Basic automatic control processes

It doesn't matter what type of generator set is used in the car. In any case, it has a regulator in its design. The automatic voltage regulation system allows you to maintain a certain parameter value, regardless of the frequency at which the generator rotor rotates. The figure shows the generator voltage regulator relay, its diagram and appearance.

By analyzing the physics by which a generator set operates, it can be concluded that the output voltage increases as the rotor speed becomes higher. It can also be concluded that voltage regulation is carried out by reducing the current supplied to the rotor winding as the rotation speed increases.

What is a generator

Any car generator consists of several parts:

1. A rotor with an excitation winding, around which an electromagnetic field is created during operation.

2. A stator with three windings connected in a star configuration (alternating voltage is removed from them in the range from 12 to 30 Volts).

3. In addition, the design contains a three-phase rectifier consisting of six semiconductor diodes. It is worth noting that the VAZ 2107 generator voltage relay-regulator (injector or carburetor in the injection system) is the same.

But the generator will not be able to operate without a voltage regulation device. The reason for this is the voltage change over a very wide range. Therefore, it is necessary to use an automatic control system. It consists of a comparison device, control, executive, master and special sensor. The main element is the regulatory body. It can be either electrical or mechanical.

How to check the generator relay regulator on a car

You can check the generator integral without removing the device from the car. The diagnostic procedure can be performed either using special tools or simple methods that require the use of only simple instruments and devices.

How to test a relay for functionality without a tester

Diagnostics of the relay regulator using measuring equipment and additional devices will require significant costs if the necessary devices are not available. The cost of a new relay regulator is relatively low, and replacing the element requires a minimum amount of time. To make sure that problems in the vehicle's electrical system are caused by this device, it is enough to have a known good part on hand to perform a simple diagnostic operation.

It is not necessary to use a new relay regulator for this purpose. It is enough to check a used spare part in advance so that at any time and without the use of additional equipment you can accurately determine the reason for the non-standard operation of the vehicle’s electrical system.

Checking the generator voltage regulator with a multimeter without installation

Even an inexpensive multimeter or pointer tester can be successfully used to diagnose the generator relay-regulator directly on the car. You can check the device without dismantling it in the following sequence:

- Set the multimeter or tester to DC current measurement mode.

- Start the car engine.

- Measure the voltage at the battery terminals at an engine speed of no more than 1500 rpm (if the part is in good condition, the voltage will be in the range from 13.2 to 14.0 volts).

- Increase the crankshaft speed to 2500 rpm. Measure the voltage at the battery terminals (with the relay-regulator operating normally, the device should show 14.8 volts (an error of 0.2 volts is allowed)).

- Increase engine speed to 3500 rpm and measure the voltage again (should not exceed 14.8 volts if the regulator is working properly).

If, as a result of the measurements, all voltage indicators did not have significant deviations, then the relay-regulator is in good condition. Otherwise, you should purchase and install a new part.

Generator operation

When the rotor begins to rotate, some voltage appears at the generator output. And it is supplied to the excitation winding through a control element. It is also worth noting that the generator set output is connected directly to the battery. Therefore, voltage is constantly present on the excitation winding. When the rotor speed increases, the voltage at the generator set output begins to change. A voltage regulator relay from a Valeo generator or any other manufacturer is connected to the generator output.

In this case, the sensor detects the change, sends a signal to a comparing device, which analyzes it, comparing it with a given parameter. Next, the signal goes to the control device, from which it is supplied to the actuator. The regulatory body is able to reduce the value of the current that flows to the rotor winding. As a result, the voltage at the generator set output is reduced. In a similar way, the mentioned parameter is increased in the event of a decrease in rotor speed.

Basic Concepts

The relay regulator, which is an important part of the on-board electrical network, is responsible for regulating the current generated by the vehicle generator. Due to the operation of the relay, the battery is prevented from overcharging, which is detrimental to it. Those knowledgeable in electrical engineering, cars and motorcycle enthusiasts will notice: according to the description, this is a regular voltage stabilizer! Essentially, that's what he is. But let's understand a little about generators.

In essence, both direct and alternating current generators are electrical machines that convert mechanical energy into electric current. Today, alternators are more common because they do not use current-collecting brushes, which tend to burn or become severely deformed as the device is used. The output voltage of both types of generators depends on the speed at which the magnetic field rotates inside it and on the magnetic force. The so-called excitation winding is initially supplied to excitation current , due to which magnetic induction is induced. The strength of this current must be adjusted. At a certain point, power needs to stop being supplied to the field winding - another point that needs to be monitored. Further, since in alternating current generators the position of the poles “ + ” and “ - ” is constantly changing, the current must be rectified. The diode bridge is responsible for this, but the range of output voltages can be quite wide. And now we can highlight the main tasks of the generator relay regulator:

- Maintain a voltage range ( 13.5 – 14.5 Volts ) in the network of a car or motorcycle, as well as at the terminals of their battery;

- Excitation current adjustment;

- Stopping the power supply from the battery to the field winding.

Essentially, the generator relay “monitors” the output voltage and current that powers the voltage winding. As soon as the output voltage becomes too high, the relay reduces the excitation current. If the situation is reverse and the generator voltage has decreased, the current to the exciting winding should increase. This happens many times, and stabilization lasts a fraction of a second . Thus, the relay ensures the normal operation of the generator, which now provides the optimal voltage for electrical receivers (radio tape recorders, for example), and saves the life of the battery, also preventing its failure due to recharging with too much current.

Two-level regulators

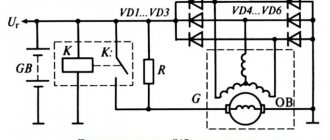

A two-level automatic control system consists of a generator, a rectifier element, and a battery. It is based on an electric magnet, its winding is connected to the sensor. The driving devices in these types of mechanisms are very simple. These are ordinary springs. A small lever is used as a comparison device. It is mobile and makes switching. The actuator is the contact group. The control element is a constant resistance. Such a generator voltage regulator relay, the diagram of which is given in the article, is very often used in technology, although it is morally outdated.

Operation of a two-level regulator

When the generator operates, a voltage appears at the output, which is supplied to the winding of the electromagnetic relay. In this case, a magnetic field arises, with its help the lever arm is attracted. The latter is acted upon by a spring, which is used as a comparing device. If the voltage becomes higher than expected, the contacts of the electromagnetic relay open. In this case, a constant resistance is included in the circuit. Less current is supplied to the field winding. The voltage regulator relay for the VAZ 21099 generator and other domestic and imported cars operates on a similar principle. If the voltage at the output decreases, then the contacts are closed, and the current strength changes upward.

Purpose and design of the relay regulator

This device is a three-element one, consisting of three independent machines. These are a reverse current relay, a current limiter and a voltage regulator. These components are mounted on a common base and closed with a common lid. To connect wires, three terminals are installed on the base.

Automatic connection of the generator to the network is carried out using a reverse current relay, provided that it exceeds the battery voltage by a certain value. When the voltage drops, the generator automatically turns off. It consists of a coil and a core with two windings - shunt and serial with a different number of turns of wire, as well as a yoke and an armature with a contact system.

Preset generator voltage limits are maintained using a regulator. It includes a coil and a core with a winding, an armature with a contact system, a yoke, a magnetic shunt, and a cylindrical spring.

One end of the coil winding is connected to ground, and the other to the generator terminal, passing through the yoke, resistance and windings. Thus, the value of current and magnetic flux depends on the voltage that the generator develops. The voltage regulator allows you to automatically regulate the charging current obtained due to the voltage difference between the battery and the generator.

Electronic regulator

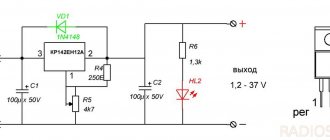

Two-level mechanical voltage regulators have a big drawback - excessive wear of the elements. For this reason, instead of an electromagnetic relay, semiconductor elements operating in key mode began to be used. The operating principle is similar, only the mechanical elements are replaced by electronic ones. The sensing element is made on a voltage divider, which consists of constant resistors. A zener diode is used as a driving device.

The modern relay-voltage regulator of the VAZ 21099 generator is a more advanced device, reliable and durable. The executive part of the control device operates on transistors. As the voltage at the generator output changes, the electronic switch closes or opens the circuit, and additional resistance is connected if necessary. It is worth noting that two-level regulators are imperfect devices. Instead, it is better to use more modern developments.

Signs of a faulty voltage regulator

A characteristic sign of a faulty voltage regulator relay is frequent discharge of the battery. This is explained by the fact that the energy storage device does not receive the necessary recharge from the generator while the engine is running. A faulty relay regulator should be suspected even if the battery is not completely discharged. For example, diagnostic signs such as dim headlights at night or an insufficiently powerful signal sound may indicate failure of this device.

The relay regulator may not supply voltage to the battery terminals or turn off on time. Such a breakdown will cause the battery to overcharge, which can lead to overheating of the internal battery plates and boiling off of the electrolyte.

Signs of a malfunctioning relay regulator may also include:

- Constantly lit battery light on the dashboard.

- The starter does not develop enough power to start the engine easily.

- Reduced engine power (can be especially noticeable at high speeds).

Even if there is one sign of failure, you should check the relay regulator for serviceability.

Three-level regulation system

The quality of regulation of such structures is much higher than that of those previously discussed. Previously, mechanical designs were used, but today non-contact devices are more common. All elements used in this system are the same as those discussed above. But the operating principle is slightly different. First, voltage is applied through a divider to a special circuit in which information is processed. It is possible to install such a generator voltage regulator relay (Ford Sierra can also be equipped with similar equipment) on any car if you know the device and connection diagram.

Here the actual value is compared with the minimum and maximum. If the voltage deviates from the value that is set, then a certain signal appears. It is called a mismatch signal. It is used to regulate the current flowing to the excitation winding. The difference from a two-level system is that there are several additional resistances.

Modern voltage regulation systems

If the voltage regulator relay for the generator of a Chinese scooter is two-level, then more advanced devices are used on expensive cars. Multilevel control systems can contain 3, 4, 5 or more additional resistances. There are also tracking automatic control systems. In some designs, you can refuse to use additional resistances.

Instead, the frequency of operation of the electronic key increases. It is simply impossible to use circuits with electromagnetic relays in servo control systems. One of the latest developments is a multi-level control system that uses frequency modulation. In such designs, additional resistances are required, which are used to control logic elements.

How to remove the relay regulator

Removing the generator voltage regulator relay (“Lanos” or domestic “nine” is not important) is quite simple. It is worth noting that when replacing the voltage regulator, you only need one tool - a flat-head or Phillips screwdriver. There is no need to remove the generator or the belt and its drive. Most of the devices are located on the back cover of the generator, and are combined into a single unit with a brush mechanism. The most common breakdowns occur in several cases.

Firstly, when completely erasing the graphite brushes. Secondly, in case of breakdown of a semiconductor element. How to check the regulator will be discussed below. When removing, you will need to disconnect the battery. Disconnect the wire that connects the voltage regulator to the generator output. By unscrewing both mounting bolts, you can pull out the device body. But the voltage regulator relay for the VAZ 2101 generator has an outdated design - it is mounted in the engine compartment, separately from the brush assembly.

Purpose of the voltage regulator relay

Regardless of experience and driving style, the car owner cannot ensure the same engine speed at different times. That is, the crankshaft of the internal combustion engine, which transmits torque to the generator, rotates at different speeds. Accordingly, the generator produces different voltages, which is extremely dangerous for the battery and other consumers of the on-board network.

Interconnection of car current sources

The vehicle contains at least two sources of electricity:

- battery - required at the moment of starting the internal combustion engine and the primary excitation of the generator winding; it does not create energy, but only consumes and accumulates at the time of recharging

- generator – powers the on-board network at any speed and recharges the battery only at high speeds

Rice. 2 In the car, the generator and battery are combined into a common network

Both of these sources must be connected to the on-board network for the correct operation of the engine and other electricity consumers. If the generator breaks down, the battery will last for a maximum of 2 hours, and without the battery, the engine driving the generator rotor will not start.

There are exceptions - for example, due to the residual magnetization of the excitation winding, the standard GAZ-21 generator starts on its own, subject to constant operation of the machine. You can start a car “from a pusher” if it has a DC generator installed; with an AC device, such a trick is impossible.

Rice. 3 Starting the internal combustion engine from the pusher

Voltage regulator tasks

From a school physics course, every car enthusiast should remember the principle of operation of a generator:

- when the frame and the surrounding magnetic field move mutually, an electromotive force arises in it

- The stators serve as the electromagnet of DC generators, the EMF, accordingly, arises in the armature, the current is removed from the collector rings

- In the alternating current generator, the armature is magnetized, electricity appears in the stator windings

Rice. 4 Operating principle of a car generator

In a simplified way, we can imagine that the magnitude of the voltage output from the generator is influenced by the value of the magnetic force and the speed of rotation of the field. The main problem of DC generators - burning and sticking of brushes when removing large currents from the armature - has been solved by switching to alternating current generators. The excitation current supplied to the rotor to excite magnetic induction is an order of magnitude lower, making it much easier to remove electricity from a stationary stator.

However, instead of terminals “–” and “+” constantly located in space, car manufacturers received a constant change in plus and minus. Recharging the battery with alternating current is not possible in principle, so it is first rectified with a diode bridge.

Rice. 5 Generator rectifier

From these nuances the tasks solved by the generator relay flow smoothly:

- adjusting the current in the excitation winding

- maintaining a range of 13.5 - 14.5 V in the on-board network and at the battery terminals

- cutting off the power to the excitation winding from the battery when the engine is turned off

Rice. 6 Purpose of the voltage regulator relay

Therefore, the voltage regulator is also called a charging relay, and the panel displays a warning light for the battery charging process. The design of alternating current generators includes a reverse current cut-off function by default.

Device check

The relay-regulator of the voltage of the VAZ 2106 generator, “kopecks”, and foreign cars is checked equally. As soon as you remove it, look at the brushes - they should be more than 5 millimeters long. If this parameter is different, the device must be replaced. To carry out diagnostics, you will need a constant voltage source. It would be desirable to be able to change the output characteristic. You can use a battery and a couple of AA batteries as a power source. You also need a lamp, it must run on 12 Volts. You can use a voltmeter instead. Connect the plus from the power supply to the voltage regulator connector.

Accordingly, connect the negative contact to the common plate of the device. Connect a light bulb or voltmeter to the brushes. In this state, voltage should be present between the brushes if 12-13 Volts are supplied to the input. But if you supply more than 15 Volts to the input, there should be no voltage between the brushes. This is a sign that the device is working properly. And it doesn’t matter at all whether the voltage regulator relay of the VAZ 2107 generator or another car is diagnosed. If the control lamp lights up at any voltage value or does not light up at all, it means that there is a malfunction of the unit.

Diagnostics of the relay regulator

It is necessary to check the operation of the regulatory device using a tester - a multimeter. It must first be configured in voltmeter mode.

Built-in

This mechanism is usually built into the brush assembly of the generator unit, so level diagnostics of the device will be required.

The check is done like this:

- The protective cover is dismantled. Using a screwdriver or wrench, the brush assembly is loosened; it must be brought out.

- The wear of the brush elements is checked. If their length is less than 5 mm, then replacement is necessary.

- Checking the generator device using a multimeter is performed together with the battery.

- The negative cable from the current source is connected to the corresponding plate of the control device.

- The positive contact from the charging equipment or battery is connected to the same output on the relay connector.

- Then the multimeter is set to the operating range from 0 to 20 volts. The probes of the device are connected to the brushes.

In the operating range of 12.8 to 14.5 volts, there should be voltage between the brush elements. If the parameter increases by more than 14.5 V, then the tester needle should drop to zero.

When diagnosing the built-in generator voltage relay-regulator, it is permissible to use a test light. The lighting source must turn on at a certain voltage interval and go out if this parameter increases above the required value.

The cable that controls the tachometer must be tested using a tester. On diesel cars this conductor is designated W. The resistance level of the wire should be approximately 10 ohms. If this parameter drops, this indicates that the conductor is broken and requires replacement.

Remote

The diagnostic method for this type of device is carried out similarly. The only difference is that the relay regulator does not need to be removed and removed from the generator unit housing. You can diagnose the device with the power unit running, changing the crankshaft speed from low to medium to high. When their number increases, it is necessary to activate the optics, in particular, the high beams, as well as the radio, stove and other consumers.

The AvtotechLife channel talked about self-diagnosis of the regulatory device, as well as the features of performing this task.

conclusions

In the electrical system of a car, the voltage regulator relay of the Bosch generator (as, indeed, of any other company) plays a very important role. Monitor its condition as often as possible and check for damage and defects. Cases of failure of such a device are not uncommon. In this case, in the best case, the battery will be discharged. And in the worst case, the supply voltage in the on-board network may increase. This will lead to the failure of most electricity consumers. In addition, the generator itself may fail. And its repair will cost a tidy sum, and considering that the battery will fail very quickly, the costs will be astronomical. It is also worth noting that the Bosch generator voltage regulator relay is one of the leaders in sales. It has high reliability and durability, and its characteristics are as stable as possible.

Reasons for failure

Relay regulators do not fail very often, but if car enthusiasts are unlucky with this, they should not ignore the problem . Here are the main reasons for device failure:

- An interturn short circuit has occurred in the excitation winding. This is the most common reason why a relay has to be replaced. It is worth noting here that even a new relay may not last long. If even a new device quickly fails, it is worth removing the generator and testing it;

- Diode breakdown. This doesn't happen very often. When diodes breakdown, the generator overheats;

- Reversal of polarity in the battery. If this problem persists for a long time, the rectifier diodes fail;

- A short circuit occurred at the control terminal of the generator relay-regulator;

- Destruction of brushes.

Also, the reason for relay failure is its natural wear and tear . As a rule, the device lasts a very long time, but even the most reliable automotive electronics, sealed in a sealed case, have to be replaced every 6-8 years. If the relay-regulator is faulty, not only the battery, but even the electronic unit of the car and the generator itself may fail.