Diesel fuel is the most popular petroleum product, which is used as fuel for diesel engines. It is obtained during the distillation of crude oil. The quality composition of diesel fuel is strictly controlled and must meet strict standards.

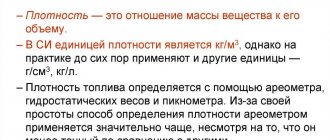

The density of diesel fuel is the main characteristic that determines the quality of diesel fuel. Fuel density parameters show the ability of the fuel to support the operation of mechanisms under any fluctuations in ambient temperature. The density of diesel fuel (specific gravity) is the amount of its mass in kilograms that fits in one cubic meter. That is, the ratio of the weight of the fuel to its volume. The unit of measurement is kg/m3 or g/cm3. The density of diesel fuel is also affected by the presence of various additives and foreign heavy fractions in it. The presence of the latter negatively affects the quality of the fuel.

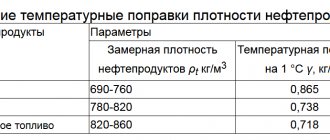

The density indicator is not a constant value, since it directly depends on temperature indicators. The higher the temperature, the lower the density of diesel fuel. This indicator is constantly monitored using an aerometer. The optimal temperature for diesel fuel is 18-20°C. When calculating density, a correction factor is used, which is 0.0007 g/cm3 per 1°C

Relationship between fuel density and diesel efficiency

The fuel density and efficiency of a diesel engine directly depend on the air temperature.

Since the combustion process of diesel fuel, which has a high specific gravity, releases a huge amount of energy, significantly exceeding the amount of energy obtained from the combustion of less dense fuel, the use of summer diesel fuel is more economical.

Using this type of fuel in winter will not increase its profitability. This is due to the fact that summer fuel, in addition to kerosene-gas oil hydrocarbons, in which the entire fuel energy reserve is concentrated, contains dissolved paraffin elements. These components have the ability to harden even with a slight decrease in the temperature of diesel fuel. At the same time, diesel fuel becomes viscous, and the throughput of the filters decreases.

To increase the efficiency of internal combustion engines, various additives are added to diesel fuel used in the cold season, which inhibit the hardening of paraffins and increase the density of the fuel. Although such additives lower the thickening temperature of diesel fuel, they affect its density to a small extent. It would seem that if an appropriate additive is added to summer fuel, it can be used as winter fuel, but this is not true. Since the component introduced into the diesel engine only lowers the thickening temperature of the paraffin components of the fuel.

At the same time, the fuel itself will not lose its density, and with a decrease in temperature it will continue to thicken, which will lead to disruptions in engine operation. Another misconception is that when adding an additive to frozen diesel fuel, it is possible to reduce its density. Accordingly, fuel density is an important indicator in the cold season. In hot weather, such characteristics as the percentage of sulfur and cetane number are more relevant.

Naturally, due to changes in the density of diesel fuel, the economic efficiency of fuel in winter is significantly reduced. This is also facilitated by factors such as ice and snow congestion on the roads, which complicate the driving process and increase fuel consumption.

What types of “winter” fuel are there?

If we order fuel in bulk, in bulk, and then fill up at a gas station, we know that the fuel in winter should be winter grade. Few people know, but winter fuel varies. Winter diesel fuel can be conditionally classified according to its filterability limit temperature and cloud point. What is the limiting temperature of filterability (PTF)? PTF is the temperature at which diesel can flow through a filter in any fuel system. Roughly speaking, this is the maximum temperature limit at which a diesel engine can start and operate. For example, for the brand of diesel fuel DT-Z-K5, the PTF is -30 C. This means that at minus 30 your engine will still work somehow, but at -31 C it will no longer work.

Cloud point is the maximum limiting temperature at which diesel fuel does not turn cloudy (white). Cloudiness occurs due to the appearance (crystallization) of paraffin crystals. The already mentioned brand DT DT-Z-K 5 has a cloud point of – 14 C i.e. 16 C higher than PTF. What does this mean? The fact is that if your fuel is cloudy, you shouldn’t be afraid, the engine will run on it. Of course, the filter may fail earlier, but this should not significantly affect the operation of the engine.

The main popular types of “winter” fuel are:

Grade F (inter-seasonal) diesel fuel. PTF = – 23 C. Turbidity temperature = – 6 C.

Variety DT-Z-K 5 (true winter). PTF = -30 C. Turbidity temperature = -14 C

DT grade –A-K5 (Arctic fuel). PTF = -53 C. Turbidity temperature = -50 C

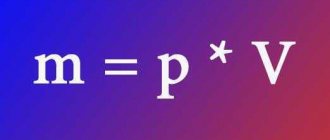

Formulas for calculating the density, weight and volume of diesel fuel

The density of diesel fuel, its weight and volume is calculated using certain formulas in accordance with GOSTs.

Based on the fact that the density indicator directly depends on temperature, for the accuracy of calculations it is worth taking into account the correction factor and the ambient temperature indicator.

According to the formula, the density of diesel fuel is calculated as the ratio of the mass of the fuel to its volume.

- V = m/p, where

- V—volume;

- m—mass;

- p – density

when calculating the density of diesel fuel is taken:

- for summer fuel 860kg/m3;

- for winter fuel 840 kg/m3.

Accordingly, 1 kg of summer fuel is 1.19 liters, and 1 kg of winter fuel is 1.16 liters.

1 liter contains 0.860 and 0.840 kg of diesel fuel

The density of the petroleum product must strictly comply with regulations. The density recorded at 20°C is taken as a standard. To simplify calculations, special tables have been compiled in which, knowing the weight and volume of the product, as well as the temperature, you can easily find the required indicator.

The weight of diesel fuel is calculated by simply multiplying the density of the petroleum product by its volume. To calculate the mass of diesel fuel in tons, use the formula:

M(mass)=V (volume in liters)*p(density kg/m3)

To calculate the mass of summer fuel having a density of 0.860 kg/m3 with a volume of 1000 liters, we have the following value:

M=1000*0.860

This formula also applies to other types of fuel with different density parameters. Quantitative indicators so far are easily converted from tons to kilograms and vice versa. The calculation of volume, accordingly, is carried out using the inverse formula - the mass of the product is divided by its density. This calculation is very important when drawing up accounting documents for fuel, in which it becomes necessary to convert the weight of fuel into volume for the correct selection of containers.

Calculation of diesel fuel from tons to liters can be done using the formula:

V = (M / 0.850) x 1000, l.

where M is fuel in tons

The average value of 850 kg/m3 is most often used as an indicator of the density of diesel fuel.

Physical characteristics of diesel

Diesel fuel refers to products obtained after distillation of oil at special enterprises (refineries). The quality and composition of the finished liquid must meet strict standards. The density value is a parameter that is involved in determining the productive performance of the fuel under various conditions.

It is important to know that density demonstrates the number of kilograms of liquid in one cubic meter.

Experts know that this parameter is not constant and depends on external factors, the main one of which is the ambient temperature. A rise in the thermometer stimulates a decrease in density, and the reverse process increases the specific gravity of diesel fuel.

To obtain a specific value, a measuring device is used - a hydrometer. During the measurement process, the unit must be lowered into a container with diesel fuel. To carry out measurements in different liquids, different types of hydrometers are used. Measurements in petroleum products are carried out using models AN, ANT-1 or ANT-2 .

The hydrometer is made in the form of a glass tube, inside of which there is a graduated vertical scale. A greater degree of immersion demonstrates a lower density and vice versa.

We recommend: Replacing the alternator belt tensioner pulley - you need to know this

The increased specific gravity of the liquid is a consequence of the fact that it contains heavy hydrocarbon fractions. Because of this, the high-quality operation of the internal combustion engine may decrease, because the evaporation of the liquid deteriorates and its good atomization by the nozzles is not ensured. An additional negative from the presence of a large number of heavy particles is that soot and various deposits form on the working surfaces.

How to check the density yourself

To ensure that the quality of the purchased fuel is not in doubt, vehicle owners should purchase it only from trusted suppliers. If you have doubts about the quality of the product, you can check the fuel density yourself.

The need for such a check arises only in the winter season. It should be carried out at a temperature of -8 – 10°C, and if the fuel is positioned as arctic, then lower.

To carry out the test, place a small amount of diesel fuel on a metal surface, and then monitor the cloudiness and spread of the product. If the fluidity of the fuel is normal, we can talk about its quality; if the liquid becomes cloudy and begins to solidify, then it is better to refuse to use it. Diesel fuel for use in the cold season should not freeze to -45°C.

Another way to check is to place a container with fuel where the air temperature is 20 degrees. When the ambient and diesel temperatures are equal, the density is measured with an aerometer and its readings are compared with GOST data.

The fastest inspection option is to visually evaluate the refueling nozzle. If the fuel at its end remains liquid, then this indicates its quality.

You can more accurately check the density of diesel fuel as follows. Diesel fuel is poured into a small container and then placed in conditions where the air temperature is around + 17 to +20 degrees for such a time that the fuel warms up to a similar temperature. Next, the density of the diesel is measured using a hydrometer. The obtained data must be compared with the standards that, according to GOST, purchased diesel fuel must meet.

What determines the density of diesel fuel?

The density of diesel fuel is not constant. It changes under the influence of temperature parameters. This indicator is based on the ratio of fuel mass to its volume. When making calculations, the brand of diesel fuel and the correction factor are taken into account. There are several main types of diesel fuel - summer and winter types. Winter fuel has a lower density, which avoids thickening at low temperatures.

The correct selection of fuel additives can to some extent affect the density of the liquid.

Density of diesel fuel and temperature are directly related to each other.

To obtain standard indicators, the density of the fuel is produced at a temperature of 20°C and normal atmospheric pressure. And to calculate density at different temperatures, correction factors or special density tables are used.

There is a certain standard according to which the fuel density is:

- in winter – 860 kg/m3;

- in summer - 840 kg/m3;

- in Arctic conditions – 830 kg/m3.

GOST standards controlling gasoline grades

The main standard that describes all parameters of gasoline is GOST 32513-2013.

This GOST establishes:

- Environmental product classes K2, K3, K4, K5 depending on the amount of heavy metals and sulfur impurities.

- Methods and determination of octane number and value for the brand:

- Lead concentration according to GOST EN237, GOST 32350, GOST 28828. The presence of lead in gasoline leads to an increase in deposits on the valves. Lead released in exhaust gases has a very bad effect on the environment. Environmentalists from all countries monitor the presence and content of lead in gasoline.

- Concentration of resins washed with solvent according to GOST 1567 or GOST 32404.

- Mass fraction of sulfur for environmental classes according to GOST 32139, GOST ISO 20846, GOST R 51947-2002, GOST 20884.

- Volume fraction of benzene according to GOST 32507.

- Volume fraction of hydrocarbons according to GOST 31872.

- Mass fraction of oxygen according to GOST EN 13132 GOST 32338.

- Tests on a copper plate according to GOST 6321, GOST 32329. Used to determine sulfur in fuel. A polished copper plate is immersed in a flask with fuel. The flask itself is kept in a water bath at a certain temperature for 12 minutes. The amount of sulfur in the fuel is determined by the color change.

- Concentrations of manganese and iron according to GOST R 51925-2002, GOST 32514. Additives based on iron and manganese are effective, but prohibited due to their negative impact on the environment, the formation of soot and a decrease in engine life.

- The volume fraction of monomethylaniline according to GOST 32515. This is also an anti-knock additive that slightly improves the quality of the fuel, but is a highly toxic substance that affects humans not only through the lungs, but also through the skin.

– according to the research method – GOST 32339, GOST 8226; – according to the motor method – GOST 32340, GOST 511.

The essence of the motor method is to compare the mixture under study with standards, the octane number of which is known at elevated temperatures and maximum loads. When detonation of a sample and a standard occurs under the same conditions, it means that their OC is the same.

The research method is similar to the motor method, but measurements are taken in engine-friendly conditions.

Resinous compounds in the fuel during engine operation are deposited on the walls of the intake tract and the combustion chamber, forming carbon deposits, worsening the combustion process and increasing fuel consumption. This subsequently leads to engine failure. Resins are divided into actual ones - those that are actually present in gasoline. Their presence is determined by the evaporation of a certain amount of gasoline heated to 150 ° C by air. The weight of the resins remaining after evaporation is estimated in mg per 100 ml.

Other resin-forming substances that are in unstable compounds and can be converted into resins under the influence of unfavorable conditions (air oxygen, high temperature) are called potential resins. Their quantity cannot be determined immediately, but if gasoline is stored improperly, they form and negatively affect the quality of the fuel.

The presence of sulfur in fuel leads to the formation of sulfur oxides during combustion. Together with water, these substances form sulfuric acid, which is highly corrosive and, like an abrasive, wears out engine parts. The amount of sulfur is standardized by environmental class.

All brands of gasoline:

– class 2 contain no more than 500 mg/liter; – class 3 contain no more than 150 mg/liter; – class 4 contain no more than 50 mg/liter; – class 5 contain no more than 10 mg/liter.

The spread between classes 2 and 5 in sulfur content is 50 times. Determined only in the laboratory. Doesn't depend on octane number.

In documents for gasoline, you should pay attention to the environmental class

Benzene is an aromatic hydrocarbon and increases the octane number of gasoline, but at the same time it settles on car parts in the form of carbon deposits. Another negative effect of benzene is its toxicity and impact on the environment.

Aromatic (but not benzene), olefinic, naphthenic, and paraffinic hydrocarbons at high concentrations in fuel increase the emission of unburned hydrocarbons.

The presence of oxygen-containing substances of about 2.7% has a good effect on the quality of gasoline. CO and hydrocarbon emissions are reduced. But using more than 5% ethanol does not improve quality in any way. But the mixture becomes leaner and corrosion of non-ferrous metals increases.

Density of AI-80 gasoline

Density at 15 °C in kg/m3 is 700-750. Leaded gasoline. Possible classes of environmental frequency 2, 3, 4.

Density of AI-92 gasoline

Density at 15 °C in kg/m3 is 725-780. Leaded gasoline. Possible classes of environmental frequency are 2, 3, 4, 5.

Density of AI-95 gasoline

Density at 15 °C in kg/m3 is 725-780. Leaded gasoline. Possible classes of environmental frequency are 2, 3, 4, 5.

Density of AI-98 gasoline

Density at 15 °C in kg/m3 is 725-780. Leaded gasoline. Possible classes of environmental frequency are 2, 3, 4, 5.

Standards for calculating the density of diesel fuel

For the unity of calculating the density of diesel fuel, unified regulatory documentation has been developed, which spells out the main components for correct calculations:

- the reference temperature is 20°C;

- a change in temperature for each degree requires an adjustment of 0.0007 g/cm3;

- when the diesel fuel temperature increases from the reference values, a correction factor should be subtracted by multiplying it by the difference in degrees Celsius;

- when the temperature decreases, a coefficient is added to the reference indicators, which is multiplied by the temperature difference in degrees Celsius.

Density of diesel fuel in summer and winter

The fuel used in summer and winter differs in its basic characteristics.

For winter, fuel that has the following indicators is suitable:

- low density;

- low viscosity;

- does not freeze at a temperature of -45O.

Low viscosity density allows the fuel not to turn into a gel and circulate freely inside the internal combustion engine. In cold weather, the use of high-density fuel is strictly prohibited in order to avoid problems with the filter system.

Summer fuel is characterized by:

- high density (not less than 0.86 kg/l);

- difficult to ignite (withstands temperature increases up to +45°C).

When winter fuel is used in the summer, engine power decreases and smoke levels increase.

The best time for summer fuel is April - September, if the temperature does not drop below -4°C. Otherwise, the diesel fuel will become cloudy, and when the temperature drops another few degrees, it can lead to problems with engine operation.

Examples of diesel fuel density at different temperatures

When calculating fuel density, the following data must be taken into account:

- fuel density indicators at reference values specified in the petroleum product passport;

- actual liquid temperature measured in the transport container;

- apply a correction factor of 0.0007 when calculating the temperature difference;

- make adjustments to the calculation. At elevated temperatures, subtract the resulting value from the density indicated in the passport, and at low temperatures, add it.

Calculation of specific gravity for 20 ◦c

The theoretical calculation of specific gravity consists of the following steps:

- The purpose of the calculation is to determine the specific gravity at a reference temperature of 20°C. At the initial stage, it is necessary to measure the density with a hydrometer and the temperature of the liquid with a thermometer in the container in which the fuel is stored.

- Determine the temperature difference between the measured parameter and 20°C.

- Calculate weight adjustment taking into account delta and correction factor.

- Add or subtract (depending on the deviation from 20°C) the correction value from the parameter read from the hydrometer. The resulting weight allows you to roughly determine the type of fuel (winter, summer or arctic). The type of fuel determines the ability of diesel fuel to be used in different temperature zones without the risk of excessive increase in viscosity or crystallization in fuel pipes.

Diesel fuel density, consumption, operation

The density of diesel fuel is the main characteristic for determining the climatic use of diesel fuel and its impact on the operation of the internal combustion engine. If the fuel is chosen incorrectly or the quality of the liquid is not high, this will significantly reduce the efficiency of the engine, especially at the time of start-up. Which, in turn, will lead to an increase in fuel consumption to increase engine efficiency. Excessive load on the fuel system can cause increased fuel consumption and even cause engine failure.

What does density say about the quality of diesel fuel?

The density of diesel fuel is determined by the ratio of the fractions that make up the fuel. If the composition of the fuel is dominated by heavy hydrocarbons, this will negatively affect the operation of the engine and reduce the injection of liquid by the injectors into the combustion chamber. Heavy fractions have a high boiling point, which reduces the mixing of fuel microparticles with air. In order for diesel fuel vapors to ignite, a higher temperature will be required, and this will cause problems in the operation of the engine and lead to increased fuel consumption.

Where did diesel fuel come from?

In the photo - diesel fuel, which appeared later than gasoline

So Rudolf Diesel has almost nothing to do with diesel fuel. He owns a patent for an internal combustion engine that runs on kerosene or fuel oil, and the fuel ignites not from a spark, as in expensive gasoline, but under high pressure. The Diesel engine was a three-meter structure that produced 17 horsepower and rotated at a speed of about 170 rpm. The efficiency of the Diesel unit was 26% and this was almost a revolution in 1893, because the steam engine was half as weak. The diesel fuel we are familiar with today appeared at the suggestion of Emmanuel Nobel. He bought a license from Rudolf Diesel and made the kerosene engine run on diesel fuel. And Diesel himself probably knew something extra, because one fine September evening in 1913 he left the house and never returned. This is how the Diesel unit would have worked, like a compressor or current generator, if Robert Bosch had not become interested in its design, he brought the diesel engine to life, equipped it with a high-pressure fuel pump, and was able to fit it under the hood of a Mercedes 5K3 truck. But that’s another story, we’re already distracted from diesel fuel.

Why does diesel fuel consumption increase in winter?

At low temperatures, fuel consumption increases significantly due to the cost of warming up the unit before starting work and increased friction in a cold engine. After the start of movement, diesel fuel consumption does not exceed summer levels, and, possibly, decreases because... torque at low speeds reduces wheel slip on snow surfaces. Thick oil in gearboxes exerts a noticeable load. At low temperatures, the specific gravity of air becomes higher, which contributes to a change in the composition of the working mixture. Cold air also increases the drag coefficient, which increases diesel fuel consumption by several percent every 100 km.

Why does diesel fuel freeze?

Some fractions that make up diesel fuel thicken at low temperatures. The viscosity index directly depends on the ambient temperature and is determined by the density of the liquid, which depends on the number of fractions with a high boiling point. If there is water in the diesel fuel, it will sink to the bottom of the tank. There it will freeze at subzero temperatures. Ice will block the entrance to the intake tube and cut off the fuel supply to the engine. To resume operation of the unit, you will need to warm up the fuel tank and fuel supply system.

Additives (additives)

Improving quality by adding additives, which has been a common practice for gasoline for many years, has recently become popular for diesel fuel (Super and Premiom diesel fuels). The main additives used are those that have multiple effects:

- additives to improve ignition increase the cetane number and are responsible, in particular, for a “softer” combustion;

- detergents are used to prevent coking of injectors;

- corrosion inhibitors (retarders) are necessary to prevent corrosion of metal parts (if water gets into the fuel system);

- Antifoaming additives serve to facilitate filling the fuel tank.

The total concentration of additives usually does not exceed 0.1%!, so that the physical characteristics of the fuel such as density, viscosity and boiling curve do not change.