Print this article Font size 16

The journal bearing is a component of the strut support. Belongs to the category of rolling bearings. Widespread use in domestic auto production is due to its versatility and ability to withstand heavy loads.

The main task of the OP is to dampen road vibrations. It provides a movable connection between the body and the vehicle's shock absorber. Plus, it affects the wheel angle settings of the VAZ 2109.

Element appearance

What is a journal bearing

In order to understand what a support bearing is and what role it plays in the structure of the VAZ 2109 car, it is necessary to get into the structure of the entire suspension. As an example, we will consider only the front suspension, but in this car it is independent, and hydraulic struts are used in its operation.

Such a rack is needed in order to dampen vibrations that occur under loads and ensure reliable operation of the shock absorber. The lower end of this mechanism is attached to the rotary cam, and the upper end to the VAZ 2109 body itself.

Any support bearing included in the design of the front shock absorber strut is similar in design properties to such a related element as a rolling bearing. Our support comrade serves to provide a movable connection between the shock absorber and the body of the VAZ 2109.

About company

Auto parts for repair and tuning for the entire range of cars produced by AVTOVAZ. Tuning of engine, transmission, brakes, suspension. Exhaust systems, body reinforcement elements, styling, auto electrics, cooling system. Sale of auto components of companies such as Autoproduct, Demfi, Stingersport, Motordetal, Sonda, SS-20, Volgaavtoprom, AutoPolimservis, Tornado, Lapter, Technosphere, Turbotema, Sachs, Luk, Valeo, Gates, Dayco, Ina, Kyb, Bilst Ein, abtechnik.pro CAR and many others.

Bearing device

A support bearing has a place in any car, so the VAZ 2109 is no exception, but they come in several varieties:

- With built-in ring. This ring can be either internal or external, and when installing it there is no need to use clamping flanges, because with this design feature there are special mounting holes to which the mechanism is attached. Such a bearing has the ability to rotate the mechanism using the outer and inner ring.

- With separate outer ring. This design means that the inner ring will be connected to the body, while the outer ring will be separated.

- With separate inner ring. Here everything is exactly the opposite, the inner ring can be separated, but the outer one remains in place.

- Bearing with single-separate mechanism. Its operating specifics are similar to the above varieties, but the difference is that the ring has a much higher rigidity.

Support bearing VAZ 2109

A small clarification should also be made, without which some may not understand the purpose of the element being described. The name “support bearing” already makes it clear what exactly this part does in the VAZ 2109 and in any other car. It is located directly in the place where the car body is connected to the rack, so the support simply must withstand not radial loads, but axial ones.

OP is the most important element in the design

Replacing a support bearing for a VAZ 2109

As you know, a support bearing or OP, as we will call it in the future, is designed to perform certain functions. Its main task is to rotate the stand around its axis. The OP is located in the front suspension and on a front-wheel drive car, such as the VAZ 2109, however, as on a rear-wheel drive car, in fact, it is the most important link. Before we move on to the direct algorithm for replacing the OP, we will find out important information regarding this bearing. So:

- The VAZ 2109, like all modern cars, has in its design not only an elastic, but also a damping device called a shock absorber to control movement. This is one of the main components of the front suspension.

Replacing the support bearing on a VAZ 2109

Note. The shock absorber strut is designed to dampen vibrations that inevitably occur when the vehicle moves, even on a perfectly flat road. It is the strut support that dampens vibrations. The stand itself is fixed with its lower end to the steering knuckle, and with its upper end - to the mudguard of the car.

- OP is an integral part of the rack support. These parts belong to the group of rolling bearings. They have found wide application in domestic mechanical engineering due to many advantages, among which I would like to highlight versatility, the perception of combined loads and much more.

- The OP is directly involved in damping road vibrations, or, to put it differently, in damping and amortizing the VAZ 2109. In this case, the OP makes a movable connection between the shock absorber and the car body, simultaneously influencing the accuracy of the wheel mounting angle settings.

OP Features

Replacing support bearings in a VAZ 2109

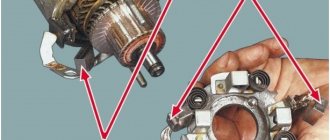

The OP still differs from the standard rolling bearing, although it belongs to the same group. Here, the role of rolling bodies is always cylindrical rollers located perpendicular to each other. In addition, each of the rollers is protected from contact with each other by a special separator. Thus, each of the rollers acts as a separate element, independently taking on loads from different directions.

Replacing support bearings for VAZ 2109

In modern cars, such as the VAZ 2109, the following types of OP are usually used:

- A bearing with a built-in ring (it can be internal or external). This type of bearing is equipped with mounting holes and does not require pressure flanges. In addition, this type of OP has built-in gaskets that ensure constant rotation accuracy. This type of OP is used for both rotation of the outer and inner rings.

- There is another type of OP, which is equipped with a detachable inner ring for rotation of the outer one. The outer ring in this type of OP is in contact with the body. This type of OP is used where precision rotation of the outer rings is usually required.

- The third type of OP is a bearing with a detachable outer ring for rotation of the inner one. In this type of OP, the inner ring is in contact with the body, and the outer one is separated. It is used where it is necessary to ensure the accuracy of rotation of the inner ring.

Replacing the support bearing on the strut of a VAZ 2109

- The fourth type of OP is called single-split. In such a bearing, the outer ring is divided at one point, which is why the rigidity of the entire bearing increases. It is again used where it is necessary to ensure high rotation accuracy of the outer ring.

Basic rules for using OP

As a rule, malfunctions of the strut support are detected while the vehicle is moving. If there is a problem with the strut, a characteristic knocking sound can be heard, especially when driving on a rough road.

Note. If such a knock occurs, it is necessary, first of all, to check the reliability of fixation of the support and if it needs to be replaced, then not only the rubber damper, but also the OP is replaced at the same time.

So:

- The OP is subjected to enormous loads while the car is moving, because it is this element that restrains the rebound movement of the shock absorber. Because of this, this bearing is checked every 20 thousand kilometers for malfunction, and every 100 thousand kilometers requires mandatory replacement, regardless of the condition of the strut itself.

Replacing support bearings on a VAZ 2109

Note. Most often, the OP on the VAZ 2109 requires replacement if for its owner the main and daily road is a dirt road, or if he often goes to the country or into nature, driving through uneven bumps and potholes.

- The shock absorber strut support is equipped with a rubber-metal element, which becomes cracked during long-term use. The wear process of this element is also influenced by sharply changing weather conditions, oil deposits and other contaminants. In this case, it is advisable to replace this element so that it, in turn, does not affect the operation of the OP.

Checking the operation of the support bearing

Due to the fact that the chassis in general and the strut in particular are subject to very heavy loads, the bearing experiences quite large shocks, and it is very important to constantly monitor its condition. The most obvious sign of a bearing failure is a knocking sound coming from the wheel when cornering or overcoming any obstacles. If, after traveling twenty thousand kilometers, the bearing does not raise suspicions, it is still necessary to check its condition in order to understand what to count on in the near future.

Verification methods

Checking the condition of the support bearing is not difficult, but the technology depends on the design features of the rack itself.

It is worth noting here that such a check will not give an accurate result; you can verify that the bearing is faulty only after removing it from the car.

But, nevertheless, by performing a number of simple steps you can determine the condition of the upper support.

If we take the VAZ-2110 model, then its support bearing is installed in the support itself.

To check its condition, you should ask an assistant to rock the car in the transverse direction (not too much), while at this time we place our hand on the protruding part of the pillar in the engine compartment.

If the bearing is worn out, play will be felt by hand. Also, in a damaged element, such rocking is usually accompanied by the appearance of third-party sounds - creaks, clicks.

If all this is found during the inspection, it’s time to inspect the support.

On models such as Lada Priora, Lada Kalina, or, for example, Nissan X-Trail, the bearing is not included in the support structure, so it cannot be checked by rocking it. The only sign of wear for them is the appearance of a knocking sound when moving.

But it is still possible to further verify that the unit is faulty.

To do this, ask an assistant to turn the steering wheel in different directions. At the same time, we put our hand to the spring.

If the bearing is heavily worn, then wedging may appear in it, which will be reflected well into the spring in the form of vibration and mild “shooting”.

Conclusion

Having gained an understanding of what a support bearing is, how this part works and what problems can arise if its wear is ignored, every motorist will begin to listen to the movement of his car while driving and when cornering. If you hear a characteristic knocking sound coming from a wheel, don’t be too lazy to go to a service station or service center and carry out a small diagnostic of the chassis, this way you will save yourself time and nerves, and your VAZ 2109 will thank you.

Few people know, but bearings are used not only in rotating parts. This article will focus on the support bearing. You will learn what it is, how to diagnose a malfunction and how to replace a VAZ support bearing?

Tuning and repair of VAZ 2110

I think everyone understands that with roads like ours, the chassis often requires repairs. Quite often after winter, when the snow has melted and the holes are not yet visible due to puddles, shock absorbers and support bearings often get damaged. Because of such situations, it is necessary to repair this component of the VAZ 2110 chassis. It is better to carry out repairs in a timely manner, since in the first stages it will result in you spending less money than if you cause a breakdown and it will lead to a more disastrous result.

This article will provide information so that you can replace the VAZ 2110 support bearings with your own hands. Moreover, we will do this in such a way that we do not have to adjust the wheel alignment. That is, we will not touch the camber bolts.

What is a journal bearing?

A support bearing is a part of a car's suspension that reduces chassis vibrations transmitted from the car's strut. Since the strut is attached to the body, its effects, after damping the vibrations of the spring, are completely undesirable for the car frame. To reduce the level of transmitted vibrations and vibrations, a special support bearing is used, which is mounted in the upper part of the rack.

In other words, the support bearing creates a movable connection between the car body and the chassis, which makes it possible to increase the service life of the joint. Such a bearing is installed in the upper part of the rack and is closed using metal fittings.

The design of the support bearing allows reducing axial loads on the body. There is a fairly large number of these parts, which have their own types. For each car, the support bearing must be selected in accordance with the make and model of the vehicle.

Replacing the bearing and buffer of the upper support of the telescopic strut of a VAZ 2110 Lada

- Repair manuals

- Repair manual for VAZ 2110 (Lada) 1996+.

- Replacing the bearing and buffer of the upper support of the telescopic strut

| EXECUTION ORDER |

↓ Comments ↓1. General information 1.0 General information 1.1. Vehicle Specifications 2. Engine 2.0 Engine 2.1 Possible engine malfunctions. 2.2 Replacing the coolant 2.3 Replacing the engine oil and oil filter 2.4. Installing the piston of the first cylinder to the TDC position of the compression stroke 2.5 Replacing the camshaft drive belt and tension roller 2.6 Adjusting the camshaft drive belt tension 2.7 Removing, troubleshooting and installing the flywheel 2.8. Replacing engine seal parts 2.9 Cylinder head 2.10 Grinding in valves 2.11 Adjusting clearances in valve drive 2.12 Removing and installing engine 2.13. Engine repair 2.14. Lubrication system 2.15. Cooling system 2.16. Exhaust gas system 2.18. Features of VAZ-2112 engine repair 3. Transmission 3.0 Transmission 3.1. Clutch 3.2. Gearbox 3.3. Front wheel drives 4. Chassis 4.0 Chassis 4.1. Checking the technical condition of suspension parts on the car 4.2. Rear suspension 5. Steering 5.0 Steering 5.1 Inspection and check of the steering on the vehicle 5.2. Steering column 5.4. Steering mechanism 5.5 Possible steering malfunctions. 6. Brake system 6.0 Brake system 6.1. Vacuum booster 6.2. Main brake cylinder 6.3. Pressure regulator 6.4. Brake hoses and tubes 6.5 Bleeding the brake system 6.6 Replacing brake fluid 6.7. Front wheel brakes 6.8. Braking mechanisms of the rear wheels 6.9. Parking brake 6.10 Possible malfunctions of the brake system. 7. Electrical equipment 7.0 Electrical equipment 7.1. Mounting block 7.2. Generator 7.3. Starter 7.4. Ignition switch (lock) 7.5. Checking and replacing spark plugs 7.6. Integrated engine management system (fuel injection system) 7.7. Contactless ignition system 7.8. Lighting, light and sound signaling 7.9. Windshield wiper 7.10 Replacing the electric motor of the radiator fan of the cooling system 7.11. Heater electric motor 7.12. Cigarette lighter 7.13. Instrument cluster 7.14 Checking the carburetor solenoid valve control unit 7.15 Possible malfunctions of the EPHH control unit. 7.16 Electrical diagram of a VAZ-21102 car 7.17 Electrical diagram of a car with a carburetor engine 2110 7.18 Engine control diagram 2111 (pin M1.5.4) 7.19 Engine control diagram 2111 (pin MP7.0) 7.20 Control diagram for engines 2111 and 2112 (pin M1) .5.4N, "January-5.1") 8. Body 8.0 Body 8.1 Possible body malfunctions. 8.2. Replacing the buffers 8.3 Removing and installing the radiator trim 8.4 Removing and installing the locker 8.5 Removing and installing the wing 8.6. Hood 8.7 Removing and installing upholstery, trim and windshield frame lining 8.8. Trunk lid 8.9. Side doors 8.10 Removing and installing the front seat 8.11 Removing and installing the upper and lower lining of the floor tunnel 8.12. Seat belts 8.13. Rear view mirrors 8.14. Instrument panel 8.15. Heater 8.16 Anti-corrosion compounds for body treatment 8.17. Features of body repair of models 2111 and 2112 8.18. Body care 9. Applications 9.0 Appendices 9.1 Fuels, lubricants and operating fluids 9.2 Basic data for adjustments and control 9.3 Filling volumes 9.4 Lamps used in the car |

Diagnosis of strut support bearing faults

A faulty bearing can seriously affect your car's suspension alignment. If it is not changed in time, the wheel camber will be disrupted, which will lead to wear of both the rubber and the shock absorber strut itself. As you know, driving on a faulty suspension can be unsafe.

To diagnose the condition of the support bearing, you need to grab the pillar with both hands, and ask a previously invited assistant to strongly rock the car in different directions. If a characteristic knocking sound appears during the swinging process, then such a part needs urgent replacement.

Basic faults

When a support bearing fails, a knock resembling dull blows appears in the front part of the car in the area of the pillars. Most often, such symptoms are observed when driving over uneven surfaces.

A knock indicates that the bearing has ceased to cope with its duties due to a violation of its integrity. This is caused by the destruction of its structure due to:

- exceeding the recommended resource;

- excessive dynamic loads;

- dirt and moisture getting inside the bearing.

However, knocking in the area of the racks may have other causes. To check the bearings and make sure that they are the ones knocking, lift the hood of the car, remove the cover of the supposed “glass”, and place your palm on the upper shock absorber support.

Rock the car up and down. If at the same time you hear the same knock and feel the corresponding vibration with your hand, immediately replace the bearing.

How to change the support bearing on a VAZ 2109 + Video

It is worth noting right away that none of the bearings can be repaired. The same applies to the supporting one. Therefore, this element can only be changed. Replacement, in turn, can occur in two ways.

- The first method involves removing the strut and steering arm together. This approach allows you to maintain the wheel angle setting and avoid camber adjustments.

- The second method involves dismantling the shock absorber strut separately from the turning mechanism, but after this, the wheel angle settings are lost.

How to check the struts of a VAZ 2114, VAZ 2115

Self-diagnosis methods are, to put it mildly, ineffective, so it is recommended to carry out diagnostic work exclusively on specialized equipment. There is one way, but it only works when the rack has already worn out. You will need to stand near the corner of the car (near the right pillar, for example).

Stand near the edge of the right headlight and place your hands on the hood or fender, then rock the car two or three times, and when it is at the bottom, sharply remove your hands. If the car then goes up and a little down and immediately stops without unnecessary vibrations, then the strut is most likely normal. We carry out similar actions on the left wing. Most often, one rack fails, so the difference in its “behavior” is obvious.

Another reason for the malfunction of the front shock absorber strut of the VAZ 2114/2115 is the failure of the upper support. The reason for replacing the upper supports is usually one of two reasons:

- ruptures and cracks in the rubber part of the support. As a rule, this occurs due to aging of the rubber. This is fraught with the fact that a support that is in this state will suppress noise and shocks while the car is moving much worse;

- failure of the upper support bearing. It occurs much more often than the breakage of a rubber element, and more anxiety is added, since the support with a broken bearing knocks loudly, even on small irregularities.

Replacement with removal of steering arms

- First, the car is placed on a flat surface, and wheel chocks are placed under the rear wheels. The gearshift lever is set to the “first stage” position, the handbrake lever is raised up. Now remove the protective cap located on the hub nut and loosen the nut. There are times when unlocking can be complicated by over-tightening the nut, in which case you will need a drill and an appropriately sized drill bit. Then you need to use a 30mm socket and a long lever to rip off and loosen the nut, but do not unscrew the end. To make the operation easier, you can ask your partner to depress the brake pedal. There are times when the nut cannot be unscrewed because the wheels begin to rotate along with the nut.

- After this, loosen the wheel bolts and raise the car using a jack. Place a sturdy stump or stack of bricks under the threshold to prevent the car from accidentally tipping over, and lower the car onto the support.

- Unscrew the bolts and remove the wheel. Unscrew the nut mounted on the steering end. Then, using a special puller, press out the steering pin, although many manuals allow pressing out using a hammer and pry bar.

- After this, the rack is removed by unscrewing three fastening nuts on top and one long bolt on the bottom.

Replacement of front struts VAZ 2108, 2109, 21099

The front struts of VAZ 2108, 2109, 21099 cars and their modifications will have to be removed and replaced or their parts in case of the following malfunctions: leakage of shock-absorbing fluid, breakdown and knocking when driving, breakage and settling of springs, replacement of anthers and upper supports with support bearings , mechanical damage to parts, front suspension tuning. We replace shock absorbers and (or) or springs of the front struts on VAZ 2108, 2109, 21099 cars in pairs (on both sides). If the stand assembly is replaced, then we also change two at once.

Required tools and accessories

— Socket wrench or socket on “13”

— Spanners for “17” and “19”

— Device for unscrewing the front strut shock absorber rod nut

Tool for loosening the front strut shock absorber rod nut

— Soft metal drift

— Blowtorch or gas torch

Preparatory work

— Jack up and remove one of the front wheels of the car

— We clean the elements of the front suspension of the car from dirt

— We disengage the brake hose from the bracket on the rack

Replacing front struts on VAZ 2108, 2109, 21099 cars

Disconnect the tie rod end from the strut housing arm

Either we remove it with a special puller, or we disconnect the connection the “folk” way (using a pry bar and a hammer). Read more: “Replacing tie rod ends on VAZ 2108, 2109, 21099 vehicles.”

We disconnect the tie rod end using a pry bar and a hammer, creating tension in the connection and hitting the end of the boss

Loosen the shock absorber rod nut

In case you plan to disassemble the rack.

Loosen the shock absorber rod nut using a special tool

Unscrew the three nuts securing the upper strut support to the body

Use a socket wrench or socket set to “13”.

Unscrew the nuts securing the strut housing to the steering knuckle and remove the bolts

It is necessary to mark the position of the adjusting bolt (the upper bolt with the eccentric) with paint or a chisel, so that when installing the rack, it can be returned to its original position. In this case, the camber angle of the front wheels of the car practically does not change.

Unscrew the bolts securing the strut to the steering knuckle of the front suspension

There may be problems at the stage of removing the bolts, as they often become soured in the holes in the steering knuckle. If it was not possible to turn the bolts with a wrench, then first tap them with a hammer, then try to knock them out through a drift. In the most severe case, we heat the steering knuckle at the place where the bolts are attached using a gas torch or a blowtorch and try to unscrew them. Read more: “How to unscrew the bolts of the front struts of VAZ 2108, 2109, 21099 cars.”

Remove the front strut assembly from the car

Pull it out of the wheel arch to the right or left of the hub. Please note that the front pillar is quite heavy.

If necessary, we disassemble the front strut and replace failed parts

We replace the second rack in the same way. The tightening torque of the rod nut is 66-81 N.m, the bolts securing the strut to the steering knuckle are 78-96 N.m.

After replacing the front struts of a VAZ 2108, 2109, 21099 car, it is necessary to check and adjust the angles of the front wheels.

Notes and additions

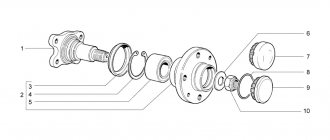

— The front strut of VAZ 2108, 2109, 21099 cars consists of a shock absorber body (“cup”), a shock absorber cartridge, a spring and an upper support with a bearing. Non-separable front struts are also available, without a cartridge, with a built-in shock absorber.

— Another option for replacing the front struts on VAZ 2108, 2109, 21099 vehicles, which does not disrupt the wheel camber angle, is to remove the strut along with the steering knuckle. To do this, you do not need to unscrew the bolts securing the strut to the steering knuckle, but rather unscrew the front wheel hub nut, disconnect the tie rod end from the steering knuckle, unscrew the two bolts securing the ball joint and remove the strut.

TWOKARBURATORS VK -More information on the topic in our VKontakte group

Changing the support bearing without adjusting the camber

- Unscrew the two bolts used to secure the ball joint. Disconnect the brake line mounting from the shock absorber strut. First unscrew the 17 bolts holding the brake caliper. After this, hang the working part of the brake mechanism to other suspension elements.

- Unscrew the strut nut, but do not do it all the way. Unscrew the three nuts that secure the shock absorber. At the same time, unscrew the CV joint nut completely. Pull the grenade and pull the rack out. Remove the springs from it using a puller.

- After tightening the spring, unscrew the old bearing and install a new one in its place. Then reassemble all components in the reverse order, depending on the chosen replacement method.

- When installing the hub nut, do not use an old fastener. The nut is disposable and is replaced after the first unscrewing. The new nut must be locked after tightening.

This completes the replacement of the VAZ support bearing. This procedure can be easily performed in a home garage if you have a certain set of tools and initial skills in using them. By performing this procedure on your own, you can save a lot on the services of service station employees.

Front shock absorber struts can last quite well for more than 100,000 km, but not every owner can boast of such a result. For many VAZ 2109-2108, the front suspension modules have to be changed almost twice as often, that is, every 50 thousand km. Using my own example, I can say that I drove about 80,000 km on factory struts, and only after that one of them leaked.

Below I will describe the procedure for replacing all module parts, from support bearings to springs and supports. To perform this repair you will need the following tools and accessories:

- Socket head for 19 and 13

- Extension

- Ratchet handle

- Vorotok

- Special key for holding the strut rod from turning

- joint puller

- spring ties

- open-end wrench or socket wrench 19

- breakdown if necessary

- hammer

HOW THE REPLACEMENT IS MADE

Let's proceed directly to the repair itself. There are several ways to carry out the work:

- removing the entire rack, with steering arms and other parts attached to it. In this case, the wheel tilt settings are saved, and you do not have to perform the wheel alignment again;

- you can disconnect the strut from the steering cam and then dismantle the remaining parts.

FIRST METHOD

- We dismantle the hub cap and unlock the CV joint

- We unscrew the CV joint until it is completely loose, while the brake pedal should be in a clamped state.

- Jack up the car and unscrew the wheel.

- Unscrew and unscrew the tip nut and press out the pin.

- Next, you need to dismantle the ball and free the brake hose from the shock absorber.

- Loosen the strut nut and unscrew the three support fixation nuts. Then the CV joint is removed and the strut is dismantled.

- Next, the spring is tightened, which is required before changing the support bearing on the VAZ 2114.

- After this, we put everything in place until the car is completely assembled.

SECOND METHOD

- We jack up the car and remove the wheel.

- Then loosen the hub mounting clamp and remove the steering tip.

- We dismantle the ball and remove the brake caliper.

- Next, loosen the strut nut and tighten the spring.

- We change the support bearing and put everything back together.

We arm ourselves with tools and spare parts.

You can't do without tools and spare parts. Replacing the rear struts of a VAZ 2114 will require the following “arsenal”:

- new shock absorbers;

- jack;

- a set of keys. 17 and 19 mm are especially useful;

- special keys for fixing and removing wheels;

- vice and puller;

- hammer and pliers.

The choice of racks deserves special attention. Their varieties:

- Oily. Traditional option. Soft and comfortable. Suitable for a quiet ride;

- Gas. Tough and expensive. Not suitable for every occasion;

- Gas-oil. A kind of compromise between the previous options. Very common.

Useful tips.

- Before direct installation, we carefully inspect the purchased parts and treat them with kerosene. Broken and unusable elements are not needed for repairs;

- A number of professionals believe that the final tightening of bolts and nuts does not require the participation of a jack;

- The struts can be checked using the wheel alignment method. This method increases the service life and increases the comfort of the trip;

- There are special stands where you can check the result of the replacement. The price of the service is small. At the same time, one’s own skill and skill is tested;

- Don't worry if the support bearing doesn't come out with the strut when you remove it.

Popular question: how often do parts need to be replaced? There is no clear answer. Vehicle operating conditions, quality of spare parts and personal skills are key success factors. If a car owner likes to “pick up” potholes and pits, then the time for repairs will inevitably approach. It is also obvious that if there are “symptoms” of a malfunction (dull knocks, fluid leakage or spring deformation), then there is no need to hesitate.

The process is simple. You just need to know clearly what and when to do. A competent selection of tools and spare parts is half the battle, and step-by-step instructions that allow you to carry out repairs yourself will help you complete what you started. Take care of yourself and your car, because health and life are the most valuable things we have.

WE CHECK THE QUALITY OF WORK PERFORMED

When doing the replacement yourself, some skill deficiencies may appear. Somewhere a nut was not tightened or any of the elements of the rack were installed much crookedly. In order to avoid getting into an unpleasant situation on the road in the future, it is necessary to check the functionality of all the mechanisms that you touched when replacing the support bearing.

First, let's rock the car and check it for extraneous knocks. Be sure to check the operation of the brakes, since the caliper was removed during replacement. If everything is normal, you can start operating, not forgetting to check the wheel alignment settings, since it is also very easy to knock them down.

The support bearing on VAZ 2108-2115 vehicles is replaced on average once every 40 thousand km. If you do not want to endanger the machine racks, replacement must be done for preventive purposes.

Also check out

- It is necessary to remove the brake hose from the strut clamp.

- Using a screwdriver, loosen the petals of the washer and unscrew the 2 caliper bolts. Remove the caliper by hanging it on a clamp or wire (but not on the brake hose).

- Loosen the strut nut (do not unscrew it). Remove the 3 support nuts.

- Unscrew the CV joint nut. Remove the struts and pull the CV joint out of the splines.

- Use spring ties to tighten the spring. To do this, secure the tie on the coils. Use a wrench to tighten each nut. After compressing the spring, you will be able to remove the support bearing.

- Install a new support bearing for the front strut of the VAZ 2110.

Assembly is performed in reverse order.