Failure of the “vacuum seal” is a rather rare failure, but unpleasant - to slow down and stop the car, the driver has to press the brake pedal hard. A sudden failure of the mechanism while driving can provoke an accident - the driver does not have time to change lanes and apply the required force at the right time. To identify signs of critical wear of an element, it is proposed to consider the operating principle of a vacuum brake booster (VBR) and diagnostic methods in a regular garage.

Vacuum brake booster device

The vacuum brake booster is designed to improve the usability of the braking system. A car without VUT would brake very hard - the force transmitted to the pedal in this case would be very significant, which would affect driving safety for the worse.

The VUT is usually located directly behind the engine shield. Structurally, this element is made in the form of a non-separable metal block connected to the main brake cylinder and the brake fluid reservoir.

The vacuum sealer includes the following elements:

- Frame.

- Separating membrane (made from flexible material).

- Check valve.

- Brake pedal pusher.

- Hydraulic cylinder rod.

- Return spring.

- Follow-up valve.

The principle of operation of the vacuum seal is based on the difference in atmospheric pressure, as a result of which a vacuum is created, which ensures the formation of pressure (and at the same time the transmitted force) in the brake system.

Inside the VUT there is a diaphragm in the form of a partition. Each of the chambers (cavities) separated by a diaphragm is sealed. Moreover, the chambers are equal to each other in volume.

One of the chambers communicates freely with the atmosphere (it is called the atmospheric part), the second is connected to a hose leading from the engine exhaust pipe. On this side, a lower pressure compared to atmospheric pressure is formed. This cavity is called vacuum; it is located on the GTZ side.

We recommend: Do-it-yourself replacement of the pump on a VAZ 2107

The atmospheric chamber, located closer to the brake pedal, contains a reverse valve. It is designed to prevent a decrease in pressure in the intake manifold of the engine. Due to this, fuel cannot enter the VUT mechanism.

The amount of vacuum in this cavity is controlled by a follow-up valve. The vacuum chamber, thanks to the reverse-acting valve, maintains the pressure at the same level. In other words, the membrane experiences the same pressure values from both chambers. The follower valve moves through a pusher, which is connected to the brake pedal. The purpose of the spring is to ensure that the diaphragm returns to its normal state after stopping braking.

In some situations, when the car is equipped with an emergency braking mechanism, the rod is equipped with a specialized electromagnetic drive.

As you can see, the design of the vacuum unit is not so complicated - in some cases, troubleshooting some VUT faults can be done on your own.

How to repair or replace parts

Hisses when braking (with video example)

In the following video you can hear this characteristic sound:

By the way, according to the instructions, the standard “vacuum unit” of the VAZ-2110 cannot be repaired, only replaced, but we “do it ourselves.” And judging by the number of different instructions for self-repairing cars posted on the Internet, it can be argued that any domestic car enthusiast with more than five years of experience can safely be awarded the title of design engineer in absentia. Therefore, we will consider the repair procedure, especially since the difference in cost between the repair kit and the vacuum booster itself is disproportionately high.

In any case, first we will have to dismantle the VUT; for this we will need a minimum of available tools.

Tools

- Open-end and socket wrenches in sizes “10”, “13”, “17”;

- Powerful flat screwdriver;

- Repair kit or VUT assembled;

- Sealant and a little desire to do it yourself.

Symptoms of a problem

- The hose that goes to the amplifier from the intake manifold has ruptured. Check the tightness of the clamp on the manifold and the condition of the hose itself.

There is a hose from the engine intake manifold to the brake booster that may be damaged.

- Various problems in the internal structure of the amplifier, for example, failure of the working valve responsible for connecting the atmospheric and vacuum chambers.

- Engine "troits"

- When starting the engine, the brake pedal does not move down

Design and operating algorithm

The first passenger cars produced in the last century were not equipped with “vacuum seals”. To sharply slow down the car in case of emergency braking, the pedal had to be pressed with a force of about 80 kg. The device of the vacuum brake booster installed on modern vehicles makes it possible to reduce the mentioned force to a light press.

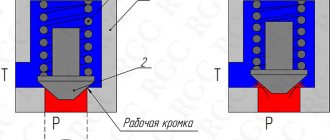

To diagnose malfunctions of this unit, you need to know its design and operating principle. The amplifier is a cylindrical metal housing, inside of which the following elements are located:

- a diaphragm pushed by a return spring;

- air valve with two channels - atmospheric and vacuum;

- in the center of the body there is a rod connected at one end to the brake pedal, the other to the main cylinder, and a diaphragm is attached to it;

- vacuum supply pipe from the engine intake manifold connected to the check valve.

We recommend: Buy truck tires in Tver in the online store

In fact, the body of the “vacuum generator” is divided by a membrane into 2 separate chambers. The first is supplied with vacuum from the power unit, while in the second the air pressure is equal to atmospheric pressure. The chambers communicate with each other through the channels of the air valve, which alternately open when the driver presses and releases the pedal.

The classic vacuum brake booster works according to the following algorithm:

- Until the driver activates the brake system, both chambers communicate via a vacuum channel. Since the pressure in them is the same, the pusher and rod remain motionless.

- After pressing the pedal, the rod moves forward and the connection between the two chambers through the vacuum channel is interrupted. The valve opens another passage connecting the atmospheric chamber with outside air.

- Due to the pressure difference, the diaphragm bends towards the vacuum, thereby helping to put pressure on the pusher and the piston of the main hydraulic cylinder.

- When the driver takes his foot off the pedal, the valve produces the opposite effect - it closes the atmospheric channel and opens the vacuum channel. The pressure in the chambers is equalized, the spring pushes the membrane back to its original position.

Reference. In diesel and some gasoline cars, the vacuum is created not by the intake manifold, but by a separate vacuum pump in the brake system. Such a scheme operates reliably in high altitude conditions with low atmospheric pressure, where a conventional membrane amplifier loses its functionality.

If the brake pedal is held down by the driver, the diaphragm also stops and exerts a constant force on the rod. Thanks to the described operating principle of the VUT, the driver’s work is greatly facilitated, and the system responds to the pedal much faster.

Let's sum it up

So, we found out what a vacuum brake booster is. This is a very important element in any car. In general, a vacuum brake booster rarely fails. This is a fairly reliable and simple mechanism. Sometimes it is not changed for 10 years. It does not have a specific resource. And malfunctions most often relate to air leaks due to the hose through which the vacuum flows from the engine to the amplifier. But if during diagnostics the pedal does not behave as it should, it is worth making an urgent replacement. Indeed, in emergency situations, you simply may not have enough distance to stop the car.

Failure of the “vacuum seal” is a rather rare failure, but unpleasant - to slow down and stop the car, the driver has to press the brake pedal hard. A sudden failure of the mechanism while driving can provoke an accident - the driver does not have time to change lanes and apply the required force at the right time. To identify signs of critical wear of an element, it is proposed to consider the operating principle of a vacuum brake booster (VBR) and diagnostic methods in a regular garage.

Checking the VUT check valve

The cause of poor performance of the vacuum brake booster may be a malfunction of the check valve to which the hose from the intake manifold is connected. To diagnose the latter, you need to remove the hose, remove the valve from the VUT body and put a rubber bulb from a syringe or hydrometer on it from the outside (to which the hose is connected) and squeeze it. If, after releasing the bulb, it remains compressed, the check valve is working properly.

Otherwise, it must be replaced. In a similar way, you can check the inlet hose for leaks in the absence of a compressor.

Diagnostics of the vacuum brake booster can be easily carried out in just a few minutes through simple manipulations without the use of any measuring instruments or tools. For a more objective check, try the various methods suggested in the article. Before doing this, do not forget to check the condition of the hose leading to the VUT from the intake manifold.

Engine misfire (misfire) when pressing the brake pedal

An air leak through the brake booster can cause misfires while the engine is running. Damage to the diaphragm or internal valve leads to the fact that the optimal ratio of air and fuel is disrupted. Misfire usually occurs when you press the brake pedal while idling.

If checking the vacuum hose, connections and check valve does not reveal anything, you need to perform the following check:

- start the engine at idle speed;

- tighten the handbrake;

- ask another person to press the brake pedal;

- pinch the vacuum hose using pliers (do not forget to place a rag so as not to damage the hose);

- If the engine does not stall and its operation stabilizes, the vacuum brake booster is the culprit for misfires.

Checking engine vacuum using a vacuum gauge

Sometimes the VUT copes well with its tasks, but the motorist still has certain doubts that it is fully operational. If the amplifier on your car did not pass or barely passed the previous tests, you need to make sure that there is enough vacuum. Such diagnostics are performed using a vacuum gauge.

- Disconnect the vacuum hose from the brake booster and connect it through a tee so that you can use a vacuum gauge.

- Start the power unit.

- The sensor should display approximately 400-540 mmHg. Art. If you see a lower value, there is a vacuum leak through the intake manifold (gaskets or crack), hose, engine (cylinder head gasket, etc.) or other components.

What to do with a faulty device?

As usual, there are two options: repair and replacement . Their choice depends on the degree of damage to the VUT. To eliminate them, you need to know the amplifier well and have a repair kit suitable for the specific model of the device in your garage.

We recommend: Changing the oil in the automatic transmission and Chevrolet Cruze engine

If the vacuum booster fails, you will have to spend more effort to brake, and the response of the braking system will be very slow. In some situations, this can lead to an accident, so if signs of failure of the VUT are observed, it should be replaced. Note that at home there is no point in trying to get the amplifier into working condition without a special set of spare parts and tools.