What is ABS (Anti-lock Braking System) probably even children know. This system allows you to perform the most effective braking to stop the vehicle as quickly as possible. The system is electronic and is equipped with many sensors and a control unit, which ensures that the wheels do not lock during braking, that is, “do not skid.” Such an invention saves hundreds or maybe even thousands of lives on the road every day. The ABS system prevents skidding and loss of control, which is very important on slippery roads, as well as in case of emergency braking.

In this article, I will tell you how to check the ABS sensor if it malfunctions, as well as if an emergency indicator appears on the dashboard in the form of three English letters “ABS”. You will learn how to test the ABS sensor at home in various ways using a multimeter.

The most common breakdown in the ABS system is a circuit break, when communication is lost between the control unit and the sensor. This can happen for various reasons, which you will learn about a little later.

Don't panic

This is a signal to the driver that a breakdown has occurred in the anti-lock braking system. Many people panic and are afraid to travel. Sometimes the car is dragged on a tow truck or on a cable, and the reason is that the ABS light is on.

No need to worry, because the brakes on the car work. Check to see if the brake fluid has leaked, try pressing the brake pedal. The car is slowing down, only the ABS system has failed. This means that on the way to the repair site you should not brake sharply so that the wheels do not skid.

Why does the indicator on the instrument panel light up?

If the ABS light comes on on the dashboard, the reasons for this may be the following:

- It lights up every time the car engine starts - this is how the system signals that it is in working condition. If the system is fully operational, the light should go out after some time. If the ABS light does not light up when you start the engine, the indicator is most likely faulty.

- If the light does not go out for a long time, this means that there are problems in the ABS system. The on-board computer, detecting errors, generates a failure code, saves it and turns on the warning indicator.

How does ABS work?

The electronics regulate the brake force on all wheels, preventing them from locking when braking, but allowing the car to stop quickly. By braking sharply, the car will not lose stability.

If the system is out of order, or it is not installed on the car at all, then the wheels will lock during sudden braking. A strong skid may occur, especially in winter, or when turning. If the ABS is working properly, this will not happen. Even when turning, you can press the brake pedal sharply - there will be no skidding.

If the ABS light is on, the reason is a system malfunction. This is easy to check - accelerate to a speed of 40 km per hour and sharply press the brake pedal to the floor. If there is no pedal vibration and the wheels are skidding, then the ABS is not working.

If the system is working properly, you can sharply press the brakes and try to go around the obstacle. In this case, no skidding will occur. If the anti-lock braking system fails, the car will skid and hit this obstacle.

The ABS light came on: why did this happen and what to do now

It is quite difficult to find a modern car without ABS installed.

The anti-lock braking system greatly helps drivers maintain control and stability when braking. At the same time, the braking distance of the car increases slightly compared to the disabled system. As with many other systems, ABS has indicators on the instrument panel that indicate that the system is not currently working. And if the driver presses the brake pedal, the wheels will be blocked. Therefore, if the ABS light comes on, it is worth finding out the reason, there are not many options.

First of all, it is worth understanding that if the ABS lights up when the engine starts and immediately goes out, this is normal and there is no need to worry. It’s another matter if the indicator flashes after starting the engine or while driving - this is a warning that must be kept in mind until the vehicle stops and taken into account when braking.

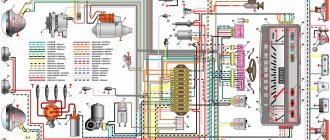

To understand why the ABS caught fire, it is worth mentioning the design of the system . It consists of four wheel rotation sensors, an ABS module, a control device, and a warning light on the instrument panel.

Therefore, the problem may be in the control unit, in the sensors installed on each wheel, with the wiring that transmits data from them, or with the crown on the hub. Often the malfunction is related specifically to the sensors - while driving, the integrity of the wires may be damaged, or the wheel rotation sensors themselves will become covered with dirt and begin to give out false information.

If the ABS lights up after any repair or maintenance work in the hub area - replacing brake discs or pads, replacing the hub, etc. - it is worth checking to see if the sensor connector is not connected back. Also, from an elementary point, it is worth mentioning checking the fuses responsible for the anti-lock braking system.

You can determine what exactly is the reason for the ABS light to come on using diagnostics using special equipment. This method will allow you to count errors in the operation of the system and find out in which part of it the problem occurred. Unfortunately, there is not always access to such equipment, so you can try to cope on your own.

For example, if the ABS lamp comes on after a significant slip , do not panic. This can be overcome by accelerating to at least 40 km/h and hitting the brakes. If the indicator goes out, it means the system has come to its senses and is working again.

Causes and their elimination

If you have repaired the ABS problem yourself, in most cases the light will go out after a few trips with the brake pressed. If everything is in order, the system will see this and turn off the lamp.

This is all the information related to self-diagnosis. It’s unlikely that you’ll be able to find anything else on your own. A good car service center will connect a scanner to your Lada Granta, which will be able to read the system and identify the cause. Most often the sensors or control unit are to blame. Subscribe, good luck to everyone on the roads, look forward to many more interesting things!

Source

Lada Granta Red Luxury Mechanics › Logbook › Granta and ABS - a surprisingly successful tandem

The brakes themselves on the Grant are ordinary; there aren’t enough stars in the sky. At reasonable speeds they are quite effective, especially on good tires.

But what is quite above average on Grant is ABS. What is ABS anyway? This is a system that, when the brakes are fully applied, seeks a balance between efficiency and controllability. This is how all ABS work, but the details are very important.

You can't comprehend the details without a glass. I'll try to explain it on my fingers)).

What types of ABS are there? Three types - 4s/2m, 4s/3m and 4s/4m. It is likely that the first two types of ABS were used previously, although I have not studied the issue and I won’t lie. I will only talk about four-modulator ABS.

ABS is a blessing. To understand this fact, I recommend taking a ride in FF2 or Logan in trim levels without ABS. There is a pressure limiting valve in the rear axle (much simpler and more reliable than the VAZ regulator), but once and for all configured in such a way that it actually deprives this axle of brakes.

For those who like exact numbers, about 50 kg of force on the rear alone is allowed. While on wet asphalt, for example, you can realize at least 200 kg. This is all done so that the rear will not be blocked before the front at all and on any surface, including the Olympic bobsleigh track.

On cars with ABS, the problem of advanced locking of the rear axle is not so acute, although, contrary to the opinion of many, it still exists. This is true, by the way.

Modern ABS 4S/4M is a subtle and vicious thing. You can configure it so that each wheel will implement the maximum possible braking force at a given time.

It's not hard to see what this will lead to in mixed doubles. Let's say the left wheels are driving on dry asphalt, and the right wheels are driving on the icy side of the road.

And then I had to brake sharply. At a minimum, there will be a sharp departure from the course towards the wheels with more grip (towards the oncoming lane). Or even a simple and vulgar spread with a flip and/or other goodies.

Tuning for a “weak” wheel is also not the optimal solution, because then the braking efficiency drops significantly.

Therefore, they achieve some average, optimal, compromise response. Due to the fact that finding this compromise is difficult, expensive, requiring roads, machine hours and very skilled man hours, it has become fashionable to do most of the work on the computer. The result is a little predictable.

About a year ago, there was a series of articles in the AR about severe bugs in the ABS operation of Polo sedans and Tiguans. There, in certain circumstances, the ABS began to think that there was some kind of crap under the wheels, such as ice, and the brakes disappeared almost completely. www.autoreview.ru/_archiv…_ID=69757&SECTION_ID=1991 www.autoreview.ru/_archiv…ID=123939&SECTION_ID=6991 www.autoreview.ru/_archiv…ID=130174&SECTION_ID=7344 www.autoreview.ru/_archiv…ID=128368&SECTION_ID =7279 As for our Soviet cars, due to poverty, we have not yet learned how to properly work on computers and do a lot of things the old fashioned way, on the road.

The result, I admit, is worth it. ABS Grants, if not the ideal of such a system, are then a very close approximation to such an ideal. Nothing can turn her away from the true path - not a mix, not a turn, not a bumpy road. It works late, allows the wheels to slide a lot, and doesn’t seem to be prone to “hanging” when the brakes are released. In the debate between braking and handling, efficiency clearly wins. This makes me very happy.

Even more gratifying is that Granta happily escaped the Nigerian problems from the links above.

It is clear that with such a balance, ABS in the direction of brake efficiency, on mixed doubles, pulls quite a bit to the side. But if there is an electric steering wheel and the driver is willing to not count crows, everything is within the limits of the rules and common sense.

And the fact that it will be difficult to drive around an obstacle on bare ice with such ABS is right; if you don’t jerk around the steering wheel on black ice, less people around you will suffer.))

Source

ABS system on a Lada Granta car

The principle of operation of the system is simple: receiving data from the rotation speed sensors of all wheels and from the vehicle speed sensor, the control unit controls the rotation of each wheel and, if the wheel locks during braking, reduces the pressure in the corresponding brake circuit.

The ABS system ensures full control of the car during emergency braking, but does not lead to a reduction in braking distance.

Therefore, you need to maintain the correct distance.

On vehicles with an ABS system installed, a four-channel system is used.

The channels are connected according to a diagonal pattern.

The executive element of the anti-lock braking system is a hydraulic modulator. This is a complex assembly in which a hydraulic pump and solenoid valves are built in.

It is installed in the engine compartment.

The operation of the hydromodulator is controlled by an electronic unit installed on the hydromodulator.

The control unit also monitors the health of all elements of the ABS system.

Wheel speed sensors are installed in the front and rear brake mechanisms.

Ways to check functionality

To determine the condition of a part, we will perform a series of steps to diagnose it, moving from simple to complex:

- Let's check the fuses by opening the unit (inside the passenger compartment or in the engine compartment) and inspecting the corresponding elements (indicated in the repair/operation instructions). If a burnt component is found, we will replace it with a new one.

- Let's inspect and check:

- integrity of connectors;

- wiring for abrasions that increase the risk of a short circuit;

- contamination of the part, possible external mechanical damage;

- fixation and connection to ground of the sensor itself.

If the listed measures do not help to identify a device malfunction, it will have to be checked using instruments - a tester (multimeter) or an oscilloscope.

Tester (multimeter)

This method of diagnosing the sensor will require a tester (multimeter), instructions for operating and repairing the car, as well as PIN - wiring with special connectors.

The device combines the functions of an ohmmeter, ammeter and voltmeter

Tester (multimeter) is a device for measuring electric current parameters, combining the functions of a voltmeter, ammeter and ohmmeter. There are analog and digital device models.

To obtain complete information about the performance of the ABS sensor, you need to measure the resistance in the device circuit:

- We lift the car with a jack or hang it on a lift.

- Remove the wheel if it prevents access to the device.

- Remove the cover of the system control unit and disconnect the controller connectors.

- We connect the PIN to the multimeter and the contact socket of the sensor (the connectors for the rear wheel sensors are located inside the cabin, under the seats).

We connect the PIN to the tester and the contact socket of the sensor

The device readings must correspond to the data specified in the repair and operation manual for a particular vehicle. If the device resistance:

- below the minimum threshold - the sensor is faulty;

- approaches zero - short circuit;

- unstable (jumping) at the moment of twitching of the wire - a violation of contact inside the wiring;

- infinity or no readings - wire break.

Attention! The resistance of the ABS sensors on the front and rear axles is different. The operating parameters of the devices are 1–1.3 kOhm in the first case and 1.8–2.3 kOhm in the second.

Video “Diagnostics of the ABS sensor”

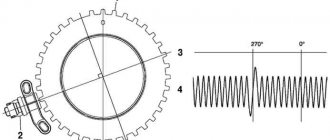

How to check using an oscilloscope (with connection diagram)

In addition to self-diagnosis of the sensor with a tester (multimeter), it can be checked using a more complex device - an oscilloscope.

Inductive type sensors

To operate the sensors installed in the front brake mechanisms, gears are made on the housings of the external hinges of the front wheel drives.

To operate the sensors, master discs are installed in the rear mechanisms under the brake drums.

Rice. 4. Rear wheel speed sensor

Pulse signals from the sensors enter the control unit.

When one of the wheels is blocked, the hydraulic modulator, at the command of the control unit, limits the pressure in the corresponding channel.

If a malfunction is detected, the control unit informs the driver using a warning lamp on the instrument panel.

The problem can be determined by the fault codes.

An ABS malfunction may be caused by a failure of the wheel rotation sensors or a malfunction of the hydraulic valve block itself.

If the ABS fails, the braking system remains operational, but braking efficiency is reduced.

Removing the ABS hydraulic unit

We install the car on a lift or inspection ditch.

Disconnect the plug block of the wires from the hydraulic unit.

We disconnect the brake pipes going to the brake mechanisms from the hydraulic unit of the anti-lock braking system. We install plugs on the tubes and holes in the hydraulic unit.

Disconnect the primary and secondary circuit pipes of the master cylinder from the ABS hydraulic unit.

Using a 13mm socket, unscrew the two bolts securing the hydraulic unit bracket to the front side member.

Remove the hydraulic unit with the bracket assembly.

Using a 10mm wrench, unscrew the hydraulic unit from the bracket.

Hydraulic unit installation

We install the hydraulic unit on the bracket and secure it with nuts. The tightening torque of the nuts is 7 – 10 Nm.

We install the hydraulic unit with the bracket assembly on the car body and tighten the two bolts with washers securing the hydraulic unit to the left side member.

We remove the plugs and attach the tubes to the ABS hydraulic unit. The tightening torque of the tube fittings is 15 – 18 Nm.

Attach the plug block. Install the battery. We bleed the brake system.

Removing and installing the front wheel ABS sensor and rotor

We install the car on a lift or inspection ditch.

Disconnect the front wheel speed sensor harness connector from the front wiring harness.

Using a flat-head screwdriver, remove the speed sensor harness block holder from the hole in the car body.

Remove the sensor harness from the brackets on the front suspension strut and the car body.

Using a TORX E8 socket, unscrew the bolt securing the speed sensor to the bracket on the steering knuckle and remove the sensor.

Installing the front wheel speed sensor

Before installation, apply AZMOL LSC-15 lubricant to the mating holes. Install the sensor in reverse order. The tightening torque of the sensor mounting bolt is 6 – 9 Nm (0.6 – 0.9 kgcm).

If it is necessary to replace the ABS rotor of the front wheel, then replace the drive assembly: (right front wheel drive part. 11180-2215010-10, left front wheel drive part. 21700-2215011-00) or the outer hinge assembly (part 11186-2215012 -00).

Removing the speed sensor and rear wheel rotor of Lada Granta

We install the car on a lift or inspection hole.

Disconnect the rear wheel speed sensor harness connector from the wiring harness.

Using a flat-head screwdriver, remove the speed sensor harness block holder from the hole in the car body.

Remove the rear wheel speed sensor harness from the mounting brackets located on the rear suspension arms and vehicle body.

Using a TORX E8 socket, unscrew the bolt securing the speed sensor to the bracket.

Remove the rear wheel speed sensor.

Before installing the speed sensor, lubricate the mating parts with grease.

The tightening torque of the sensor mounting bolt is 6 – 9 Nm.

Removing the rear wheel rotor

Place the car on a lift and remove the rear wheel.

Using a 7mm socket, unscrew the guide pins securing the drum.

We insert the pins into the threaded holes of the brake drum and screw the pins in sequence. Thus, compressing the brake drum.

Removing the brake drum

Removing the rear wheel rotor

In the rear block of a car with an ABS system there is a hole into which the tip of the speed sensor fits.

Installation

Apply grease to the hub seating belt, install the brake drum and tighten the guide pins. The tightening torque of the pins is 7 – 15 Nm. Install the wheel.

Reviews

“Using a 7-head socket, unscrew the guide pins securing the drum.”

Using a 7-head socket, we unscrew the guide pins of the wheel rim, which are also used to secure the drum.

Source

Self-correction of ABS light coming on

Let's consider what measures need to be taken to fix the problem without going to a car repair shop:

- Lift the hood, disconnect the wires leading to the battery.

- The ABS electronic control unit is located directly under the hood. As a rule, it is located together with a hydraulic modulator, which distributes braking forces. This element can be recognized by the large number of brake pipes connected to the block and a bunch of auto wires with a connector.

- Next, you need to disconnect the connector and carefully examine whether there is any damage or liquid on its surface. If necessary, you need to blow out the connector and dry it thoroughly.

- Check the fuses. It's better to do this first, but it's okay if you take such actions at this stage.

The anti-lock braking system is controlled by several fuses. They are most often located in the mounting block located under the hood.

Then everything is a little more complicated:

- It's good if you have a car lift to look at. If there is no such installation, you can use a jack. The main thing is to first look at the wires that are connected to the wheel sensors to avoid damage. In most cases, the wiring rubs against the surface of the wheels or flies off the retaining mounts - this leads to the light bulb coming on.

- The design of the sensor on wheels involves connecting it to a wire with a connector attached to the end. The wire can be up to 1 meter long. You need to locate these connectors, check whether they have contact and what quality it is. Inspect the connector surface for moisture or rust.

- If your efforts have led nowhere, and the ABS light is still on, a visit to a car repair shop is necessary. It happens that it is not possible to eliminate the error by “rebooting” (by removing the battery terminals).

Above we described the steps for independently detecting a malfunction in which the ABS light is on and eliminating it. Car service specialists will connect your car to computer diagnostic equipment, and with its help they will determine the cause of the breakdown. From time to time, quite serious cases arise that require immediate professional help.

What is vehicle stability control system?

Modern Lada cars can have up to six different active safety systems. Such correction and driving assistance systems are highly likely to prevent accidents. Let's look at what exchange rate stability systems are available on Lada cars and how they work.

Lada cars (Priora, Granta, Kalina, Vesta, Niva, Largus and others), depending on the model and configuration, can be equipped with the following electronic stability control systems:

ABS function

The anti-lock braking system prevents the vehicle's wheels from locking when braking. The main purpose of the system is to ensure optimal braking efficiency (minimum braking distance) while maintaining vehicle stability and controllability. However, when braking on a road with uneven or loose surfaces (gravel, sand, unpacked snow), a slight increase in braking distance may occur compared to braking under the same conditions with locked wheels.

Braking, controlled by ABS, begins at speeds above 5–8 km/h and is accompanied by slight pulsation of the brake pedal and characteristic noise of the actuators. ABS stops regulating when the vehicle speed drops to 3–5 km/h.

When braking in an emergency, press the brake pedal as quickly and as hard as possible and do not release it until the end of braking. When changing direction while braking, do not release the brake pedal.

Warning ! Intermittent braking (releasing and pressing the brake pedal again) with ABS working will increase the braking distance.

The ABS status is indicated by the “ABS” indicator. The indicator lights up yellow when the ignition is turned on and goes out after the engine starts (self-test mode).

ATTENTION ! In all other cases, when the warning light comes on, this indicates an ABS malfunction, which must only be repaired by dealers.

If an ABS malfunction occurs, the operation of the hydraulic brake drive is not disrupted, and braking remains possible as on a car without ABS.

What to do if the ABS system starts to work incorrectly and the indicator blinks?

This situation is one of the most complex system failures. The thing is that the sensors read incorrect information and transmit it to the control device, which for this reason gives incorrect commands to the actuators. Unfortunately, most vehicle owners, when detecting this malfunction, simply turn off the ABS system, since this is an effective measure to prevent serious consequences while driving. For example, spontaneous activation of the system while driving at a speed of more than 90 km/h can lead to serious damage to the suspension, which will provoke an emergency situation as a result of loss of control over the car. In this case, you need to do this:

- perform system diagnostics at a car service center;

- if the ABS system is installed on a domestic car, it must be disabled;

- it is quite possible that after repairing the ABS, the ECU will need to be reflashed, but this measure is applicable mainly for foreign cars;

- disabling the anti-lock system is not a solution to the problem, since on most vehicles its presence is simply necessary and is determined by the design features of their chassis, body and frame;

- You should not completely rule out the presence of faults in other components of the car that cause interruptions in the operation of the ABS.

It is necessary to remember that only diagnostics using special equipment will help to establish the real reason for the incorrect operation of the anti-lock system, which may lie in the malfunction of its components or other components of the vehicle. Therefore, you should be prepared for anything. But in many cases the problem can be solved quite simply. The cost of restoring the ABS system will depend only on its design and the make of the car. But the need to carry out this work is dictated by the safe operation of automotive equipment, the design of which includes such a system.

Problems caused by the ABS system cannot be called difficult to solve, but in any case they require immediate elimination. As you can see, the banal shutdown of the system, which most car owners consider a panacea in the event of a malfunction, is not always this magic remedy. All that needs to be done is to correctly identify the malfunction and eliminate it, because in most cases, it is not related to the functioning of the anti-lock system.

EBD function

The brake force distribution system is a continuation of the development of the ABS system. The fundamental difference between the system and basic ABS is that they help the driver control the car all the time, and not just during emergency braking.

EBD provides an optimal ratio of braking forces between the front and rear wheels of the vehicle during unregulated ABS braking and in the event of an ABS malfunction. The EBD status is indicated by the “Brake Failure” indicator. The indicator lights up red when the ignition is turned on and goes out after the engine starts (self-test mode).

Warning ! The simultaneous lighting of the “ABS” and “Brake failure” indicators, with the exception of the self-test mode when the ignition is turned on, indicates a malfunction of the ABS and EBD. In this case, when braking, the rear wheels may lock prematurely and the vehicle may skid dangerously. The fault must be repaired by dealers as quickly as possible.

What to do first?

It is necessary to check the ABS sensors located near each wheel hub. Your task is to detect a violation in the connection of the sensors, a broken wire or damage to the ABS sensor housing. In any of these cases, you will one way or another see the corresponding indicator on the panel, well, provided that the system control unit itself is working and not “buggy”.

Checking the ABS sensor - measuring the resistance

- We jack up the wheel on which you think the inoperative or faulty sensor is located, or each wheel in turn if you don’t know exactly which sensor is faulty.

- Next, remove the wheel and gain access to the sensor.

- Remove the housing, as well as the protective control unit and connectors that supply power to the sensors.

- After that, we insert wires into the circuit of wires with PIN connectors and connect them with the sensor and multimeter.

- We measure the resistance and compare it with the one that should be by default (you can find it in the manual) or with a representative of the manufacturer of your car.

- We check the wiring for breaks or short circuits.

- Rotate the wheel while watching the multimeter readings, the resistance should change.

- Device - leg - 5-26 Ohm.

- Device - "ground" - from 20 kOhm or more.

For more details on how to check the ABS sensor, watch this video:

Checking the ABS sensor using a tester - measuring the voltage

- Let's jack up the wheel.

- Turn on the multimeter, set the DC voltage measurement mode.

- We connect the electrodes of the device to the connectors and check the readings, while rotating the wheel (about 1 rpm).

- A working ABS sensor will show voltage on the device

0.25-1.2 Volts. If the wheel rotation speed is higher, the readings will increase accordingly.

How to check a sensor with an oscilloscope?

To diagnose the serviceability or malfunction of the ABS sensor, you can even use an oscilloscope or, more simply, a tester. When connected, a graph will be displayed on the device; using amplitude analysis, you can judge the serviceability or malfunction of the sensor.

The problem is that this device is not available at every service station, not to mention the garage in which you are going to conduct all your “experiments”. The device is expensive and quite difficult to understand, so to work with it you need to have certain knowledge and skills.

ESC and TC function

After starting the engine, ESC and TC are switched on automatically.

To turn off ESC and TC when driving in difficult road conditions (mud, sand, deep snow), press and hold the “ESC” switch button pressed for 0.5–1 seconds. Disabling functions only works when the vehicle speed is less than 50 km/h. The functions are activated by briefly pressing the “ESC” switch button or automatically when the speed reaches 50 km/h.

The operation of ESC and TC is accompanied by a characteristic noise of the actuators. The activation of ESC and TC indicates that the limit of tire adhesion to the road surface has been reached. To avoid losing control of the vehicle, you must adapt your driving style to the actual road conditions.

The ESC and TC status are indicated by the “ESC” and “ESC OFF” indicators. The warning lights light up yellow when the ignition is turned on and go out after the engine starts (self-test mode). Triggering of ESC and TC is accompanied by flashing of the “ESC” indicator. When the functions are disabled using the “ESC” switch, the “ESC OFF” indicator lights up with a constant light.

Attention ! In all other cases, the lighting of the “ESC” indicator indicates a malfunction of the ESC and TC, which must be repaired only by dealers.

Attention ! To avoid limiting the performance of ABS, EBD, ESC and TC, do not install tires of different sizes on the vehicle.

How the vehicle's stability control system works is also shown in the video:

Signs of ABS malfunction

The first sign of a system failure is an indicator on the dashboard. When the sensor does not go off within 6-10 seconds or turns on while driving, the system is faulty and is not functioning properly. It is important to know that module failure cannot be detected only when the vehicle is stationary; some failures can only be recognized when driving at speeds of 25 km/h. Before you start looking for problems, remember if you have changed the tires on your wheels. Since often, in order to save money, many install studded tires in winter only on the drive wheels. And since the diameter increases slightly, the wheels begin to rotate at different speeds, which causes the system to blink. In addition, there are cases when the sensor lights up during slipping, but, as a rule, in both cases the indicator does not light up for long or flickers from time to time.

HHC function

Prevents the car from rolling away when starting on an incline. When stopping on an incline greater than 4%, depress the brake pedal with sufficient force to keep the vehicle stationary. When you subsequently release the brake pedal and press the accelerator pedal, the HHC function maintains hydraulic pressure in the brakes until the vehicle starts, but for no more than 2 seconds, which prevents the vehicle from rolling away.

The operation of the HHC is accompanied by a characteristic noise of the actuators. HHC does not operate when the parking brake is applied, the driver's door is open, or the ESC malfunctions.

Let us remind you that other reviews of Lada cars can be found in this category.

Source

Braking system design Grants

Before you start adjusting and checking, you should find out what the Lada brake system is like and what its features are. The design includes the following parts:

To ensure efficient and safe braking, Grant has a double-circuit (diagonal) pipeline system. The tasks of the first circuit include blocking the left rear and right front wheels. The second circuit is designed to block the left front and right rear wheels. The front wheels have disc brakes, and the rear wheels have drum brakes.

The process of controlling the master cylinder on the Lada Granta is carried out using a vacuum amplifier. This device is designed to improve controllability of the brake system. To do this, you need to press the appropriate pedal. It is necessary to take into account that an anti-lock braking system may be included in the Lada Granta, or ABS will be absent. The Lada Granta system under consideration is equipped with a hand brake that blocks the rear wheels by spreading the corresponding pads in the drums. These parts are moved through levers and by moving a steel cable located inside the vehicle.

The vacuum amplifier is a diaphragm. This element shares the rarefied atmosphere of the vacuum booster with external pressure. The pressure difference helps to reduce the effort exerted on the corresponding pedals. When the brakes are released, the atmospheric and vacuum chambers are connected to each other using a special valve.

ABS brake bleeding process

In order to efficiently complete the task, it is advisable to carry out bleeding with an assistant, starting with pumping the brake system from the front wheels, then the rear wheels (right and left).

Pressure is released by discharging the pressure accumulator. To do this, turn off the ignition and press the brake pedal about 20 times. And then to proceed to the next stage of bleeding the brakes, disconnect the connectors on the brake fluid reservoir.

General principle of how to bleed ABS brakes

Sequence of removing air from the vehicle

We start pumping the brakes from the front right , and then the left. The procedure takes place with the ignition turned off (position at “0”) and the terminal on the TJ tank removed.

The rear wheels are pumped with the ignition on in key position “2”.

To properly bleed the ABS brakes on the rear left wheel, the sequence of actions needs to be slightly changed.

Connector for hydraulic unit ABS 2190, 21901 with wires

Dear customers, in order to avoid errors when sending connector 1928405167R for the ABS hydraulic unit 2190, 21901 of a new type with wires, in the “Comment” line indicate for which ABS unit, your car model, year of manufacture.

Contact carrier 1928405167R with wires for connection to the ABS control unit (hydraulic unit) 21900-3538010-00 / 21901-3538010-01 is used in Lala Kalina, Priora, Granta cars and their modifications and for flashing control units. Can be used to make your own firmware cable for an ABS unit or another. The contacts are already crimped onto the wires (wire length 100 mm) and inserted into the connector according to the pinout sufficient for programming the ABS unit. Can be installed on a car.

Hydraulic unit (ABS) ABS 2190/21901 Bosch for cars with manual transmission and automatic transmission, is most often replaced by the following terms: stability control unit, ABS control unit, ABS brake hydraulic unit unit, anti-lock brake system unit. Therefore, if you hear these terms, then know that we are talking about the same thing.

If you brake hard on a slippery road, problems may arise. The anti-lock braking system (ABS) takes over this action and saves your nerves.

Bosch unit 21901 is part of the vehicle's stability control system with automatic transmission. Structurally, it consists of an electronic control unit (ECU 0 265 242 344), a hydraulic modulator and containing electromagnetic valves (EMV), a return pump and a return pump electric motor (ERM).

Based on received commands, the hydraulic modulator, by turning on or off the solenoid valves, reduces, increases or permanently fixes the pressure of the brake fluid in the wheel brake cylinders, thereby ensuring the best adjustment of the braking forces. When the pressure decreases, excess brake fluid is pumped by the return pump into the main brake cylinder.

The anti-lock braking system (ABS) is part of the vehicle's working braking system and is designed to mechanically regulate the degree of wheel slip in the direction of their rotation during braking due to the metamorphosis of brake fluid pressure in the working brake cylinders with the intention of preventing loss of control and stability of the vehicle and increasing braking performance.

The ABS control unit 2190/21901 continuously checks the locking of each wheel and controls each valve to regulate the brake fluid pressure if required.

The ABS control unit 2190/21901 also checks that the components are working properly and turns off the ABS if a fault is detected.

If the ABS control unit 2190/21901 is faulty, the brake system operates as a standard brake system.

Other article numbers of the product and its analogues in catalogues: 1928405167R.

Applicability: VAZ 2170, VAZ 2192, VAZ 2194, VAZ 21925, VAZ 2190.

How problems with the ABS hydraulic unit manifest themselves in a VAZ family car.

How to independently replace the ABS hydraulic unit on a VAZ family car.

When dismantling the hydraulic unit and pipelines, take measures to prevent brake fluid from spilling.

With the online store Discounter AvtoAzbuka, repair costs will be minimal.

Don't forget to share the information you find with your friends and acquaintances, because they may also need it - just click one of the social networking buttons located above.

Is it possible to repair the ABS sensor?

The question of whether it is possible to repair this sensor is difficult to answer unequivocally; it increasingly depends on the degree of its damage and malfunction. If it’s all about simple damage to the wiring, then solving the problem will not be difficult. If the damage is more global, the core or winding is damaged, then most likely repairing such a sensor will simply not be possible and will require a complete replacement. Despite the fact that 99% of experts recommend replacing the sensor if it malfunctions or has problems with the winding, there are those who successfully restore these sensors at home using improvised means. You can find out more about this repair in the video below.

This video clearly demonstrates how to repair an ABS sensor at home.

That's all for me. Thank you for your attention, I hope you found it interesting and were able to learn something new for yourself. I look forward to your comments on this topic, perhaps you have encountered such a problem or managed to solve it. Until next time, bye.

ABS sensors play an important role in the operation of the car's braking system - the braking efficiency and uninterrupted operation of the unit as a whole depend on them. The sensor elements send data about the degree of rotation of the wheels to the control unit, and it analyzes the incoming information, building the desired algorithm of actions. But what to do if you have doubts about the serviceability of the devices?

Replacing brake fluid

To complete the work, you will need an assistant, as well as a rubber bulb.

1. We prepare the car and the necessary equipment to perform the work.

2. Remove the tank cover

To prevent air from entering the hydraulic drive of the brake system, when replacing the brake fluid, make sure that its level in the reservoir does not fall below the MIN mark.

3. Use a blower to remove the working fluid from the master brake cylinder reservoir.

4. Fill the tank with new fluid up to the top edge of the tank.

5. We pump the circuits of the hydraulic drive system, starting with the rear wheels of the car.

6. We pump each wheel cylinder until new (lighter) brake fluid begins to emerge from the fitting.

7. After replacing the fluid in both circuits, we check the operation of the hydraulic drive and bring the fluid level in the master brake cylinder reservoir to normal.

Handbrake diagnostics

As you know, any repair begins with diagnostics. We figured out how the handbrake indicator works. Now you should lower and raise the handbrake several times. If the handbrake light is constantly on, without reacting in any way to these actions, you need to look for the reason for this behavior of the LED in the form of an exclamation mark.

First, check the fluid level in the hydraulic brake system. This is quite simple to do, and if necessary, everyone can add liquid to the expansion tank.