To start the power unit of the VAZ 21099 car, a starter is used. It sets the rotating movement of the crankshaft of the internal combustion engine. Over time, the starter wears out, leading to breakdowns.

The car stops starting normally, which brings a number of difficulties to the car owner. Therefore, it is important to pay due attention to the starter and, when symptoms of a malfunction appear, carry out diagnostics, based on the results of which repair or replace failed elements.

Problems with the starter on the VAZ 21099 and their elimination

If the starter does not turn and the VAZ 21099 does not start, but you can hear the traction relay clicking, then the culprit is most likely a dead battery. Insufficient battery charge leads to a drop in the network voltage, which causes the relay to jerk. To resolve the problem, charge the battery to its nominal level. If the battery does not hold a charge, it is recommended to replace the battery with a new power source.

The weak point of VAZ 21099 starters is the bushing. It wears out relatively quickly and is easily damaged. To troubleshoot, you should disassemble the assembly and carefully inspect the surface in contact with the armature shaft. If there is damage, the bushing must be replaced.

In an electrical circuit, brushes are the most susceptible to wear. During inspection, you should measure their size. If it approaches 12 mm, then the brushes must be replaced. The presence of mechanical and thermal damage on the surface is also unacceptable.

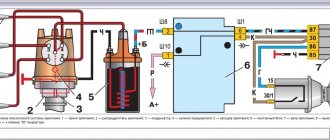

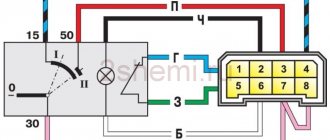

Instead of permanent magnets, a conventional winding is used in the stator. By assembling the circuit shown in the image below, the car owner can check the integrity of the wire and the absence of a breakdown in the body.

Also, attention should be paid to the anchor. By connecting the light bulb, as in the image below, you can check that there is no breakdown on the body. If the insulation is damaged, the armature must be replaced.

Geared vs conventional: which starter should you prefer?

A conventional starter does not have a gearbox; the rotational motion is transmitted directly to the crankshaft. Therefore, its design is simple and allows you to carry out repairs at home. Due to the fact that the electric current supplied to the device instantly engages the flywheel crown and gear, the engine starts, which is called “half-turn”. Classic units, due to their simple design, are reliable devices that can withstand electrical influences, but can fail when exposed to low temperatures.

The principle of operation of the gear unit is the same as that of the classic unit - the conversion of electrical energy into mechanical energy.

The difference is in the design - a gearbox is included, which is located between the armature and the bendix. In addition, the windings are equipped with permanent magnets, which increased the reliability of the mechanism. Geared devices are increasingly conquering the car market. In order to figure out which starter is better, you should find out the advantages and disadvantages of each of them.

Advantages of the classic version:

- simplicity of design;

- high maintainability;

- availability of spare parts;

- low cost.

The disadvantages include the following:

- the need for high starting current;

- rapid wear of parts;

- unstable operation at low temperatures;

- large weight and dimensions.

In general, an ordinary unit can be assessed as a reliable device when used correctly.

The gear unit has the following advantages:

- light weight and small size;

- can operate in a wide temperature range;

- long service life;

- economical energy consumption (40% less than usual).

Thanks to the presence of a gearbox, starting reliability at low temperatures has increased. Since a small current is required to start the power unit, the likelihood of a successful start increases in winter.

The disadvantages are the following:

- lack of spare parts;

- complex repairs;

- low quality gearbox.

The reliability of a device depends on the quality of its components. Therefore, a mechanism with high-quality components will last a long time without repair.

Photo gallery

Article number and approximate price for the original VAZ 21099 starter

The original starters for the VAZ 21099 have a factory index of 29.3708 and 5712.3708. For a new product, the car owner will need to pay more than 3,000 rubles. The wide popularity of the VAZ 21099 led to a large number of used starters for the car at car dismantling yards. For a supported node you will need to pay from 1200 rubles. The problem with such a purchase is the inability to determine the residual life of the product.

Starters for VAZ 21099, which go on retail sale, have article numbers 21130370801000 and 2108370801006. Their price starts from 3,200 rubles. The nodes have similar operational characteristics.

What affects the price?

In addition to the brand name, as well as the components used of one quality or another, the retail price of a VAZ 2109 starter is influenced by the following parameters:

- Series (3 in total)

- Rated power.

- Rated current.

- Supply voltage.

- Model (original or analogue)

The most affordable starters are those produced in Russia and Ukraine. Their warranty period is 1 year, instead of 3 months for Belarusian analogues.

Catalog number and cost of a good starter for VAZ 21099

The original VAZ 21099 starters, regardless of whether it is an injector or a carburetor under the hood, have very mediocre quality and satisfactory performance characteristics. Car owners complain that there are a large number of defects among original units. Therefore, experienced drivers recommend purchasing products from third-party manufacturers. Analogues often have more attractive performance characteristics, which are combined with a very reasonable price. The best alternative options for original starters, which have proven themselves excellent during operation on the VAZ 21099, are shown in the table below.

Table - Good analogues of the original VAZ 21099 starter

| Manufacturer | vendor code | Approximate cost, ruble |

| HC Parts | CS332 | 2700-3500 |

| As-pl | S9008 | 1600-2100 |

| Bosch | 986014950 | 7800-8900 |

| Unit | 1100351 | 3300-3900 |

| Eldix | ELDST2108 | 2700-3900 |

Required Tools

In order to remove and install the starter on a VAZ 21099 car, you will need the tools from the table presented below.

Table - Tools required to replace the front strut

| Name | Note |

| Head | “at 8”, “at 10”, “at 13”, “at 15” |

| open-end wrench | “at 8”, “at 10”, “at 13”, “at 15” |

| Vorotok | With ratchet and extension |

| Penetrating lubricant | For example, WD-40 |

| Wire brush and rags | To clean dirt |

Most operations for replacing a starter on a VAZ 21099 can be performed through the top of the engine compartment. Despite this, it is extremely inconvenient to unscrew the lower fastening of the unit, even with a ratchet and extension. Therefore, if possible, it is advisable to carry out part of the work on dismantling and installing the product from the bottom of the machine. To do this, you will need a lift, inspection hole or overpass. According to reviews from car owners, in extreme cases you can do without them.

Types of goods and how much do they cost?

Like any other car, two types of starters can be installed on the VAZ 2109, namely:

- With electromagnetic excitation (standard model) – RUB 2,171-4,890 .

- With excitation from permanent magnets (geared, new type) - 2,300-6,500 rubles .

All models of starting devices on sale can also be divided into 3 series, or more precisely:

- 2101, 1970-1988.

- 2108, 1984-2003.

- Priora (2170), 2007.

Products from these series are installed on the VAZ 2109 without any modifications, including replacement with elongated studs for the clutch bell.

Starter replacement process

In order for the starter replacement to be successful, you must follow the step-by-step instructions given below.

- Secure the vehicle from unauthorized movement with the parking brake.

- Open the hood.

- Unscrew the nut that secures the power wire terminal.

- Remove the wire shown in the photo below.

- Disconnect the terminal with the control wire from the traction relay.

- Unscrew the fasteners securing the starter to the seat.

- Since the lower starter mount is quite difficult to reach through the top of the engine compartment, an inspection hole must be lowered.

- Access to the place where the starter is located is blocked by engine protection. It should be removed by unscrewing all the fasteners.

- Unscrew the lower starter mounting.

- Remove the old starter from the seat and engine compartment.

- Install a new node.

- Reassemble everything in the reverse order of disassembly.

- Perform a test run of the power plant to check that the starter is installed correctly.

Characteristics of the VAZ starter of the ninth model

Every driver knows that if the car does not start, the reason may be a faulty starter. In order to diagnose and repair a mechanism, you need to know its structure.

Location and purpose

The main purpose of the starter is to spin the crankshaft, thanks to which the engine starts. Naturally, it is located close to the engine. It is usually located in the engine compartment on the driver's side under the power unit. Depending on the location, when dismantling the unit, you will need to remove either the engine protection or the air filter. Finding a starter is not difficult. It has the shape of a cylinder, and wires are connected to it, which are secured with a nut.

Design and principle of operation of the unit

This unit is a small electric motor. Its design consists of a bendix with brushes, two windings and a movable rotor. Magnetic fields of opposite values are created on two windings - starter and rotor. The mechanism is supplied with voltage, which is transmitted to the rotor using graphite brushes. Thanks to Bendix, rotational movements are transmitted to the flywheel.

The device includes:

- a sleeve that connects to the solenoid relay;

- overrunning clutch, which ensures movement in only one direction;

- gears.

Over time, the parts of the Bendix wear out and it begins to slip. In this case, it needs to be replaced. The cause of the malfunction is contamination of the mechanism, but cleaning does not help restore functionality. Mechanism parts wear unevenly; after washing, they cannot fully perform their functions.

The principle of operation of the starter mechanism is to convert the electrical energy it receives from the battery into rotational movement of the drive gear. An electric current is applied to the poles of the electric motor using a brush assembly. At the same time, the clutch extends and the flywheel crown is connected to the gear. The starter rotates the crankshaft and thus helps start the engine. When the engine is started, the clutch takes its original position (video author - Mikhail Nesterov).