The performance characteristics of an internal combustion engine directly depend on the compression in the cylinders. Car owners often complain that the engine is not as playful as before, the car accelerates worse, is reluctant to start, and at the same time consumes more fuel and oil. Taken together, these signs indicate a drop in compression, which, in turn, is often caused by stuck piston rings. You can finally verify the drop in compression using a pressure gauge. It is necessary to measure the pressure in each cylinder and compare the readings with those that should be, according to the technical documentation. In addition, you should pay attention to whether there are differences in the pressure gauge readings for each cylinder. If the motor is working properly, the differences should remain within plus or minus 0.5 atm.

Why do the rings lie?

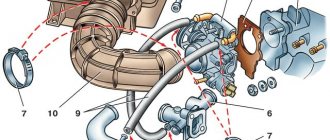

To understand the reasons for the occurrence, you should remember how they work. The piston rings are located in the grooves of the piston. The grooves themselves are wide enough to allow the rings to move fairly freely. The rings placed on the piston do not fit closely to it, but, on the contrary, are pushed apart. Thus, the expanding force forces them to fit tightly against the cylinder walls, providing high pressure inside the combustion chamber at the end of the compression stroke.

This entails all the symptoms indicated at the beginning of the article: difficulty starting the engine, especially in cold weather and a drop in power due to the presence of compression rings, as well as increased oil and fuel consumption and thick blue smoke from the exhaust pipe, for which the oil scraper rings are to blame.

There are several reasons for the appearance of deposits in grooves:

- the car is not used for a very long time, as a result of which the engine oil loses its properties, thickens and begins to play the role of glue;

- The car often takes short trips, during which the engine does not have time to fully warm up. In this case, a large amount of carbon deposits forms in the cylinders, which does not have time to completely burn out due to the engine operating time being too short;

- low-quality motor oil, which burns out much more intensely than high-quality lubricant.

Causes of oil burn

The most common reason is oil loss due to aging. As soon as oil additives lose their characteristics, the oil begins to actively evaporate and evaporates through the ventilation system into the intake manifold, then enters the cylinders, where it burns along with the working mixture.

But degraded oil can also decompose with the formation of heavy fractions that will accumulate on the oil scraper rings and impede their mobility. As a result, the oil scraper rings will no longer press tightly against the cylinder walls and will begin to leak oil, which burns in the cylinders. In an advanced situation, it comes to coking and blocking of the drain holes in the piston - then the oil consumption for waste becomes comparable to fuel consumption.

Impaired oil drainage leads to the formation of hydrocarbon deposits on the piston. The result is varnish and carbon deposits on the surfaces of parts.

Impaired oil drainage leads to the formation of hydrocarbon deposits on the piston. The result is varnish and carbon deposits on the surfaces of parts.

An increased appetite for oil can also be caused by boosting the engine. We increase power and torque, which means we increase the oil temperature. In this case, the volatile fractions begin to burn, which leads not only to an increased oil appetite, but also to coking of the oil scraper rings. By the way, even a loosely twisted candle can cause oil burn. “Under-rotation” leads to glow ignition, resulting in engine detonation and a significant increase in temperature in the combustion chamber. This means that the oil begins to burn more.

Carbon deposits and varnish form not only on the piston rings, but also on the surfaces of the combustion chamber and valves. This is facilitated by a contaminated crankcase ventilation system, gas breakthrough into the intake pipe, as well as the frequent use of low-quality oil and fuel.

Carbon deposits and varnish form not only on the piston rings, but also on the surfaces of the combustion chamber and valves. This is facilitated by a contaminated crankcase ventilation system, gas breakthrough into the intake pipe, as well as the frequent use of low-quality oil and fuel.

Prevention and control of ring deposits

It is desirable that the tachometer needle stays in the region of 5.5–6 thousand rpm.

During the trip, the cylinder-piston group should completely clean itself. This will become clear from the increased thrust of the power unit. If the symptoms of the occurrence have not disappeared, you can repeat the soaking procedure again. Instead of the kerosene-acetone mixture, you can purchase special products at the auto store. After the problem is fixed, you need to change the engine oil and oil filter, since both are unsuitable for further use. If, despite all efforts, the problem remains, it means that the rings are not stuck, but are physically worn out, in which case a major overhaul is inevitable.

Preventing a problem is easier than solving it, so to avoid rings getting stuck, you need to make fairly long trips by car at least once a month (at least 50 kilometers). When traveling, you should sometimes let the engine run at high speeds (about 4 thousand rpm) for one to two minutes. During this time, the carbon deposits, if there were any, will have time to completely burn out.

Among the problems of an internal combustion engine, the first place is increased fuel consumption, a drop in power and a decrease in compression due to stuck piston rings.

Diagnosis of ring jams is inextricably linked with the specifics of assessing the condition of piston rings:

- there is no objective method for monitoring the condition of the piston rings without dismantling and disassembling the engine;

- the process of compression and combustion of the mixture depends on the condition of many parts, the cylinder-piston group works in a complex, so it is very difficult to identify the specific culprit of the problems;

- The nature of the operation of the piston rings greatly depends on the condition of the piston, the walls of the cylinder liner, and the intake valves.

Let's sum it up

Any problem is easier to prevent, so the best option is to use additives at the first sign of ring sticking. A completely coked engine can only be saved by a major overhaul. However, there are still ways to reduce the contamination of ring grooves with dirt:

- do not skip oil changes, carry them out strictly according to the regulations prescribed in the car manual;

- warm up the engine, even if you go to the store for bread and back, this burns deposits;

- use only branded high-quality oil, avoid counterfeits;

- use only recommended oils for your engine;

- After the car has been parked for a long time in the garage or on the street (for example, all winter), it is better to change the lubricant before driving it again.

How to decarbonize piston rings, watch the video:

How does the position of piston rings relate to their performance?

In order to ensure the required degree of sealing of the gap between the outer surface of the piston and the inner surface of the cylinder, the so-called cylinder mirror, the ring must be sufficiently elastic and strong, on the other hand, not exert excessive pressure on the walls of the liner, have high wear resistance, but not destroy the working cylinder surface.

The degree of thermal expansion of the cast iron liner is more than two times less than that of the aluminum alloy piston. When heated, the piston will expand more than the cast iron cylinder wall. The outer diameter of the piston is made with a small gap to compensate for thermal expansion. Modern internal combustion engines always use several piston rings. The occurrence of one of the compression rings creates a problem of tightness when compressing the air-fuel mixture. The term “occupancy” refers to the situation when the piston ring is compressed and completely recessed in the annular groove of the piston, while the remains of unburned petroleum products under the influence of high temperature turned into carbon formations, tightly, like glue, fixing the ring in one position.

Conditions and reasons for stuck piston rings:

- The lower oil scraper ring, due to wear or damage, does not fully perform the function of removing the oil film from the cylinder mirror. Part of the engine oil from the engine crankcase in the form of film residues accumulates in the grooves of the piston rings and intensively decomposes with the release of cementitious mineral residues;

- the remainder of the fuel of the rich mixture does not burn in full, its high-boiling fractions in the form of a viscous liquid enter the grooves of the piston rings and further enhance the bedding effect;

- The engine of the car was in a mothballed state for a long time (3-5 years). Piston rings that are compressed and fixed in one position lose their elasticity over time. To prevent the piston rings from sticking, it is enough to start the engine for 10-15 minutes once a month.

If a relatively “young” car begins to catastrophically lose acceleration dynamics, oil consumption has sharply increased, the first option to consider is that the piston rings are stuck. The disease affects relatively “young” cars with mileage less than 80 thousand km. The main problem and cause of stuck piston rings is considered to be low-quality gasoline and motor oil.

As a rule, the occurrence of piston rings occurs unevenly along the diameter of the annular groove. In a normally operating ring, the pressure forces on it are distributed evenly over the working surface, which prevents the occurrence of local metal fatigue zones. If it gets stuck, the ring sticks to the piston groove in one small sector of the circle, begins to work (compress and decompress) in an off-design and asymmetrical mode, and local fatigue microcracks appear.

We make diagnostics and check for signs of stuck piston rings

We measure the compression value in each of the cylinders without oil, but using 5-10 ml of engine oil in each of the cylinders. If an obvious gap is detected in the measurements, for example, three cylinders showed a compression of 12 units, and one showed a compression of 5 units, then there is a possible burnout of the piston or valve.

To clarify the diagnosis, oil is added to each cylinder and the compression is measured again. If the compression readings in the problem cylinders have not changed, there is burnout of the valve or piston walls. Otherwise, we take as a basis the option with the accumulation of carbon deposits in the piston ring grooves.

It is necessary to check the operation of the ignition system and power supply system. The condition of the spark plugs - no carbon deposits on the electrodes, a clean and uniformly colored surface of the spark plug insulator skirt (1), indicates normal combustion of a high-quality air-fuel mixture. Regular oiling and coking of spark plugs indicates poor combustion, low gas temperatures and a large amount of unburned petroleum products (2).

Examination

Before you sin when compression drops on the rings, perform a simple, harmless to the engine and basic test. Measure the compression in the cylinder using a compression gauge. Then, through the spark plug hole, pour 5 cc of the motor oil you use in your engine into the cylinder. After this, measure the compression again:

- If it has increased, it means the ring is to blame, and then we move on to the cleaning methods described below.

- If, after adding oil, the compression does not increase, then the rings have nothing to do with it, look for the reason in the valves and the gas distribution mechanism. This does no less harm to the engine, so find and eliminate the cause.

We treat piston ring sticking disease

The three most common options for restoring piston performance.

- Removing carbon deposits, coke, petroleum product residues using various types of washing liquids, solvents and carbon deposit modifiers;

- evaporation of heavy fractions of petroleum products, tar and asphalt substances using hot steam;

- burning out, or “decoking” with the help of hot combustion products.

The so-called soot washing is used most often - the most expensive and effective option.

Why do piston rings stick?

Prolonged operation of the internal combustion engine, untimely oil changes, use of low-quality lubricants, as well as certain engine problems can lead to a frequent and widespread problem - stuck piston rings. The main reason for the occurrence of rings is active carbon formation and coking in the engine combustion chamber.

In parallel with the formation of carbon deposits, coking of the piston ring grooves occurs, as a result of which these rings lose their mobility and are unable to provide proper sealing. Often, coking of the combustion chamber of a working engine, as a result of which the piston rings become stuck without other visible reasons, occurs in the following cases:

- if the car is constantly driven without pre-warming the engine in difficult conditions. These include short-term city trips at low speeds; the engine does not have time to reach operating temperatures and quickly cokes.

- the engine is filled with oil different from that recommended by tolerances or of low grade, and the interval for its recommended replacement is constantly extended, etc.

In the first case, lubricant of unsuitable properties or low quality gets into the combustion chambers abundantly, is heavily wasted and causes coking of the engine. In the second case, the oil recommended for use in this type of engine simply loses its properties from prolonged use. Next, we will look at the main signs by which you can determine the occurrence of piston rings, and also talk about available ways to eliminate such a malfunction with your own hands.

Prevention

Now we know why the rings are stuck in the engine and what to do about it. But in order not to encounter such a problem, it is better to know preventive measures. They are quite simple and clear:

- It is necessary to monitor the condition of the valve stem seals. Their malfunction will be indicated by high oil consumption. There is no need to delay replacing these caps.

- Fill only with proven oil. It must also meet all tolerances. A quality product should not burn out in the engine. If the engine begins to eat it up, adding oil with a higher viscosity will not solve the problem.

- Maintain the engine according to the regulations. Moreover, in our conditions it is recommended to reduce the oil change interval to 10 thousand kilometers. Regular replacement will prevent such situations, since the fresh product has persistent additives and does not burn out, leaving carbon deposits.

If the mileage of the car is more than three hundred thousand, the rings may already be worn out. This is a natural process, so in case of oil leaks on older engines, it is recommended to immediately repair the CPG. But, of course, it’s better to start with the valve stem seals (especially if the problem is only oil consumption, but the power and other characteristics remain the same).

How to understand that the piston rings are stuck

Let's start with the fact that most often the oil scraper rings are installed first, and only then the compression rings. The list of main signs of stuck piston rings includes:

An increase in engine oil consumption and smoking makes it possible to determine with a high degree of probability that the rings are stuck. This is due to the fact that during engine operation, part of the lubricant penetrates through the leaks between the rings and the wall into the combustion chamber, where the oil is then heavily consumed as waste. In this case, the engine emits blue exhaust. Blue engine smoke is especially noticeable after warming up, as well as with increasing speed under load.

Why is oil intensively consumed?

In a working engine, valve stem seals and rings are responsible for removing residual lubricant from the valve stem and cylinder walls, respectively.

At high speeds, the performance of this process decreases, but in general, oil consumption does not exceed the norm prescribed by the manufacturer. For some it is 1 l/10,000 km, for others it is 0.3 l/10,000 km, and still others may not add anything at all between service intervals, since they do not turn the engine above 3,500 rpm. Naturally, when lubricant consumption suddenly increases, say, to 1 l/1,000 km, and even blue smoke comes out of the exhaust, this is a signal of a violation of the oil scraper functions. There are several reasons for this:

- The oil scraper rings are stuck.

- The caps have become stiff.

- The valve guides are worn out.

As a result, it would be nice to determine without disassembly which particular group of parts failed. Whether this is possible is the topic of the next paragraph.

Decarbonization of piston rings

The concept of decoking of piston rings should be understood as the removal of soot, coke and other deposits from the combustion chamber. You can independently eliminate stuck piston rings using a method that is based on supplying special cleaning fluids to the engine combustion chamber.

- The simplest and most affordable solution is to mix kerosene and acetone in a 1:1 ratio, after which this mixture is poured into the engine cylinders through spark plug wells. You can also use only kerosene to decarbonize piston rings. The car is left with the cleaner poured in for several hours. During acidification, it is recommended to periodically rotate the crankshaft several times by 5-15 degrees.

- The end of the cleaning procedure is cranking the engine with the starter with the spark plugs removed. This allows any remaining cleaner to be removed from the combustion chamber. Next, you can tighten the spark plugs and start the internal combustion engine. Afterwards, you need to let the engine idle, and then make a test drive for several kilometers, gradually loading the power unit and raising the speed to 2/3 or more of the maximum.

- Next, it is imperative to change the engine oil and oil filter, since part of the composition and deposits washed away during decarbonization inevitably enter the engine lubrication system.

Let us add that this method of combating sticking of piston rings is viewed with skepticism by experienced drivers and auto mechanics, especially with regard to worn-out engines. The fact is that quite often after decoking the rings, rubber seals and oil seals begin to leak, compression drops, and the engine does not start. In such cases, it will be necessary to carry out not only replacement of the piston rings, but also a number of other repairs.

Complete engine cleaning

If the rings are stuck in the VAZ-2115 engine, what should you do? You can resort to complete cleaning of the power unit. This operation is called decoking. This method is more difficult, but effective. How the operation is performed:

- The engine is warmed up to operating temperature.

- Unscrew all the spark plugs. If rings are stuck in a diesel engine, what should you do? In this case, the injectors are unscrewed.

- The crankshaft turns. This is necessary in order to set the pistons to the middle position. This way the flushing liquid can get into all cavities.

- To fill the liquid you need to use a syringe. You can use a medical, disposable one (preferably with a volume of about 20 milliliters).

- The candles are put in place.

- Wait the time specified in the instructions for the flushing fluid. This usually takes no more than a day.

- To ensure that the mixture is evenly distributed, periodically rotate the crankshaft in both directions by 10 degrees.

- Cover the spark plug rings with a rag.

- Rotate the crankshaft until the fluid is completely removed.

- The candles are installed in place. Next, you need to start the engine and let it idle for a few minutes.

If the rings are stuck in a boxer engine, what should you do without disassembling the engine? This method does not involve disassembling the engine, and therefore anyone can clean the rings themselves.

Tips and tricks

To protect the piston rings and prevent coking of the combustion chamber, it is necessary:

- change engine oil promptly;

- use high-quality fuels and lubricants;

- warm up the engine before driving;

You can also use engine additives (discussed using the example of a diesel internal combustion engine):

- into the oil, which contribute to “soft” decoking of the piston rings;

- into fuel, which is another way to delicately clean the combustion chamber from carbon deposits;

These solutions are presented by various manufacturers and are recommended for use for preventive purposes, since they are not capable of effectively removing thick layers of deposits.

Use of anti-wear, anti-smoke and other additives to reduce oil consumption. Pros and cons after applying the additive to the engine.

What does the color of carbon deposits on a spark plug indicate, and why does carbon deposits of one color or another form? How to clean spark plugs from carbon deposits with your own hands, tips.

Should the engine consume oil and what oil consumption is normal for the engine. Increased lubricant consumption, main causes, frequent malfunctions.

Carbon formation and consequences of engine coking. The occurrence of piston rings, the appearance of deposits and varnish on parts. How to remove carbon deposits yourself.

Low compression in engine cylinders: the main reasons. How to increase engine compression without engine repair, available methods. Tips and tricks.

Gradual or sudden increase in diesel engine oil consumption. Potential faults, diagnostics and solutions.