementation compartment, therefore the repair of electronic engine control units is trusted only to competent technicians at legal service stations.

If diagnostics of the engine control unit, carried out under special conditions using the necessary tools, showed that repairing the ECU is impossible (but it needs to be replaced), you should not hope for chance and try to “bypass” the nature of the electronic “brain” of the car.

The safety of your traffic depends on the efficiency and uninterrupted operation of the control unit, so listen to the opinion of experts and do not skimp on your own health and the lives of other road users.

Comprehensive repair of the engine control unit of cars and trucks: best prices, quality guarantee

So, the repair scheme for the engine control unit consists of the following steps:

- diagnostics

- correct replacement of a defective peripheral system or ECU;

- warranty obligations for the service provided.

They trust us with the whole range of activities for diagnosing, repairing and replacing ECUs, because the service from AvtoBloki is:

- full range of automobile brands;

- high level of professionalism of the craftsmen;

- modern equipment and one of the best material resources in Moscow;

- installation of components and new ECUs from leading world brands;

- loyal prices;

- quality assurance;

- Individual approach to each client.

In the ECU repair sector, we are one of the best and you have a chance to see this.

How to independently diagnose the unit?

At first glance, it may seem that diagnosing an ECU is a difficult task that not everyone can handle. Indeed, checking your block is not so easy, but having theoretical knowledge, it is quite possible to apply it in practice.

Required tools and equipment

To check the functionality of the module yourself, you will need to perform a number of steps to connect to the ECU.

To perform the test you will need the following devices and elements:

- Oscilloscope. It’s clear that not every car enthusiast has such a device, so if you don’t have one, you can use a computer with the necessary diagnostic software pre-installed on it.

- Cable for connecting to the device. You need to select an adapter that supports the KWP2000 protocol.

- Software. Finding diagnostic software today is not a problem. To do this, just monitor the network and find a program that is suitable for your vehicle. The program is selected taking into account the car, since different control units are installed on different cars.

1. Laptop for testing

2. Connection adapter

3. KWP_D diagnostic software

Algorithm of actions

The diagnostic procedure for the electronic control system is discussed below using the Bosch M 7.9.7 module as an example. This control unit model is one of the most common not only in domestic VAZ cars, but also in foreign-made cars. It should also be noted that the verification process is described using the example of using the KWP-D software.

So, how to check the ECU at home:

First of all, the adapter used must be connected to a computer or laptop, as well as the ECM itself. To do this, connect one end of the cable to the output on the unit, and the other to the USB output on the computer. Next, you need to turn the key in the car's ignition, but you do not need to start the engine. By turning on the ignition, you can launch the diagnostic utility on your computer. After completing these steps, a window with a message should pop up on the computer screen, which confirms the successful start of diagnosing malfunctions in the controller. If for some reason the message does not appear, you need to make sure that the computer successfully connected to the controller

Check the quality of the connection and connection of the cable to the unit and laptop. Then a table should be displayed on the laptop display, which will indicate the main technical characteristics and operating parameters of the vehicle. At the next stage, you need to pay attention to the DTC section (it may be called differently in different programs). This section will present all the faults with which the power unit operates

All errors will be displayed on the screen in the form of encrypted combinations of letters and numbers. To decipher them, you need to go to another section, which is usually called Codes, or use the technical documentation for your car. If there are no errors in this section, then you now don’t have to worry, since the vehicle’s engine is working perfectly (the author of the video about ECU repair at home is the AUTO REZ channel).

But this verification option is most relevant if the computer sees the block. If you have problems connecting to it, then you will need an electrical diagram of the device, as well as a multimeter. The tester or multimeter itself can be purchased at any specialty store, and the electrical circuit diagram of the ECM should be in the service manual. The diagram itself needs to be studied most carefully; this will be required for verification.

In the event that the ECM points to a specific block, and does not show erratic data, then in accordance with the diagram it needs to be found and called. If there is no accurate information, then the only way out is to diagnose the entire system; as we said above, breakdowns are considered one of the main faults.

After the breakdown is found, it is necessary to check the resistance and determine exactly where the cable is fixed. You will need to solder the corresponding new wire parallel to the old one; if the reason lies in the breakdown, then these actions will eliminate the problem. In all other cases, only qualified specialists can solve the problem.