Propane-butane is a liquefied petroleum gas. The substance itself is obtained from condensed petroleum associated gases and oil itself. To ensure that the resulting mixture remains in a liquid state, it is stored and transported under special pressure. The process of refueling with propane is not much different from simple refueling with gasoline.

In our country, the use of propane-butane is growing at a rapid pace. In many cases, this is due to the advantage of this substance as a fuel over gasoline. For example, for cars, installing propane-butane gas equipment means using environmentally friendly fuel with a high octane number and high performance properties at a price of 50% of the price of gasoline. The last factor is especially relevant, since the production of propane-butane is cheaper than gasoline.

When working with this material, it is extremely important to know about its quality. This characteristic can be clearly understood by such a parameter as the specific gravity of propane butane.

Basics of the physical meaning of transformation

The physical meaning of the transformation is not a big problem. In this case, the conversion method for any gas is similar to that for liquids and bulk materials. The calculation is made according to the following method:

1 m³ = 1,000 liters

Accordingly, 1 liter contains 0.001 cubic meters. If the meter shows that natural gas was consumed in the amount of 0.3 m³ during the day, then in liters this value will be 0.3 x 1000 = 300.

Features of the conversion of liquefied gases

In modern industry, liquefied gases are used in the following areas:

- at industrial enterprises;

- in the production of heat and electricity;

- as reserve stocks during the cold season when consumed by the population;

- as an alternative fuel for vehicles;

- at home.

At home, liquefied gas cylinders are used if there is no centralized mains connected to the house. In this situation, the temperature of the supplied fuel is not taken into account, but only the volume is determined. In some cases, in some regions, temperature corrections may be applied when calculating volume if the meter is not equipped with an appropriate device for compensating the readings.

The mixture is prepared by liquefying butane with propane in various ratios. It is not economically feasible to use methane. When the ambient temperature rises to room temperature, this mixture expands with such intensity that the manufacture of cylinders requires the use of thick walls or the use of expensive, high-strength materials.

The proportionality of the transition of the volume of a gas mixture during its evaporation from a liquid state depends on the following indicators:

- chemical elements included in the composition;

- temperature characteristics and pressure level;

- molar mass and degree of density.

It is not possible to determine the exact proportional ratio of the mixture in the cylinder, so an approximate value is taken into account. It is assumed that at a room temperature of 20 degrees, considered standard, when one liter of fuel evaporates in a liquefied consistency, about 200 gases will be released.

The calculation is performed using the following formula:

Vcube = Vl/5,

- Vcub – volume indicator in cubic meters;

- Vl – indicated value in liters.

When performing the calculation, you should clarify the obtained value, based on the fact that according to safety rules, gas containers are not filled to 15 percent of the total volume.

If we calculate the number of cubes in a filled propane-butane cylinder holding 50 liters when connecting a gas meter, we get the following value:

- 21 kg of gas is pumped into the cylinder;

- the number of cubic meters of gas fuel is 50/5 = 10;

- after adjustment due to incomplete filling of the cylinder, we get the value 10 x 0.85 = 8.5 cubic meters.

The obtained value depends on the ambient temperature, since this indicator affects the pressure level inside the container.

The above calculation provides only an approximate answer. But the molar mass of the gas and its calorific value are of decisive importance in determining the indicators for the use of liquefied gaseous fuel. In this case, gas is calculated in kilograms.

Cubic meters are taken into account only when supplying gaseous fuel in a centralized manner, when determining the consumed volume using an individual metering device. In this case, the conversion from cubic meters to liters is carried out in the standard way, multiplying by 1000.

Gas cylinder color

Rules PB 03-576-03 state that the outer surface of vessels intended for transporting gases must be painted in the appropriate color. It depends on the type of gas that will be filled.

Red cylinders are provided for butane and other flammable gases. Moreover, for some gases not only a color is provided, but also a corresponding color stripe.

Inscriptions and stripes are applied with durable paints and if they are erased during use, then re-application occurs at filling stations or testing points. That's why gas cylinders always give away their contents.

In addition, the standards establish an identifying inscription that should be applied to the vessel. The word “Butane” must be printed on the butane cylinder, and “Propane” on the propane cylinder. The text color of the inscription on a vessel with hydrocarbon gas is white. Read more about the types of gas cylinders below.

How does a liter compare to a cubic meter?

The liter is a measure of capacity that is not included in the international SI system, but is used very widely. Moreover, it is the liter, and not the “abstract” cubic meter, that is the most common unit of volume measurement in everyday life. For example, it is measured in liters:

- capacity of various vessels intended for household use (buckets, pans, bottles, canisters, containers);

- trunk volume of passenger cars,

- internal volume of refrigerators, freezers, microwaves and ovens;

- capacity of city and tourist backpacks.

The "official" definition of a liter has changed several times. From the beginning of the 20th century until 1964, according to the decision of the General Conference on Weights and Measures, a liter was defined as the volume occupied by a kilogram of water. However, this definition turned out to be not very convenient: the ratio of the volume and mass of a liquid depends on many factors - from atmospheric pressure to air humidity. Therefore, experts abandoned the “reference” to the mass of water. And now a liter means a volume that exactly corresponds to a cubic decimeter - the volume of a cube, each edge of which has a length equal to exactly 10 centimeters, which corresponds to 0.1 meters.

How many liters in a cubic meter: conversion formula

So, a liter is equal to a cubic decimeter (dm^3). In order to calculate the volume of a cube, you need to raise the length of the edge to the third power. A decimeter is equal to 0.1 meters. That is, liter = 0.1 m X 0.1 m X 0.1 m = 0.001 m^3 (one thousandth of a cubic meter).

Thus, one thousand liters “fit” in a cubic meter. And the formula for converting one unit to another will be very simple:

- volume in cubic meters X 1000 = volume in liters.

- volume in liters / 1000 = volume in cubic meters.

By the way, sometimes (extremely rarely, since large volumes of liquids or bulk mixtures are most often measured in “cubes”) to denote a volume equal to a cubic meter, the derivative “kiloliter” can be used, where the prefix kilo- just means a thousand.

How to convert cubic meters to liters and vice versa: examples of calculations

Example 1. The packaging of plastic garbage bags indicates that their volume is 30 liters. What is the capacity of such a package in cubic meters?

Simple solution : 30/1000 = 0.03. The volume of the package is 0.03 (three hundredths) cubic meters.

Step by step, this solution can be described as follows: 30 liters = 30 dm^3 = 30 X 0.1 m^3 = 30 X 0.001 m^3 = 0.03 m^3.

Example 2. According to statistics, on average in Russia one person uses 6 cubic meters of water per month. How many liters of water will an “average” family of three use per day, if we assume that there are 30 days in a month?

Calculation option: A family of 3 people will use 6 X 3 = 18 cubic meters of water per month. Let's convert cubic meters into liters, multiply by 1000 - and we end up with 18,000 liters per month. Divide by the number of days in a month: 18,000 / 30 = 600. As a result, it turns out that the daily water consumption for the family as a whole will be 600 liters.

Example 3 . The size of the bowl of the children's inflatable pool is 2 x 3 meters, the depth of the pool is 1 meter. How long will it take to fill it to the brim if water flows into it at a rate of 30 liters per minute?

Calculation option: Let's calculate the capacity of the pool in cubic meters. 2 m X 3 m X 1 m = 6 m^3. Let's convert to liters: 6 X 1000 = 6,000 liters. It remains to divide the volume in liters by the amount of water flowing per minute: 6,000 / 30 = 200 minutes. Thus, the pool will fill in 200 minutes (3 hours 20 minutes).

The number of liters contained in a cubic meter of gas is not as simple a question as it might seem at first glance, given the peculiarities of using gas fuel. Let's consider ways to convert the volume of gases used as fuel, taking into account their characteristics.

How many cubic meters of gas are in a 50 liter cylinder?

Technical gases in 50 liter cylinders

Technical gases (for more details see here https://www.nvph.ru/texnicheskie-gazyi) are special substances obtained from the atmosphere, during a chemical reaction, as well as from hydrocarbon raw materials. Technical gases are used for industrial and domestic purposes, as well as when performing welding and other construction work.

Types of technical gases

There are many types of technical gases obtained by any of the above methods. Among the main ones we can highlight the following:

- Oxygen.

Nitrogen.

Argon.

Carbon dioxide.

Helium.

Propane.

Acetylene.

The gases oxygen, nitrogen, carbon dioxide and argon are obtained by dividing air into two components - oxygen and nitrogen, for this purpose special devices and apparatus are used - air separators.

Helium is obtained by extracting helium-containing natural gases, propane https://www.nvph.ru/Propan-gaz is produced during the extraction of carbon raw materials. By a chemical method, acetylene is produced by adding water and calcium carbide through a chemical reaction.

In addition to the main types of technical gases, one can also distinguish medical gases, which are actively used in the operation of many devices, as well as in some therapeutic and resuscitation procedures. An example of such a substance is medical oxygen.

In addition, in modern industry, gas mixtures that consist of several gas components are very often used. The use of such a mixture helps to significantly improve the result of work. Welding gas mixtures are in particular demand, which include protective gas mixtures, the main components of which are argon and carbon dioxide, as well as test gas mixtures used in metrology, created on the basis of pure technical gas.

Physical meaning of translation

In a physical sense, everything is quite simple. The translation is carried out in the same way for any gases, liquids or bulk materials as follows:

- 1 cubic meter contains 1000 liters,

- 1 liter equals 0.001 cubic meters

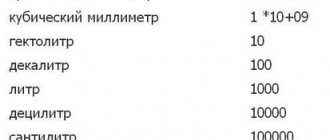

- the table shows the quantity contained in 1 cube (1 cube = 1000 cubic decimeters, etc.).

For example, 15 cubic meters of natural gas used by the meter equals 15,000 liters. When converting these values, the temperature of the fuel, the amount of impurities and other factors do not matter.

Use of liquefied gas

It’s a little more complicated with liquefied gas. It is widely used:

- in modern industrial production;

- in thermal and electric power engineering;

- as a reserve stock during the period of the most intensive consumption by the population;

- as a replacement for traditional gasoline or diesel fuel for road transport;

- for domestic purposes.

In the household, it is advantageous to use liquefied gas in cylinders for the operation of gas-consuming household appliances, provided there is no centralized supply line.

Various mixtures of propane and butane are used for liquefaction. The use of methane is not economically profitable, since at room temperature the pressure in the system increases so much that to ensure safety it is necessary to create containers with large wall thicknesses and use materials of increased strength.

The change in gas volume during the transition from the liquid phase to the gaseous phase is determined by the following factors:

- chemical composition;

- pressure;

- temperature;

- density and specific gravity.

To calculate the number of liters of liquefied gas per cubic meters of fuel that have turned into a gaseous state, it is necessary to use the specified characteristics. But since it is difficult to reliably establish the exact composition of the mixture in the cylinder, it is necessary to be guided by an approximate ratio, according to which at a standard temperature of 20 degrees, 1 liter of liquefied gas will produce 200 - ordinary gas. Therefore the formula applies:

Okub = Ol/5

- Cube – volume in cubic meters;

- Ol – volume in liters.

When making calculations, it is necessary to additionally take into account that, for safety reasons, gas cylinders are filled to no more than 85 percent of the total volume.

Steel gas cylinder design

For transportation and storage of light hydrocarbons such as propane, propane-butane or butane, composite cylinders with a capacity of up to 47 liters can be used.

However, more capacious, 50 liter vessels for liquefied hydrocarbons are made of steel. To store other liquefied or compressed gases, only steel tanks of various capacities are used.

GOST 15860 describes in detail the types, characteristics and permissible sizes of gas cylinders for hydrocarbons. GOST 949-73 specifies the parameters of gas tanks suitable for operation, with internal pressure up to 19.6 MPa.

The wall thickness is dictated by GOST standards regulating the design of cylinders. The blanks for steel 50 liter cylinders are seamless pipes made of steel grades: 45, 34CrMo4, 30ХМА and 30ХГСА

Both GOSTs indicate that for safe transportation and storage of gases, each vessel must have the following structural elements:

- Support shoe.

- A body consisting of a shell, lower and upper bottom and a backing ring.

- Information plate.

- Neck.

- Valve or tap.

Modifications are allowed that include a collar, handle/handles and a cap.

In addition to the basic standards for the manufacture of gas cylinders, there are additional standards that manufacturers must comply with.

Supporting documentation includes safety rules: PB 03-576-03 “Rules for the design and safe use of pressure vessels.” They describe in detail the requirements for valves and other auxiliary mechanisms.

Calculation example

It is necessary to determine how many cubic meters of gas one cylinder with a 50-liter propane-butane mixture contains if you pass its contents through a gas meter:

- the mass of the gas mixture pumped into it is about 21 kilograms;

- volume in m³ is equal to 50/5 = 10;

- after adjusting for the filling of the cylinder, we get 10 × 0.85 = 8.5 m³.

This indicator may vary depending on the ambient temperature, since when it decreases, the pressure inside the container decreases, with a corresponding decrease in the volume of fuel.

But the use of liters of gas in cubic meters is only relevant as an approximate calculation. When purchasing this type of fuel, kilograms of the gas mixture and the pressure inside the container are important, and when using individual metering devices, a standard unit of measurement is used - cubic meters, the conversion procedure of which does not depend on the composition of the gas and is determined by a simple arithmetic calculation in the ratio of 1 to 1000.

How to calculate how many cylinders are needed to heat 1 square meter. living space during the heating season? How to effectively heat a private house using gas cylinders, will it be profitable?

You need to know the density of propane to determine the volume in cubes, and you also need to take into account temperature and pressure.

There are 1000 liters in one cubic meter.

We further assume that liquefied propane has a density of 508 g/l.

Its molecular weight is 44 grams/mol (all these indicators can be found in special reference books and tables).

Divide one number by another.

508: 44 = 11.5 (with a small remainder, 11.5 is the amount of g/mol of gas in one liter of liquefied propane).

That's it, now we find out what volume this amount of propane (liquefied, during evaporation) will occupy; if the conditions are normal (temperature, pressure), then this is 22.4 cubic meters.

Now multiply g/mol (11.5) by volume (22.4 liters).

We get 11.5 x 22.4 = 257.6 liters.

There are 1000 liters in a cube, divide 1000: 257.6 = 3.8 liters (with remainder).

We have one liter in question.

Divide 1 by 3.8 = 0.263 (again with the remainder) cubic meters of gas (in this case, liquefied propane) in one liter.

But most often in household gas cylinders, a mixture of propane and butane is used, where the weight and volume indicators are already different.

- In 1 liter of pure liquefied propane there is 0.263 m3 of free propane gas. But we do not receive pure propane gas at retail points of sale. We are offered a mixture of propane and butane. From 1 liter of such a gas mixture you will get 0.230 m3 of free gases at room temperature. At sub-zero temperatures, even less, since butane may not evaporate at all, liters of propane, constituting from 60 to 80% of the mixture, will turn into gas.

- In order to calculate how many cylinders are needed to heat your premises, you need to know at least two parameters - the volume of the cylinders and the power of your boiler. And of course, indirect adjustments will be made by the area and a practical assessment of the efficiency of the entire heating system. Cylinders are mainly used with a standard volume of 50 liters. The useful displacement of 43 liters is swept away. Multiplying by 0.232 we get 9.89 cubic meters of gas in each cylinder. Next, we look at the manual (instructions for the boiler) and look at its maximum gas volume consumption per hour. Of course, the outside temperature will not be as low as possible throughout the entire heating season, and the boiler will only operate at full capacity. The average value can be taken as 80% of the maximum boiler power, even in fairly cold regions. We calculate the total amount of boiler operation during the heating season.

- Now about the benefits of heating with gas from cylinders. The most important condition for profitability is logistics and gas price. Profitability is always “made” by any even the slightest conditions for reducing the cost of production. For example, wholesale gas delivery will be cheaper than replacing each pair of cylinders weekly. The remoteness of the gas filling station also matters (no one has yet canceled transportation costs). Strict control over the quality of the product (proper pressure and quality of the mixture, preference for bona fide suppliers) will help to “squeeze” more calories out of the product for the same money. Heating cylinders with a propane-butane mixture helps to have up to 20% more fuel mixture. The problem is that propane evaporates faster. And if you heat the cylinder using a warm air mixture supplied from the boiler, for example through corrugated pipes, or heat it in other safe ways, then you can make butane evaporate more intensely, and this is also your money. If you want, even at the maximum possible capacity of gas cylinders you can have a certain percentage and here's why. Several times I drained liquid condensate of unknown consistency from empty cylinders, turning them upside down. And such condensate can amount to almost two liters, and with large volumes of bottled gas consumption this is not a small loss in the weight of the clean gas and, accordingly, lost calories. You just need to approach this wisely. Don't be wasteful. By definition, gas is the cheapest type of fuel, and if you use its energy wisely, it will be profitable.

striker_truda

Notes of a Traveling Locksmith – Malaga Truth

How much gas is in the cylinder

Oxygen, argon, helium, welding mixtures: 40 liter cylinder at 150 atm - 6 cubic mAcetylene: 40 liter cylinder at 19 atm - 4.5 cubic mCarbon dioxide: 40 liter cylinder - 24 kg - 12 cubic mPropane: 50 liter cylinder – 42 liters of liquid gas – 21 kg – 10 cubic meters.

Oxygen pressure in the cylinder depending on temperature

-40С – 105 atm-20С – 120 atm0С – 135 atm+20С – 150 atm (nominal)+40С – 165 atm

Welding wire Sv-08 and its derivatives, weight 1 kilometer along the length

0.6 – 2.222 kg0.8 – 3.950 kg1.0 – 6.173 kg1.2 – 8.888 kg

Calorific value (calorific value) of liquefied and natural gas

Natural gas – 8500 kcal/m3 Liquefied gas – 21800 kcal/m3

Examples of using the above data

Question: How long will gas and wire last when welding semi-automatically with a cassette of 0.8 mm wire weighing 5 kg and a cylinder of carbon dioxide with a volume of 10 liters? Answer: Welding wire SV-08 with a diameter of 0.8 mm weighs 3.950 kg 1 kilometer, which means on the cassette 5 kg approximately 1200 meters of wire. If the average feed speed for such wire is 4 meters per minute, then the cassette will go in 300 minutes. Carbon dioxide in a “large” 40-liter cylinder is 12 cubic meters or 12,000 liters; if you convert it to a “small” 10-liter cylinder, then it will contain 3 cubic meters of carbon dioxide. meters or 3000 liters. If the gas consumption for purging is 10 liters per minute, then a 10-liter cylinder should be enough for 300 minutes or for 1 cassette of 0.8 wire weighing 5 kg, or a “large” cylinder of 40 liters for 4 cassettes of 5 kg each.

Question: I want to install a gas boiler at my dacha and use cylinders for heating, how long will one cylinder last? Answer: A 50-liter “large” propane cylinder contains 21 kg of liquefied gas or 10 cubic meters of gas in gaseous form. We find the boiler data, for example, take the very common AOGV-11.6 boiler with a power of 11.6 kW and designed for heating 110 square meters. meters. The ZhMZ website indicates the consumption in kilograms per hour for liquefied gas - 0.86 kg per hour when operating at full capacity. We divide 21 kg of gas in a cylinder by 0.86 kg/hour = 18 hours of continuous burning of such a boiler on 1 cylinder. In reality, this will happen if it is -30C outside with a standard house and the usual requirements for the air temperature in it, and if outside If it is only -20C, then 1 cylinder will last for 24 hours (day). We can conclude that in order to heat an ordinary house of 110 square meters. meters of bottled gas in the cold months of the year you need about 30 cylinders per month. It must be remembered that due to the different calorific value of liquefied and natural gas, the consumption of liquefied and natural gas at the same power for boilers is different. To switch from one type of gas to another, boilers usually need to change jets/nozzles. When making calculations, be sure to take this into account and take the flow data specifically for a boiler with jets for the correct gas.