If the ignition coil on a VAZ 2107 fails, you will not be able to start the car. The only thing left for the driver in such a situation is to ask passing drivers to tow the car or call a tow truck. And once he gets to the garage, the driver can replace the ignition coil himself. Let's figure out how this is done.

- Ignition coil design

Types of ignition coils - Location and connection diagram

- Video: faulty ignition coil

- Test sequence

- Coil replacement sequence

Connection diagram for VAZ 2107 switch

The contactless ignition system of the VAZ 2107 includes:

- Candles.

- Ignition distributor (sensor).

- Anti-interference screen.

- Non-contact slider position sensor.

- Switch that controls spark generation.

- Ignition coil.

- Assembly block.

- Ignition switch relay.

- Ignition switch on the steering column.

Wire “A” goes to the positive terminal of the car generator output. The connection diagram for the VAZ 2107 switch is shown in the figure:

Signs of a malfunction of the VAZ 2107 switch

The main symptom of a switch failure is the absence of a spark at the spark plugs. Alternatively, the spark may not be powerful enough or disappear periodically. In this case, the engine starts poorly, runs intermittently, stalls at idle, loses power, or its speed constantly fluctuates. It should be remembered that all these signs can also appear due to malfunctions of other parts of the ignition system: the Hall sensor. wires and spark plugs, ignition coil, distributor. The spark also disappears when the timing belt breaks and there is no contact in the power supply circuit of the ignition system. To accurately determine the cause, it is necessary to separately check the functionality of the switch.

Egnition lock

Removing the “seven” lock

The ignition system on the domestic seven includes two main components - a coil and a module. The lock, in turn, consists of several parts - the switching mechanism itself, as well as the contact circuit. Each of these components is independent in its design, so if one of them breaks, it can be replaced without completely changing the lock. As for repairs, the VAZ 2107 ignition module can be repaired at home if you have all the necessary tools and an idea of how this procedure is performed.

On a carburetor or injector, the functionality of the lock can be determined using a special tester - a multimeter. To check contact ignition, the multimeter probes should be connected to the outputs on the lock one by one, and the output should correspond to one or another position of the key. If the contact group is operational, the multimeter will display a resistance that tends to zero. If the resulting indicator is different, this indicates the need to repair the contact group or replace it. In some cases, such parameters may be due to oxidation or burnt contacts, which can be corrected without replacing the group.

Types of ignition systems VAZ 2107

The evolution of the VAZ 2107 has transformed the ignition system of this car from an unreliable mechanical design into a modern computer-controlled electronic system. Changes occurred in three main stages.

Contact ignition of carburetor engines

The first modifications of the VAZ 2107 were equipped with a contact-type ignition system. This system worked as follows. The voltage from the battery was supplied through the ignition switch to a transformer (coil), where it increased several thousand times, and then to a distributor, which distributed it among the spark plugs. Since voltage was pulsed to the spark plugs, a mechanical breaker located in the distributor housing was used to close and open the circuit. The breaker was subjected to constant mechanical and electrical stress, and it often had to be adjusted by setting the gaps between the contacts. The contact group of the device had a short resource, so it had to be changed every 20–30 thousand kilometers. However, despite the unreliability of the design, cars with this type of ignition can still be found today.

The contact ignition system requires adjustment of the gap between the breaker contacts

Contactless ignition of carburetor engines

Since the beginning of the 90s, a contactless ignition system was installed on carburetor VAZ 2107, where the breaker was replaced with a Hall sensor and an electronic switch. The sensor is located inside the ignition distributor housing. It reacts to the rotation of the crankshaft and sends a corresponding signal to the switching unit. The latter, based on the data received, supplies (interrupts the supply) voltage from the battery to the coil. Then the voltage returns to the distributor, is distributed and goes to the spark plugs.

In the contactless ignition system, the mechanical breaker is replaced by an electronic switch

Contactless ignition of injection engines

The latest VAZ 2107 models are equipped with electronically controlled injection engines. The ignition system in this case does not provide any mechanical devices at all, not even a distributor. In addition, there is no coil or commutator as such. The functions of all these components are performed by one device - the ignition module.

The operation of the module, as well as the operation of the entire engine, is controlled by the controller. The principle of operation of such an ignition system is as follows: the controller supplies voltage to the module. The latter converts the voltage and distributes it among the cylinders.

When should you turn on the ignition?

The first thing you should know is that there are no regulations for this operation, since the ignition timing is set or adjusted only if necessary. It may be caused by the following reasons:

- You recently purchased a “Seven” on the secondary market and are trying to “bring it to mind.”

- After engine repair, accompanied by its disassembly.

- After unscrewing or removing the main ignition distributor (distributor), regardless of the reason why this was done.

- When switching from high-octane fuel to gasoline with a lower octane number and vice versa.

- After replacing the contact group or bearing in the distributor (in cars with an old ignition system).

- mechanical with contacts. switches;

- contactless;

- controlled by an electronic unit (ECU).

Note. On VAZ 2107 vehicles equipped with an electronically controlled injector, the reason for checking the spark generation system may be the flashing of the Check Engine display on the instrument panel. True, it behaves in a similar way when a dozen more malfunctions occur. So ignition problems must first be diagnosed by contacting a service station.

In the vast majority of cases, the sparking moment is set as a result of a violation of the settings after disassembling or repairing the engine. A separate issue is the transition to high-octane gasoline, which requires ignition with greater advance, for which adjustments are being made.

It is advisable to check the timely formation of a discharge on the electrodes of the spark plugs in cases where unstable engine operation is observed, popping noises are heard in the carburetor and exhaust pipe, accompanied by an increase in fuel consumption. If you have not yet discovered the “gluttony” of the car, then pay attention to the color of the smoke; with high gasoline consumption, it is black, as is the carbon deposits on the electrodes of the spark plugs.

Types of systems

For decades, until the release of the VAZ 2107 (from 1982 to 2012), it was equipped with three types of ignition systems:

The note. The first 2 grades were placed on the “seven” of the carburetor, the latter is represented by an injector.

In the mechanical embodiment, the contacts opened by the camshaft cam open the low voltage circuit, initiating the formation of a powerful pulse in the secondary coil winding. This discharge is directed to the fuel spark plug electrodes in the cylinder, where the piston rises to top dead center (TDC) and the compression stroke is completed.

The contactless circuit works on the same principle, only the Hall sensor signals an open circuit, and its switch implements this. Therefore, the ignition settings on the “seven” carburetor are almost identical. One more thing. These are nozzle machines that have a new system that not only has the contacts, but also the distributor and any moving parts. Here, the spark torque is determined by the ECU controller by focusing on the signals from different sensors.

Distributor

The ignition distributor (distributor) is designed to transmit high-voltage current pulses that come from the coil to the spark plugs. The distributor consists of:

- aluminum body;

- shaft;

- Hall sensor;

- vacuum and centrifugal ignition timing regulators;

- runner;

- covers with four fixed contacts.

In “sevens” with contactless ignition, distributors of type 38.3706 are used.

A Hall sensor is installed on the distributor 38.3706

Table: technical characteristics of distributor type 38.3706

| Characteristics | Indicators |

| Supply voltage, V | 12 |

| Permissible speed, rpm | 3500 |

| Switching on the centrifugal regulator at, rpm | 400 |

| Maximum angle of the centrifugal regulator, o | 15,5 |

| Turn on the vacuum regulator at, mm. Hg Art. | 85 |

| Maximum angle of the vacuum regulator, o | 6 |

| Operating temperature range, oС | -40 — +100 |

| Weight, kg | 1,05 |

Where is the distributor located in the VAZ 2107

The ignition distributor is mounted on the left side of the engine cylinder block. Its shaft is driven by the auxiliary drive gear. The number of revolutions of the distributor shaft directly depends on the speed of rotation of the crankshaft.

The distributor is located on the left side of the cylinder block

Malfunctions of the VAZ 2107 distributor and their symptoms

The most common breakdowns of the “seven” distributor include:

- burning of the fixed contacts of the cover;

- mechanical damage or electrical breakdown of the cover;

- burning of the runner.

As for the symptoms, for the listed problems they will be similar:

- unstable engine operation;

- reduction in power characteristics of the power plant;

- increased fuel consumption.

To diagnose major distributor failures, it does not need to be removed from the engine. It is enough to disconnect the high-voltage wires from the cover and unfasten the two latches that secure it to the body. By removing the cover and inspecting the contacts with the slider, you can visually assess their condition and draw a conclusion about how suitable they are for further work. If the contacts cannot be cleaned, the device cover must be replaced. Such a part costs about 200 rubles. The runner will cost half as much.

The distributor cover is attached to its body using two latches

Contactless (electronic) ignition, carburetor

Many car owners are switching to a more accurate (electronic) type of ignition. To adjust the device yourself, you need to have skills in working with the electrical part of a car. If you do not have sufficient knowledge, entrust the work to experienced specialists.

Prepare the instrument for tuning. You will need keys (for “eight”, “ten” and “thirteen”), a Phillips screwdriver, a drill and a pair of self-tapping screws.

Pre-install the contactless system itself, consisting of the following elements:

- Trambler. Start by replacing the distributor by lifting the cover of the latter (this is how you gain access to the “slider”). Place the slider in a position that can be easily adjusted during installation. It is desirable that the notch be on the block opposite the middle mark of the device scale.

Use a “thirteen” wrench to tighten the fastening nut, and then dismantle the assembly. Now disconnect the central wire connecting the coil and the distributor. Mount the non-contact type sensor and adjust the slider taking into account the previously made mark. Align the distributor body along the notches. Replace the cover and return the wires to their place.

- Coil. In the next step, move on to the ignition coil. Take the eight key and twist the wires that are connected to the device. Now use the key to “ten” to push the assembly away from the car body.

Install the new coil taking into account the position of contacts “B” and “K”.

Fix the coil and connect the discarded and new wires to the contact group. Pay attention to the colors of the latter (as a rule, they are identical for the old and new devices). Connect the brown wire to terminal “K” and the blue wire to “B”. Now connect the center wire.

- Switch. Start by choosing a location for this node. In the "seven" the best point for installation is between the headlight on the left side and the washer. In this area there is a flat area on which the device is placed. To begin, lean the switch and mark the mounting locations. After this, screw in the screws. Do not rush to tighten the second fastener - place a black wire under it.

As soon as the described work is completed, check the quality of the connection of the wiring elements and start the engine. The next stage is installing the ignition of the VAZ-2107, which will be discussed below.

Instructions for setting the ignition

If you strictly followed the instructions, connected all the wires according to the diagram and did not misalign the marks, then the motor will start without problems. To adjust the ignition, you need to ensure stable engine operation, so first warm it up for a few minutes, without letting it stall by pressing the gas pedal.

Adjustments can be made on a warm engine using two methods:

- without the use of special devices - “by ear”;

- fine adjustment using a strobe light.

A strobe is a device with a light bulb that flashes simultaneously with the transmission of a pulse by the Hall sensor. When the switched on strobe is brought to the crankshaft flywheel with the engine running, the position of the notch becomes visible. Hence the possibility of precise adjustment.

This is what a strobe looks like for fine-tuning the ignition

To set up, connect the strobe power supply to the battery, and the thick wire to the high-voltage wire of the spark plug of the 1st cylinder. Loosen the distributor fastening nut and bring the flashing lamp to the pulley. Slowly turn the distributor body until the notch on the pulley aligns with the short notch, then tighten the nut.

Tuning in the traditional way “by ear” is done like this:

- Start the engine and loosen the nut holding the ignition distributor.

- Rotate the distributor smoothly and slowly within 15°. Find the position at which the motor operates most stably.

- Tighten the fastening nut.

When adjusting, turn the distributor by the membrane body

It is quite natural that after installing a contactless ignition system, the engine idle speed will increase to 1100-1200 rpm due to the increased spark power. Set the rate to 850-900 rpm by tightening the idle screw on the carburetor and using the tachometer as a guide. On VAZ 2105-2107 carburetors of the “Ozone” type, this screw is located in the lower section of the unit on the right side and is large in size. The VAZ 2108 carburetors of the Solex type (these were also installed on the “seven”) have a long plastic handle protruding from the right (in the direction of travel). The second screw, which regulates the composition of the air-fuel mixture, cannot be turned.

The arrow shows the idle speed adjustment screw.

Ignition adjustment in static position:

- Find a strobe light. If this is not the case, do the work by ear.

- Loosen the nut holding the ignition coil.

- Start the engine and warm it up.

- Rotate the distributor housing left and right.

- Command your assistant to watch the speed (they should be at 2000 rpm).

- Listen to the engine noise. Try to catch the moments when there are “dips” or changes in rotation speed.

- Achieve a situation where the engine runs smoothly and produces the highest speed. In this case, the work should be as rhythmic as possible.

- Tighten the distributor nut and operate the car.

Setting the ignition timing of the VAZ-2107 in motion:

- Warm up the engine to a temperature of 80-95 degrees Celsius.

- Accelerate to a speed of 40-45 km/h, then move the gearbox selector to the fourth speed position.

- Step on the gas and listen to the engine. If the ignition is set correctly, detonation appears, and after a while the engine speed increases. If you hear a clear knocking of the valves, turn the distributor as the clock hand rotates by about 1-1.5 degrees.

- Perform the manipulations described above until the extraneous sound disappears completely.

- If the speed decreases sharply after pressing the gas, turn the distributor to the same angle, but in the opposite direction.

Remember that adjusting the advance angle may not be enough - often the carburetor itself needs to be adjusted. To do this, find a couple of screws. With one of them you regulate quality, and with the other you regulate quantity. Also clean the carburetor from time to time.

As can be seen from the described technique, setting up electronic ignition on the “seven” is not difficult. At the same time, you can count on serious savings, because at the service station this service will cost a considerable amount.

How to carry out repairs

If a breakdown is detected, the damaged coil must be removed. To complete the work you will need a set of wrenches.

Removing the module

To remove a faulty unit, you will need:

- Disconnect the battery from the on-board network and remove the air filter housing.

- Disconnect the high-voltage cables and wiring harness.

- Remove the 3 nuts that hold the assembly to the mounting pad.

Replacement features

You can install the coil without using a special tool. The ignition system of injection engines does not require any adjustments. The throttle position is adjusted in idle and maximum gas modes. In case of malfunctions, it is necessary to check and align the crankshaft position sensor to the marks on the drive pulley of external units.

https://youtube.com/watch?v=h-b_85f0QMI

Carrying out repairs

The module is repaired if it is not possible to buy a new product. The lower part of the case is opened, and then the damaged tracks are restored. It is impossible to repair the coils in artisanal conditions; the parts are not supplied to the spare parts market. To perform installation work, soldering equipment and skills in working with equipment are required. Rebuilding ignition coils is not recommended.

REPLACING THE DEVICE

If the indicators do not correspond to the above values, the ignition coil is considered faulty. Such a device must be replaced with a working one, which can be purchased at almost any spare parts store. When purchasing the device, you must inspect it and check the availability of documents: technical passport and certificate.

Removing the ignition coil on a VAZ2107 car is carried out with the battery disconnected. Use a wrench to unscrew the nuts on the contact and mounting studs. The faulty device is removed. A spare part is installed in its place and secured and connected. Now you can connect the battery and start the engine.

Sources

- 7vaz.ru/remont/diagnostika-i-zamena-katushki-zazhiganiya.html

- autocentrum.ru/brands/lada/17209-obzor-sistemy-zazhiganiya-vaz-2107-katushki-i-drugih-elementov-posobie-po-vystavleniyu.html

- drive2.ru/l/487397562748240344/

- 21074.ru/elektrooborudovanie/kak-proverit-modul-zazhiganija-vaz-2107-inzhektor-multimetrom/

- bumper.guru/klassicheskie-modeli-vaz/elektrooborudovanie/zazhiganie/zazhiganie-2107/katushka-zazhiganiya-vaz-2107.html

The process of replacing spark plugs

Required tools and materials:

- Spark plug head 16 mm;

- Spark plug head 21 mm;

- Candle tube;

- Clean rags.

Step-by-step instructions for replacing spark plugs in a Chevrolet Niva:

- Open the hood of the vehicle.

- Remove high voltage wiring. If necessary, take a photo or note the sequence of wire installation.

- Using a feeler gauge, check the gap between the spark plug electrodes.

- Check the gap of the new spark plugs.

- Screw the new parts back in with a torque of 31-39 Nm (the order in which the spark plugs are installed does not matter).

- Install the ignition wires in the same sequence as removal.

The procedure for replacing spark plugs on a Chevrolet Niva has been completed.

About the drive mechanism

To transmit torque to the distributor shaft on the “six”, a helical gear is used, rotated by a timing chain (in common parlance – “hog”). Since the element is located horizontally and the distributor roller is vertical, there is an intermediary between them - the so-called fungus with oblique teeth and internal slots. This gear simultaneously turns 2 shafts - the oil pump and the distributor.

The distributor drive consists of two transmission gears with oblique teeth

Both transmission links - the “hog” and the “fungus” - are designed for a long service life and are replaced during engine overhauls. The first part is removed after disassembling the timing chain drive, the second is pulled out through the upper hole in the cylinder block.

The VAZ 2106 distributor, equipped with a contact breaker, is a rather complex unit consisting of many small parts. Hence the unreliability of operation and constant failures of the spark generation system. The non-contact version of the distributor creates problems much less frequently, but in terms of performance characteristics it still falls short of modern ignition modules, which have no moving parts.

Repair

Ignition module VAZ 2107

The design of the ignition module is quite complex: it includes one or more coils, a board, contacts and wires. Of all the above elements, only contact connections can be repaired; in some cases, replacement of parts (transistors, coils) is possible.

The module is dismantled and opened for repair purposes. For this you will need:

- Socket wrenches with heads 1, 13 and 17.

- Hexagon 5.

- Screwdriver.

- Soldering iron.

- Flux for aluminum.

- Stranded wire.

- Nail polish.

Opening the ignition module

Repair of the ignition module is carried out in the following order:

- On the removed device, open the case by prying it off with a screwdriver.

- Remove the silicone film covering the board.

- All aluminum is removed from the explosive contacts.

- On the board, new wires are soldered in place of all the dismantled old ones. To do this, the surface of the collector is cleaned of deposits, after which the board is heated to 180°C (a characteristic smell will indicate when the desired temperature has been reached). During the soldering process, the ends of the wires are connected to the module.

- At the end of the operation, all contacts, the board and the module are covered with nail polish.

- The device is assembled in the reverse order, installed on the car and the engine is started. In case of normal operation, the ignition module is sealed tightly with sealant, while the wires are tucked inside the cavity so that they are not pinched at the edges by the plate.

If the device does not work, then a breakdown inside the module should be looked for more carefully. The transistor, electronic component may have failed, or there may be a break in the coil. Such a repair makes sense only if its price is significantly lower than the cost of a new part.

Ignition module

The ignition module is a device designed to convert DC voltage from the on-board network into electronic high-voltage pulses with their subsequent distribution among the cylinders in a certain order.

In the injection VAZ 2107, the ignition module replaced the coil and switch

Design and operating principle

The design of the device includes two two-terminal ignition coils (transformers) and two high-voltage switches. The voltage supply to the primary windings of the transformer is controlled by the controller based on the information received from the sensors.

The operation of the ignition module is controlled by the controller

In the ignition system of an injection engine, voltage distribution is carried out according to the idle spark principle, which provides for the pairwise division of cylinders (1–4 and 2–3). A spark is formed simultaneously in two cylinders - in the cylinder in which the compression stroke is coming to an end (working spark), and in the cylinder where the exhaust stroke begins (idle spark). In the first cylinder, the fuel-air mixture ignites, but in the fourth, where the gases burn out, nothing happens. After turning the crankshaft half a turn (180), the second pair of cylinders enters the process. Since the controller receives information about the exact position of the crankshaft from a special sensor, problems with sparking and its order do not arise.

Location of the ignition module VAZ 2107

The ignition module is located on the front side of the cylinder block above the oil filter. It is secured to a specially designed metal bracket using four screws. It can be identified by the high-voltage wires coming out of the housing.

The ignition module is located on the front of the cylinder block above the oil filter

Factory designations and characteristics

VAZ 2107 ignition modules have catalog number 2111–3705010. As an alternative, consider products numbered 2112–3705010, 55.3705, 042.3705, 46.01. 3705, 21.12370–5010

They all have approximately the same characteristics, but when purchasing a module you should pay attention to the engine size for which it is intended

Table: technical characteristics of the ignition module 2111–3705010

| Name | Index |

| Length, mm | 110 |

| Width, mm | 117 |

| Height, mm | 70 |

| Weight, g | 1320 |

| Rated voltage, V | 12 |

| Primary winding current, A | 6,4 |

| Secondary winding voltage, V | 28000 |

| Duration of spark discharge, ms (not less) | 1,5 |

| Spark discharge energy, MJ (not less) | 50 |

| Operating temperature range, C | from -40 to + 130 |

| Approximate price, rub. (depending on manufacturer) | 600–1000 |

Purpose and characteristics

Coil 2111-3705010 is intended for:

- formation of high-voltage pulses;

- distribution of signals between the spark plugs in accordance with the firing order of the cylinders.

Main technical parameters of the unit:

- operating voltage – 12 V;

- current in the primary circuit – 6.4 A;

- voltage in the secondary circuit – 28 kV;

- spark duration – at least 1.5 ms;

- discharge energy – 50 MJ.

Read, it may be useful: Links to electrical circuit diagrams.

Checking the ignition coil

The coil is checked based on two indicators: the presence of a short circuit and an open circuit. Before diagnostics, the ignition coil must be disconnected. After this, one probe of the device is connected to the central contact of the coil, the second to the body (ground). If the display shows resistance equal to infinity, there is no short circuit.

The primary winding of the coil for a break occurs differently. The probes of the device must be connected to the right and left contacts. The resistance between them should be within 3-3.5 Ohms.

If the resistance of the primary winding does not correspond to the norm or there is a short circuit in the coil to the housing, it must be replaced.

Procedure for checking ignition system devices

The main reason for the failure of this device is a wire break in the primary or secondary winding. This ignition system device is checked using a multimeter set to resistance measurement mode. The operation can be performed either directly on the car or after it has been dismantled.

Open the hood of the VAZ2107 car and disconnect the battery. The coil installed on the mudguard in the engine compartment is disconnected from the on-board network and cleaned of contaminants. At the first stage, we check the resistance in the primary winding; its value should be in the range from 3.0 to 3.5 Ohms. We perform the same operation for the secondary winding, acceptable values are from 7.4 to 9.2 kOhm.

How to check the ignition of a VAZ 2106 with a multimeter

In order to check the coil with a multimeter, we need the multimeter itself and, of course, the ignition coil itself. take a multimeter and set it to 200-ohm, then check the terminals (B - K), the resistance should be at least in the range of 04.0-ohm, the resistance range is from 03.8 to 04.5-ohm, this is the norm; there’s clearly something wrong with the coil; now we need to check the high-voltage part; we set it measurement mode 20-klom 1 any probe on mark B or K another on the high-voltage contact resistance 7.6 klom 7 to 8 klom this is the norm This means your coil is intact, but also do not forget that there may be an internal breakdown of the coil, that is, a breakdown of the insulation between the high-voltage and low-voltage winding and also the interturn one, and you also need to check the case, that is, also at 20 kL, we leave the relative mass for each contact, we check because we came across coils, so we check everything is fine on the case, it breaks through, and if there are no short circuits between the winding and interturn circuits, then it will function.

Pros and cons of contactless ignition

At the moment, 100% of manufactured cars using gasoline or liquefied gas as fuel are equipped with an electronically controlled spark generation system. Mechanical ignition is outdated and a thing of the past. The reason is its unreliability during operation, frequent malfunctions and low spark power. Compared to the BSZ contact system, it has the following advantages:

- There are no contacts whose surfaces constantly burn from high voltage, causing the sparking power to drop sharply.

- The distributor of the electronic system has no wearing parts, which had to be changed every 15-20 thousand kilometers.

- Thanks to the contactless circuit and the new coil design, the voltage supplied to the electrodes of the spark plugs was raised from 18 to 24 kV. This had a beneficial effect on the ignition and combustion of the air-fuel mixture in the cylinders.

- Reliable operation and durability.

Powerful spark from contactless ignition

Reference. In past times, the owners of the VAZ “classic” quite often had to remove a protrusion that had burned on the surface of one of the contacts, which required a flat needle file. But a depression formed on the second contact, which was quite difficult to clean out, so manufacturers began to make contact groups with through holes.

Among the significant disadvantages of the BSZ, one can be noted - the non-repairability of the Hall sensor. If the mechanical contacts are cleaned, then the faulty sensor only needs to be replaced, so it is advisable to carry it with you. On the other hand, this device is very reliable in operation and lasts 40-50 thousand km without problems.

This is what a Hall sensor looks like, replacing the contacts

Reference. Owners of VAZ 2107 cars equipped with the first BSZ sets, in addition to the Hall sensor, also had to carry a spare switch. But after 2 years, its design underwent modernization, which is why the electronic units no longer fail.

About their device

Before finding out the importance of the elements of the ignition system in question, it is necessary to understand their structure. Structurally, the high-voltage wire consists of the following parts:

- A conductor through which current flows.

- Insulation - rubber or silicone is used as an insulating material.

- Protective caps on both ends.

- Metal contacts.

Each element performs corresponding tasks, and at the slightest violation of integrity, it will be necessary to replace it. Armored wires cannot be repaired, since they play one of the main roles in the car’s ignition system, and also belong to the category of consumables.

To distributor or MZ

It is a mistaken belief that armored wires on a car are ordinary wires that are designed to transmit current from a source to a receiver. As you know, VAZ 2107 cars were produced in two variations of the fuel supply system - carburetor and injector. Although many parts and mechanisms on the carburetor and injector are the same, this does not apply to the GDP. The carburetor VVP differs from the injection one on the VAZ 2107 in the following parameters:

- The length, on which the amount of resistance also depends. The wires on the injection unit are shorter than on the carburetor.

- Fasteners that connect to the distributor on the carburetor and the ignition module on the injector.

- The amount of GDP. There are four of them on the injector, and five on the carburetor.

- Type of caps.

Knowing the design differences, you must also understand that high voltage flows through the wire. The current comes from the distributor or MG through the wires to the spark plugs. The slightest malfunctions lead to the fact that current is not supplied to the spark plug, and a spark does not occur. If a spark does not occur, the cylinder does not work, which negatively affects the operation of the engine.

Lost spark in carburetor seven

The search for a breakdown in the form of a lack of spark should begin directly with an inspection of the high-voltage cables, coil and distributor. The cause of the malfunction may be an armored wire whose contact has moved away from the distributor or spark plug. If the high-voltage wire is working properly, then you need to resort to checking for the presence of a spark in the spark plug.

To check the presence of a spark in the spark plug, you need to unscrew it from the cylinder and place it on the engine, connecting it to the armor wire. After this, one person should try to start the engine by turning the starter, and the second should observe the presence or absence of sparking. The presence or absence of a spark can indicate malfunctions:

- If a spark is present, this indicates a malfunction in the spark plugs, high-voltage wires or distributor distributor.

- The absence of a spark means that the breakdown has occurred in the switch, ignition coil or Hall sensor.

After such an easy test, you can understand in which direction to look for a breakdown. To identify a breakdown, you should check each part listed above.

We identify the reasons for the disappearance of the spark

If there is no spark on a carburetor VAZ 2107 with contactless ignition, then the cause of the breakdown can be identified independently by checking every part of the car’s ignition system. How to check each element of the ignition system, we will consider further:

- If the coil fails, to check it, you need to measure the resistance of the windings and insulation. To do this, you will need to use a multimeter, setting it to resistance measurement mode. Depending on what type of coils is used, the resistance value will differ. Initially, you need to set the multimeter to the 200 Ohm measurement mode, and touch the “+” and “K” contacts with the probes. The device should show a value ranging from 0.2 to 3 ohms. At the next stage, you need to turn the multimeter into the 20 kOhm resistance measurement mode. One probe touches the “K” contact, and the second one needs to touch the central terminal to which the high-voltage wire is connected. The resistance value that the device should show is 2-4 kOhm. If it is not possible to check the coil with a device, then you must use a known good one.

- If the switch is faulty, you will need an oscilloscope to check it. However, not everyone has such devices, so the easiest way to check is to install a known-good device. There is a simple test method by which you can determine whether this device is working properly. To check, the following manipulations are performed: disconnect the wire from the ignition coil that is from the switch, and then connect it to a 12V lamp. The second end from the lamp should be connected to the ignition coil terminal. After this, you need to try to start the engine. The lamp should blink. If it does not blink, the device is faulty.

- Hall sensor malfunction. Using a voltmeter, you need to check the serviceability of the sensor. To avoid removing the sensor, we check it in the following way - using pins, we pierce the insulation of the green and white-black wires with them. After this, touch the pins with the probes of the multimeter, setting the voltage measurement mode. The crankshaft rotates, and at the same time we monitor the readings of the device. The readings should drop to 0.4V and rise to 9-12V. Such readings mean that the sensor is working.

- If the low voltage circuit is broken, it is necessary to check the integrity of the supply wires for insulation damage. To determine the presence of a break in the supply wires, you need to use a multimeter in continuity mode.

Product delivery options

Note! Below are the shipping methods available specifically for this product. Payment options may vary depending on the delivery method.

Detailed information can be found on the “Delivery and Payment” page.

Parcel by Russian Post

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 5 to 12 days.

Parcel by Russian Post 1st class

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 2 to 5 days. More expensive than regular delivery by Russian Post, approximately 50%. Parcel weight up to 2.5 kg

Express Parcel EMS

Available payment methods:

- Cash on delivery (payment upon receipt)

- Using cards Sberbank, VTB, Post Bank, Tinkoff

- Yandex money

- QIWI

- ROBOKASSA

Shipping throughout Russia. Delivery time is from 3 to 7 days. More expensive than regular delivery by Russian Post, approximately 100%.

Video about adjusting the ignition on a “classic” Zhiguli

The best indicator of successful installation and configuration of a contactless ignition system is checking the VAZ 2107 while driving. It’s worth driving the car for several kilometers to check it in different modes - acceleration, driving in a straight line and coasting with the gear engaged. You will probably like the behavior of the car, and the annoying cleaning of contacts will be forgotten forever.

- Author: Sergey Sergeev

Rate this article:

- 5

- 4

- 3

- 2

- 1

(18 votes, average: 4.4 out of 5)

Share with your friends!

The principle of operation of the ignition system of the VAZ 2106

Almost all classic models are traditionally equipped with a standard contact-type ignition system (KSZ). An exception is 21065, which uses a non-contact transistor circuit in which an interruption of the primary winding power circuit is realized using a breaker mounted in the distributor. Below we will consider in more detail how the contact ignition system of the VAZ-2106 is designed and works.

VAZ 2106 ignition system diagram

The design of the ignition contact circuit includes the following components:

- lock (switch);

- coil (short circuit);

- breaker (MP);

- distributor (MR);

- regulators, centrifugal and vacuum (CR and VR);

- candles (SZ);

- high-voltage wires (VP).

Let's take a look at the ignition coil and take a closer look at what it is needed for and what it is responsible for.

Disadvantages of injection models of the VAZ 2107 engine

Of course, as usual, in addition to the advantages of the injection “seven”, there are also negative aspects, which consist in the following situations:

• Problematic access to some components due to the location of the engine and other mechanisms under the hood in the same format as in older models. Although at the same time, the system providing fuel injection is reliable and does not require frequent maintenance during operation.

Photo of VAZ 2107 under the hood

• The injection VAZ 2107 is equipped with a catalyst, which is very easy to damage when driving on a bad road with large bumps and obstacles. In such cases, of course, you need to be careful when driving on problematic roads.

Photo of VAZ 2107 catalyst

• The presence of an injection engine increases the requirements for fuel quality, in contrast to the carburetor version. If you use low-quality gasoline, you cannot avoid clogging the fuel system. This leads to unplanned vehicle maintenance.

• If the injection system breaks down, it is not possible to repair it yourself in a garage. Here you only need to contact professionals at a specialized service station.

Signs of a faulty ignition coil

If, after turning the key in the ignition switch, you hear that the starter is turning, but the engine does not start, then, as a rule, this may mean that the ignition coil is not working correctly or has failed. Although there are many reasons why the engine does not start when you try to start it: spark plugs, explosive wires, problems in the fuel system (pump, fuel filter, clogged line), and so on...

But if, after all, the reason is in the ignition coil, then this can be understood by the following symptoms:

- There is no spark at the spark plugs;

- There is no current on the BB wires;

- Visual defects (cracks and chips on the reel body);

- A burning smell under the hood, which leaves traces of melting of the ignition coil (the primary or secondary winding has burned out).

The principle of operation of the VAZ 2107 injection engine

The injection system's operating methods are fundamentally different from the operating principles of the carburetor system, in which the air-fuel mixture is prepared in the carburetor chamber. In the VAZ 2107 injection engine, the fuel mixture is injected directly into the cylinders. For this, it received the name “distributed injection system”.

Injection systems are characterized by their operating principle and the presence of different numbers of injectors. The “seven” is equipped with a separate injection system with 4 nozzles. That is, injection occurs in each cylinder, which is controlled by a microcontroller of the electronic engine control unit. Using special-purpose sensors, information about the operating mode, gas pedal position and other important parameters is read. Based on this, there is a controlled flow of fuel into the cylinders.

Photo of ECU VAZ 2107

Not only the quantitative proportionality of fuel and air entering the engine combustion chamber, but also control over the creation of a spark on the spark plugs depends on the electronic control unit (ECU).

A few words about the BZS (Contactless ignition system) VAZ 2106

The coil operating as part of a contactless circuit differs in the number of turns of the primary and secondary windings. Simply put, it is more powerful than the old version, since it is designed to create pulses of 22-24 thousand volts. The predecessor supplied a maximum of 18 kV to the spark plug electrodes.

The cable with connectors is used for reliable connection of the terminals of the ignition distributor and the switch. The structure of these two elements should be considered separately.

In terms of reliability, the BSZ is significantly superior to the outdated contact ignition of the “six”; problems arise much less frequently and are easier to diagnose.

All elements of the system are connected to each other and to the engine as follows:

- The distributor shaft rotates from the motor drive gear;

- The Hall sensor installed inside the distributor is connected to the switch;

- the coil is connected by a low voltage line to the controller, a high voltage line to the central electrode of the distributor cover;

- high-voltage wires from the spark plugs are connected to the side contacts of the main distributor cap.

The threaded clamp “K” on the coil is connected to the positive contact of the ignition switch relay and terminal “4” of the switch. The second clamp marked “K” is connected to contact “1” of the controller, and the tachometer wire also comes here. Terminals “3”, “5” and “6” of the switch are used to connect a Hall sensor.

One of the effective options is to replace the standard ignition system with a non-contact ignition system (abbreviated as BSZ), where electronics are in charge of sparking

Connecting and replacing VAZ short circuit

The procedure for removing and installing the ignition coil on old VAZ models:

- First, disconnect the central high-voltage wire leading to the distributor (ignition distributor).

- Disconnect all power wires from the coil contacts. Since they are fastened with nuts, you will need an 8 wrench for this.

- If you don’t know which wires to connect to which connector later, it’s better to immediately remember or mark them somehow, so that later during installation you can connect them correctly.

- Unscrew the coil housing. It is attached to a clamp (clamp), which is pressed to the car body with two nuts.

- After the work has been done, you can remove the ignition coil and replace it if necessary.

For new type VAZ cars:

- We remove the “minus terminal” from the battery.

- Remove the top protective cover of the engine. If the engine volume is 1.5 liters, then this part is missing and this step is skipped.

- We remove the high-voltage wires from the coil.

- Now, using a 13mm wrench, unscrew the two fasteners.

- Using a 17mm wrench, loosen one bolt securing the coil.

- We take out the module.

- Use a hexagon to unscrew the coil from the holder.

- Assembly is carried out in reverse order.

Particular attention should be paid to the connection, since high-voltage wires must be located in the strict order provided for by the design. If this is not done, the car will stall or the engine may not start at all.

Replacing the ignition coil on a VAZ is quite simple. Even a novice motorist can do this in his garage, and if everything seems too complicated, contact a car service. Particular attention should be paid to the choice of product, since this will determine how well the engine and ignition system will work.

The main components of the distributor and a description of its operation

VAZ classic distributor device

Device

The distributor is assembled in a housing. Inside it, a contact group is mounted on a bearing: moving and fixed contacts or a Hall sensor (for contactless ignition). To correct the advance angle, the vacuum regulator can rotate the contact group at a small angle relative to the housing. The capacitor is attached to the bottom of the case with screws. A drive roller is mounted on bushings in the center of the body. Its bottom has splines with which it engages with the drive gear. In the upper part of the roller there are contact drive cams (for contact ignition) or a steel cup with four slots - a screen (for contactless ignition). At the very top, on a steel platform, two weights and two springs of the centrifugal ignition regulator are installed. A plastic housing with a moving contact and noise suppression resistance of the high voltage distributor (slider) is screwed onto the top with two screws. The entire structure is closed with a lid on two spring latches. The body and cover have a tongue and groove so that they fit together in only one position. The cover contains contact terminals for high voltage wires from the spark plugs and from the ignition coil. The distributor is secured to the engine block using a stud, nut and pressure washer. To adjust the ignition timing, the housing can be rotated relative to the block.

Job

The distributor is connected through the drive to the engine crankshaft and rotates with it. For two full revolutions of the crankshaft, the distributor shaft makes one revolution. This is due to the fact that our engine is four-stroke. When installing the distributor in place, the roller is oriented in strict accordance with the operating order of the engine. This is done so that the contacts open and the spark jumps on the spark plug when the piston of each cylinder, compressing the combustible mixture, does not reach top dead center (TDC) by a few millimeters. This is called ignition advance. When the number of revolutions increases, the distance must be increased, and when it decreases, it must be decreased, which is what the centrifugal regulator does. Its weights, under the influence of centrifugal force, which is greater the higher the engine speed, diverge to the sides and move the cams relative to the roller, making ignition “earlier.” When the engine speed decreases, the springs return the weights to their place and the ignition becomes “later”. This is necessary to increase engine power and efficiency. In addition to the centrifugal one, a vacuum ignition timing regulator is also installed on the distributor. Its function is to fire “earlier” at low throttle opening angles and “later” at sharp throttle opening angles. At idle and at full throttle, the vacuum seal does not work. The regulators are adjusted only at the stands, so there is no need to change the settings yourself.

What are the advantages of VAZ 2107 injection models?

• The VAZ 2107 injection engine consumes less fuel. At the same time, it is more powerful than a carburetor engine with the same volume. This is achieved through the optimal formation of the qualitative and quantitative composition of the fuel mixture. Accordingly, the efficiency of an injection engine is higher than that of a carburetor.

• Thanks to electronic speed control, the engine runs more reliably at idle, stalls less when starting, and starts well at low ambient temperatures.

• Compared to a carburetor engine, an injection engine does not require frequent adjustments to the ignition and fuel supply systems.

• The air-fuel mixture that enters the cylinders has the most favorable composition. And the existing catalyst controls the minimum amount of harmful exhaust gases. This plays a big role in preserving the environment and taking care of health.

• There is no need to manually adjust the mechanism, since this is done by the hydraulic chain tensioner and hydraulic valve clearance compensators. They also guarantee less noise (noise insulation) when the engine is running.

• Torque graphics are “smooth”, a larger rpm range allows high torque to be achieved.

WORTH NOTICE! On an engine with an injection system, it is possible to install gas-cylinder equipment not only of the 2nd, but also of the 4th generation. This is a more modern and attractive option, since the installation of the 4th generation of gas equipment provides greater savings and reduces the occurrence of “pops” in the engine to zero.

Prerequisites for failure

In situations where there is a malfunction, VAZ 2107 owners replace the spark plugs. Old factory spark plugs are usually replaced with iridium spark plugs from NGK or Denzo. Do not forget that only those spark plugs that are designed for the appropriate type of injection are suitable here.

The type of ignition system is no less important in determining the parameters of the spark plug. Often such manipulation does not provide much improvement (plugs have a fairly long service life), so the non-contact ignition system undergoes a full diagnosis.

Diagnostics of how the ignition module and each individual coil operates is carried out using a special device called a multimeter or ohmmeter. Its functional task is to show the voltage value supplied by the ignition module. As a result of diagnostics, it is possible to identify the source of current loss in the circuit and, accordingly, the nature of the malfunction. To facilitate painstaking work, it is recommended to dismantle the module outward before starting the process.

Non-contact ignition system checks for short circuits

First, pay attention to the coil winding. To get started, connect a multimeter, which determines the resistance value

There is a recommendation regarding the lubrication of the tip of a high-voltage wire: a special product for the VAZ 2107 or technical petroleum jelly is used here.

- the module is disconnected from the tips;

- one terminal of the device is connected to the central contact, which has a coil;

- the other terminal of the device is connected to ground.

The process of checking the secondary windings of the module includes:

Here we focus on an indicator whose value will be no less than 7 ohms. Recommendation: if at least one coil does not meet the specified indicator, the module as a whole must be replaced, otherwise it will not be possible to avoid a malfunction of the system with a VAZ 2107, where an injector is used.

The ignition coil of the VAZ 2107 is located in the engine compartment on the left side of the engine and is secured to the body with two nuts. The ignition coil is an independent element of the vehicle's electrical equipment that converts low voltage current into high voltage current up to 10-20 kV, which should be sufficient to break the gap on the spark plugs and sufficient to ignite the combustible mass. The coil is non-separable, which means that if it fails, it cannot be repaired and must be replaced with a new one.

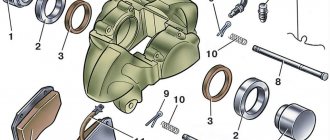

The ignition coil is a transformer consisting of an internal magnetic circuit, primary and secondary windings, as well as an external magnetic circuit connected to the ignition distributor.

To remove the coil you will need a ten and eight wrench, also disconnect the battery.

- Disconnect the central magnetic circuit from the coil.

- Unscrew the two nuts securing the power wires with a wrench.

- Using a ten-socket wrench, unscrew the two nuts securing the coil to the car body, remove the ground wire and remove the coil from the studs.

At this point, work on removing the ignition coil of the VAZ 2107 is completed. Before replacing it with a new one, you need to make sure that it is not working; for this you will need a multimeter. Before checking, thoroughly clean the primary winding leads on the coil body (two studs to which the power wires are attached) from dirt and oxides.

- First, let's check the resistance of the primary winding. To do this, connect the ohmmeter terminals to the terminals of the primary winding (two pins on the body) and take measurements. Depending on the type of coil being tested, the resistance should be: B-117A = 3-3.5 Ohm; 27.3705 = 0.45-0.5 Ohm.

- Now we check the resistance in the secondary winding circuit. To do this, we connect one ohmmeter probe to the terminal of the high-voltage wire, and leave the second at the terminal of the primary winding. The resistance should be equal: B-117A = 7.4-9.2 kOhm; 27.3705 = 5-0.5 kOhm.

At this point, the repair work on removing and checking the ignition coil of the VAZ 2107 is completed. If, after checking, deviations from the norm are found, it is recommended to replace the coil with a new one.

Sources

- https://semerkavaz.ru/ehlektrooborudovanie/zamena-i-regulirovka-modulya-zazhiganiya-na-vaz-2107/

- https://autodont.ru/system-of-ignition/rabota-s-modulem-zazhiganiya

- https://remont-vaz2106.ru/katushka-zazhiganiya-vaz-2107

Display Guide

So, we figured out where the VAZ module and ignition coil are located and what functions they perform, now let’s talk about setting them up. If the system torque is set incorrectly, this will cause increased gasoline consumption, as well as detonation of the power unit (the “fingers” will start knocking). In general, the operation of the motor will be unstable.

To set up the ignition of a VAZ 2107, you need to perform several steps, all of them are described in detail below:

- First, you need to correctly adjust the gap that exists between the interrupter device. To do this, you should dismantle its cover in advance and clean the contact surface. At the same stage, it is necessary to check the connection of the contacts - the elements must come into contact over the entire surface, and not just in certain areas. If the contacts are poorly connected, you should try to bend them slightly. You can also try sharpening the plane a little.

- Having done this, we move on to an important stage. You need to turn the crankshaft until the contacts open as much as possible. Using a feeler gauge, you need to increase the gap to approximately 0.45 mm. It should be noted that during this, the probe between the contacts should move with low resistance.

- The crankshaft rotates until the “ignition timing” mark marked on the pulley itself. Having done this, a voltmeter should be connected to the terminal of the interrupting mechanism; if it is not there, a regular test light can be used. We are talking directly about the breaker terminal, which is connected to the coil. Using a 13mm wrench, you need to slightly loosen the nut securing the breaker to the BC.

- After these steps, you need to turn the key in the lock, but do not start the engine; at the same time, the breaker body must be turned counterclockwise. When you notice that the light has gone out, you need to start turning the housing in a different direction until the light comes on again. If the control light is on, this indicates that the moment of spark transmission through the high-voltage wires has been set. Once the torque has been established, the breaker fixing nut should be tightened until it stops.

As for checking, this is easy to do. When the car is traveling at a speed of 40 km/h, you need to press the gas so that the vehicle quickly gains power. During rapid acceleration, a brief detonation should occur until the car can accelerate to 60 km/h. If this is so, then the moment was set correctly and for some time you can forget about this procedure.

Sorry, there are no surveys available at this time.

Troubleshooting

The first sign of loss of vacuum booster seal is not deterioration of the brakes, as many sources on the Internet describe the malfunction. When air just begins to leak through the leaky membrane, the VUT continues to function properly, since the motor manages to maintain a vacuum in the front chamber. The first symptom is changes in the operation of the engine itself:

- due to air leaks into the third cylinder, the engine begins to “trouble” at idle;

- crankshaft revolutions “float”, the stronger the suction, the greater the amplitude of oscillations;

- a running engine reacts to the brake pedal and stalls when pressed sharply;

- Gasoline consumption increases.

Air leaking into the engine through the VUT causes the third cylinder to turn off - the engine begins to “trouble.”

If the car owner ignores the primary symptoms, the situation gets worse - the pedal becomes harder and requires more physical effort to slow down and stop the car. The car can be used further; a breakdown of the VUT does not lead to a complete failure of the brakes, but it significantly complicates driving, especially if you are not used to it. Emergency braking will become a problem.

How to make sure that the vacuum booster is leaking:

- Loosen the clamp and remove the vacuum pipe from the fitting on the manifold.

- Plug the fitting with a tight homemade plug.

- Start the engine. If the revs level out, the problem clearly lies in the amplifier.

- Remove the high voltage wire and remove the spark plug for cylinder III. If the VUT fails, the electrodes will be smoked with black soot.

Whenever possible, I use the old “old-fashioned” method - I simply pinch the vacuum hose with pliers while the engine is running. If the third cylinder starts working and idle speed is restored, I proceed to checking the brake booster.

Similarly, the problem can be temporarily fixed while on the road. Disconnect the pipe, plug the fitting and calmly go to the garage or service station - the power unit will operate smoothly, without excessive fuel consumption. But remember, the brake pedal will become hard and stop responding instantly to light pressure.

Additional diagnostic methods:

- Press the brake 3-4 times and start the engine while holding the pedal. If it does not fail, the valve has probably failed.

- With the engine not running, disconnect the hose from the fitting, remove the check valve and firmly insert a pre-compressed rubber bulb into the hole. On a sealed amplifier it will retain its shape, on a faulty amplifier it will fill with air.

Using a bulb, you can accurately determine the location of the defect, but the vacuum booster will have to be removed. While pumping air into the chamber, wash the edges of the joints and the stem seal - bubbles will indicate the location of damage.

Operating principle of BSZ

Electronically controlled spark generation operates according to a fairly simple algorithm, which determines the reliability of such a circuit. When the driver turns the key in the ignition switch, a constant voltage from the on-board network is applied to the primary winding of the coil, causing a magnetic field to form around it. Then the system works like this:

- The starter turns the crankshaft and drives the distributor shaft along with the slider.

- The Hall sensor, which reacts to the passage of a metal mass nearby, registers the rotation of the shaft along the protrusion on it and sends a signal to the switch.

- The electronic unit, based on a signal from the sensor, turns off the voltage supply to the primary winding of the coil.

- At the moment the circuit breaks, a high voltage pulse (up to 24 kV) is formed in the secondary winding of the coil. It is directed along a thick wire to the moving contact of the distributor.

- The slider redirects the impulse to one of the fixed contacts built into the cover. From there, the voltage goes to the spark plug of the cylinder where the piston is at top dead center.

- At this moment, the fuel is already in a compressed state in the combustion chamber. When a spark jumps across the electrodes of the spark plug, it ignites.

- The runner rotates and transmits a spark to all cylinders according to the 1-3-4-2 scheme, after which the car engine starts and starts working.

Note. In old VAZ 2107 cars there was no switch, and the electrical circuit was broken mechanically - the shaft cam opened the contact group.

Outdated circuit with contact breaker

Ignition coil design

Almost all ignition coils on VAZ cars are conventional step-up transformers equipped with two windings - primary and secondary. Between them is a massive steel core. All this is placed in a metal case with insulation. The primary winding is made of copper wire coated with varnish insulation. The number of turns in it can vary from 130 to 150. It is this winding that is supplied with an initial voltage of 12 volts.

The design of the ignition coil on the VAZ 2107 cannot be called complex

The secondary winding is located on top of the primary. The number of turns in it can reach 25 thousand. The wire in the secondary winding is also copper, but its diameter is only 0.2 mm. The output voltage supplied to the spark plugs from the secondary winding reaches 35 thousand volts.

Types of ignition coils

Over the years, different types of ignition coils were installed on VAZ cars, which differed in design:

- common coil. One of the earliest devices that was installed on the very first G7s. Despite its venerable age, the coil is still installed on the VAZ 2107 today. The design of the device was described above: two copper windings on top of a steel core;

- individual reel. It is mainly installed on cars with electronic ignition systems. In these devices, the primary winding is also located inside the secondary, but individual coils are installed on all 4 VAZ 2107 spark plugs;

- twin coils. These devices are only used on vehicles with electronic ignition systems. These coils differ from all others in the presence of double wires, thanks to which the spark is supplied not to one, but to two combustion chambers at once.

Location and connection diagram

The ignition coil on VAZ 2107 cars is located under the hood, near the left mudguard. Attached with two long studs. A rubber cap with a high-voltage wire is connected to it.

The ignition coil on the VAZ 2107 is located under the hood on the left, near the mudguard

The coil is connected according to the diagram below.

The connection diagram for the VAZ 2107 ignition coil is not particularly complicated

About the choice of ignition coils for the VAZ 2107

The latest VAZ 2107 cars are equipped with contact ignition systems that use a domestically produced B117A coil. The device is quite reliable, but every part has its own service life. And when the B117A fails, it is quite difficult to find it on sale.

Standard coil VAZ 2107 - B117A

For this reason, motorists prefer to install a 27.3705 coil. It costs more (from 600 rubles). Such a high price is explained by the fact that the 27.3705 coil is filled with oil inside, and the magnetic circuit in it is of the open type. It is this device that is recommended to be used when replacing a burnt out coil.

Coil 27.3705 - oil-filled, with an open core

The third option should also be noted here: coil 3122.3705. There is no oil in this coil, and the magnetic circuit is closed. Despite this, it costs more than 27.3705 (from 700 rubles). Coil 3122.3705 is as reliable as 27.3705, but given its inflated price, most car owners opt for 27.3705. Foreign-made coils are not installed on the VAZ 2107.