Braking distance of a VAZ 2107 car with a permissible maximum weight during emergency braking from a speed of 80 km/h, no more than, m PARAMETERS VALUE Year of production of engines of this type 1972 - our time Power system Injector/carburetor Engine type Inline Number of pistons 4 Cylinder block material cast iron Cylinder head material aluminum Number of valves per cylinder 2 Piston stroke 8 0 mm Cylinder diameter 76 mm Engine capacity 1452 cm 3Power 71 l. With. at 5600 rpm. Maximum torque 104 Nm at 3600 rpm. Compression ratio 8.5 units Oil volume in crankcase 3.74 l

This engine uses AI-93 fuel. In practice, motorists can fill in completely different fuels. The most common deviations from the norm are the flooding of AI-92 and AI-95. You can read more about this below.

Its dimensions (characteristics are indicated in millimeters):

| Height | Width | Length |

| 665 | 541 | 565 |

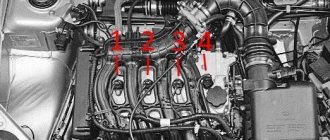

Installation of shafts according to marks

There is a drilling on the camshaft gear on the inside of the engine. It must be aligned with the protrusion on the camshaft housing.

In this position, the piston of the fourth cylinder will reach top dead center during the compression stroke. This is a very convenient position of the marks for accurately determining the position of the camshaft. Their combination is enough to accurately set the camshaft in the desired position for adjusting the valves.

Because in one engine cycle. The camshaft makes one revolution. The crankshaft turns two times.

- That is, in this position at top dead center there are pistons of cylinders 1 and 4. 4 cylinder in the compression stroke in the first cylinder the exhaust gas emission stroke has ended and after the piston passes TDC the fuel mixture intake stroke begins.

- If you turn the crankshaft half a turn 180 degrees, the camshaft will turn a quarter turn 90 degrees. The compression stroke will begin in the second cylinder.

- When the crankshaft is rotated another 180 degrees, the compression stroke begins in the first cylinder.

- Another 180 degrees and the compression stroke will be in the third cylinder

As mentioned above, to begin adjusting the valves, you need to align the mark on the camshaft pulley with the casting on the camshaft housing. And check the position of the crankshaft at the TDC mark.

In this position, the pistons of cylinders 1 and 4 and the fourth cylinder will be at TDC on the compression stroke.

Numbering of cylinders in different types of internal combustion engines

As for the standards for numbering combustion chambers, there are none. The way they are numbered in the internal combustion engine is influenced by the following factors:

- Type of drive;

- ICE type, block layout;

- Transverse or longitudinal arrangement of the unit under the hood;

- Side of rotation.

On standard front-wheel drive cars with a transversely mounted engine, the numbering begins on the timing side. So, near the timing belt there is the first cylinder and then all the others. The latter is located near the checkpoint.

Article on the topic: How to check a car for arrest, bail

Examples

In multi-cylinder V-twin engines, the first cylinder is located in the bank on the driver's side.

The procedure for adjusting the valves of the VAZ 2107

Since the valves of cylinder 4 are completely closed. Then you can adjust both the intake and exhaust valves. But the engine designers suggest adjusting the clearances on the 8th valve in a row, this is the exhaust valve of the fourth cylinder, and on the sixth valve of the third cylinder.

Numbering of valves along the engine stroke

There is nothing strange about this. Because the sixth valve is also closed. The piston of the third cylinder is at bottom dead center. it has completed the gas expansion stroke; the intake valve is closed; the exhaust valve will begin to open before the start of the exhaust gas emission stroke.

Therefore, in this position it is more convenient to adjust valves 6 and 8. This is due to the fact that the rockers are installed at an angle to the horizontal axis of the engine.

The seventh valve cam is in an awkward position for installing the adjustment probe. Therefore, an adjustment scheme is provided.

How to turn shafts.

The crankshaft rotates clockwise. 180 degrees every time. Half a turn. It always raises doubts in which direction to turn the shaft. This can be determined simply. You need to stand in front of the hood and imagine that the engine is turning over using a crooked starter. This will be the correct direction of rotation, clockwise.

Now you need to figure out how much the shafts should rotate. The camshaft must be rotated 90 degrees each time. That is, the mark should move 90 degrees. You can put your marks on the pulley by dividing the pulley into 4 parts

You can navigate by the distributor slider. It should also rotate 90 degrees each time.

More precisely, it is enough to unscrew the spark plugs and bring each piston to TDC using a screwdriver.

- That is, feel for the piston and bring it to TDC. After valves No. 6 and No. 8 have been adjusted

- The crankshaft rotates 180 degrees. In this case, the piston of cylinder 2 must be at TDC and valves No. 4 and No. 7 are adjusted.

- After adjusting them, rotate the shaft 180 degrees. In this case, the mark on the crankshaft pulley again consults the TDC mark on the front engine cover. Here the piston of the first cylinder is exactly at TDC and valves No. 1 and No. 3 are adjusted.

- The last time we turn the crankshaft 180 degrees, the piston of cylinder 3 should reach TDC. In this case, valves No. 2 and No. 5 are adjusted. In this case, you can use a screwdriver to make sure that the piston of cylinder 3 is at TDC.

Great precision is not required. Therefore, it is enough to simply visually divide the camshaft pulley or the circle that the distributor slider describes into 4 parts.

VAZ 2107 valve adjustment table

Numbering of cylinders on different types of engines

As such, there is no strict international system for the location and numbering of engine cylinders. And that's bad. Therefore, before you begin any type of repair of the engine or ignition system, immerse yourself in the Operating and Repair Instructions for your particular car.

Rear-wheel drive 4- and 6-row engines in the USA have a master cylinder number 1 from the radiator, the remaining cylinders are numbered towards the passenger compartment. But there is also reverse numbering, when the master cylinder is considered to be the one closest to the passenger compartment.

For French engines, cylinder numbering occurs on the gearbox side. And the numbering of the cylinders of V-shaped engines comes from the right side, i.e. on the torque side.

Front-wheel drive cars typically have a transversely mounted engine. Here the cylinders are numbered on one side, and cylinder No. 1 is located on the passenger side.

V-twin multi-cylinder engines have the driver's side master cylinder in the bank closest to the passenger compartment. Then there are the odd-numbered engine cylinders, and on the opposite side (closer to the radiator) there are the even-numbered ones.

Therefore, in order to ensure that you are not completely confused due to the lack of a unified international standard for the location and numbering of engine cylinders, use the manufacturer’s Operating Manual.

Good luck learning the numbering and arrangement of engine cylinders.

VAZ 2107 was produced from 1982 until 2012. During this time, he managed to become a truly people's car. And no wonder. Cheapness, good reliability of components and assemblies, as well as the ability to repair a car almost “on the knee”. As you know, the “heart” of a car is the engine. And in this article the VAZ 2107 engine will be discussed in detail.

Adjusting VAZ 2107 valves using a feeler gauge

The clearances on the intake and exhaust valves are the same and amount to 0.15 mm.

A special probe with a thickness of this size is provided. It must be inserted between the valve lever (rocker) and the cylindrical part of the cam. The cam becomes as necessary if the valve adjustment order is followed correctly.

Probe for adjusting valves VAZ 2107

The gap is adjusted using a screw. The screw is screwed into the cavity of the block head and secured with a lock nut. To adjust, you need to unscrew the lock nut and use the adjusting screw to press the feeler gauge between the rocker and the cam. The probe should not be jammed. When tightened, it should move easily with little force.

There is a sign on the dipstick. A kind of reminder. It shows the procedure for adjusting the valves according to their count from the front of the engine.

What engine can be installed on this car?

Initially, 2 types of engines were installed on the VAZ 2107 model, these are:

There were also 1.3 L and 1.2 L engines, but they are very few in number and practically never found.

It is also possible to install an engine from a VAZ with front-wheel drive, but it is too labor-intensive and unjustified.

This is interesting! Sometimes the English letter “i” is added before the name of the car. This means that the VAZ 2107 engine is an injector.

Injector – fuel sprayer. Nozzle. The principle of operation of injection gasoline engines is very similar to diesel engines.

Adjusting the valves of the VAZ 2107 with an indicator

Adjusting the VAZ 2107 valves with an indicator is required to determine a more accurate gap between the cylindrical part of the camshaft cam and the rocker.

The use of an indicator is necessary if there is a development on the contact plane of the rocker and cam. A dimple forms on the surface of the rocker.

When installing the adjustment probe, this hole is blocked. As a result, no matter how hard you try, you won’t be able to set the gap exactly. The figure shows that when adjusting with a feeler gauge, the thickness of the feeler gauge will add another gap to the working depth

The indicator allows you to set the gap taking into account the fact that wear has occurred. It measures the actual distance from the rocker to the cam.

To use the indicator, you need to secure the bar above the rockers. Install the indicator on the bar. So that the tip of the indicator rests against the edge of the rocker.

Next, the required gap is set and the indicator is moved along the bar to the next rocker.

To be honest, purchasing an indicator is quite expensive to adjust the valves only on your own car. Take from someone. Not everyone will. It is easier and cheaper to change the rocker if there is existing exhaust.

If a development has appeared. The cementation layer on the rubbing surface of the rocker is damaged. Further production will increase even more. And even with an indicator. The valve adjustment process will be repeated after a shorter period of time. Valve clearances will have to be constantly adjusted.

The procedure for adjusting valves on injection and carburetor engines

No different. Since the operating order of the cylinders is the same. The valve clearances are also the same. There are also no differences in valve adjustment on all VAZ cars from 2101 to 2107; differences in engines do not affect the timing system. Engines may differ in piston diameter. Piston stroke. Accordingly, crankshafts, pistons, and connecting rods of different sizes are used. The design of the timing mechanism on all engines of these models does not change. Except that the engines of the VAZ 2105 car were equipped with a C belt drive mechanism. But the principle of valve adjustment remained unchanged on this model.

When adjusting valves, it is not so important to know the adjustment procedure and how to set the gap correctly. This is painstaking work. It is not always possible to lock the adjusting screw the first time. So that it is not pinched or loosened. Therefore, if the first time it doesn’t work out, it’s a big deal. The procedure can be repeated.

Valve adjustment, why the engine needs it. The opening and closing times of the valves depend on the correct clearances. With increased valve clearance, the valve will open later and close earlier. Accordingly, the combustion chamber does not receive the required amount of fuel mixture. And the exhaust gases will not completely exit the cylinder cavity.

If the valves are tight. They will not close completely. This is a reduction in compression. And as a result, a decrease in engine power. In addition, there will be a breakthrough of expanding gases that have a high temperature. As a result, valves and valve seats burn out. The engine fails.

How are the cylinders located in engines?

There are different engine models - these include vintage one- and two-cylinder internal combustion engines, traditional in-line four- and six-cylinder models.

The straight-six, which was very popular in Europe in the 80s and 90s, has now become an endangered species.

It’s not worth talking about eight-cylinder models - they said goodbye to this arrangement long ago back in the 30s.

Why? As the volumes increased, the blocks also grew larger. This created a lot of problems for designers and engineers during layout.

For example, it was possible to squeeze an inline eight into a front-wheel drive car in only two cases - the Austin Maxi 2200, which was produced in the 60s, and the Volvo S80.

In two rows

How to make a large inline internal combustion engine shorter and more compact?

Article on the topic: How to calculate the heat balance of an internal combustion engine

The engine can be “cut” in half, set the two parts side by side and have the pistons rotate one crankshaft. These motors are shaped like the letter “V”.

Here the combustion chambers are arranged in two rows at an angle to each other. This configuration is very popular among manufacturers and is second only to the in-line “four”.

And the one who developed and launched the traditional boxer engine familiar to everyone is Ferdinand Porsche. The first batch of Zhuk cars was equipped with these internal combustion engines in 1937.

A similar design was used on Ford A, C, F. In 1920, the Bavarian automobile concert proposed its own design of a boxer engine.

Motors W

In these power units, a number of combustion chambers are connected to a VR arrangement. In each row, the cylinders are placed at an angle of 15 degrees.

Both rows are at an angle of 72 degrees. In the case of an eight-cylinder engine, the block consists of two V-shaped blocks that are at an angle of 72 degrees.

What to do if the number is unreadable

If the VAZ 2110 engine number is not readable, you should contact the traffic police. Employees will order an examination. The procedure itself is free. But experts should be paid for their work.

A similar problem is often encountered when removing or registering a car. But, if the car owner independently noticed that his license plate has rotted, he should contact the traffic police.

The examination procedure consists of the following steps:

- Employees will check to see if the number is truly unreadable. Then they will give you a ticket.

- According to the date specified in the coupon, the car owner will need to come for the procedure.

- Experts will come and remove all the parts from under the hood to make the job easier.

- For about an hour they will lubricate the rotted number with various reagents in order to find at least some clue.

- They will take photographs of the place where the encoding is located from different angles. Then they will compare photos and try to read the engine code.

If you still manage to read the engine coding after exposure to chemical reagents, then the car owner will write this number in the vehicle’s technical passport. Now it must be lubricated with lithol so that it does not rot completely after exposure to chemical reagents.

If the number has completely rotted, then it will take experts about half a month to check. When it is determined that the car is not registered as stolen, when they can determine the actual engine number, it will also be registered in the car owner’s title. The passport will indicate that the encoding has rotted naturally.

If it turns out that the VIN code is different, then a criminal case may be opened. What to do if the engine identification code is broken is written in the block above.