Shock absorbers are necessary to dampen body vibrations and absorb part of the shock loads acting on suspension parts when driving over uneven surfaces. Shock absorption struts not only affect the softness and smoothness of the ride, but also largely determine the adhesion properties of the wheels with the road surface and the directional stability of the car in various conditions.

Let's look at how a car's behavior on the road changes if a shock absorber leaks. Let's talk about the design and testing of shock absorber struts, faults and methods for diagnosing them. Based on the characteristics of common breakdowns, we will consider whether it is worth restoring (restoring) shock absorbers or whether it is better to replace worn struts with new ones.

The shock absorbers (struts) are leaking. What to do and is it possible to drive? What will be the consequences

Shock absorbers are an integral part of the suspension, which you simply cannot do without! They dampen spring vibrations, which in turn make the suspension more comfortable. If there were no shock absorbers, then the car would simply shake like a swing, jump on any bump, and the oscillatory movements up and down would last about 30 seconds, maybe a little more or a little less, that’s not the point. With such a “swing”, the bottom can be smashed into pieces, and so can the suspension. The shock absorber is that protective “buffer” that removes these vibrations, thus, even after driving through a deep hole, your car will not “pump”, you will continue to move confidently. I think everyone knows the principle of operation - but it was worth reminding a little.

Load on the car body

The old, old-fashioned method is to rock the car body and see how the racks work out this movement. If after one shock the shock absorber has made more than 1 translational movement, then it is time to change it. But you need to remember: this method will only be relevant if the shock absorber is completely “dead”. It will also allow you to identify a jammed shock absorber. It will be simply impossible to rock the body.

Why do shock absorbers leak?

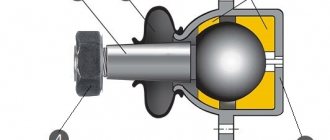

It’s all about the design of the rack itself; now, for this period of time, you can find only three main designs:

The operating principle of one or the other is almost the same - roughly speaking, it is a cylinder that is filled inside with oil, or gas, or both at once (divided into chambers).

So - so that this oil does not go beyond the limits of our cylinder (rack housing), and so that the rod does not release oil or gas, it is locked from above with special sealing and rubber gaskets. Therefore, the internal component of gas or oil cannot leave the housing.

However, due to excessive wear of the rod, or wear of the gaskets, oil or gas begins to escape from the top of the housing and begins to ooze. If the gas is not visible and the shock absorber remains dry, then the oil flows from top to bottom and the shock absorber becomes wet. This tells us that it has failed, or is gradually failing! It needs to be changed. This is why the shock absorbers are leaking - it has simply exhausted its service life, or is broken (on our roads).

Why do shock absorbers leak?

Gas or oil can escape from the cylinder if the seals are damaged. Rarely is the problem global in nature, and in most cases the oil leaks out of the shock absorbers slowly, leaving smudges that the driver can pay attention to, for example, when changing tires.

The reasons for damage to shock absorber seals are commonplace: the service life has reached the end, poor performance of the part or physical damage due to driving on bad roads.

What to do and is it possible to drive?

Of course you can drive, in general you can “drive” without shock absorbers - but how? Of course, if you have one strut leaking, then you may not notice it, but if there are two at once, or as my friend had three (two in front and one in the back), then the car will “swing” like on a roller coaster. Even low speed and reaction to small irregularities caused the car to sway, I’m already silent about some sharp maneuvers (turns, for example), the car was simply drifting!

What to do - change it urgently , the sooner - the better, otherwise, due to your incorrect savings on racks - then you will pay more.

Is it possible to drive:

Guys, I understand that original shock absorbers are expensive, but they need to be changed! YES, and you can find quite sane originals, for example KAYABA, very sane quality and more or less prices.

Consequences if not changed

Well, my dear, you are frugal - if you don’t change 1 leaking rack on time, then the rest will follow it in a circle. Why? Yes, everything is simple - the car is designed to hold 4 sides, that is, all 4 shock absorbers must work. If one fails, the entire load is transferred to 3 sides, but they are not designed for it - and they begin to break. And with each failure, the load is redistributed into two, etc.

In simple words - if you don’t replace 1 strut in time (as you noticed right away, you can drive for up to a week while you wait for the part), then in a month the second one will come out, then the third one and then the last one. That is, there is a big chance that if you don’t replace one, you can replace them all at once!

If this doesn’t scare you, well, I’ll ride in a rocking car, so what, let’s read other consequences:

I repeat again guys, you need to change it as soon as you notice “snot” (smudges). After all, if the rack is “snotty” and has just started to leak, it still holds for some time until all the oil comes out of the housing, but then it becomes empty and simply does not work.

So you have a week - well, two at most. Order and change, you will save others from damage.

That's all, I think it was useful.

Did you like the article? Subscribe to the channel to stay up to date with the most interesting materials

Source

Why is a leaking shock absorber dangerous?

Shock absorbers are necessary to dampen body vibrations and absorb part of the shock loads acting on suspension parts when driving over uneven surfaces. Shock absorption struts not only affect the softness and smoothness of the ride, but also largely determine the adhesion properties of the wheels with the road surface and the directional stability of the car in various conditions.

Let's look at how a car's behavior on the road changes if a shock absorber leaks. Let's talk about the design and testing of shock absorber struts, faults and methods for diagnosing them. Based on the characteristics of common breakdowns, we will consider whether it is worth restoring (restoring) shock absorbers or whether it is better to replace worn struts with new ones.

How does a dry shock absorber work?

Again, to understand the essence of the issue, it is useful to go from afar. Namely from where the shock absorber strut has not yet leaked. That is, it is in good condition. By itself, it works very simply. When the corresponding wheel moves up or down, the load is partially mitigated by the suspension spring. And the shock absorber strut only does what it “holds” the forward movement of the suspension. As if, it does not allow the wheel to move too quickly under the influence of a sudden load and spring. In addition, the shock absorber dampens the vibrations that the spring seeks to transmit to the wheel.

The stand does this job extremely simply. Moving in one direction or another, the wheel on the suspension pushes or pulls the shock absorber rod. That, in turn, is made inside in the form of a piston moving in an oil environment. Since the piston cannot quickly transfer fluid to the adjacent compartment, the movement of the rod is inhibited.

Now let’s look at how a working shock absorber and one that has leaked work in different situations:

- When hitting a hole . The wheel tends down to the bottom of the pit. The expanding spring contributes to this. However, a working shock absorber “holds” the wheel, preventing it from going down too sharply. Under certain conditions (a small hole and sufficient vehicle speed), the wheel may not even “feel” the hole, simply flying over it. If the shock absorber is leaking, it cannot hold the suspension in such situations. Accordingly, it turns out to be a rough blow.

- When hitting a tubercle . In this case, a working shock absorber at the first stage is even harmful. When hitting an uneven surface, the impact is softened by a spring, but the strut, on the contrary, does not allow you to “take” the entire shock load upon yourself. But when the wheel reaches the highest point of the obstacle, by inertia it tends to go up and further. But the stand doesn’t allow him to do this. As a result, the wheel does not hit the body, and contact with the road surface is restored faster. When the stand is dry, it does not hold anything back. On serious bumps, the wheel hits the body, contact with the road is not restored for a long time, and the car also sways under the influence of the inertia of the spring.

- When accelerating . The vehicle's mass shifts rearward. When the shock absorbers are in good working order during sharp acceleration, they prevent the nose of the car from lifting up and the stern from “squatting.” This is especially important if the car is front-wheel drive, since the grip of the wheels with the road does not deteriorate. When the shock absorber is leaking, the car, during any confident acceleration, looks like that high-speed boat planing through the water.

- When maneuvering . The vehicle's mass shifts in the direction opposite to the direction of rotation. If the struts are in good condition, they partially restrain the strong roll, which has a positive effect on the safety and comfort of the car. Additionally, the anti-roll bar is also responsible for this. If the drains have started to flow, then the car will tilt unpleasantly and dangerously at every sharp turn, and after the maneuver is completed it will also sway.

- When braking . The vehicle's mass shifts forward. Serviceable shock absorbers prevent the body from leaning forward sharply and strongly. If the struts are leaking, the car will nod off when braking. Moreover, due to an even greater mass shift, the traction of the rear wheels with the road deteriorates. In the event of emergency braking, this increases the braking distance and can lead to an uncontrolled skid.

- On a bad road . The suspension works constantly, trying to dampen vibrations and return the wheels to the road surface as quickly as possible. If the shock absorbers leak, the shocks are not fully softened, the vibrations are not damped, and the car’s handling is reduced (sometimes completely lost).

From all this it follows that dry racks are simply useless. That is, they don't work.

How to check car shock absorbers?

To determine a faulty shock absorber, it is necessary to swing the car with sufficient amplitude by pressing the wing, and then allow the suspension to dampen the vibrations. If the shock absorber struts are working correctly, the body will make one more oscillatory movement of sufficient amplitude, then another barely noticeable rocking motion, after which it will completely stabilize. If, after forced rocking, the body makes 2 or more swings with sufficient amplitude, the shock absorber must be replaced.

When diagnosing a car's suspension, all shock absorber struts must be visually inspected. Oil smudges on the shock absorber indicate a leak of working fluid.

It is important to carry out comprehensive diagnostics, since a dry shock absorber body is not yet a guarantee of its proper operation. Leakage of inert gas from the working cavity does not always manifest itself as oil fogging, but significantly affects the performance characteristics of the shock absorber strut.

If we are talking about rear shock absorbers, it is additionally necessary to check the rubber-metal all-vulcanized hinge (“ear” of the shock absorber mounting to the beam/knuckle). If the rubber part is peeled off, the bushing is broken, or the mounting bolts are not tightened sufficiently, you will experience dull knocks when driving over uneven surfaces.

You will need assistance to perform the test as the vehicle must be rocked during the test. When the body is swinging in the transverse direction, you must place your palm on the hinge. In the case of the defects described above, you will feel a characteristic displacement of the shock absorber body relative to the knuckle.

Suspension knocks and creaks. How to fix

Extraneous sounds often occur in the suspension and shock absorbers. These are knocks and creaks. Most often this is present in the front part of the suspension. Moreover, the reason does not necessarily lie in the rack itself. Sounds can be made by:

- Tie Rod;

- support bearing;

- spherical bearing.

Problems in these units arise more often than in shock absorber struts. Therefore, if extraneous sounds occur, you must first check them. Usually the problem lies in the bearing. Replacing it is not a problem even if you have no experience. A minimal set of tools is enough. The situation is similar with the ball joint.

But sometimes the problem lies precisely in the shock absorber strut. One of the common problems is that the bump stop makes strange sounds. It just falls down the stem. Which leads to squeaking.

The problem may lie in the strut washer: when it does not press the bushing of the support itself well against the bearing. It is necessary to immediately change the washers and supports at the same time. Creaking often occurs in certain situations. For example, on bumps. In this case, the reason in almost 1000% of cases lies in the shock absorber struts. There is only one way to fix this - complete replacement.

How dangerous is it to drive a car with leaking struts?

If the shock absorber strut has passed the body vibration damping efficiency test, but there is oil staining on the body, the car can still be used for some time. Most likely, the seal leakage began to manifest itself recently, and therefore the shock absorber has not yet lost its performance characteristics.

If you detect the first symptoms of a faulty shock absorber, we recommend replacing or properly restoring the part. It is impossible to predict the mileage or time after which a leaking shock absorber will lose its effective properties.

Driving with a faulty shock absorber is fraught with increased braking distance, poor handling and poor directional stability. Improper operation of a car's suspension can provoke a loss of control over the car with all the ensuing consequences.

Reasons for shock absorber failure

If we talk about the technical side, shock absorbers have several characteristic faults:

Speaking about the reasons for shock absorber leakage, it would be fair to mention the following negative factors:

In the frosty season, for the first 1-2 km after being idle, it is necessary to avoid high-speed passages of sudden influxes and deep holes with sharp edges.

If the shock absorber fails immediately after replacing the supports, springs or support bearings, most likely the reason is the mechanic’s failure to follow service recommendations.

The previously widespread belief about the need to pump shock absorbers before installation is not supported by anything in modern realities. After installation, shock-absorbing struts are pumped independently after the first 100-300 m of travel. A simple action of compressing and releasing the rod is necessary only to convince yourself that the new part is working, and not to prevent leaks in the shock absorber.

Video: SHOCK ABSORBER LEAKS - EVERY MOTORIST SHOULD KNOW THIS

What is the reason?

Most likely, your racks need replacement.

The clearest evidence that

the shock absorbers have worn out

is that they are leaking.

Outwardly, it seems as if you drove into a puddle, but for some reason only the counter is wet.

Your car goes through even the smallest potholes

with a hard impact.

The car seems to be pecking its face or its backside into the hole (in some cases, both).

It looks like this

It looks like this

Replacement or restoration?

Analyzing the reviews about restoration collected on the Internet, in a situation where the shock absorber strut is leaking, we are still inclined to replace the part with a new shock absorber. It is worth trying to restore only rare shock absorbers, which are no longer manufactured or are produced in limited quantities and because of this are very expensive. And even in this case, before sending the shock absorbers, it is worth studying reviews about the organization or the specific master who will be involved in the restoration. In the event of an unqualified repair attempt, individual elements may become unusable.

But even with the purchase of new shock absorber struts, not everything always goes smoothly. Choose trusted suppliers and use all the verification tools for the original product offered by the manufacturer (bar code, coded sum of a combination of numbers, etc.).

Source

Restoring the functionality of the front struts (they leaked and clattered in severe frost)

It all started this winter, in severe frosts. For a couple of weeks the temperature dropped to minus 40-45 degrees. We had to drive to work every day, and our roads were bumpy or pothole-filled. At this time a knocking sound appeared in the front suspension. Since everything that could be changed has already been changed, the A-pillars came under suspicion. This was confirmed by the fact that the knocking intensified in cold weather, and as soon as it became warmer, the knocking decreased. The racks were installed new only 2.5 years ago.

Once, looking under the wing, I discovered fogging of the lower coils of the spring, it became clear that the struts were leaking and releasing gas. I started looking for an office that could inflate the racks with gas, I found one, but they couldn’t help. Our racks have a thin rod and a pin with a skirt is welded at the end, so it would not be possible to put on a device to restore the racks' functionality. After thinking a little, I decided to order new stands (not Kayaba) from one of the online stores. I picked them up and started checking them, but after comparing them with my old racks, I returned them to the store because... the effort they developed cannot be compared with the ones I have. On the new ones, the rod lowered with the force of one finger, I can imagine how it would rock the car on bumps or break through the suspension to the bump stops. Since then, and this is already a month, I have been waiting for money to return the goods. Until I received the money back, I decided to “collectively farm” the old racks. (I recently called the manager, the refund will only be at the beginning of May, this turns out to be almost 2 months since I bought these racks. This procedure takes a very long time...)

As they say, “the collective farm is a voluntary matter.” I started looking for topics about independently restoring the functionality of non-demountable racks and found it on one of the forums. Everything was described as I had imagined. To prepare for the work, you needed: 2 nipples from a tubeless tire (one per rack), a torch, solder, flux, a soldering iron, a drill and a compressor, and some small items of electrical tape, a syringe, and a small funnel. On top of everything else, I decided to replace the liquid itself in the racks. For a long time I couldn’t find what exactly to fill, many people recommend ATF, the first time I did that (yes, yes, I removed and put back the struts 2 times))), then I found another liquid for hydraulic systems.

Remove the strut and free it from the spring. We clean it so that there is less dirt on it. We take the wheel nipple, it must be cleared of rubber, shortened if possible, leaving only room for the nipple. Unscrew the nipple in advance. It is better to take a brass nipple, because... aluminum can melt during soldering.

You need to select a place on the stand to solder the nipple. I chose this place - immediately under the spring cup on the side, when looking from the side of the wheel at the installed rack. We clean this place with a grinding wheel or just sandpaper. We tin this place using a torch to heat the metal, and we also tin the nipple. We apply it to the soldering area on the stand and add solder around the perimeter to strengthen the structure and make the joint airtight.

Next you will need a drill with a 2 or 3 mm drill bit. We simply drill a hole in the post through the nipple. After this, we prepare a container into which you can drain the liquid that is in the rack and turn it down with the nipple towards this container and pour/pump out all the liquid from the rack, pushing and pulling the rod of the rack, periodically turning it over until everything flows out. If the rod moves freely from start to finish without stopping or effort, then all the liquid has come out.

After this, we take a small funnel, wrap the nipple with electrical tape and place it on top so that it sits tightly and does not let in the liquid that we will pour into the rack. We take a new liquid, a syringe and gradually stretching the rod, add it into the funnel, counting ml. Approximately 200 ml fits into the rack. I drained about the same amount of old liquid, maybe a little less, but taking into account the fact that in winter some part was still squeezed out through the seal, I poured in more.

As soon as all the fluid has entered, you need to screw the nipple into the nipple and begin the pumping procedure. But before that, we pump air into the rack with a compressor. I know that air will act as an oxidizing agent, but for such a small volume I don’t think it will have any big effect. For ease of pumping, you should grind off 4-5 threads from the nipple, because... The volume in the rack is very small and there is no way to pump it up like a wheel. It is necessary to immediately “unfasten” the compressor fitting from the nipple at the moment of full inflation, otherwise you will lose atmosphere. I pumped it up at about 8-9 atmospheres. You need to pump it in a horizontal position with the nipple up, pressing the fitting tightly, otherwise it will splash with liquid from the stand during shooting.

To do this: 1. The shock absorber should be turned upside down and slowly, without sudden movements, compress it; 2. In this position, the shock absorber rod must be fixed for 2-3 seconds; 3. Without releasing the rod, you need to turn the shock absorber over with the rod facing up, and fix the shock absorber in this position for about 3-6 seconds; 4. After 3-6 seconds and leaving the shock absorber in a vertical position, smoothly extend the rod until it stops (end of stroke); 5. Next, you need to position the shock absorber with the rod down, pause for 2-3 seconds. and repeat operations of points 1, 2, 3, 4 approximately 5-8 times; 6. When bleeding the shock absorber, following the entire above sequence, stop at step 4; 7. Holding the shock absorber in a vertical position, with the rod up, perform the last, let’s call it, a control operation (with sharp movements you need to press the shock absorber rod a little at a time and with proper pumping, the piston should move smoothly and without failures). If the shock absorber is pumped correctly, the piston moves smoothly, without dips.

After pumping is completed, the shock absorber must be kept in the working position, VERTICAL and ROD UP, until final installation on the vehicle. After bleeding, under no circumstances should the shock absorber be tilted or turned over before installation.

Many people install a shock absorber directly from the box, without proper bleeding; in this case, the life of the shock absorber is reduced by 3-5 times, and the shock absorber cannot perform its functions normally (does not work correctly)

Bottom line

all the “fraud” done - with a mileage of more than 1500 km on bad and good roads in 3 regions, no knocks were heard. The racks work much smoother, it even seems that they were not like this from the “new” ones, maybe due to the fact that I didn’t pump them up quite correctly initially. There are no leaks around the nipples, the seals on top do not sweat, they hold pressure.

Source

Why did the new shock absorber leak?

There are times when you buy new shock absorbers for your car, come to a service station, they remove the old shock absorbers on your car and install new ones. Together with them they install a new service kit (boots and shock absorber bumpers), and you drive away in your car with new shock absorbers installed.

With the old shock absorbers, you felt that the car was somehow “sluggish” and “shaky.” I didn’t keep the road on a “washboard”, the extraneous knock on a not entirely smooth road (which in our city, and not only in our city, is about 99%) was just “sick”... You stopped at a service station. This service station was recommended to you by your good friends - they get their car repaired here. True, your car is a different brand than your friends. But, according to most car owners, the cars are the same. They (cars) all have four wheels, the wheels are round, and all cars are controlled by a steering wheel.

So, after installing new shock absorbers,

– we immediately felt the difference in driving. Everything became different. And immediately your car became somehow “knocked down”. Something in it has stopped annoyingly knocking, as they explained to you - this knocking was caused by wear of the shock absorber rod in the “working comfort zone”. This doesn't tell you much. You are happy with the result: although the shock absorbers are not cheap, the result is obvious.

But... After some 20-30 kilometers, it began to seem to you that the car began to “knock” again and stopped holding the road, returning to its condition, which was before replacing the shock absorbers and bumper guards. You begin to think that the reason is that you bought non-original shock absorbers. “Maybe I should have put on the original?” – you begin to think.

The next day, you come to the service station where your shock absorbers were changed. Tell us your thoughts about original and non-original shock absorbers. They listen to you carefully, say: “Perhaps,” and drive the car onto a lift for diagnostics.

When you lift the car, the defect immediately becomes obvious! Both shock absorbers leaked... There was some kind of smile on the faces of the mechanics. But this smile gives way to an incomprehensible grimace of bashful horror when they remove the shock absorber from the car and expose the shock absorber rod, removing the bumper boot from it... The shock absorber rod has traces of scuffing. Moreover, these scuffs on the rod are not longitudinal (in the direction of shock absorber operation), but transverse. It’s as if someone specially took and “pulled” the rod with some kind of tool, but it’s not clear why?!

Later it turns out that the careless mechanic who changed the shock absorbers had no idea how shock absorbers are changed correctly, as described in the technical literature. Later, of course, the owner of the service station will be forced to apologize to you and eliminate the defects in the work performed by his employee - at the expense of the service station. You no longer care about the fate of that careless mechanic; you want to leave the service station faster with a repaired car.

What can we advise to avoid getting into such situations? Defects at work and careless employees are found in many areas of human activity. “He who does nothing makes no mistakes,” the proverb tells us.

But, still: trust the repair of your car only to professionals. Buy spare parts only in a car store that you have verified and where you liked both the level at which you were served and the professionalism of the employees.

Share link in: List of articles »

m. Kharkiv Telephone: +380(67) 57-19-19-7 +380(57) 716-42-44

The shock absorbers (struts) are leaking. What to do and is it possible to drive? What will be the consequences

THE CONTENT OF THE ARTICLE

Shock absorbers are an integral part of the suspension, which you simply cannot do without! They dampen spring vibrations, which in turn make the suspension more comfortable. If there were no shock absorbers, then the car would simply shake like a swing, jump on any bump, and the oscillatory movements up and down would last about 30 seconds, maybe a little more or a little less, that’s not the point. With such a “swing”, the bottom can be smashed into pieces, and so can the suspension. The shock absorber is that protective “buffer” that removes these vibrations, thus, even after driving through a deep hole, your car will not “pump”, you will continue to move confidently. I think everyone knows the principle of operation - but it was worth reminding a little.

The shock absorber is leaking, what should I do?

Greetings, dear motorists! And again, we continue to study individual systems, components and parts of your car.

Quite a lot of motorists, in particular beginners, believe that the purpose of batteries is only to provide comfort while driving. This is true, but it is just one of the functions. How amazed novice motorists are when they don’t pay attention to leaking shock absorbers, and as a result they end up in a ditch. You wouldn't wish this on anyone!

Why do shock absorbers leak?

It’s all about the design of the rack itself; now, for this period of time, you can find only three main designs:

The operating principle of one or the other is almost the same - roughly speaking, it is a cylinder that is filled inside with oil, or gas, or both at once (divided into chambers). A special piston with an attached rod moves through this “mass”, which does not compress or stretch it; it moves in the liquid thanks to special small holes called “jet” holes. And since the holes are small, the rod cannot move quickly - the movement is very difficult. Thanks to this structure, vibrations are damped (in short, there will be a detailed article about the operation and design of shock absorbers).

So - so that this oil does not go beyond the limits of our cylinder (rack housing), and so that the rod does not release oil or gas, it is locked from above with special sealing and rubber gaskets. Therefore, the internal component of gas or oil cannot leave the housing.

However, due to excessive wear of the rod, or wear of the gaskets, oil or gas begins to escape from the top of the housing and begins to ooze. If the gas is not visible and the shock absorber remains dry, then the oil flows from top to bottom and the shock absorber becomes wet. This tells us that it has failed, or is gradually failing! It needs to be changed. This is why the shock absorbers are leaking - it has simply exhausted its service life, or is broken (on our roads).

What comes out of shock absorbers

To understand the question of why shock absorbers leak, you need to understand their design and operating principle. The shock absorbers themselves look like cylinders filled with liquid or gas. A piston with a rod is installed in them, and the element is sealed using rubber seals and gaskets.

During operation of the shock absorber, the piston and rod move through the mass inside the shock absorber. Since the travel is small due to the filling of the shock absorber and the tightness of the element, suspension vibrations can be damped, and only a small part of them is felt by drivers and passengers inside the car.

At the moment, oil, gas or mixed (in which there are separate chambers with oil and gas) shock absorbers are installed on cars. Only oil or mixed versions of the part can leak, and when gas escapes, the problem will be noticeable only by the “behavior” of the car.

What to do and is it possible to drive?

Of course you can drive, in general you can “drive” without shock absorbers - but how? Of course, if you have one strut leaking, then you may not notice it, but if there are two at once, or as my friend had three (two in front and one in the back), then the car will “swing” like on a roller coaster. Even low speed and reaction to small irregularities caused the car to sway, I’m already silent about some sharp maneuvers (turns, for example), the car was simply drifting!

What to do - change it urgently , the sooner - the better, otherwise, due to your incorrect savings on racks - then you will pay more.

Is it possible to drive:

Guys, I understand that original shock absorbers are expensive, but they need to be changed! YES, and you can find quite sane originals, for example KAYABA, very sane quality and more or less prices.

Consequences if not changed

Well, my dear, you are frugal - if you don’t change 1 leaking rack on time, then the rest will follow it in a circle. Why? Yes, everything is simple - the car is designed to hold 4 sides, that is, all 4 shock absorbers must work. If one fails, the entire load is transferred to 3 sides, but they are not designed for it - and they begin to break. And with each failure, the load is redistributed into two, etc.

In simple words - if you don’t replace 1 strut in time (as you noticed right away, you can drive for up to a week while you wait for the part), then in a month the second one will come out, then the third one and then the last one. That is, there is a big chance that if you don’t replace one, you can replace them all at once!

If this doesn’t scare you, well, I’ll ride in a rocking car, so what, let’s read other consequences:

I repeat again guys, you need to change it as soon as you notice “snot” (smudges). After all, if the rack is “snotty” and has just started to leak, it still holds for some time until all the oil comes out of the housing, but then it becomes empty and simply does not work.

So you have a week - well, two at most. Order and change, you will save others from damage.

That's all, I think it was useful.

(

45 votes, average: 4.42 out of 5)

Source

Faulty stand: the essence of the problem

Why this is so is clear from the design. Inside hydraulic shock absorbers there is a chamber filled with oil. The strut dampens the energy of the spring by pumping oil through a piston mounted on the rod, slowing down its movement. To prevent oil from leaking out, sealing elements are installed between the rod and the body. They fail due to aging, exposure to road reagents, and cold. There is no liquid inside gas products - gas works.

An experienced driver is able to identify a malfunctioning strut while driving. To fully verify this, it is enough to alternately rock each of the four points of the body while the car is stationary. By pressing down on the body, it should immediately return to its original position in one go. Rocking up and down and stopping after two or three moves indicates that it’s time to change the stance.

Basics of diagnosis

In the era of intensive automobile production, we have been taught that only a service station can give a complete verdict on the condition of the suspension. In fact, there are a number of tests, based on the results of which you can judge the condition of the chassis components without leaving the garage. Thus, a common cause of failure of a shock-absorbing strut is leakage of working fluid/gas escape. This breakdown, first of all, can be visually inspected: traces of oil are clearly visible on the shock absorber body (it is commonly said that it is “snotty”), while a serviceable part always remains dry. It is clear that this only applies to oil and gas-oil struts. Gas analogues do not contain liquid.

The essence of the second test is to evaluate how a single shock absorber dampens body vibrations (read: reacts to swaying). To do this, near each rack you need to push the body down. A serviceable shock absorber element has the following reaction:

- The body returns to its original position the first time without swaying.

- The body returns to its original state smoothly and evenly.

- During operation of the suspension, a characteristic sound (“zilch”) is clearly audible.

A defective rack does not perform its main function - absorbing swing energy. Because of this, instead of one “down-up” oscillation, the body makes two or three. Also during the reverse stroke (upward) no resistance is felt, i.e. the body of the car quickly returns upward, and by definition there is no characteristic sound.

( 2 ratings, average 4.5 out of 5 )

Is it possible to drive if the shock absorber strut has leaked?

Normally, the load is distributed between four shock absorbers. When one of them fails, its functions are distributed among three workers. Loading in excess of the nominal value and deviation from coaxial motion leads to rapid breakdown of the rest of the trinity. Moreover, the diagonally located rack will be the first to suffer.

For reasons of economy, it is better to replace one rack at the dawn of its failure than all four, but two months later. The oil does not flow out immediately, but over a long period of time. Therefore, if leaks are detected, it is necessary to immediately replace it. The reference option is to replace two racks located on the same axis at once. The identical characteristics of the shock absorbers lead to the fact that factory controllability is restored, there is no distortion of the sides of the body and their service life increases.

If the failure of one shock absorber does not make significant adjustments to the vehicle's directional stability, then three empty struts pose an extraordinary danger. And here it is better to refuse daily use, and if you drive, then do it very carefully, with minimal speeds both in turns and on uneven roads.

What to do if the shock absorber starts to creak

One day during a trip, you heard that the rear or front shock absorbers began to creak. This means that it’s time to carry out not only diagnostics of the car’s suspension, but also diagnostics of the shock absorbers. If the shock absorber squeaks, this is a warning for you. When diagnosing the suspension, visually inspect the shock absorbers. If, upon inspection, you find that the shock absorber is leaking, then you should immediately repair or replace it.

Can you guess why? Yes, it’s simple, in the “best” case, only the suspension will suffer, in the worst case, you can become involved in an accident at any moment. How do you like this prospect? If you close your eyes to this, you will spend even more money, not only repairing the shock absorber, but also repairing the suspension. We advise you not to be lazy and visually inspect the shock absorbers systematically. Moreover, there is nothing complicated about it - you turn the wheels and make sure that the shock absorber is not leaking, that everything is normal. Most novice motorists, when diagnosing the condition of shock absorbers, make hasty conclusions about the malfunction of the shock absorbers when they see oil deposits on them. However, there is nothing wrong with this, this is a completely normal condition. But if you notice oil leaks, then replacement or repair certainly cannot be avoided.

Attention! Professionals strongly recommend replacing both shock absorbers on the same axle, even if one of them is in good condition and does not have any faults. Just like brake pads or brake discs, shock absorbers are paired parts, therefore, they also need to be replaced in pairs.

What happens if you don’t change leaking shock absorber struts?

The economic disadvantage of this tactic is obvious: due to uneven distribution of the load, over time the remaining three shock absorbers will fail and all four will have to be replaced. This idea is far from beneficial in terms of driving comfort: the car sways for a long time after overcoming a bump. However, there are more dangerous consequences:

Moreover, driving with three or more faulty struts is extremely dangerous. Due to the fact that the car sways easily and continues to sway for a long time, there is a risk of overturning in turns and driving into oncoming traffic. And this, for a moment, is a serious accident.

Another risk of driving on faulty shock absorbers is damage to the underbody and muffler. The body sways more than usual, and it becomes easier to catch the bottom of an uneven surface.

Indirect signs of malfunction

To see that the shock absorber strut is leaking, just look at the suspension from below. However, it is not always possible to do this. And on some cars, due to the design of the shock absorbers, they are simply not completely visible. Accordingly, it will be useful to know about indirect signs that the rack is leaking.

This includes the following signals:

- long rocking of the car even on a flat road;

- knocking when driving over uneven surfaces;

- beating in the steering wheel;

- severe body roll when accelerating, braking or maneuvering.

This is more difficult to notice, but when shock absorbers leak, fuel consumption and braking distance increase, the car handles worse, and does not hold the road during aggressive driving.