The VAZ 2110 was equipped not only with an injection engine, but also with a carburetor. Great popularity and the rest of the years of production, the tenth Lada model was produced with an injection engine. The injector helped the “ten” improve its technical characteristics, increased the reliability and stability of the internal combustion engine. As you know, injection engines are equipped with a large number of different electronics and sensors aimed at maintaining the operation of the entire car. With the advent of the injector, the VAZ 2110 began to work much better, softer, and the dynamics began to please. Fuel was injected into the combustion chamber under pressure using fuel injectors; the fuel was atomized under pressure, which was pumped by a fuel pump.

Quite often, fuel injectors become dirty due to poor fuel quality, which makes their flow rate slightly lower and leads to a lack of fuel and loss of vehicle power.

In this article we will talk about fuel injectors on the Lada 110, namely their purpose, design, location, signs of malfunction, methods of washing and replacement.

Purpose

Fuel injectors are designed to spray fuel, which is mixed with air to form a fuel mixture and then enters the combustion chamber. The injectors replaced the old carburetor injection, which produced mono injection on all 4-cylinders, and the injectors allowed individual injection for each cylinder. Based on this, we can define the purpose of fuel injectors - this is the supply of fuel under pressure into the combustion chamber of a certain cylinder. There are a total of four fuel injectors on the VAZ 2110, which are connected into one system, to the fuel rail.

Device

A fuel injector is an electromechanical part that, under the influence of an electric current, opens a channel and passes the compressed fuel through the nozzle into the combustion chamber. The injector is an electromagnetic valve, the armature of which has a locking bar; when voltage appears on the injector winding, the armature is retracted, thereby opening the channel for the passage of fuel.

The injector consists of many parts, but most often the mesh filter is at risk of contamination, which becomes clogged due to fuel combustion products and low-quality fuel.

The nozzle consists of:

- O-ring;

- Strainer;

- Electrical connector;

- Windings;

- Return spring;

- Anchors;

- Housings;

- Needles;

- Pin;

Location

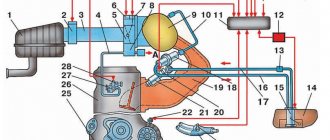

The injectors are located opposite each cylinder and are inserted into special milled holes in the cylinder head on one side, and on the other hand they are assembled into a single system through the fuel rail. All 4 injectors are connected in parallel and spray the same amount of fuel into the cylinders.

The location of the injectors depends on the engine type. For example, in an 8-valve engine, the fuel rail with injectors is located at the rear of the cylinder head, above the exhaust manifold.

In a 16-valve engine, the fuel rail is located on the front of the cylinder head, under the intake receiver.

Fuel rail can be removed

- This is how it looked:

- Soaked them in carburetor cleaner:

- While the injectors were soaking, I put together a diagram for cleaning them:

The light bulb in the circuit was 10 W, a simple halogen. I brought the button without locking and the wire from work. I didn’t use anything to supply the cleaner to the nozzle - I just put the nozzle on the can and it fits quite tightly.

ready-made cleaning scheme

- The injector is connected as follows: the left contact is positive, and the right contact is negative.

Then I cleaned each nozzle in two passes of 10-15 sprays. I didn’t take a video or photo of the spray torch - it was inconvenient to take pictures, because... he did everything alone. In principle, the nozzles were not dirty - the spray pattern did not change much, and from the very first presses it sprayed normally. Then I checked the winding resistance of all injectors. Values in the region of 11.9-12.2 Ohms are within the norm.

You can start assembling, but before that you replaced the O-rings on the injectors - replaced 4 out of 8, because half of the rings were in excellent condition (at the injector-ramp transition). I removed the ones to replace:

- Assembling the ramp with injectors:

At the same time I cleaned the cylinder head cover

- Before installing the receiver with the throttle valve, I also cleaned the valve; since the last cleaning it has become quite dirty:

- Also, when removing the receiver, two pillows to which it is attached fell apart - I had to go get new ones:

- We collect everything, check it and start it.

Started with half a kick. Since in general the injectors were not dirty, I didn’t expect much of an effect, but here I was pleasantly surprised. According to the first sensations, the engine began to run more softly, and responded somehow better to the gas pedal. Let's check whether this procedure helped during a cold start in the cold winter. But the most unexpected effect was a decrease in average consumption by almost a liter.

If before this my average consumption recently was consistently 9.2-9.4 liters per 100 km, then after five days of commuting to work the average consumption is already 8.6 liters per 100 km. And at XX it used to be 0.8-0.9 l/hour, but now it’s 0.7-0.8 l/hour. So it was not in vain that I climbed into the injectors and spent several hours.

Symptoms of a problem

Quite often, injectors fail due to winding burnout or contamination, which seriously affects engine performance. If in the first case the injector fails completely and it is difficult not to notice, then in the second case, if it is dirty, it is quite difficult to determine whether the injector is faulty, but still it will show signs by which you can find out whether the injector is working or not.

Signs of a broken injector:

- The engine is tripping;

- Loss of power;

- The car's dynamics disappeared;

- The internal combustion engine starts poorly;

All these symptoms are indirect and can be observed with other problems in the car; in order to more accurately determine faults in the injectors, it is necessary to diagnose them.

Main symptoms

Lack of fuel mixture in the injector. Often, the presence of this symptom does not indicate a malfunction of the injector itself, but a failure of the fuel pump, or its incorrect installation after repair work. In some cases, the reason may be a clogged fuel mixture inlet into the fuel pump.

The fuel pump has failed

Significant increase in fuel consumption. A fairly common phenomenon that indicates a clogged injector. Due to the small diameter of the injector nozzle, even slight contamination can significantly disrupt the mixture formation process, reducing the percentage of engine efficiency. This is explained by the fact that a clogged nozzle no longer forms a cone-shaped cloud of gasoline, which means that a significant amount of fuel begins to burn out in the exhaust manifold. The consequence of these processes is a deterioration in the dynamic characteristics of the vehicle and an increasing load on various electronic equipment of the car: coil, spark plugs, wiring, etc.

Examination

The injectors can be checked by measuring the fuel pressure, but the injectors can be checked in more detail only after they have been removed.

Checking fuel pressure

This test is quite primitive and will not determine the failure of the injector with 100% effect, but this test consists of determining whether the injector is leaking. Fuel injectors must maintain gasoline pressure and not leak it; it often happens that they begin to leak fuel, which then flows into the cylinders.

By measuring the fuel pressure, you can determine whether there is a leak or not, but it should be noted that this procedure without removal will not give an accurate result, since the pressure may drop for other reasons.

Check after removal

It is necessary to apply pressure directly to the injector and see if it allows fuel to pass through when the valve is closed.

The second step is to check the clarity of the fuel atomization, that is, for contamination of the injector. To do this, you need to connect the injector to the stand, or assemble your own circuit for washing the injectors.

Cleaning VAZ 2110 injectors

You can wash the injectors in three ways: using a special wash, at a service station (service station) and with your own hands. The first method does not give the desired effect and often even worsens the situation, and washing at a service station costs a pretty penny, which not every car enthusiast wants to spend on such an easy procedure. Therefore, it would be best to do the washing yourself.

For self-washing, it is necessary to make a power supply circuit for the nozzle; for this we need:

- Carburetor cleaner;

- Wires 2 m;

- ON/OFF button;

- 12V lamp;

- Injector connector;

- Syringe;

Electrical circuit assembly

To flush the nozzle, it is necessary to supply power to it; for this you will need to assemble an electrical circuit according to the diagram presented below. It is not difficult to assemble such an assembly; you just need to look carefully at the drawing and everything will become clear.

Washing video

Injector repair kit

If the injectors cannot be washed and they are already in a deplorable condition, you can use a repair kit for fuel injectors for the VAZ 2110, it is sold in regular auto parts stores for domestic cars. The cost of this kit is small and amounts to approximately 200-300 rubles.

The repair kit includes:

- O-rings;

- Nets;

- Fasteners;

- Filters, etc.

Replacing injector consumables will help correct contamination.

Cleaning methods

There are three main ways that will allow you to clean your injectors. Decide for yourself which one to use.

Peculiarities

Quite effective, but financially expensive. Plus, working with chemicals is risky because it is very dangerous to your health. Cleaning is carried out only in full compliance with safety regulations

Car services will now do everything for your money. But you'll have to pay a lot. Don’t forget that finding a really good, responsible and inexpensive service station is something out of the realm of fantasy. Therefore, either questionable quality of work, or impressive money for effective cleaning

The most economically profitable way to save money and complete the task efficiently. You should choose this option only if you have an idea about the design of the motor, the location and functions of the injectors

Do not carry out cleaning yourself if you have never climbed into the engine compartment yourself to replace or repair engine components. Trust trusted specialists, do not take risks.

Before and after cleaning

Removing the injectors

In order to remove the injectors, you will need a special tool necessary for this work. It should be noted that the process of removing injectors on a VAZ 2110 depends on the type of engine; in an 8-valve engine, dismantling them is quite simple, but in a 16-valve internal combustion engine you will have to tinker. Let's look at each of the engines in detailed instructions.

Tool you will need:

- Flat and Phillips screwdrivers;

- Set of open-end wrenches;

- Set of hexagons;

After preparing the instrument, you can begin removal.

Dismantling the injectors of an 8-valve internal combustion engine

- We relieve the fuel pressure by disconnecting the fuel pump connector, which is located under the rear seat of the car.

- We start the engine and let it run until it stalls, after which we proceed to remove the injectors.

- We unscrew the fuel supply and return pipes (if there is one) with two 17 mm wrenches.

- Unscrew the tubes from the fuel rail.

- We unscrew the ramp from the cylinder head using a hexagon (2 bolts).

- Pull the ramp away from the cylinder head and remove it.

- Then remove the injector clamps and pull it out of the ramp.

Dismantling the injectors of a 16-valve internal combustion engine

- We relieve the fuel pressure by disconnecting the fuel pump connector, which is located under the rear seat of the car.

- We start the engine and let it run until it stalls, after which we proceed to remove the injectors.

- We unscrew the fuel supply and return pipes (if there is one) with two 17 mm wrenches.

- Unscrew the tubes from the fuel rail.

- Unscrew the two nuts securing the receiver.

- We unscrew the clamps from the cuffs connecting the receiver and the intake manifold.

- Disconnect the receiver from the intake manifold.

- We unscrew the ramp from the cylinder head using a hexagon (2 bolts).

- Pull the ramp away from the cylinder head and remove it.

- Then remove the injector clamps and pull it out of the ramp.

Video

Preparation for dismantling

Replacing injectors may not be necessary for much longer if you purchase special additives added to the fuel. Thanks to them, the injector stays clean longer. But you shouldn’t shift all the responsibility onto them, because with prolonged use, dirt and deposits formed create a kind of blockage for the passage of fuel, and this, in turn, causes irreparable damage to the engine.

Of course, you can contact a service center, where they will not only clean the injectors, but also check the machine. However, you can carry out the repairs yourself, because this way you can save a lot. Please keep in mind that the ramp on which the injectors are located is a kind of “center” in each machine. Any independent intervention, including cleaning the injectors, can result in significant damage.

To replace, you must purchase the goods that will be required for the job. First of all, this is a special product for cleaning the injector; it is sold in special aerosol cans. It is advisable to replace the rings on the injectors themselves. It would be useful to purchase any button, a light bulb whose power will not exceed 21 W, and a chip used to connect the wires to the injectors.

It is also necessary to pay attention to some features of dismantling. Before removing the injectors, be sure to ensure that the engine has cooled down. Then it is necessary to completely de-energize the fuel pump. To do this, all wires responsible for power will need to be disconnected. Next, you need to reduce the pressure in the motor as much as possible. They simply start the engine and wait for the engine to stall. Repeat several times until the engine stops starting.