October 12, 2015 Lada.Online 271 864 21

Various sensors are responsible for the operation of all systems of a modern car. They take readings and transmit them to the electronic engine control unit (ECU). If the sensor malfunctions, an error is stored in the memory, and in some cases a Check Engine error appears on the instrument panel.

Injection system

Nowadays, cars have become more advanced and technologically advanced. The control process from a carburetor engine switched to an injection engine. A car engine injector is much more reliable than a carburetor.

The injection system will allow you to more correctly control the car engine, which allows you to use fuel more economically. Modern cars are equipped only with injection engines, since using a carburetor engine is not advisable.

The injection system uses a large number of different sensors that send signals to the electronic engine control unit. Since the injection system uses a large number of sensors, they often fail. This is due to aging or improper operation of the car.

In this article we will talk about all the sensors installed on Lada cars, what role they play and what they are needed for.

Factory and actual fuel consumption for Lada Priora

4180 14

Lada

Nowadays, the criterion for the efficiency of a power plant is no less relevant than the number of horsepower or the time it takes to reach the first hundred. The engines of the updated VAZ line, being in good working order, fully meet modern requirements, both in terms of appetite and potential.

Factory fuel consumption figures

The average fuel consumption for a Priora 16 valves (98 hp) with manual transmission is 6.9 liters per hundred kilometers. Until recently, Priora, which was the flagship model, armed with 106 hp, was no less economical - 6.8 liters per “hundred”. Updated advanced configuration with 106 hp engine. and a five-speed automatic transmission, it has the lowest consumption in mixed mode - 6.6 liters per 100 km.

It is no secret that the most economical mode is driving on the highway at a speed of about 90 km/h. Under these conditions, the on-board computer will show the minimum figures for the current consumption per “hundred”:

- 5.5 l. – for 1.6 l variants. (98 hp + 5MT and 106 hp + 5AT);

- 5.6 l. – for configuration with a 106-horsepower engine and manual transmission.

The bustle of the city does not characterize the efficiency of any engine from the best side. However, for the flagship VAZ series, the balance of energy consumption is normal:

- 8.5 liters per “hundred” (106 hp + “automatic”);

- 8.9 liters per 100 km (106 hp);

- 9.1 l/100 km (98 hp).

Actual fuel consumption of a Lada Priora with a 16-valve engine and various gearboxes

An experienced owner of any car probably knows that achieving ideal fuel consumption indicators is practically impossible. Thus, in winter and in urban conditions this figure shows a particular tendency to increase. In the warm season and on suburban highways, fuel consumption can decrease even below the declared level.

You can summarize the real indicators of mixed fuel consumption on three modifications of the Lada Priora with 16 valves as follows (in terms of “per hundred”):

- winter/city – 12-14 l;

- summer/city – 9-11 l;

- winter/road – 8-9 l;

- summer/track – 5.5-6.5 l

First of all, the possibility of achieving a low consumption of high-octane composition is determined by the 100% serviceability of all vehicle systems. However, correct driving techniques are no less relevant:

- maintain tire pressure of about 2.0 atm;

- drive with the windows closed and without a roof rack;

- adhere to a moderate pace of movement, without sudden acceleration and braking (on the highway - 80-90 km/h);

- apply engine braking;

- warm up a cold engine on the road;

- fill only with 95-grade gasoline;

- drive with the climate control switched off.

Mass air flow sensor

The mass air flow sensor, also known as mass air flow sensor, is installed on all fuel-injected Lada and VAZ cars. The sensor is located between the intake receiver bellows and the air filter box. This sensor is involved in the process of forming the fuel-air mixture. It also estimates the amount of intake air, taking into account its temperature. If there is a malfunction, the “CheckEngine” light does not always light up.

Signs of sensor malfunction:

- Loss of vehicle dynamics;

- Unstable idle;

- Jerking when moving;

- Difficulty starting the engine;

- High fuel consumption;

How to repair a Priora mass air flow sensor

Communities Lada Priora Lada Priora Club Blog The MAF ignition coil

costs a lot. According to the laws of the market, there are reasons for this. However, everything is much simpler! We have to pay a high price for the sensor due to our ignorance. Few people imagine how the mass air flow sensor works. Also, few people know why it stops working. Sellers always impose the opinion that if the mass air flow sensor starts to mope, then you definitely need to buy a new one.

The structure of the sensor is simple. But if you cannot find the fault in its malfunction, then it is better to visit a car repair shop. It is difficult to overestimate the role of the sensor. In order for the controller to monitor the uninterrupted operation of the ignition and injectors, it must more accurately know the air flow of the engine. The engine may lose power, increase fuel consumption, and worsen acceleration dynamics just because the mass air flow sensor has begun to produce inaccurate data.

When repairing a Priora, the mass air flow sensor should be checked with a diagnostic device, the scale of which is up to 2 V. The wire from the device is inserted between the rubber seal and the yellow wire. Do this until the contacts rest. Measure the voltage at this contact point. To do this, turn the ignition key. The ideal option is 0.99 V. When measuring, inaccuracy is allowed, but not more than 1.03 V. If the readings are higher, someone immediately runs to the store to buy a new sensor. But let's not rush.

Using pliers, unscrew the screws that secure the measuring element to the sensor. It is better to select self-tapping screws for a Phillips screwdriver. It will be easier for you to unscrew them in the future. Now you need to work with the removed element. Prepare washing equipment in advance. This will be an aerosol carburetor cleaner. Bend its tube at an angle of 90˚.

To do this, heat the tube in the flame of a match. After this, cut it so that the tube itself is straight and the stream is directed to the side. Insert it into the upper valve of the removed element by 10 mm and rinse the resistor. Repeat this procedure after a couple of seconds. Remember that the resistor cannot withstand any force. Forget about brushes, cotton swabs and compressed air.

Allow the cleaner to dry. Only then insert the sensor back into the housing. After this, the voltage measurement should be repeated. If during the measurement everything remained the same, then the mass air flow sensor on the Priora really did its job.

After flushing the sensor, some engine characteristics may change. In this case, it is worth checking the exhaust toxicity and adjusting it if necessary. If, during the check, the measurements returned to normal, then you can safely continue driving.

Speed sensor

The speed sensor is installed on the gearbox housing and is designed to measure the speed of the vehicle and calculate the kilometers traveled. The speed sensor also provides readings for preparing the air-fuel mixture while the car is moving. You can notice that when the car is rolling at neutral speed, the idle speed is slightly higher than when the car is stationary. When there is a malfunction, the “CheckEngine” light almost always comes on.

Signs of sensor malfunction:

- There are no increased speeds when driving at neutral speed;

- Speedometer does not show speed;

- The odometer does not work;

- EUR does not work;

Coolant temperature sensor

Coolant temperature sensor, also known as DTOZH. Installed in the thermostat housing. Serves to prepare the air-fuel mixture when starting the engine. It also simultaneously displays coolant temperature readings on the car’s dashboard and turns on the engine cooling fan. If there is a malfunction, the “CheckEngine” light does not light up.

Signs of sensor malfunction:

- Loss of vehicle dynamics;

- Unstable idle;

- Jerking when moving;

- Difficulty starting the engine;

- High fuel consumption;

- Difficulty starting in the cold season;

Main set of sensors for 16-valve VAZ-2112 engines

The ECU must control many parameters at once. The most important information will be the position of the crankshaft. You can turn off all sensors except the DPKV, and this will not lead to the engine stopping.

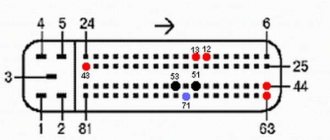

Sensors connected to the ECU

Let's list all the elements one by one:

Let's take a look at how all the elements look in real life. Shown are pictures of VAZ-2112 sensors (16-valve internal combustion engine).

Each element will be easy to find under the hood

Everything said above is true for two engines at once - for units 21124 and 21120 (1.6 and 1.5 l).

You cannot unscrew the DTOZH sensor without draining the coolant. And to disconnect the sensor means to disconnect the connector, but not to dismantle the sensor itself.

Where is which sensor located - engine compartment diagram

Let's look at another picture.

Engine compartment and engine 21124

It is important to understand where the following elements are located:

The location of the phase sensor is indicated in the previous chapter.

Never unscrew the speed sensor. It will be difficult to install it in a way that maintains a seal.

Crankshaft position sensor

Crankshaft position sensor, also known as DPKV. Installed on a bracket near the generator belt drive pulley. Works on the law of electromagnetic induction. Reads readings from the crown of the generator drive pulley. Sets the ignition timing angle (IAF). If there is a malfunction, the “CheckEngine” light comes on.

Signs of malfunction:

- The engine runs intermittently;

- The engine does not start (no spark);

Phase sensor

The phase sensor is installed on an engine with 16 valves, located near the fuel rail. Based on the law of electromagnetic induction, it takes readings from the intake camshaft master pulley. Participates in the process of formation of the air-fuel mixture for each cylinder separately. In the event of a malfunction, the engine begins to operate in emergency mode. When there is a malfunction, the “CheckEngine” light almost always comes on.

Signs of malfunction:

- The engine runs intermittently;

- Increased fuel consumption;

- Unstable engine operation at idle;

Total

The factory fuel consumption figure for Priora with 16-valve engines is 6.6-6.9 liters per mixed “hundred”. In reality, the appetite ranges from 8 to 14 liters. in winter and 5.5-11 l. in summer.

Increased fuel consumption can be caused by malfunctions in the fuel system, in the ECM, a clogged air filter, a clogged catalyst, incorrect operation of the air purge valve, or air leaks. Tire pressure and driving style also determine energy consumption.

Sooner or later, the euphoria from the new car wears off, and the owner begins to pay more and more attention to the fuel level needle, comparing the manufacturer’s stated figures with the real state of affairs. The dependence of these values on tire pressure or problems with the ignition system is clear even to novice motorists. But this is not always the root cause of excessive fuel consumption; sometimes the sources of the problem have to be looked deeper.

Idle speed control

The idle speed regulator, also known as IAC, is installed in the throttle valve. Designed to regulate idle speed on engines without the E-GAS system. The sensor is quite unreliable and fails very often. It is a motor with a worm gear. If there is a malfunction, the “CheckEngine” light does not light up.

Signs of malfunction:

- Not smooth idle;

- The revolutions are floating;

- Troubles the engine;

Malfunctions and their elimination

One of the problems of APS Priora is the implementation of a data exchange mechanism between the immobilizer and the vehicle's ECM via a diagnostic line. In this case, malfunctions occur in the system - the immobilizer signal lights up on the instrument panel and the engine does not start.

The code in the immobilizer may go wrong:

- from connecting diagnostic equipment;

- from the appearance of induced currents from the cell phone transmitter,

- from voltage surges in the vehicle's on-board network.

- from zero charge in the battery.

In the latest Priora models, an emergency shutdown procedure for the anti-theft system has been implemented. It is necessary to activate this function and register a password in the ECU. Then, if an emergency situation occurs with the APS, you can, by manipulating the gas pedal according to the factory instructions, start the car, ignoring the immobilizer blocking.

Throttle Position Sensor

The throttle position sensor (TPS) is installed on the throttle valve on cars without the E-GAZ system. Designed to regulate engine speed. The sensor is not reliable and often fails. If there is a malfunction, the “CheckEngine” light does not always light up.

Signs of malfunction:

- Not smooth idle;

- The revolutions are floating;

- Troubles the engine;

- When starting the engine, the speed is increased;

- Spontaneous increase or decrease in speed;

Oil pressure sensor

The oil pressure sensor is installed in the cylinder head. Designed to indicate oil pressure and indicate oil pressure when the engine is running. A very reliable sensor that rarely fails. The “CheckEngine” light does not light up when there is a malfunction.

Signs of malfunction:

- The oil pressure light is constantly on;

- The oil pressure light does not light up when the ignition is turned on;

Where to buy car accessories

Spare parts and other products for the car are easily available for purchase at auto stores in your city. But there is another option that has recently received significant improvements. You no longer need to wait a long time for a parcel from China: the AliExpress online store now offers the opportunity to ship from transshipment warehouses located in various countries. For example, when ordering, you can specify the “Delivery from the Russian Federation” option.

Follow the links and choose:

Oxygen sensor

The oxygen sensor is installed in the exhaust manifold of the car. Serves to monitor exhaust gases and adjust the air-fuel mixture. A reliable sensor rarely fails. If there is a malfunction, the “CheckEngine” light does not always light up.

Signs of sensor malfunction:

- Loss of vehicle dynamics;

- Unstable idle;

- Jerking when moving;

- Difficulty starting the engine;

- High fuel consumption;

- Black smoke when driving at high speeds;

Articles

For oxygen sensors, the designation 21120-3850010 was first used. Then an article appeared with the numbers 1118 (see photo). It appears to be a new type of sensor. It will be easier to use BOSCH articles.

Exhaust system of VAZ-21120 engine

We list the article numbers of the remaining sensors:

The last three sensors are not connected to the ECU. However, a rough road sensor (2123-1413130) can be connected. It affects the operation of the engine, although it is attached to the body.

Engines with ECU January 4.1 do not have oxygen sensors.

In general, on VAZ-2112 hatchbacks, sensors may be different from those indicated in the list. But then we are talking about an 8-valve engine. And everything that we indicated applies to 16 valves, here is a diagram of this engine.

Knock sensor

The knock sensor is installed on the cylinder block under the intake receiver. Based on the principle of the piezo element. Engine detonation is measured and the air-fuel mixture is adjusted. Quite a reliable sensor. If there is a malfunction, “CheckEngine” does not light up.

Signs of sensor malfunction:

- Loss of vehicle dynamics;

- Unstable idle;

- Jerking when moving;

Repair

The types of work performed depend on what signs of malfunction were identified during the diagnosis.

Wiring repair

If visible or internal violations are detected, the wiring must be repaired or replaced.

Connector repair

In case of mechanical failure of the connector, it must be replaced, since it will not provide insulation of the connected contacts.

If the connector becomes oxidized, it must be reconnected and the contacts cleaned.

Cleaning (temporary measure)

During the operation of the vehicle, a significant layer of carbon deposits accumulates on the surface of the sensor.

Cleaning is carried out using phosphoric acid and a brush made of soft material. The outer electrode and protective casing must be soaked for about 20 minutes until the accumulated carbon deposits are removed, or cleaned with a brush.

It is not recommended to use products made from hard materials, for example: metal brushes, screwdrivers, sandpaper.

After cleaning, the lambda probe must be completely dried.

Replacement

Replacing the first or second sensor consists of the following steps:

After repairing, cleaning or replacing the elements of the lambda probe, it is necessary to recheck its operation by starting the engine and warming it up to operating temperature.

Air conditioner sensor

The air conditioning sensor is installed under the bumper next to the air temperature sensor. Designed to turn on the air conditioner or protect against turning on at low temperatures. Let us remind you that the air conditioning in Lada cars only works at outside air temperatures of +5 degrees. Reliable sensor, no breakdowns were detected.

Signs of malfunction:

- The air conditioner clutch does not engage;

Mechanical engineering keeps up with the times, so new sensors appear quite quickly in car engine control.

What does it consist of?

Oxygen sensors for Lada Priora consist of:

- metal case;

- four-pin connector for connecting electrical wiring:

- external electrode (platinum);

- internal electrode (zirconium);

- electrode insulator (ceramics);

- sensor electric heater;

- protective casing of the external electrode.

The lambda probe elements are resistant to high temperatures, as well as to its constant changes. This is due to the fact that its installation location is the engine exhaust system, some areas of which heat up to 900 °C.