Brake pads are a working element of the brake system, which slows down the speed of rotation of the wheels by braking torque due to friction against the surface of the wheel or brake disc. Replacing brake pads is not a complicated procedure and can be done even by a novice car enthusiast, even without experience in such a procedure.

Each part of the car has its own working life, which decreases over time. The wear of brake pads depends on many factors and in each individual case the brake pads will have to be replaced after a different time.

Working principle of brake pads

This mechanism is attached to the central part of the wheel, called the hub, and is something between the wheel itself and the hub. This arrangement allows the blocks to perform their function of reducing vehicle speed. Disc-type mechanisms are located on the front of the rotating axis, while drum-type mechanisms are located at the rear.

The drum mechanism acts on the pads, maintaining them in a compressed state, which is achieved thanks to two special springs. The upper part of the pads fits into the grooves of the brake cylinder, while the lower part fits into the hub.

- When you press the brake pedal, pressure appears on the pistons, which leave the cylinder.

- They push the pads, overcoming the resistance provided by two springs.

- Due to the friction that occurs between the drum and the pads, the drum slows down, which in turn leads to a decrease in the rotation speed of the wheel.

- The more pressure on the brake pedal, the more intense the friction, and the faster the speed drops.

When working with disk-type mechanisms, a slightly different operating principle is observed.

Cost of working in a car service

In car services in different regions, the cost varies significantly, but on average such work costs from 1000 rubles.

At such stations there is a device for replacing brake pads, so the work will be done efficiently and quickly.

If you live in the Moscow region, the replacement procedure will cost more, approximately 2000-3000 rubles.

Now you know how to replace front brake pads with your own hands. We wish you success!

Diagnosis of brake pad wear

As you already understand, brake pads are the main element in the braking system. And they are the ones who ensure the safety of the car while driving. However, like any other spare part, they have to be changed from time to time.

Due to frequent interaction with other parts that are located too close to them (drum, disk), friction occurs between them and special friction linings. The latter, in turn, wear out, and there is a need to replace them.

To determine the degree of brake pad wear, pay attention to the following signs:

- While braking and until the vehicle comes to a complete stop, you hear a high-pitched squealing sound. It is this that indicates that the surface of the linings has completely worn out. Consequently, the drum is now in direct contact with the metal.

- If you notice that your vehicle starts to brake too hard or takes a long time to slow down, this also indicates that there is empty space between the worn out linings and the drum. Moreover, you need to apply much more effort when pressing the gas pedal. Additional effort when pressing provokes a slowdown in the braking process. In the case of a complete absence of friction linings, braking will be harsh, since the friction between the pad and the disc will increase. This, in turn, will cause damage to the drum or disc itself.

- If you notice a vibration in the brake pedal, this is also a sign of a problem. This is explained by the fact that the pads are worn unevenly.

If you notice at least one of the above signs, do not delay repairs.

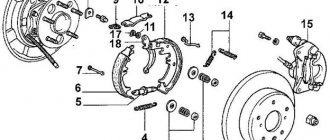

Device

Before disassembling, you need to know the structure of the braking system. The VAZ 2110 has hydraulic brakes with distributed circuits. One circuit is the front right and rear left mechanisms, the second circuit is diagonal.

The hydraulic drive includes a (also dual-circuit) pressure regulator. It helps regulate the brake fluid pressure on the rear brake systems. It is through the regulator that the fluid flows to both rear mechanisms.

Hydraulic brake circuit diagram

Adjustment is carried out through four chambers. Their design is as follows: two are connected to the main cylinder, and two, respectively, to both cylinders of the rear brakes.

For high-quality braking, it is necessary that the entire system works smoothly, there is correct adjustment and reliable mechanisms.

What affects the reliability of the braking system?

It should be noted that there are points that have a great impact on the reliability and service life of brake pads.

These include the following points:

- How and what are the pads made of?

- Driver's driving style: aggressive, moderate.

- Quality of roads.

- Climate and time of year.

- Lifetime.

As mentioned earlier, the car’s braking system requires the most responsible care. You shouldn't skimp on it. Choose only high-quality spare parts from trusted manufacturers.

Moreover, if the pads you choose do not fit the dimensions of your car, do not under any circumstances attempt to modify them.

Understand that any impact in the future can disrupt the progress of their work and lead to irreversible consequences, the least of which will be the rapid failure of the pads themselves.

It is necessary to check the condition of the brake mechanism every 10 thousand km. Factors indicating the need to replace parts are:

- If the thickness of the residual friction layer is 2 mm or less.

- If there is damage on the pads that was not obtained naturally.

- If the mechanism has chips, cracks, grooves and irregularities.

How to replace front brake pads

Replacing the front pads is easier than doing the same with the rear ones due to their design features.

The algorithm of actions is as follows:

- Place the car on a flat surface.

- Set the vehicle's parking brake. Make sure it does not roll back when changing position.

- Loosen the bolts that secure the wheels.

- Use a jack to raise the desired part of the car.

- Now you can remove the wheel from the hub and assess the condition of the brake system.

- If there is severe wear, unscrew the caliper bolt and carefully remove the caliper itself from the disc.

- Now you can remove the pads.

Before replacing the part, be sure to lower the piston completely into the cylinder. This is done so that the caliper can be reinstalled in its place.

Since the caliper is made of aluminum, you can apply force to it without damaging it.

Now you can install new pads, put the caliper and wheel back in place, and return the car to its previous position.

What tools will we need?

- Lifting support.

- Set of wrenches.

- “Wheel wrench” (wrench for removing wheels).

- Jack.

When you have prepared everything you need, you can begin work. We will look at an example of how to replace brake pads on a Solaris with your own hands.

But it doesn't matter that we chose this car; it has a standard drum brake system. First, we will look in detail at how to change the front pads of a car, and then the rear ones.

How to replace rear brake pads

If there is a drum-type mechanism, replacing the above-mentioned parts becomes much more difficult.

- You need to jack up the car and remove the wheel. To remove the drum, open and unscrew the nut that is attached to it. After this, the part is carefully removed from the hub. Be sure to pay attention to the bearing, which, if there is a parking brake, must be removed.

- Now you can start removing the springs. This action will require a lot of effort, as it creates significant pressure. After this, the clamps are removed from the pads. Now it seems possible to remove the pads themselves.

- As in the case of the front part of the car, the piston should also be recessed here.

- New elements are installed, fixed using clamps and springs, and the bearing is returned to its place.

- Now you can put the drum and wheel back in place.

After this, you need to take into account the fact that you cannot replace either the rear or front pads separately. Replacement must be done immediately and on all wheels.

Parsing order

It is better to carry out the repair operation on an overpass (you can use an inspection hole), or just a flat area with a hard surface, because you will have to remove the rear wheels, naturally, first jacking up the car.

So:

- Remove the wheel and disk;

- We unscrew the guide bolts, of which there are 2, and remove the drum;

- A common problem is the drum sticking, so sometimes it is not so easy to remove it. The problem has long been solved by tapping a drum with a hammer (through a board);

- Using pliers, remove the tension spring;

- After this, a fixing guide spring holding the block;

- We remove the block from the support bar that is not connected to the handbrake rod. To do this, pull its free edge to the side and along the shield;

- Loosen the upper spring. To do this, you need to turn the block to the side until you can disconnect the spring;

- We do the same with the spring of the second pad;

- Remove the spacer bar;

- Disconnect the handbrake rod from the cable;

- We note to ourselves or sketch how the connection to the rod is made;

- Unhook the spring, remove the cotter pin, and disconnect the brake pad.

Using a 12" wrench, unscrew the two guide pins. Scroll the drum evenly, apply light blows to its end with a hammer or the edge of a mounting blade. Use a screwdriver to disconnect the end of the upper tension spring from the block. Remove the spring.

Use a screwdriver to remove the guide spring from engagement with the block. Disconnect the lower tension spring and remove the front block. Remove the lower tension spring.

We remove the expansion bar. Having disconnected the guide spring from the rear brake shoe, remove the lever for manual drive of the shoes from the cable tip. To replace the guide spring of the block, remove it from the hole in the brake mechanism shield.

Thus, the disassembly process is completed.