In a modern gasoline engine, the combustible mixture is injected into the cylinders by injector nozzles at the command of the electronic control unit. Typically, diagnostics of the engine fuel supply circuit is carried out in a car service center, although the car enthusiast can determine obvious problems on his own. To find the cause of the malfunction, you need to check the pressure in the fuel rail and other points in the system.

What pressure should be in the fuel system?

The pressure level in the fuel supply circuit depends on the design of the system. In cars where the RTD and the discharge tube - “return” - are located in the engine compartment, the pressure gauge should show 2.7 Bar. The upper and lower permissible limit is 2.7–3.0 Bar. If the measured values are outside the specified range, you should continue the diagnosis and find the cause of the problem. On many cars, including VAZ, the pressure regulator and the fuel return hose are located next to the fuel pump. The normal manifold pressure for such machines is 3.8 Bar, the maximum value is 4 Bar. If during the measurement process periodic pressure surges within 0.2 bar are observed, the primary strainer needs to be cleaned or replaced. Typically, it is installed in the gas tank along with an electric pump.

Parameters of the Bosch model 0580453453

If you are interested in a VAZ 2110 Bosch fuel pump, the characteristics of the models will differ in the length and sometimes in the diameter of the body. The diameter of the body is adjusted using a gasket made of gas-resistant rubber. Also, devices may differ in pressure, placement of chips on the terminals. The device grid does not differ in the number of seats, but may vary in shape. You can remake the chip for a terminal or install it from a VAZ car. The length of the fuel pump determines its performance when the volume of fuel in the tank is low. If it is located in a module, then compliance is required to install it. The length of the Bosch model 0580453453 is 105 mm, 0580453449 is 65 mm, and for Bosch 0580453465 this figure is 90 mm. The pump is located in the car tank, it is immersed in fuel. It contains an electric motor that drives the pumping element. A combination of these components supplies fuel under high pressure. As a result, the fuel pump is noisy and needs cooling. Therefore, the equipment is immersed in a tank of fuel, as it serves as a coolant and noise-insulating compound.

Pump replacement

Here you will need to initially buy a high-quality pump. It is recommended to buy one that was previously installed . You can also buy a part from BOSH.

You will need:

- The key is "17".

- Head at "10".

- Screwdriver.

- Pliers.

Before carrying out work to remove the pump, it is worth reducing the pressure in the system and disconnecting the battery. Next, you will need to remove all the pipes that fit the pump and unscrew the bolts securing it to the motor.

The work should be carried out carefully, as a certain amount of fuel may remain in the system.

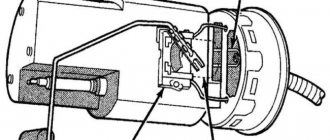

Remove the gas tank flap under the rear seat.

Disconnect the block and fuel hoses.

Unscrew the pump mounting nuts.

After removing the pressure ring, pull out the fuel pump.

Assembly work is carried out in reverse order.

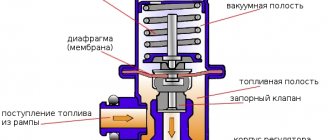

Characteristic symptoms of fuel pressure regulator malfunctions

By what signs can you determine that an RDT is not working:

- the engine is very difficult to start, you need to turn the starter for a long time and at the same time keep the gas pedal pressed in order for the engine to start;

- The engine idles unsteadily or the speed is very low, the engine often stalls. At the same time, it does not gain power at all; when trying to accelerate, it results in a deep failure;

- The spam engine changes speed sharply, this is especially noticeable at idle:

- Fuel is leaking from the fuel hoses. Attempts to tighten and replace clamps and replace hoses do not help.

How to check fuel pump pressure? Using an air pressure gauge

Are you a novice car enthusiast and don’t know how to check the fuel pump pressure? Then this article is for you. The pressure in the fuel system of a car is an important parameter that needs to be measured periodically. When diagnosing an engine, auto repair shops first measure the gasoline pressure, and only then carry out all other related work. This parameter determines the quality of engine operation in various modes. How to check the fuel pump pressure with your own hands? You can do it yourself in several ways. On the open market, you can find a special device that includes a pressure gauge and other components. A similar measuring device in a car dealership will cost you 1,500 rubles (+/-). By the way, when you stop at a service station, they will carry out the procedure for measuring the pressure of the fuel pump for 200-300 rubles. If you are not eager to shell out money for a measuring device or visit a service station, then there is a way to measure pressure using an air pressure gauge designed to determine the pressure in car tires.

We measure with available means: Most likely, every car owner has a pressure gauge that allows you to measure tire pressure. Therefore, this method is perfect for novice car mechanics. I would like to immediately say a small note about this method. Air pressure gauges, as a rule, are designed to measure high pressure, about 16 atmospheres. Fuel pressure gauges have limits around 6 atm. The first type of pressure gauges have small errors at the initial scale values.

Checking individual elements

When measuring the pressure in the fuel rail shows a deviation from the norm, the following reasons must be considered:

- the electric fuel pump is unable to develop the required performance;

- the regulator has failed, causing the gasoline pressure in the circuit to decrease or increase above normal;

- the fine filter is completely clogged, preventing the normal passage of fuel;

- Worn injector valves leak – the engine “floods” with fuel.

One way to check the fuel pump is to press the return hose located in the engine compartment with pliers. When the return line is blocked, the pressure gauge should show at least 5 Bar, with a new pump - 6 Bar. A pressure of 4 bar is critically low. Since the above method does not give an absolutely accurate result and is not applicable to all car models, it is advisable to check the fuel pump by directly connecting a pressure gauge. Other elements of the system should be excluded - pipelines, fine filter and regulator. Remove the back seat of the car, get to the unit and connect the meter directly to the outlet fitting.

If the readings on the ramp and on the pump fitting are equally low, change the pumping unit. Otherwise, the problem needs to be looked for elsewhere, following the algorithm:

- Purge the fuel line and change the filter, then test again.

- Reconnect the pressure gauge to the ramp, start the engine and remove the vacuum pipe (coming from the suction manifold) from the RTD fitting. If the pressure does not change, install a new regulator.

- To make sure that the injectors are working properly, you need to measure and compare two indicators: the pressure on the manifold with the return hose pinched and the maximum pressure created by the pump when connected directly. If the second value is much higher, part of the pressure is lost at the injectors.

If you find problems with loss of pressure on the manifold itself, remove the ramp and check each injector separately. Faulty parts cannot be replaced one by one - you will have to buy and install a complete set. The easiest way to check injectors for leakage is to test them in operation together with the manifold. Remove the ramp without disconnecting the fuel line, place a rag and turn on the ignition. If the injector valves are worn out and lose their tightness, gasoline will begin to drip from them. The working elements should be checked again - with the return hose crushed.

Diagnostic instructions

The first step is to free access to the ramp and fitting installed at the end of the manifold. Remove elements that interfere with measurements - air duct, filter housing, crankcase ventilation pipe, etc. (the list of parts depends on the car model). Proceed to measuring, following the instructions:

- Unscrew the protective plastic cap from the diagnostic fitting on the ramp.

- Place a cut-off plastic container and use a cap to unscrew the spool valves to release the pressure previously pumped up by the pump. You can press the valve or turn the spool 2-3 turns.

- Place one end of the gasoline hose onto the pressure gauge fitting and secure with a clamp. Unscrew the spool from the manifold, pull the second end of the hose onto the pipe.

- Turn on the ignition, and the electric fuel pump will pump fuel into the system. Make sure there are no leaks at the joints of the diagnostic tool.

- Start the engine and record the fuel pressure in the rail using the pressure gauge.

Advice. It is better to take readings from the device twice - after turning on the ignition and starting the engine. If you notice a difference, you need to additionally check the regulator and fuel pump.