Fuel pressure diagnostics

© Alexey Pakhomov, aka Is_ 18, Izhevsk

Fuel pressure is one of the most important engine parameters from a diagnostic point of view. The composition of the mixture, and therefore the behavior of the car in various modes, depends on it. Let's try to integrate diagnostic methods based on fuel pressure into a system. Naturally, you will need a fuel pressure gauge to work. It is best to purchase a device with a large, easy-to-read scale, the measurement limit is 5 - 6 kgf/cm 2. For example, like the one in the photo. The use of pressure gauges with a limit of up to 10 - 12 kgf/cm 2, used in the diagnosis of foreign cars, is hardly advisable due to the relative inaccuracy in the range of 2 - 3 kgf/cm 2. So, we connect the pressure gauge and diagnostic scanner.

1 . First of all, we evaluate the operation of the pressure regulator. To do this, turn on the pump with the engine not running. The pressure gauge should show 3. 0 +/- 0 . 2 kgf/cm2. If the pressure is below 2. 8 kgf/cm 2, it is better to change the RTD, because in power modes the machine will be dull. We pronounce the final verdict on RDT only after the next point.

2. Next, check the zero supply pressure. The name of the parameter speaks for itself - this is the pressure developed by the pump, as they say, “to the plug”, that is, fuel is not supplied. Indirectly, this parameter indicates the residual life of the pump; as it wears out, it gradually decreases.

So, take the pliers and pinch the “return”. This needs to be done quite sharply. The pressure gauge needle should literally shoot towards the limit value. If it rises slowly, then the fuel filter or fuel inlet mesh may be clogged. The limit value itself speaks volumes. If the pump is new, it will reach 5 - 6 kgf/cm2, and on pumps made in the Czech Republic - up to 7 kgf/cm2. In any case, if the pressure exceeds 5 kgf/cm2, then the pump has a sufficient resource. The manuals give different values of zero supply pressure at which the pump supposedly requires replacement. But in practice, if the pump “on the plug” presses at least 4 kgf/cm 2, it can still go on and on. In reality, customers complain about the dullness of the car when this parameter no longer reaches three “points”.

3. Turn off the pump. The pressure should drop to approximately 0. 7 kgf/cm 2 and remain at this level. If it immediately drops to zero, then either the pump check valve or the RTD is faulty. This defect, of course, is not fatal, and is often eliminated by briefly squeezing the return line. If it turns out that the RTD is at fault, it can be replaced, but changing the fuel pump due to the check valve does not seem advisable, at least according to customers.

4 . We start the engine. We carefully monitor the pressure gauge needle. This is where the larger scale comes in handy. The needle may tremble slightly, this is a consequence of large pulsations of absolute pressure (pressure in the intake receiver). These pulsations are a topic for another discussion; let’s forget about them for now. But if the needle does not tremble, but “walks”, and within a fairly wide range (up to 0.3 kgf/cm2), then the gas inlet mesh is probably clogged. For example, like in the photo. (note from Sim - this is not the most extreme option - see more “cool” cases HERE)

5 . With the engine running, the pressure will be about 2. 3 kgf/cm2. If you remove the vacuum hose from the RTD, it will rise sharply to 3 kgf/cm2 (or to the value obtained in step 1). Put the hose back on. Smoothly raise the speed to about 3000. If the pressure gradually drops, then this is another sign of a “dead” pump.

6. You can also check the performance by unscrewing the fuel supply line and applying power to the fuel pump. About 1 should run up in a minute. 5 liters. To be honest, in all my practice I have never done this; I somehow made do with the pressure gauge readings.

7. The most extreme option is a pressure of about 1 “point” and an uneven sound of the pump. The reason is there is no gasoline in the tank. Not funny. I regularly send my cars to refuel once a month.

That's all simple science. If you had to disassemble the gas tank, it makes sense to look into it with a flashlight. At the bottom you will find water, rags of dirt, sand and other unnecessary substances. They need to be removed with a pear. Or better yet, if you have one, use a vacuum unit for changing the oil. Since we remembered the tank, one more piece of advice. To prevent the gas tank from turning into a cake in winter, drill its cap from the back side. The method is stupid and not recognized by all experts, but it is radically effective. Good luck!

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

Take a pressure gauge (in the photo a device for measuring tire pressure). We wind the foam (plumbing flax) under the pipe and put on an oxygen hose with an internal diameter of 9 mm. Secure with clamps. Place a rag on the generator (so as not to start a fire under the hood). Unscrew the plastic cap on the fuel rail.

Under the cap there is a hole with a nipple. Unscrew it from the wheel cap. Due to the residual pressure in the rail after removing the nipple, gasoline will splash out.

If desired, you can relieve the pressure in the vehicle's fuel system . To do this, you need to remove the fuel pump fuse (under the right trim of the center console near the ECU, where there are 3 relays and 3 fuses. Usually the fuel pump fuse is on the far left) and wait until the car is running and does not stall.

We put the second end of the hose on the ramp hole and secure it with a clamp. We remove the rag from the generator and start the engine. Don’t forget to cover the generator with a rag again before removing the hose from the ramp. That's it, now you know how to check the pressure in the fuel system in the field .

By the way, instead of clamps, you can use the bushing of the classic adjusting bolt (item 27 in the figure). It screws perfectly onto the “tens” ramp fitting. To seal, we put a suitable rubber ring on the fitting. On the other side of the bushing we solder a fitting onto which we put a hose with a pressure gauge.

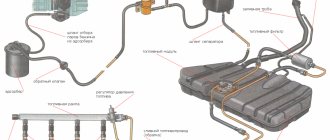

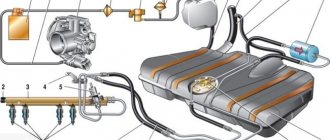

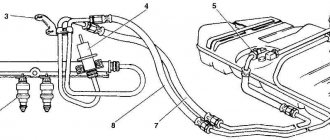

1 – fitting for checking the pressure in the power system; 2 – fuel rail; 3 – nozzles; 4 – fuel line; 5 – fuel tank; 6 – fuel pump module (in the fuel tank); 7 – fuel filter; 8 – tee.

Video showing the process of checking the pressure in the fuel system of a car:

Car diagnostics using fuel pressure

Problems in the operation of the car's fuel system are expressed by failures at high speeds, jerking of the car, or the car does not move when you need to accelerate sharply, and sometimes it simply stalls. Now knowing how to check the pressure in the fuel system of a car, we can diagnose the car ourselves. We can determine which component of the fuel system has failed (fuel pump, fuel pressure regulator (FPR), injectors, filters, etc.), but first we need to understand how the fuel system works: The fuel pump continuously pumps fuel while the engine is running. Excess gasoline is stupidly dumped through the RTD into the return line. The pressure in the ramp changes (increases) not so much with the speed, but at the moment of accelerating (this is clearly visible in the video), because at this moment, the vacuum (vacuum) in the receiver drops and the RTD adds pressure to the ramp. If you turn off the engine, the pressure in the ramp will slowly begin to decrease exponentially. The rate of decline (from several minutes to several hours) depends on the quality of the check valve, which is located on the back of the fuel pump motor.

When diagnosing, pressure measurements in the system are made in different ways:

Checking the fuel pump “for a plug” is quite simple; you need to pinch the return line with pliers (for 2-3 seconds) with the car running and watch the pressure gauge readings.

Another way to check the fuel pump: smoothly raise the engine speed to 3000 rpm. If the pressure gradually drops, then this is a sign of a “dead” pump.

Signs of a fuel system malfunction

Low or excessive pressure in the fuel rail leads to the following consequences:

- unstable engine operation;

- not smooth idle;

- engine tripping;

- increased consumption;

- power drop;

- the engine stalls at idle;

- increased CO content in exhaust gases.

If you encounter one of these problems, and ECU diagnostics do not give any results, then the first thing you need to do is measure the pressure in the fuel system.

The pressure in the fuel rail is measured according to the same principle as in the tires.

Pump operating principle

The VAZ 2109 fuel pump has a fairly simple design; the injector functions only thanks to it. It is based on two elements - an electric motor and a pump with a filter element. Please note that the “diaper” (as people call the filter for its similarity) needs to be changed on time - try not to let it work for more than 20 thousand km. Otherwise, it becomes saturated with metal shavings, dirt and other rubbish, which gets into the line and clogs the injectors.

We take a measurement in the fuel rail.

To work we need a “pressure gauge”. But not every pressure gauge is suitable, it all depends on the pressure limit that it can measure. In our case, we need a pressure gauge with a measurement limit of up to 7 atmospheres. If you have a pressure gauge measuring up to 17 atmospheres, then such a device will show incorrect data, because it has too much error at low pressure.

In addition to the pressure gauge itself, we will need “plumbing flax”. We wind flax under the pressure gauge nozzle and put a hose with an internal diameter of 9 mm on it. Next, we tighten the whole thing with a clamp. Our device is ready for use.

In a store, such a device with a hose and drain will cost you about 1200 rubles. Measuring the fuel system at a service center will cost you about 200-300 rubles.

- Open the hood, turn off the ignition, find the fuel injector rail.

- We unscrew the plug of the fitting for fuel pressure, then use a spool to unscrew the nipple that appears, carefully placing a container or rag, because gasoline will spray due to remaining fuel pressure.

- Place the pressure gauge hose over the fitting and secure it with a clamp.

You need to check the pressure in 4 operating modes:

- measure the pressure when the ignition is turned on;

- measure the pressure at idle;

- measure the pressure with the tube removed from the fuel pressure regulator;

- measure the pressure with the return pipe pinched.

What pressure should the fuel system have?

A normal fuel system should have the following indicators:

- at idle 2.5 atm;

- ignition – not lower than 3 atm;

- when removing the vacuum tube 3.3 atm;

- when squeezing the drain tube - 7 atm;

- when accelerating, it jumps to 3, then drops to 2.5 atm.

Important! Make sure that the fuel line does not contain any holes: fuel is not leaking anywhere, otherwise the pressure measurements will be false.

- After we have pumped fuel into the system, turn off the ignition and look at the behavior of the pressure gauge. The pressure in the rail should drop to 0.7 bar and remain at this level, but if the pressure immediately drops to 0, then the problem is in the fuel pressure regulator (how to remove and replace the RTD), or the check valve of the fuel pump motor.

- We raise the engine speed to 3000 and look at the pressure gauge readings; if in this mode, the pressure gauge needle drops, the problem is a dying fuel pump.

- If the fuel pump takes a long time to build up pressure, the fuel filter or strainer in the tank may be clogged.

If, after replacing the fuel cells, your problem remains, then check other systems: IAC, TPS, MAF, compression in the cylinders.

Checking and replacing the fuel pressure regulator

As you can see, a malfunctioning pressure regulator has symptoms very similar to a malfunctioning fuel pump or a clogged fuel filter. At the very beginning, we note that if problems with this element are detected during the inspection, then it is preferable to replace the RTD with a new one. The fact is that replacing individual parts, cleaning attempts and other manipulations often do not allow the device to return to proper functionality. Considering that the price of a fuel pressure regulator is quite affordable, then any repair attempts can be considered impractical.

Measurements should show changes in pressure in the system within a certain range. The fuel pressure should increase, being within the range of 0.3 - 0.7 Bar. If this does not happen, then first you can try replacing the vacuum hose, and then repeat the measurements. To check the fuel pressure at the end of the ramp, you will need to unscrew the fitting plug. This plug also has a special ring for sealing. The specified ring should be checked for integrity; the element should remain elastic. If there are defects, then the ring or the entire plug also needs to be changed at once.

replaced the RDT, the old RTD was somehow removed from the ramp by... at first the bolt on the hexagon couldn’t be unscrewed, I don’t know how to say, even where the hexagon engages)) a friend helped))) they unscrewed it, ATP helped him out a lot. then the fuel line from the RTD could not be unscrewed)) it was unscrewed with a hammer))). 1 spare part was found to be defective or a handicraft in general HZ))) it was leaking gasoline from the RTD where the RTD is attached. I bought the second one and it’s holding up well))) well, here are the results in the photo, there are few photos until I had time to take all the measurements. Well, it already feels much better than it was and most importantly it doesn’t stall in neutral)))

We check the pressure in the fuel rail with a regular pressure gauge (for example, from a tire pump).

Disconnect the negative cable terminal from the battery.

We put an oil and petrol resistant hose (with an internal diameter of 12 mm) onto the threaded fitting of the pressure gauge and secure it with a clamp.

Unscrew the fitting plug on the fuel rail.

shown on the removed ramp

Using the wheel valve cap, unscrew the spool valve from the fuel rail fitting, gradually releasing the fuel pressure

We put a pressure gauge hose on the ramp fitting and secure it with a clamp

We start the engine and when idling, check the fuel pressure, which should be 2.8-3.2 bar (280-320 kPa).

Signs and symptoms of low pressure in the system

Weak pressure is expressed primarily by the presence of dips. You try to accelerate, press the gas pedal, nothing happens. Stopping the engine and then starting it helps (this way the pump pumps fuel). However, after ten or fifteen kilometers the situation repeats itself.

Some drivers even change the fuel filter or pump strainer in the hope of improving the situation, but this does not help. Replacing the mesh in this case is considered as a more correct option. The fact is that the pressure can drop due to a poorly functioning pump.

If the problem is not in the mesh, then the pump itself is dying. There is another reason - it is the vacuum of the fuel tank. This is how it is checked. You need to stop the car if it starts leaking, sneezing, etc. But don't turn off the engine. Then open the tank flap and loosely close it again. Continue driving, if the dips disappear, it means there is definitely a vacuum in the tank.

The lid may not be closed at all to allow air access. When there is a vacuum it is not enough. If the problem repeats, the failures do not disappear, the fuel pump must be considered the culprit.

A clogged fuel line and a malfunction of the sensor that regulates the fuel pressure immediately before injection can also cause low pressure. To reliably verify why exactly the pressure is jumping, it is necessary to carry out competent measurements. First measure the pressure of the pump, then the lines (before and after the filter), and then directly in the ramp. Such instrumental monitoring will allow us to identify a specific cause.

This sensor is often ignored by motorists, but it is its malfunction that can lead to insufficient pressure. Symptoms of a failed sensor:

- loss of car dynamics;

- Unstable engine speed in idle mode;

- difficulty starting;

- failures;

- increased fuel consumption;

- reduction in power.

Violations with RTD occur quite often, since the design of the sensor is mechanical.

- The membrane springs weaken. As a result, the valve cannot cope with the air pressure coming from the manifold, which leads to a decrease in pressure and the amount of incoming fuel.

- The valve jams, the connections lose their tightness. Because of this, the RTD becomes clogged. In general, a stuck valve can lead to an uncontrolled flow of fuel into the manifold. Fuel consumption instantly increases, the engine stops starting normally due to interruptions.

You can verify that the RTD is faulty by determining the pressure value.

| Mode | Indicators |

| Ignition on | 2.9-3 kg/cm2 |

| Engine is running | not less than 2.5 kg/cm2 |

| Vacuum hose disconnected | 3.3 kg/cm2 |

| The return line is pinched | 7 kg/cm2 |

| Peregazovka | 2.5-3 kg/cm2 |

The pressure regulator is checked first, because it is due to its malfunction that the pressure drops. If it is in order, you need to test the operation of the pump. This is done by squeezing the fuel drain check valve.

Video: how to check fuel rail pressure

Forget about fines from cameras! An absolutely legal new product - Traffic Police Camera Jammer, hides your license plates from the cameras that are installed in all cities. More details at the link.

- Absolutely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter connector;

- Does not cause interference to radios and cell phones.

Main elements of the fuel system of an injection engine

The injector is a complex mechanism for supplying fuel to the cylinders. The entire fuel supply process is controlled by the engine's electronic control unit (ECU). The fuel supply system also uses a parallel air supply.

Fuel pump glass

The fuel pump cup is a collection of the main elements of the fuel system assembled on one site.

The fuel pump glass includes:

- Gasoline pump

- Coarse filter

- Fuel level sensor

- Fuel pressure regulator (only in 1.6 liter engine versions)

Gasoline pump

It is one of the main elements of the fuel system. Serves to supply fuel to the cylinder block under pressure. A fuel pump is a kind of electric motor. Its operation is based on the principle of centrifugal force. Under the influence of the magnetic field formed in the stator of an electric motor, its armature is given rotation. A pump volute is installed on the anchor shaft, which directly pumps pressure into the fuel system.

The gasoline pump is very capricious and picky about the purity of the fuel consumed. Most often, the fuel pump fails due to low-quality fuel or its lack in the tank. In order for the gas pump to last as long as possible, it is necessary to refuel at proven gas stations and keep at least 25% of the tank volume in the car’s tank. If you drive with the fuel light on, the fuel pump will most likely fail much faster, since if there are bumps, the gasoline in the tank will squish from side to side and the fuel pump will suck in air.

Injectors and fuel rail

The fuel rail serves as a kind of case for the injectors; it is in it that they are installed.

The injectors of an injection engine are also one of the most important elements of the fuel system. Designed to supply fuel to the engine cylinder block under pressure. The injector sprays fuel into small droplets for better and easier ignition in the cylinder.

The injector is installed directly on the car engine, namely in the cylinder head. The number of injectors depends on the number of cylinders of the car. Lada cars have 4 cylinders, therefore there will also be 4 injectors.

Injectors are also very sensitive to fuel, but are less susceptible to damage since the fuel supplied to them is filtered through 2 filters: a coarse filter and a fine filter. But more about them a little later.

Fuel pressure control

The fuel pressure regulator (FPR) is a sensor installed on the fuel rail in 1.5-liter engine versions and installed in the tank on the fuel pump cup in 1.6-liter engine versions. It serves to ensure the required fuel pressure in the system and regulates the fuel pressure by releasing excess fuel pressure into the return line.

The RTD is a very reliable element and fails extremely rarely. The cause of its breakdown may also be poor quality fuel or the aging factor.

Fuel line

A fuel line is a set of fuel pipes designed to transport fuel from the tank to the internal combustion engine. The highway in Lada is located under the bottom of the car and is protected by plastic covers.

Fuel pump pressure VAZ 2109 injector

The fuel pump for the VAZ 2108 2109 21099 is installed with an electric injector. That is, it is turned on by supplying +12V voltage from the battery to it. It is located in the gas tank of the car. The task of the fuel pump is to supply fuel under pressure into the fuel rail, from where it is sprayed directly into the working cylinder using the injection system. Checking the performance of the fuel pump VAZ 2108 2109 21099: 1) When the ignition is turned on, the pump should start working. That is, the sound of its operation should be heard in the rear seat area. Therefore, the very first thing you need to do is check the fuse and the fuel pump relay. The assignments of the relays and fuses are labeled on the back of the mounting block cover. If the fuse is intact and the relay is working properly, then you need to remove the back seat of the car and measure the voltage at the fuel pump itself. This is done using a multimeter or wires with a 12V light bulb.

The injection VAZ 2109 has an electric fuel pump

If there is voltage at the pump, then everything is fine with the electrical part; you need to look at the fuel system. If voltage is not supplied to the fuel pump, you need to check the wire from the mounting block to the fuel pump; it may be damaged. 2) On the VAZ 2108 2109 21099 injector, it is not recommended to allow the fuel level in the tank to be less than 10 liters. Not the most convenient requirement, given that the car’s gas tank capacity is 45 liters. However, there is a reason for this: if the fuel level in the gas tank is low, the gas pump may catch air, which is unacceptable.

The operation of the pump is checked by measuring the pressure in the fuel rail. There is a special hole in the rail for connecting a pressure gauge. If there is voltage to the pump, but there is no pressure in the fuel rail, you need to check the fuel filter. If it is in order, check the fuel line from the tank to the ramp; if it is also not damaged, then the fuel pump is most likely faulty.

For further diagnostics, the VAZ 2108 2109 21099 fuel pump must be removed from the car and try to install a new one. If everything works with the new fuel pump, then the old pump is faulty. If, even with the new fuel pump, there is no pressure in the fuel rail and the car does not start, then the problem will be in the fuel system.

If you do not have a pressure gauge, the operation of the gas pump can be checked by the amount of fuel pumped per unit of time. Having unscrewed the spool, we connect a hose to the ramp, which we lower into the container for measurement. On Kalina and Grant, the pump should pump 35 liters per hour, or 0.5 liters. in a minute. At ten, the pump pumps 1 liter. in a minute. If much less fuel has leaked out, all filters must be checked. Under the bottom, next to the gas tank, there is a high-pressure filter. Another filter that needs to be checked is located in the tank itself on the fuel module. What to pay attention to: To remove the fuel pump from the car, you must remove the fuel tank. The VAZ 2108 2109 21099 fuel pump and injector cannot be removed directly from the passenger compartment, you can only check the voltage supply to it.

When considering the fuel system, you should definitely mention the VAZ 2109 injector fuel pump. The injection system consists of several components, which are basic. On our website you can also find information for newer VAZ models, for example, 2110. Nines are also equipped with electric fuel pumps that supply gasoline under a certain pressure to the ramp. Moreover, the pressure must be constant, otherwise the operation of the engine will be unstable. So, what is the injection nine fuel pump and how does it work.