It is quite possible that a considerable part of our readers do not even know the meaning of this word. Indeed, this term is extremely rare in everyday life, except in places such as service stations or car services.

But the word shock absorber is familiar to all car owners. Of course, it is associated exclusively with the chassis of the car. Meanwhile, shaking and vibration are harmful not only to parts and components of the chassis. Considering the quality of Russian roads, one can imagine the loads the power unit is subjected to. And although it has standard protection against such troubles, in some cases it is clearly not enough.

The same can be said about the steering wheel - an organ that for the driver is the very place through which he is constantly in contact with his car. And such contact does not always bring satisfaction - if the steering wheel shakes, it causes quite noticeable discomfort to the driver.

Special dampers help avoid such situations. Essentially, these are miniature shock absorbers that allow damping (smoothing) vertical and other types of vibrations and vibrations.

What is a damper, its functions

There are many similar devices, but most often they use dampers that protect the power unit and steering controls from unnecessary loads.

However, many sports and racing cars have such shock-absorbing devices installed as standard. Ordinary passenger cars are not equipped with such dampers, so they must be purchased separately and installed independently or with the help of car service specialists.

Structurally, and to some extent technologically, the damper is a universal device that allows installation on any type of vehicle. The main task is to ensure reliable fastening, and here you will need to show a lot of ingenuity. In some cases, they even resort to welding, thus attaching the fasteners required to fix the damper to the bottom or body elements.

In car dealerships, such shock-absorbing equipment is usually sold together with a minimum set of fasteners, thanks to which the choice of installation method is greatly simplified.

In what cases will a damper be a really useful and even necessary purchase? If in your daily travel area the road is ideal or close to it, the need for this part will be minimal or close to zero. In the absence of excessive loads on the car, a standard shock absorber will cope perfectly with small and rare potholes and humps. But if, due to circumstances, you are forced to often drive off-road or on paved roads that are in terrible condition, the shock-absorbing system will not be able to cope with the damping of vibrations that constantly occur with different frequencies and amplitudes. This is where an additional damper comes in handy, the effect of which will be combined with the work of the suspension.

Car dampers are devices specially designed to absorb vibrations that shock absorbers cannot cope with. Be it the steering or the engine housing along with all attachments.

Since not a single, even the most expensive and high-quality shock absorber is able to completely eliminate vertical and other vibrations, the main task facing the damper is to suppress the amplitude of such vibrations as much as possible. A high-quality device copes well with this problem, while having compact dimensions. The car owner’s task is to install it correctly. It is highly desirable that they be invisible, or even better, invisible.

Dampers are equipped with one-way (in such cases it is usually supplied with a spring) and two-way shock absorbers. Externally, such a device is very similar to a classic shock-absorbing strut, typical for the suspension of any vehicle. The principle of operation of the damper is also similar to modern shock absorbers.

You can also find budget versions on sale, in which the role of a damping element is played by a liquid (most often oil) placed in a special tank with a partition.

The design of the damper provides for the presence of valves or relief holes, through which the driver can adjust the degree of vibration smoothing.

All modern dampers are structurally divided into two categories:

- telescopic devices that are mounted along the protected part (for example, on a steering column). This is precisely the principle used in standard shock absorbers. The composition of the damper is also similar: it is a cylinder with a piston inside;

- rotary damping devices, which work on the same principle, but are structurally designed in a completely different way. Such devices are considered more reliable, characterized by increased strength. They are able to withstand not only vibrations and vibrations, but also impacts of decent force. It is no coincidence that they are usually installed in bikes and sports cars.

Application

Hydraulic and pneumatic dampers are used in hydraulic systems, automatic regulators and measuring instruments. Hydraulic dampers are divided into pulsation dampers, flow stabilizers, pulsation dampers and water hammer dampers. Also, to varying degrees, standard piston, balloon and diaphragm accumulators are used as hydraulic dampers.

In electrical machines, a damper (damper winding) is an inductor that prevents a sharp increase in switching currents or voltages in electrical circuits; for example, in the event of a short circuit or interference.

In stringed musical instruments, a damper is a device for stopping string vibrations, consisting of separate blocks (for a piano) or strips (for a harp), covered with soft felt (filt).

Suspensions of cars and other vehicles use damping devices called shock absorbers.

In acoustic systems (so-called “speakers”), a damper is a rim that secures the membrane of the sound element to the frame. Usually made from polymer materials (for high-frequency elements), rubber or foam rubber (for mid- and low-frequency elements). Used to dampen residual vibrations of the membrane.

In aviation: aeroelastic oscillation damper of an aircraft is an independent on-board electronic system or subsystem as part of an automatic flight control system (ACS), designed to automatically dampen short-period oscillations of an aircraft in flight, which inevitably arise when flight conditions change and, most importantly, to prevent involuntary rocking of the aircraft by the pilot, which can lead to significant overloads and structural failure. In technical terms, it consists of a group of gyroscopic sensors that control the angular movements of the aircraft in space, an electronic circuit for processing and amplifying damping signals and actuators connected in series to the mechanical control wiring, or these signals are mixed with other ACS control signals

The problem of longitudinal progressive swing was acutely manifested on the supersonic bomber Tu-22, for the same reason the experienced Su-27 was lost. The problem of lateral movement is still relevant for almost all heavy (including passenger) aircraft, and is referred to as the “Dutch step”. Almost all large passenger aircraft have automatic damping.

- In risk management, a damper

is a threshold value of safe risk for an enterprise. The risk damping mechanism involves analyzing possible threats or factors that give rise to these threats, determining security thresholds, and identifying the range of conscious risks that an economic entity is ready to take. - In programming, a damper

is a system for balancing the load on system components during surges in the data arrival rate.

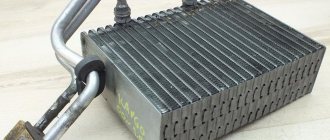

Engine damper

A damping device for damping vibrations of a power unit first appeared in tuning studios as one of the important attributes of sports cars. But, as often happens with many innovations used in motorsports, they gradually migrated to production cars. Today this is still a rarity, but finding a motor damper in the most seedy auto shop is no longer a problem.

It is well known that vibrations with maximum amplitude on the engine occur during gear shifts. This behavior is especially typical on high-speed engines installed in luxury and sports cars. This is largely facilitated by the aggressive driving style, when a sharp change in the amount of torque is followed by a “sharp” pressing of the clutch and an equally rapid gear change. The result in most cases is a very noticeable and at least unpleasant jerk. On a regular car in city mode, such switchings are rare, but on the race track this is quite an ordinary occurrence. Standard pillows are powerless against it, regardless of their design. In addition, frequent jerks accompanied by shaking provoke accelerated wear of the pillows. An engine damper helps to avoid all these troubles.

So if you are asked what an engine damper is, you can safely answer: it is a miniature additional shock absorber that functions exactly like its larger brother, and is tailored specifically for the power unit. That is, vibration damping occurs due to the fact that the rod, together with the upper mount, moves in a chamber filled with oil under decent pressure, according to an inverse exponential relationship: first quickly, and then rapidly slowing down.

The principle of installing engine dampers is the same for all models, although the size and shape of the mounts are slightly different. Typically, these devices are attached to the studs of the body cups, at the location where the support bearing is mounted. The upper end of the damper is fixed to the block, most often in the area of the pillow.

When purchasing such a mini-shock absorber, you should take into account that they are manufactured focusing on a specific model or series, which allows you to take into account the parameters, shape, dimensions and features of the location of the motor. But you can also find universal products equipped with adjusting bolts that allow you to customize the damper to suit your needs.

Since installing a damper assembly is a one-time operation, it is best to do this at a service station. But if you want and have the appropriate skills, nothing prevents you from doing it yourself. The degree of rigidity is adjusted after installation in accordance with the individual preferences of the driver. The installation task is simplified if the kit includes fasteners - such kits are not uncommon.

How necessary it is to install a damping device on your car is up to you to decide. If the problem of vibrations practically does not bother you, if you are not a fan of tuning for the sake of tuning, then you shouldn’t bother buying and installing it. But when you often travel off-road, it’s worth considering.

Important! Before installing the engine damper, make sure that the cushions are in satisfactory condition. If this is not the case, it’s worth replacing them first - perhaps the shaking problem will go away immediately, and then installing a damper will not bring any tangible benefit.

Advantages and disadvantages of auto dampers

If you have not yet decided whether you need such a device or can do without it, you should familiarize yourself with their advantages and disadvantages.

Let's start with the pros:

- significant shock mitigation. The wheel axle is the first to take on the load when hitting road irregularities, but standard shock absorbers do not cope with their task completely and not always. A modern damper reduces the vibration force by about 30%, both in relation to the steering wheel and in relation to the engine. Obstacles such as tram tracks, slab joints, wide cracks in the road surface, and even speed bumps will be overcome much more smoothly;

- Suspension knocks are always an unpleasant sound. Steering/engine dampers allow you to get rid of it, if not completely, then significantly;

- Vibration of a car during heavy braking is also not a pleasant phenomenon, as is the case when accelerating above 100 km/h. It is also worth mentioning a similar phenomenon with deformed disks, in the absence of proper wheel balancing. Additional shock absorbers will eliminate this problem;

- A steering damping device can improve vehicle handling when driving at above-average speeds.

But this node cannot be called ideal either, and here’s why:

- When installing a damper on the steering wheel, at first you will have to get used to the “wobbiness” of the steering wheel, and it is far from a fact that you will come to terms with it;

- the same can be said about the effort applied when rotating the steering wheel.

However, according to a statistical survey, over 80% of drivers who have installed additional shock-absorbing units on their cars are satisfied with their performance.

At the same time, there is a risk that you will fall into the opposite camp - every fifth car owner either did not feel the difference before and after installing the damper, or was dissatisfied with its performance.

General information

Translated from German, the word “damper” means “to dampen, muffler.” By and large, this device is a kind of shock absorber, which is designed to prevent vibrations that occur in various systems, devices, machines, structures and structures during their operation. How to define the concept of “damper” in a general sense? What this is is quite simple to understand, since all devices that act soothingly and softly can be called this term.

How much additional damping is needed?

Let us immediately note that this equipment is optional; its installation on the vehicle is not required. It is positioned as a means of increasing the comfort of being in a car, helping to reduce driver fatigue (if it is a mini steering shock absorber) and reducing the load on the engine (engine vibration damper). One can note more even wear on the tire tread and better grip on the road surface, but all these “goodies” are more cosmetic than real.

So the question of how necessary such an element is remains open - each car enthusiast must decide for himself how much he will gain compared to what he will lose.