Purpose of the sixth gear of the gearbox for a VAZ

There is an opinion that 6th gear is needed exclusively for moving on the highway, that is, we enjoy the absence of engine roar at high speeds.

Others see other advantages in this, such as faster, more dynamic and smooth acceleration, while maintaining maximum speed. And still others are trying to reduce gasoline consumption by installing a sixth gear in a VAZ. Despite a number of advantages of 6-speed over 5-speed, there are also opponents of such modification of the gearbox. They argue that there is no point in doing such tuning if there is a standard engine under the hood. In any case, whether to install 6th gear or not is up to you, but here is the approximate price tag:

Buy a 6th gear kit for VAZ 2108..2110

| Previously, cars were equipped with 4-speed gearboxes and at that time this was quite enough. Currently, the requirements have changed, and the speeds are completely different, which is why many modern foreign cars have a six-speed gearbox. Is it possible to install sixth gear on a VAZ of the tenth family and what will it change? |

| In online stores you can find many kits, including for the standard range of gearboxes. The approximate cost is 13 thousand rubles. |

Technical characteristics of the VAZ 2170 gearbox

| Type | Mechanics |

| Number of gears | 5 |

| For drive | front |

| Engine capacity | up to 1.8 liters |

| Torque | up to 170 Nm |

| What kind of oil to pour | Lukoil TM-4 75W-90 GL-4 |

| Lubricant volume | 3.5 liters |

| Change of oil | once every 75,000 km |

| Replacing the filter | every 75,000 km |

| Approximate resource | 160,000 km |

Classification by structure

Volkswagen Passat Das graue Auto Logbook Replacing the gear shift cable

According to the structure, car gearboxes are divided into the following types: two-shaft and three-shaft. Both have their own advantages and features.

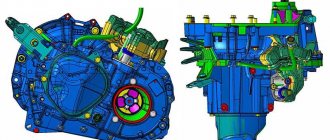

Twin-shaft box: device and principle of operation

The drive shaft of such boxes guarantees connection with the clutch. The driven shaft has a parallel arrangement and contains a gear block. If necessary, the differential helps provide different angular speeds.

Mechanism

Communication can be provided through special cables and rods. The simplest option is cables. It is the most common and convenient for experienced drivers and beginners.

The operating mechanism of this device is similar to the principle of a three-shaft gearbox, the main difference lies in the gear shifting features. The division of the lever, when the gear is engaged, is carried out in the longitudinal and transverse directions. Gear selection occurs through the functioning of all elements and their interaction.

Three-shaft manual transmission

The structure contains a drive shaft and a driven shaft, both contain synchronizers with gears and a switching mechanism. The drive shaft provides connection between the mechanisms and the clutch system. Parallel to it there is an intermediate shaft, which includes gears in the block.

The mechanism responsible for switching is located on the body. Its design includes a control lever and sliders equipped with forks. To prevent both gears from operating simultaneously, remote control is provided.

Principle of operation

This type of gearbox does not involve transmitting torque to the front wheels. The consequence of movement of the control lever is movement of the clutch. As a result, thanks to the clutch, speed synchronization is ensured.

Disadvantages, breakdowns and problems of the Lada Priora box

Most often, owners complain about howling transmissions and rattling manual transmission knobs.

Drivers are also annoyed by unclear shifting and poor lever locking

Many oil seals begin to leak oil even at low mileage of the car.

The gearbox control drive and clutch require periodic adjustment

Synchronizers, bearings and gears wear out quite quickly here

You can contact the site administrator by email: [email protected]

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

Gearbox – gearbox. Transmissions can be mechanical, robotic, CVT, or automatic. The VAZ 2114 2113 2115 is equipped with a 5-speed manual transmission with a rocker drive. In principle, the box remained from the same “eight”, but with a different main pair.

Which gearbox is suitable for Priora?

If you need to replace a gearbox that cannot be repaired, it is best to install exactly the same one: then a minimum of alterations will be required.

Important: even the first generation manual transmissions (2170) were produced in two modifications, differing in the type of starter (on one it was secured with three bolts, on the other - with two).

If, in principle, you are not satisfied with the standard gearbox of the Lada Priora, install a French manual transmission, a Japanese hydraulic automatic transmission or a Russian-German robot from Kalina or Vesta. Such units will cost significantly more than the original ones, and will also require significant modifications to the car, but will provide a higher level of comfort.

For example, an automatic transmission from Granta will fit into a Priora without major modifications, but it is better to use a robot rather than a hydraulic automatic transmission: then you will be able to save a lot of money.

If this option doesn’t suit you, then it might be easier to change the car: a remodel can cost several hundred thousand rubles. And for 100-150 thousand you can get a good foreign car 15-20 years old, which will be much more reliable and comfortable than the Priora. Buying a contract unit or taking a transmission from a disassembly unit is a lottery in which not everyone is lucky. An inexpensive hydraulic automatic machine from a Japanese or German car will cost 30–50 thousand rubles, and no one knows how long it will work.

Which car is suitable for the gearbox on the Priora?

It will cost at least the same amount to install the unit and remodel the car, after which you will have to prove for a long time and painfully to the traffic police that no unacceptable changes were made to the design of the vehicle. And those that exist are within the permitted limits. The evidence will be an expert opinion, which is very difficult to get for free.

As a result, the total costs can easily exceed 200 thousand rubles, which is comparable to the cost of a fresh Priora or a ten-year-old well-maintained foreign car. Therefore, often, instead of asking which cars are suitable for the gearbox on the Priora, they switch to someone else: isn’t it cheaper to buy a foreign car?

Thus, the gearbox from any front-wheel drive VAZ is best suited for the Priora.

Main couple

The main pair is the main shaft of the box (main gear). The main pair serves to reduce the speed transmitted from the engine. On average, the main pair reduces the number of revolutions by 4 times: the engine spins 4 thousand. rpm - main pair 1 thousand. rpm The main pair as standard has a gear ratio: 3.7. By changing the main pair, you can significantly change the dynamics of the car. Depending on the size of the main pair, you can change the length of all gears, hence the maximum speed and acceleration. (By the way, the nine has a 3.9 main pair, due to this it has a lower maximum speed, but is faster at acceleration).

Advantages of the 4-speed option

Gearboxes

Many drivers praise the common four-speed gearboxes and do not trust the newfangled six-speed automatic transmission. They make the following arguments:

- Unreliability. Four stages are better because they have been invented a long time ago and are more reliable, and automatic transmissions with a large number of gears will break down more often.

- Money spendings. Firstly, the six-speed gearbox itself is more expensive than a four-speed gearbox. Secondly, its repair will require additional costs, since the automatic transmission mechanism there is more complicated, and in combination with the first point, the six-speed gearbox generally becomes a huge hole in the budget of the owner of a car with such a transmission.

- No differences. Also, supporters of the four-speed automatic transmission claim that there are no differences in driving sensations with different automatic transmissions, and they do not see the difference at all. Moreover, in their opinion, there are no differences in the technical part: fuel consumption, speed, smoothness of switching.

However, one should not draw hasty conclusions, since all these arguments are erroneous. A six-speed automatic transmission is far from a new item in the automotive industry, and all the errors (which may have occurred in the first generations of cars with such gearboxes) have long been corrected. The designs of these boxes are very similar, which means it is impossible to judge which automatic transmission is more reliable and practical - most likely, they are the same in this parameter.

Gear ratios (row)

Gear ratios are the gears of each gear, which also have their own size.

Gear ratios characterize the speed characteristics of a car in a particular gear. In a standard VAZ, the following numbers are used:

3,636

1,95

1,357

0,941

0,784

3,53

The characteristics shown above are just with standard gear ratios.

The standard range on the 2114 is far from ideal: First gear is too short – second gear is too long. Due to this, there is a sharp drop in dynamics when switching from first to second. Not only is there a failure, but when switching sharply, the second gear synchronizer slowly dies.

Therefore, there are sports series where the gap between 1st and 2nd is removed, and not only: sports series are selected according to the type of engine: it can just be a good city engine, or a sports one, or tailored for 402-meter racing. There are also “turbo” gears - designed for a turbo engine.

Installing the sixth speed gear

Installation instructions and execution procedure:

- Take a standard set of tools for removing and disassembling the box and the tool described above

- It is necessary to follow all procedures and take safety measures as when removing the box

- Removing the gearbox (see VAZ 2109 gearbox repair: how to do it correctly) according to all the rules with an assistant

- Disassemble the box up to and including removing the housing from it.

Box disassembled before removing the case

- We replace the rod for the 5th speed fork with the rod of the 5th-6th speed

- Screw the housing back

- If it was not possible to immediately install the 5th gear gears of the secondary shaft due to lack of space for the needle bearing, then take a grinder and grind either the bearing or the spacer ring (grind down one millimeter)

- Then we put the lower retaining ring of the synchronizer hub on the bushing of our secondary shaft

- Then we insert the spacer ring we ground off from below, press the bushing onto the secondary shaft (you may need to use a hammer in this case)

- When disassembling, most likely, it will be necessary to sacrifice the synchronizer hub; it will hardly be possible to compress it without damaging it

- Insert the 5th gear needle bearing

- Then install the spacer ring for the 5th speed gear

- We insert the 5th speed gear together with the gear block of the 5th-6th speeds of the input shaft

- Then we install the block. Ring for 5th gear synchronizer

- Next, we install our synchronizer (from the former 5th gear) on the synchronizer hub for first and second gears.

- We press the hub complete (assembled) with the fork and coupling onto the bushing from the secondary shaft until the fork is screwed to the rod

- We put on the second locking ring

- Installing the block

- Then the 6th speed synchronizer ring

- We push the 6th speed gear of the secondary shaft into its place, to do this we lift the 5th-6th gear block of the primary shaft

- This is done without a bearing, because otherwise it simply won’t fit.

- If this manipulation fails, you will have to assemble the 5th-6th speed unit in your hands

- The 6th gear needle bearing can then be inserted

- Engage 2nd gear using the rod

- We turn on the 5th gear with our hands, without turning off the second

- Using a 12mm hex wrench, tighten the input shaft nut

- Then we make a mark for the M6 bolt on the nut opposite the hole in the 5th-6th speed unit

- Unscrew the nut back

- We make a special fixing hole on it, use a grinder for this (it will be clear to you where exactly)

- We reduce the height of the head of the bolt from the RTD so that it no longer touches the bearing

- Be sure to lubricate all the shaft nuts with Loctite, then tighten them

- We tighten the fixing bolt with M6 thread

- We press the internal parts from the roller bearings onto the shaft nuts

- Press the remaining bearing parts into the box lid

- We replace two studs in the gearbox housing with purchased ones

- We put on the lid. It will touch the steel plate

- Therefore, when installing it, we will have to grind the cover with a drill and a cutter

Gearbox configurations

Below are the most successful gearbox configurations depending on the engine. For a more detailed selection, you can use a calculator on the Internet.

- The most suitable gearbox configuration for a civilian naturally aspirated engine: 18 row gearbox + main pair 3.9.

- The most suitable gearbox for a sports naturally aspirated engine: 7 row gearbox + main pair 4.3.

- The most suitable gearbox configuration for a turbo civilian engine: row 104 + main pair 3.5.

The differential is two-satellite, the tension is adjusted by different thicknesses of the adjusting ring.

Sports cars often use a differential lock.

A differential lock is a mechanism that locks the differential so that both wheels rotate evenly. Initially, locking was used on SUVs to ensure that the front and rear axles rotated evenly.

In our case, screw locks are especially popular, because... are easily installed in the gearbox, increase cross-country ability on wet roads, and provide an advantage during acceleration due to uniform constant rotation of the wheels.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

The price of installing sixth gear at a service station will be no less than half of this cost.

6th gear kit for VAZ and the necessary tools

The kit includes: 1. Gearbox cover. 2. Fork rod. It is the same as the standard one, but there is a groove for the ball for sixth gear. This part can be made in a garage.

3. Gears of the 5th and 6th gears of the input shaft. They are made as one unit. Slide onto the splines of the input shaft. 4. Bushing for the secondary shaft gears (extends the shaft). 5. Nut (if you can call it that) of the input shaft. The nut is inserted into the gear block and screwed into the input shaft. The inner race of the bearing is pressed onto it on top. 6. Secondary shaft nut. The design is similar to the primary nut. It is worth understanding that the 5th and 6th gears of the input shaft are a single unit, so the 5th gear must correspond to a number of gearboxes. That is, you cannot, for example, with the 7th row installed, set the 5th gear from the 6th row. (this is possible if the 6th gear is from the 6th row).

Need to purchase:

- Roller bearings. They are pressed into the lid. In my case, the standard bearings of the primary and secondary shafts (small and large) were suitable.

- 6th gear gear of the secondary shaft. In our case (7th row) it was the stock 4th gear.

- Needle bearing.

- 1st-2nd gear synchronizer hub.

- Block. synchronizer ring.

- Retaining rings (standard from 1-2 gears) - 2 pcs.

- Bolt from RTD (M6, hex head).

- M8 studs about 70 mm long - 2 pcs.

Backstage

On modern cars, including the new Grants, Kalinas, and Priors, gearboxes with cable-driven gears are installed, thanks to which gear shifting becomes easy and precise. In Samara: 2114 -2113-2115 the gear drive is carried out not by a cable, but by a rocker.

The slide is a development from the 80s, so the gears may not engage the first time, may not engage well, etc.

On sports tuned cars they often install a “short-throw” rocker.

The essence of the short-throw shifter is that the path of the gearshift lever from neutral to gear becomes shorter than it was. Simply put: the gears are easier to engage, the lever travel is shorter - which gives a significant advantage when shifting.

When is replacement better than repair?

Repairing the gearbox eliminates the problem, but does not affect its cause, and also does not change the transmission parameters, with the exception of installing more powerful shafts and gears with a different gear ratio. However, it is impossible to repair the structural defects of the box if it does not meet the tasks set by the driver. In this case, the gearbox is changed to a more suitable one. For this reason, AvtoVAZ abandoned a number of rocker boxes. The potential for their modernization was exhausted, and without reworking the design, it was impossible to eliminate the cause of the claims made by drivers.

When the management of AvtoVAZ realized this, instead of rocker boxes they installed more advanced cable ones, which immediately eliminated the causes of two main complaints: difficult gear shifting in the cold and rattling of the gearshift lever even with a fully functional gear selection mechanism (GSM).

Review of the gearbox

VAZ front-wheel drive gearboxes have the same problems. They all howl and make noise; the gears have significant play between them, which causes jerking when releasing the gas while moving in gear. As mentioned above, the first gear is too short, and the second is too long, which causes failure during acceleration and increases wear. Installing a different row of gears may solve the problem of failure, but all sports rows have more noise during operation than a regular gearbox, which is not particularly quiet in operation anyway.

Four-speed and five-speed manual transmissions

So, the so-called “four-step” was quickly replaced by a “five-step”.

Let us immediately note that the five-speed manual gearbox is not very different from the 4-speed gearbox in design (the shape of the rear cover and other elements are similar). The main distinguishing feature is the placement of the fifth stage (speed, gear), which is located at the end of the secondary shaft. The five-speed gearbox has the same ratios as the four-speed gearbox. Most of the parts are also the same, since the five-speed gearbox is based on the four-speed one. The 5MT gearbox has a primary, secondary and intermediate shaft. Structurally, the input shaft is the same as the four-speed gearbox, but the output shaft has a slightly different rear end where the fifth gear components are installed.

More precisely, at the rear end of the intermediate shaft there is a threaded hole into which a bolt is screwed in to secure the fifth gear gear block, as well as the reverse gear. The fifth gear itself and the reverse gear are located in the cavity of the rear cover; the hub of the fifth gear synchronizer clutch is installed together with the reverse driven gear on the secondary shaft. Next, behind the hub, a thrust washer and a bushing are installed where the fifth gear gear is located.

This additional fifth gear was used to allow the engine to operate at lower speeds when driving at high speeds. On the one hand, this solution increases the service life of the internal combustion engine and gearbox, and on the other hand, it saves fuel.

In simple words, owners of cars with a 4-speed manual transmission are very familiar with the situation when, when driving on the highway at a speed of 100-120 km/h and above in fourth gear, the engine speed is high, the engine and gearbox are very noisy under load, and fuel consumption is increased. To increase comfort, all that remains is to reduce the speed.

It was to solve this problem that the designers introduced 5th gear to reduce the load on the engine and gearbox, reduce noise and increase fuel efficiency.

As a rule, fifth gear is an overdrive (overdrive), it is recommended to engage it at a speed of 80-100 km/h on a flat road. At the same time, a further increase in the number of stages is possible and practiced (for example, MT6), but often most manual transmissions have 5 gears. The reason is the need for the driver to constantly change gears, which makes it difficult to control the vehicle.

Speaking of disadvantages, a 5-speed gearbox is more demanding on the oil level in the gearbox than a four-speed gearbox. If there is not enough oil in the box, it often happens that it is the 5th gear that fails first, and the gearbox begins to howl and make a lot of noise under load.

Installing a shop short-throw rocker on a VAZ 2114

If you purchased a ready-made unit, but don’t know how to change the rocker on a VAZ 2114, you just need to follow these steps one by one:

- Remove the decorative casing.

- We put the car in a pit or lift it on a jack.

IMPORTANT! Do not forget about safety precautions; place a support under the rear wheel on the opposite side of the jack, or under diagonally opposite front and rear wheels when working in a hole.

IMPORTANT! Changing the rocker is the ideal time to replace such components as the cardan, hinge, and oil seal. They are very short-lived, so if you are changing the rocker itself, change the accompanying units to delay the next meeting with the bottom of your car as far as possible.

Pros and cons of a short-throw rocker

The motorist should understand that replacing the VAZ 2114 backstage will bring not only positive aspects to his life, but also some difficulties, which is worth knowing in advance.

So, the clear advantages of such modernization include:

There is only one downside: reducing the force lever leads to an increase in the load on the synchronizers, which increases the rate of their depreciation by two or more times.

How not to confuse the first and reverse speeds of a VAZ Priora

The figures given in the table are different for different machines. You can determine the upper limits for your vehicle using a tachometer.

As a rule, the upper limit is 5.5 thousand. The most important thing is that I drove like this for about 2 months, until one good driver told me that all this, of course, is great, but sometimes you can drive differently. I was amazed, but most importantly, I just didn’t know it was possible to do this. Look at the following table. Now let's discuss the details. Your car has started to move, first gear is engaged, the clutch pedal is fully released, and you are driving at low speed.

Immediately move the gear shift lever to the neutral position for one or two seconds, at which time the gears in the gearbox equalize the rotation speed, and switch to second gear. After changing gear, you need to quickly, smoothly release the clutch pedal and increase pressure on the gas pedal. Have you mastered driving in third gear? It's time to move on to the fourth, and then to the fifth.

Inspection and repair

After dismantling, parts and assemblies are cleaned and their condition is checked. The crankcase and clutch should be free of chips and cracks. The sliding surfaces are inspected for signs of wear or damage. The bearing clearance should not be more than 0.05 mm. The wear of the seals should not exceed 1 mm. The teeth and landing shafts must be free of chips, cracks and nicks. The shafts must not have any dents. If defects are found, the parts should be replaced with new ones.

If you replace or repair the gearbox yourself, the warranty on the unit will be lost. It is retained only when serviced at certified service stations.

If you need to replace the VAZ 2114 gearbox, you can save money and install a rebuilt unit. It will cost 30-70% less than new. If you decide to make such a purchase, choose only proven companies that have been operating on the market for more than one year.

The device of a manual box with 3 shafts

The three-shaft gearbox consists of a main input shaft, as well as a secondary shaft, on which the main gears with synchronizers are located.

All these elements are located in the transmission housing and have high-friction plain bearings.

provides the transmission with initial movement from the engine. There are splined connections on the primary element on which it is installed. Behind the primary shaft there is an intermediate one, which is located parallel, in turn, gear blocks are rigidly fixed to the secondary shaft.

Synchronizers are fixed between the gears of the main drive; their main task is based on measuring the inclined transmission speeds of the main and secondary shaft, this is created using friction forces.

The synchronizer blocks have a rigid engagement with the main shaft and also have two components. The movement of the synchronizer blocks is carried out in the longitudinal direction thanks to splined guides. Old gearboxes do not have a full set of synchronizers; fortunately, modern transmissions are fully equipped with this set.

The transmission shift mechanism itself, which has three shafts, is located directly on the housing itself. From a design point of view, this device consists of a lever and special guides, which, using a fork, change speeds. Such a mechanism can be equipped with remote control. The gearbox housing is designed to accommodate various parts and other elements, as well as oil for lubricating rubbing parts.

When the lever is in neutral, all torque is not transmitted to the driven wheels. At the moment when the control lever moves, special guides move the synchronizer block, which in turn stops the input shaft and the gears can freely engage.