Is it necessary to know the thickness of the metal body on a car? After all, the body is one of the most important parts of the car. And all the parts inside can be replaced one way or another.

And any driver will have to tinker with problematic body metal. Therefore, those car enthusiasts who prefer to buy used cars on automobile markets first inspect the body part.

What can the body tell about the car?

Body metal is quite an expensive part of any car. It is very important to monitor his condition carefully.

After all, this place of the car is exposed to undesirable weather conditions: strong sun, humidity and temperature fluctuations.

Often, the entire history of a given car can be traced by the condition of the body.

A professional auto mechanic will always be able to distinguish serious body damage from minor, cosmetic repairs. Based on the condition of the body, you can determine whether the car was involved in an accident and how serious the damage was.

And also how these damages were hidden. Body repairs have their own nuances that need to be taken into account when selecting a car.

Gaps, welding and shagreen: assessing the quality of Lada Vesta painting with an expert painter

When it comes to choosing between a foreign car and a domestic car, the high corrosion resistance of imported cars is often cited as an example. They remember the rapidly rotting Zhiguli of the nineties and the “eternal” Passats .

Of course, now the legend is infinitely far from reality. Owners of golfs that are not yet old are faced with serious corrosion after only five or six years, but our cars have learned to look great even after three years of operation in Moscow or St. Petersburg. But the release of the new Lada Vesta once again makes us wonder how durable the body of the new product will be, will it be better or at least at the same level as its competitors?

They didn’t rely on their own eye – auto journalists, of course, have a little more experience than the average motorist. However, the painter always knows better. Therefore, to inspect Vesta, we used the help of bodywork specialist Evgeniy Mikhailovich Slepak.

And the first thing the specialist notes is the very high quality of painting and the absence of coating defects. Vesta is now available in 9 colors, and the line will be expanded. The quality, which is more typical for foreign cars than for domestic cars, is undeniable. The neat, even shagreen pattern (relief of the paint coating) on all metal parts to be painted is slightly different from the texture of plastic parts, but visually the difference is indistinguishable. The reason is different technologies for painting plastic and metal parts; this is normal on most cars.

Inspection of doorways, arches and internal compartments also does not reveal any traces of negligent approach. All areas that are difficult from the point of view of the paint shop are painted carefully and without visible defects, and have no signs of damage during assembly - characteristic scratches and abrasions. Well, the level of degradation - damage during assembly - at AVTOVAZ and LADA Izhevsk has indeed decreased significantly over the past couple of years. Only the absence of a layer of varnish on the inner surface of the hood attracts attention.

A rough measurement of the thickness of the paintwork shows high uniformity of the coating on all vertical surfaces with a paint thickness of about 120–135 microns. Our car has already passed some small impact tests; there is a chip on one of the doors from a stone, and judging by it, the elasticity of the coating is generally low, even taking into account the newness of the car. But the adhesion of the soil deserves respect - the metal was not exposed at the place where the paint chipped, and the soil itself at the site of damage survived.

In addition to the actual quality of paint, the quality of application of shockproof coatings on the bottom, sills and arches is also important for the long life of the car. The outer surface of the threshold is clearly different in texture from the rest of the body. This indicates the presence of a paintable anti-gravel coating under the paint layer. But there are no films on the rear arch and doors. This cannot be said to be a drawback - the need for coverage is strictly individual, but most likely these are traces of savings. During operation it will be clear whether there is a real need for such “reinforcement”.

The inner surfaces of the arches are protected with a thick layer of mastic; there are no factory lockers here. But the thickness of the coating and its uniformity allow us to hope for a long and successful service. Seam sealant was equally carefully applied to all visible joints and seams. By the way, all experienced car owners are probably aware of how much trouble the internal rolling of the rear wing and arches causes - most often, corrosion on the car begins to develop from there.

The condition of the paintwork is almost perfect

A used car may not have excellent surface condition. There are always small scratches and chips: on the front part, grille, hood.

There are scratches from shoes on the sills. If you do not notice such flaws. And the coating looks like a new car, most likely, it was repainted.

The size of body gaps

There can be no factory-made uneven or asymmetrical gaps in the areas where the panels connect to each other. If you see anything like this. Most likely there was physical damage to the body, which was subsequently painted over. For the same reason, the doors in the car should not stick and have a clear opening order.

Fasteners, bolts and handles

During factory assembly, not all fasteners are painted along with the body. Some of them are installed on the car after finishing the painting work. It is worth carefully inspecting the car's handles; they are often ignored during repairs. Therefore, they can reveal what defects a particular car had.

Features of the paint layer at the factory - thickness and composition

Not all potential car buyers on the free market understand why there is such a stir around paintwork. Many brands of modern cars even indicate the exact thickness of the paintwork in the car documents. When choosing a used car with the right approach, it is necessary to examine the paintwork layer to check for its thickening in certain places. The thing is that the values from the table are of great importance for some reasons:

- Only high-quality components are used in the factory layer of paints and varnishes;

- the guarantee of the absence of putty gives hope for a long service life of metal body parts;

- with any car body repair, the quality of the paint will no longer be the same as it was at the factory;

- even budget brands try to do the painting as efficiently as possible to protect all parts;

- if the thickness of the paint layer is too small or too high, problems in car operation are guaranteed.

This is why you need a thickness table, which will help you find out the original parameters for each model. But the thickness of paint on cars must be assessed qualitatively. For this purpose, special equipment called a paint thickness gauge is used. With such a simple feature, you can examine the entire car and draw conclusions on the condition of the paintwork. To conduct such research, you do not need to be an expert in the field of auto enamel and painting processes.

How to determine damage using a thickness gauge?

It will not be difficult to conduct research on any brand of car using such a tool. You will need the original paint thickness on the car, which can be found in the table. Write down or remember this value. Then use the device to determine the paintwork indicators on all parts of the car. This procedure is carried out in a few minutes and does not require any special skills. But it is important to do everything accurately and without doubt.

The only caveat worth remembering here is the quality of the device. Sometimes the data from the table will not agree completely because the thickness gauge can be a little deceiving. If the deviation is within 10-15%, you can ignore such moments. But exceeding the permissible values by several times is a guarantee of poor-quality body repairs to the car. Most often, paintwork in such places can be visually distinguished from factory coatings.

Determining the size of paintwork on a passenger vehicle

Different types of cars have more or less the same level of paintwork. Standards from the factory suggest a level of 100-140 microns.

However, during body modifications and further painting of the car, in some places there is a deviation of the cover from this norm.

Due to the increased presence of putty. In these places, the coating thickness can increase to 200 microns.

For body parts where it is difficult to determine this indicator with the eye, a special tool is used to identify this thickness - a thickness gauge.

If on one car you observe a spread of coating from 110 to 310 microns. Most likely, such a car was undergoing repairs and was repainted.

This device is present in all major auto repair shops. Therefore, if you need a detailed assessment of your car, you always have a chance to contact specialists in this profile.

The most expensive high-level thickness gauges can determine the thickness of paint on individual parts: aluminum or plastic.

Don’t forget that American cars usually have a thicker factory coating layer than Russian or Japanese ones.

The device determines the length of the interval from the sensor to the base of the car body. The closer the thickness gauge magnet is to the metal body, the greater the angle the needle moves.

To accurately determine the thickness of the paint layer, there is a special table of factory indicators. Which must be followed for an accurate conclusion.

Factory paint performance

Factory paint provides protection to the metal base of the body, as well as other layers that are applied to it - galvanization, primer. Only strict adherence to technology ensures the required durability of the body service. How much will the total thickness of the coating made at the factory be? For most cars, the indicator is in the range of 70-180 microns, while the spread across the car can be 20-25 microns, for one part - 10-15 microns. For the following elements, a layer thickness of 50-90 microns is allowed:

- door pillars;

- thresholds;

- trunk;

- engine compartment space.

It is impossible to paint a car without this error, even at the factory. The paint and varnish product may be unevenly distributed in different areas: for example, in horizontal areas the layer will inevitably be thicker than in vertical ones. Also, during painting, shagreen appears - surface roughness. Painting indicators also differ for parts made of non-ferrous and ferrous metals. Thus, even on a new car, the readings may vary when measured by the device.

Body metal thickness by car brand

For accurate measurements, you need to attach the device to the car body. Smoothly move it along the surface, starting from the front edge. To ensure accurate results, measurements must be repeated 3-5 times.

Then calculate the average, taking into account all measurements. And then be sure to compare your measurement options with the indicators in the factory table.

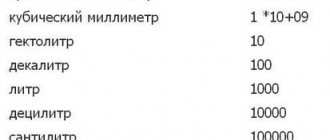

Metal thickness on cars table

| Automobile | Model | Paintwork thickness (µm) |

| Audi | A1, A3, A4, A5, A7, A8 Q3, Q5, Q7 | 80-100 110-165 |

| BMW | 1-series, 2-series, 3-series, 5-series, 7 series X1, X3 X5, X6 | 100-165 90-110 120-165 |

| BYD | F3 | 75-100 |

| Cadillac | Escalade,CTS | 120-150 |

| Chery | Amulet, Tiggo | 100-120 |

| Citroen | C5, C-Elysse C4, C3, Picasso, Berlingo DS4 | 110-140 75-125 205-230 |

| Daewoo | Nexia, Matiz | 90-120 |

| Fiat | Albea, Punto | 100-140 |

| Ford | Focus Explorer, Kuga Mondeo | 150-165 135-145 115-130 |

| Hyindai | Accent, IX35, I30, I40, SantaFe, Elantra Tucson, Solaris, Sonata | 70-110 90-130 |

| Honda | Accord Civic Fit, CR-V | 130-150 100-135 80-100 |

| KIA | Sportage, Sorento, Cerato, Cee'd, Picanto Soul, Rio, Venga, Optima Quoris | 100-140 120-140 150-180 |

| Lexus | RX, ES, LX CT, GX, LS IS | 140-150 120-150 110-140 |

| Mazda | CX-7, CX-5 3.6 | 85-120 110-130 |

| Mercedes-Benz | C, E, S GL, ML | 165-180 90-140 |

| Mitsubishi | Lancer, Pajero L200, Outlander XL, ASX | 90-125 55-75 |

| Nissan | X-trail, Patrol, Juke, Qashqai, Murano, Tiida, Pathfinder lmera, Teana | 80-120 130-150 |

| Opel | Astra, Corsa, Mocca, Zafira, Insignia, Vectra | 110-160 |

| Peugeot | 208, 308, 508, 3008 4008 | 100-120 60-80 |

| Renault | Logan, Koleos Fluence, Duster, Megane, Sandero | 180-230 100-140 |

| Skoda | Octavia, Yeti, Superb, Fabia, Roomster | 100-140 |

| Subaru | Forester, Impreza, Outback, Lagacy, Tribeca | 100-140 |

| Suzuki | Grand Vitara SX4, Swift, Splash | 70-100 90-120 |

| Toyota | LC200, Camry, Highlander, Auris, Verso Avensis, Corolla, Prado, Prius, RAV4 | 110-130 80-110 |

| Volkswagen | Polo, Golf Tiguan, Passat, Caddy, Multivan, Amarok Touareg, Jetta | 80-110 110-140 140-180 |

| Lada, VAZ | Kalina, Priora Granta, Niva Largus | 60-100 110-140 180-230 |

Table and explanations for checking the optimal paint thickness

Only original data from the manufacturer may be used. But in reality, you don’t even have to look at the table, sticking to the data for all cars. This range is up to 165 microns, but not thinner than 75, as we discussed above. It is in this spectrum that painting mechanisms operate in factories. To keep track of such a parameter as the thickness of paintwork on cars, a table is not always needed. You can use a simple method for determining the quality of paintwork:

- take a thickness gauge and apply it to three points on large body parts, write down the data;

- then use the device to check the most frequently repaired areas on the car body;

- record the thickness of the paint on the fenders, sills, bumper, front of the hood and rear of the trunk lid;

- then the easiest way is to identify repaired places and ask the car owner a question about these locations;

- If a more thorough check is required, you can send the car to a service station and carry out expert diagnostics.

You can check the car yourself in two minutes if you know the original paintwork indicators or stick to the middle spectrum. You should only be careful in cases where the car has been completely repainted. In such a situation, you may not understand the difference between different parts and take the obtained indicators as original. But when painting with a conventional spray gun, it will never be possible to achieve a uniform paint thickness within the factory standard.

Tips for using a thickness gauge

There are simple recommendations for effective use of the thickness gauge. Which experts of this profile give:

- You should purchase a device depending on your situation and the surfaces you intend to inspect. If you need to evaluate the quality of coating on steel. Then an expensive thickness gauge for ceramics is not so relevant for you. You can also rent equipment to reduce costs. Or use the metering service at a service station.

- After purchasing a device, you need to take time to calibrate it. There are special samples made of plastic and steel, on which a layer of paint is applied. Check your measurement data with the readings on the samples and, if necessary, adjust the device.

- For each individual measurement plane, it is better to make separate settings for the thickness gauge. And your measurements will be more accurate.

- Slight differences in values are acceptable. Even in the field of one body component, the values are variable: for example, the roof can show 80 microns, and the doors 140 microns.

- Each body element must be measured in at least five places: in the corners and in the middle. This way your measurements will be as effective as possible.

Measuring the thickness of paintwork - why is it done?

The thickness of the paint layer on car parts is an indicator that reflects the distance from the surface of the body to the metal base itself. Paintwork can be measured in millimeters (mm), but on most modern cars it is so thin that it is measured in microns, also known as micrometers (µm). One micron is equal to 0.001 mm. Even such a small layer is enough to protect the car from water, dirt and oxygen.

This value is set at the factory depending on the vehicle model, but in accordance with accepted standards. There is no general standard and thickness can vary widely. It will depend not only on the wishes of the manufacturer, but also on the following factors:

- mode, drying temperature;

- staining method;

- number of paint layers;

- brand of paint.

Why do you need to measure the thickness of paint on a car? The coating from the factory is very different from what most auto repair shops do. Perfect coloring is an expensive option, so craftsmen save on paint. A weld may be hidden under its layer if the car is a “constructor”. Putty and paint are often used to cover rot, holes, and pits in old equipment. All this is revealed by special measurements. The following data can also be checked using the meter:

- degree of wear of the machine;

- the fact that body repairs have been carried out in the past;

- presence of polished scratches;

- places where paint thickens during rough repairs;

- too frequent polishing.

Since it is almost impossible to achieve factory parameters under normal conditions, all deviations are easy to identify, which will allow you to refuse the purchase or demand a serious discount.

How metal is made for cars

One of the large-scale manufacturers of metal for cars is the plant in Cherepovets. The plant has 4 blast furnaces. Including the largest oven in the world (over 100 meters high).

The cast iron is melted and taken to the steelmaking department, where it is put into molds and combined with additives and scrap metal. The composition of this metal mixture is clearly defined for each type of car. The resulting steel castings are cooled and rolled into rolls.

Next, the rolls are cut with gas cutters and thinned under special rolling to the size of automobile sheets. Then the sheets are rolled into rolls and sent to the galvanizing shop. Galvanization occurs at high temperatures.

This allows the zinc atoms to penetrate deeply into the leaf structure. The metal is then cut into sheets, secured into rolls and packaged for shipment to the customer.

Steel is the main material from which body parts are made. This increases body rigidity. And the weight of the car itself decreases. Also, body elements can be made of aluminum.

Which began to be used in recent years. With the same strength as steel, aluminum elements have less weight. Aluminum also makes it possible to produce parts of any shape.

Plastic parts

The thickness gauge does not work on plastic parts. Modern cars have bumpers, door handles, exterior mirror housings, and sometimes other parts made of plastic. For example, the Peugeot 408 has plastic front fenders.

It is better to study the features of a specific car model before inspection. To do this, just watch 5-10 videos with an inspection of the car you need on YouTube.

A thickness gauge on a dirty car may fail or break.

It is wrong to use a thickness gauge on a dirty car. Firstly, the readings may be incorrect. Secondly, using a thickness gauge on a dirty body spoils both the device and the car’s paint.

Wash your car before checking. You need to inspect a clean car. This is useful not only for the thickness gauge, but also for finding defects. It looks better when clean.

Lada Granta

Grant body

Grant's liftback is a 3-volume body, implying a successful combination of the luggage compartment lid and the rear window. It is noteworthy that during the Soviet era, liftbacks as such did not exist. There was such a model – IZH-2125 Combi, but it only embodied some of Liftback’s ideas. In fact, such a word was not legalized in the CAS, although such concepts as fastback, phaeton and even breg were found there.

Thus, the Lada Granta Liftback restores historical justice, because in addition to the new name, the car was produced precisely at IAZ, now referred to as OAS.

Liftback is not just a word. So, this type of body looks enviably good in terms of LCD performance. This figure has become twice as high as that of hatchbacks, although less than that of sedans due to design features.

Also interesting: Protective vinyl film for Niva

In particular, the difference in design features between a liftback and a sedan lies primarily in the “rear cross member”. The liftback does not have this part at all; it is not provided for, but in sedans it goes behind the back of the rear sofa.

Trying to somehow compensate for the loss in the LCD/c, the engineers went to the following. They added amplifiers in some places, thus significantly increasing the figure, and only falling short of the sedan's result.

In addition, due to the introduction of amplifiers, the liftback became 15 kg heavier, and this, in turn, had a negative impact on the torsion indicator.

A few comments

- Some deviation from the readings indicated in the table of factory values is allowed. For example, on a BMW 3, the thickness gauge showed 170 microns (and according to the standard it should be in the range of 100-165), but this does not mean that the component was repaired. Much depends on the year of manufacture, place of assembly, and whether polishing was done.

- Some motorists are frightened by some scatter of values during the measurement process. Here you need to take into account that such a spread occurs even on a car that has just left the showroom. If the fender shows 100, the hood 140, the door 120, then this is normal.

- Practice has proven that the thickness of the paintwork on domestic and Japanese cars, even according to the table, is a thin layer - about 100 microns. The European manufacturer paints with a thicker ball of paint - 150 microns.

- The internal elements of the body have a layer of 40-90 microns, because external influence on them is not provided.

- Minor dust or dirt on the surface does not particularly affect the final measurement result, but a crust of dirt will be a serious obstacle to obtaining correct results.

Lada Priora

The next domestic model produced at the Volzhsky Automobile Plant is the Lada Priora. Today it is produced in 4 body variations. The line of models also includes the Priora Coupe - which, however, has not yet gained any popularity among Russians.

Lada Priora

An important parameter of the Priora body, again, is the LCD/c value. It is noteworthy that for the Priora this figure is 12,000 Nm/deg in the sedan version. In other variations, except for the coupe, it is a row lower.

Despite this, there are general indicators for all 3 models, implying body dimensions. Thus, all body types (except coupe) have the same wheelbase, ground clearance and width. As for the length, let us recall that the sedan’s figures are 4350 mm, the hatchback’s are 4,210 mm, and the station wagon’s are 4,340 mm. The heights of the bodies are also different: the sedan is 1420 mm, the hatchback is 1435 mm, and the station wagon is 1508 mm.

Initially, the weak areas of Priora bodies were considered to be the roof, hood and trunk. It is for this reason that experts insist on the mandatory treatment of all internal surfaces of problem areas by the car owner himself with an anticorrosive agent.

Priora body protection against corrosion is provided for 6 years. In practice, this period is determined by: zinc coating of the sills, bottom and arches, as well as the use of low-alloy steel.

Dimensions of Priora

Indeed, practical experience has proven that the Priora body is incredibly resistant to corrosion. If problems start, the first ones at risk are the bumpers, then bubbles form on the paintwork in the winter, and the paint peels off.

The 12 thousand Nm/deg indicator on the Priora sedan is not a large value. Even the VAZ-21106, not to mention foreign cars, has a higher figure. Thus, Priora owners who prefer active driving would do well to strengthen the car’s frame. In particular, strengthening should involve the installation of strut struts and modernization of the SPU on the rear axle.

Read news about the new Niva

- AVTOVAZ increased prices for LADA Niva for the second time in 2022 » Lada.Online - all the most interesting and useful about LADA cars

- Sale of new VAZ (LADA) Niva cars 2022