Purpose of snow chains

The cost of high-quality snow chains starts from 5 thousand rubles. Moreover, this does not require special knowledge and experience, since if you have the instructions specified in the material, you can make the products yourself.

Snow chains (lugs) are products that are put on the drive wheels, increasing the maneuverability of the vehicle. By installing such products on wheels, the driver receives the following benefits:

- High cross-country ability on snowy roads.

- Overcoming ascents and descents on sections of highways in icy conditions with a low probability of loss of control.

- Improving the quality of driving on snowy and icy road surfaces.

- Improving the vehicle's propulsion properties when driving through muddy sections of the road.

It is important! Snow chains are installed on wheels only when it is necessary to overcome a difficult section of the road. It is not recommended to use them constantly, as this negatively affects the vehicle.

The negative impact is due to the following factors:

- Increased load on the steering mechanism, as well as transmission elements.

- Inability to move quickly.

- Increased tire wear.

- Lack of comfort.

- The occurrence of extraneous noise.

- Negative impact on suspension elements.

In addition to this, it is prohibited to operate a car with hooks on asphalt, as this will contribute to the destruction of the coating. The products in question should always be in the trunk of the car in order to be able to use them if necessary. This applies not only to crossovers and SUVs, but also to passenger cars with one-wheel drive.

Ways to increase vehicle cross-country ability

To improve the vehicle's maneuverability on muddy or snowy road surfaces, drivers use various methods to improve the traction of tires on a sticky road.

There are two ways to improve a car's cross-country ability:

- Buy and supply tires with deep treads with a certain pattern, for example, herringbone.

- Buy or make your own bracelets or snow chains.

Tires with appropriate patterns and deep treads create a lot of resistance while driving, which increases fuel consumption. In addition, all-terrain tires are heavy and noisy.

A FullFree device has appeared, which, according to manufacturers and sellers, reduces fuel consumption and protects internal combustion engine parts from low-quality fuel. Let's find out whether fuelfree experts are telling you whether it's a scam or true.

Using the second option, to put on the chains, you need to use a jack or by unfolding the chain and driving over it, followed by fixing it.

Varieties and how they differ

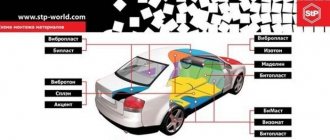

Many drivers, having become familiar with the disadvantages of lugs, make a negative decision about purchasing or manufacturing them. However, sooner or later a situation comes when the presence of chains will not hurt. Grunts are divided into several types. The main distinguishing parameters are: the material of manufacture and the geometric pattern of the chain product on the tire.

This is interesting! The above parameters have a corresponding impact on the car and its off-road performance when moving.

Depending on the material of manufacture, lugs are divided into the following types:

- Tough.

- Soft.

Rigid lugs

Rigid types include products made from the following types of metals: titanium, steel, aluminum. The strength of the product depends not only on the material, but also on the thickness of the links. The larger the dimensions of the links, the higher the vehicle’s cross-country ability. However, the indicators of negative impact on the car are also higher.

On the one hand, thick chains increase the vehicle’s maneuverability, on the other hand, they negatively affect the suspension and steering rack

The disadvantage of rigid products is the high noise level, as well as accelerated tire wear. On chains of this type you cannot reach speeds higher than 40 km/h. In addition, the massiveness and heaviness of the chains negatively affect the vehicle. Not all types of passenger cars can use rigid chains due to the small space between the wheel arches.

Soft lugs

Soft lugs are made from non-metallic materials, such as rubber, polyurethane and even plastic. To increase the strength of products, a method such as reinforcement is used. Soft versions of lugs for cars are more gentle, as they contribute less to rubber wear, and they are also almost silent. A car on such lugs can reach speeds of up to 80 km/h, while providing high-quality traction with the road surface.

Soft chains can hardly be called “chains” in the literal sense of the word, but when driving around the city they do just as good a job

Like hard chains, soft lugs have disadvantages that are clearly manifested when moving on ice. Soft chains perform well when moving around the city, without having a negative impact on the road surface. However, they are not able to ensure effective passage through snowy areas and mud, so in such situations only rigid chains should be used.

Anti-skid bracelets

Such equipment is distinguished by the absence of longitudinal elements . The bracelets are attached across the entire circumference of the wheel at the same distance. Easy to install, but less effective off-road.

Bracelets, photo

Negative features of bracelets

Naturally, chains also have disadvantages that can limit their use. You should pay attention to them to avoid unpleasant situations.

- First of all, you need to take into account that the suspension and steering will be subject to increased loads. Accordingly, along with high cross-country ability, increased wear will be obtained. The steering rack will suffer especially badly if chains are installed on the front wheels.

- Another important factor is that tire wear will increase. Accordingly, their service life will be greatly reduced.

- Do-it-yourself anti-skid bracelets will lead to wear and tear on the front transmission.

- The speed of movement will be limited to 50 km/h.

- We should not forget about acoustics - circuits can produce quite a lot of noise.

Varieties of lugs according to geometric pattern

Depending on the geometry of the pattern, there are three types of snow chains:

- "Ladder".

- "Rhombus".

- "Honeycombs".

Each option has its own advantages and disadvantages, so we will consider them in detail.

"Ladder"

The “ladder” is a base in the form of longitudinally arranged branches. These branches are evenly distributed around the entire circumference of the wheel. To secure the chain on the wheel, the appropriate type of locks are used. Externally, this type of lug resembles a ladder, which is where the name comes from.

This lug option is one of the most popular, effective and in demand. Among the disadvantages of this type of chain it is worth noting:

- parallel arrangement of chains on the wheel, so the car will dig in when overcoming snowy or soil areas;

- low lateral stability, which is also due to the parallel arrangement of the chain branches;

- heavy load on the transmission.

Despite the high raking properties, ladder-type chains are practically useless on snowy ground

It is recommended to use chains of this type only when it is necessary to overcome a risky section of the route. This option is one of the cheapest, so when the need arises, most drivers prefer this option without delving into its features.

"Rhombus"

The diamond lug design is a modernized "Ladder" design. For this purpose, there are longitudinal branches that form a diamond-shaped pattern, eliminating all the negative factors that are characteristic of the “Ladder”.

The geometric shape in the form of a diamond is intended for the use of lugs when it is necessary to overcome a snowy or swampy area. The diamond shape is shown in the photo below.

Diamond-shaped chains have increased strength and high traction characteristics

The diamond-shaped shape of snow chains is popular among SUVs and crossovers, since this type of pattern on the lug increases the vehicle's cross-country ability several times. This is especially true for snow-covered and icy road sections.

"Honeycomb"

An analogue of a rhombus are “honeycombs”, which have transverse branches similar to a rhombus, but are additionally connected by straight connectors. Diamond and honeycomb are improved types of lugs, in which the products are in constant contact with the road surface. This is a big plus for both rubber and transmission, so when making lugs it is recommended to pay attention to the last two models.

“Honeycombs” ensure constant contact with the road, therefore giving the car a high level of lateral stability

It is also worth noting that when purchasing snow chains, you need to consider their size. The lugs produced in production are divided not only by size for wheels, but also depending on the type of car.

How to increase bicycle chain tension

The situation with high-speed bicycles is much more complicated. How to tension a chain on a bicycle at high speeds?

The transmission unit of bicycles with speeds, the element of which is the bicycle chain, consists of cassettes with several stars. Therefore, repair work to eliminate chain slipping and sagging on such bicycles has its own nuances. To understand the causes of the problem you need to:

- If the chain constantly falls off on a high-speed bicycle, it is worth checking whether the sprockets are damaged. If one of the sprockets in the cassette unit is deformed, the chain can be transferred to another sprocket to continue movement. But in this case, you need to understand that the speed cannot be changed. This method is suitable for getting to your home for better repairs. To eliminate the breakdown, the deformed sprocket will have to be replaced, and if the unit is not dismountable and there is a malfunction of the entire cassette, then it is necessary to replace it.

- The chain falls off on a high-speed bicycle; the reason is a failure in the speed settings. You should check the quality of the setting. Very often, failures in speed settings cause the chain to hit. The setup is carried out according to a special scheme.

- Once the root cause has been eliminated, the chain must be put back into place.

To properly fit the chain on a speed bike, you need to release it using a wringer. If you take a new chain, then you need to measure the required length, for which the chain is thrown onto the large stars of the cassette blocks and connected, measuring the required distance. The excess piece of chain is removed using a special squeezing tool. By rotating the screw, the link axis is displaced and the unnecessary section of chain is removed. Next, the chain is passed between the speed switches and connected using the same tool.

If the chain on a children's bicycle falls off, then, depending on the design, the same actions are performed as with an adult bicycle.

A malfunction of the transmission unit on a high-speed bicycle can threaten the health and life of its owner; the cyclist can fly out of the saddle by inertia, so you must not forget to carry out preventive maintenance of the chain, check the condition of the speed switch and the integrity of the main parts

It is especially important to carry out a technical inspection of your vehicle before you start driving, if you make long bicycle walks and crossings. Timely diagnostics of your bike is a guarantee of safety

Snow chains and bracelets: which is better?

Analogues of chains for cars are bracelets, which are a pair of pieces of chains fixed on the wheels with belts. The chain sits on top of the bar and the belt sits in the hole between the rim. In this case, the bracelet, unlike the chain, is firmly tightened on the bar, which allows the chain to be located in one place.

To increase efficiency, it is recommended to attach at least three anti-skid bracelets to one wheel

Typically, three bracelets are installed on one wheel, which is enough to reach a hard surface, creating friction and pushing away the car. Unlike chains, bracelets have the following advantages:

- Speed and ease of installation. If it is recommended to install chains only before crossing a snowy or marshy area, then the bracelet can be installed even when the car is stuck.

- Compact, as they do not take up much space in the trunk, unlike chains.

- No need to jack up the wheel.

- Versatility. While chains are designed for a specific wheel diameter, bracelets are suitable for any wheel size.

- Unlike chains, bracelets are several times cheaper.

- Long service life.

Like chains, bracelets are divided into hard and soft. Some of the cheapest options for bracelets are plastic products. They are suitable for all types of cars: from small cars to SUVs, so every driver can afford them.

Bracelets, like chains, are divided into hard and soft

How else do chains differ from bracelets? Numerous observations of drivers show that the chains have better adhesion to the road surface, which has a positive effect on cross-country ability. Chains can be used to overcome snowy and icy areas until they are finished. The bracelets can only be used for short-term use up to 5-10 km.

It is important! If one link on the chain breaks, this poses a threat to the car body. Damage to the paintwork may occur, which ultimately contributes to the formation of a corrosion area.

When you know what chains and bracelets are, you can conclude:

- If you are planning a long road through marshy, snowy and icy areas, then it is recommended to use chains.

- Bracelets are used exclusively when rare trips around the city or outside of it are planned in bad weather. Even if during a trip you forget to put on a bracelet, you can do this at any time, even if the car gets stuck.

Preparation of materials

For such a design, you will actually need:

- The chain itself;

- Welding machine;

- Bulgarian;

- Pliers;

- Two carbines.

The chain length for one wheel should be calculated as follows:

- You will need two longitudinal pieces of chain, each approximately 10% less than the circumference of the tire;

- It is necessary to find out how many “steps” our “ladder” will have. That is, calculate the number of segments that will run across the tire; most often, 8 such segments are used;

- Each transverse segment should be approximately 15-20% larger than the width of the tire. We multiply their number by the length, add it to the doubled length of the longitudinal piece and get the length of the chain we need, to which we should add another 10 percent of the reserve.

Project of an anti-skid device for a car

We were inspired by last year's research to get creative. Then we chose what was better to buy: chains or anti-slip bracelets. The verdict was that there is nothing to do with anti-slip belts on serious off-road conditions. In addition, the cuffs damage alloy wheels, which is critical for many owners. But the real help in making something with your own hands was the price list for the Konig chain. Last year they demanded about 9,000 rubles for the ZIP Ultra model. For a moment, for the same money a ready-made set of winter tires with above-average quality for the now popular 15-inch is sold. Agree, this is impressive.

Choosing a chain weaving pattern

Before purchasing and making anything, you need to have a project in hand: this principle underlies any serious invention and the tire chain is no exception. When designing wheel attachments that increase your vehicle's ability to maneuver in snow, it is important to choose a weaving pattern that suits your needs.

| Ladder | Honeycomb | Rhombus |

| +The most powerful traction force + Low price + Simplicity of design | +Excellent for storming the rut +Smooth ride on hard ground +Best handling in class +Good lateral grip | +Excellently gets out of ruts + Good handling |

| —Doesn't go well —Worst lateral grip in class —Increased load on transmission units on hard surfaces | —Average traction level | —Rows mediocre —Does not prevent the machine from sliding sideways —High vibration load of the transmission |

| Suitable for driven axle | The best choice for mountain roads and light off-roading | Not recommended for use. Pay attention to the honeycomb or ladder |

Link size

Not just a drawing. The caliber of chain links also determines a number of important characteristics, including cross-country ability and durability. This way, a thin chain won’t last long, but a larger option may not fit into the wheel arch. Strictly speaking, in this matter you should not focus on just one parameter:

- As the caliber increases, traction capabilities in snow and mud improve, the service life of the anti-slip product increases, but rubber wear occurs.

- Small-link snow chains cling to ice well, have a moderate appetite for rubber, but wear out quickly.

This is abstract reasoning. For each class of car, “working” ranges of link sizes have long been determined and, admittedly, they grow with increasing vehicle weight:

- Passenger cars and crossovers: 3.5-6 mm. Our colleagues from Autocomfort have experimentally determined that it is better to equip a two-ton SUV with 6 mm chains. It’s even better to choose an asymmetrical shape of 6x8 mm - then the machine demonstrates everything that it is capable of. As for the smaller size, a 5 mm chain will be too small for those over 2,000 kg.

- Trucks and special equipment: 6-19 mm.

Accessories

When you see branded kits, it becomes clear that the anti-skid device does not consist of one chain at all. The design also provides:

- Two connecting lines linking the chain sections at the back and front of the tire.

- A tightening device that tightly fixes the chain on the wheel (lock).

- Fasteners that fasten metal sections together directly on the tread (connecting rings).

What exactly can serve as one or another component is determined by the budget and range of equipment available. Here are examples for each of the three groups of fittings:

- The best option for connecting lengths of chain on the sides is to use a chain of the same gauge. In this situation, maximum strength and durability are guaranteed. The only thing that discourages this decision is the high cost. This is why the second version appeared - to use a cable for these purposes. A linear meter of cable rope is noticeably cheaper, but it can fray and unravel, and is therefore less reliable.

- The signature chain tie is also made from chain. It is difficult to implement such a solution in everyday life, so turnbuckles and peculiar locks, known from anti-slip devices “Made in the USSR,” have taken root on homemade products. The widespread use of lanyards is due to their availability in retail sales and the absence of the need to make anything with your own hands. At the same time, such a fastening scheme has poor dirt protection. This led to the belief that the turnbuckle was difficult to loosen after several trips. The advantage of the Soviet lock design is reliability and trouble-free operation. However, the lock has only one drawback: it is difficult to manufacture (additional equipment is required).

- The easiest way to connect straight and diamond-shaped sections in the tread area (applies to “honeycomb” and “diamond” weaving patterns) is to use special rings. If it is difficult to get them, then you can get by with a well-known technique: cut the link with a grinder, engage it and weld it with a welding machine.

The listed accessories are the backbone of the anti-slip device. Depending on the manufacturing technology, a number of mandatory parts are selected:

- Cable circuit for linking the chain on the sides of the tire. Additionally, you will need thimbles, shackles and clamps to secure the cable from unraveling.

- Chain linkage on the sides of the wheel. What is needed are plates connecting sections of the chain along the perimeter of the front and rear walls of the tire + removable brackets used on the section of fastening the lock/turnbuckle.

How to properly put chains on wheels

Spread the chains out on a flat surface in front of each wheel. Moving at minimum speed, drive onto the prepared devices so that the wheels are fully seated on them . Fasten all the carabiners and put on the tension adjusters.

If there is not enough space, it is possible to “dress” the wheels one by one with anti-slip equipment using a jack .

Be sure to check the chains for damage and twisting.

Installation method without jacking the car

Before you begin installing a homemade chain on car wheels , you should carefully lay it down, preventing the links from twisting. Next we proceed point by point:

- Drive the drive wheel onto the product.

- Put the car on the handbrake.

- Place the chain so that the tensioning device with hook and carabiner is on the outside.

- From the inside, connect the hook and the last link of the longitudinal element.

- From the outside, place the carabiner coupling onto the tensioning mechanism and secure it.

- Distribute the transverse parts and tighten them.

Installing a chain on car wheels with your own hands using a jack is similar to the technology described above, its only advantage is that it makes the task easier. For a better installation, you must first reduce the tire pressure, but after the operation do not forget to restore normal parameters. This procedure will allow the product to fit as tightly as possible to the tire.

Dressing rules

Installation of chains can be carried out in two ways - it all depends on the type of device, weather conditions and your skills.

The first method is using a jack.

Everything is simple here. It is necessary to secure the car with special stops and set the parking brake.

Next, lift each wheel one by one with a jack, put on the chain, and snap the locks.

Requires certain skills (no jack needed). Park the machine on a level area and place the chains in front of the wheels.

Make sure that the locks are located on the outside. It is very important that the links and nodes are not twisted.

Now all that remains is to smoothly lay out the snow chains in front of the wheels and drive over them. In this case, about 25-30 cm should remain to the end.

Next, a long section of chain is thrown onto the wheel, and the inner and outer parts are fastened. That's all. All that remains is to tighten the product with an adjusting cable.

Before crossing any obstacle, it is advisable to drive a few tens of meters on the chains, tighten them and then hit the road.

Otherwise, the effectiveness of the products will decrease.

What are the dangers of using snow chains?

With the constant use of snow chains, the following negative consequences :

- The load on the steering device increases.

- The suspension wears out quickly.

- The chains make a lot of noise when driving.

- Tire wear increases.

- Unable to maintain high speed.

- It's not comfortable to move around.

Do not use these rigid devices when driving on asphalt roads - this will damage the road surface. Observe the speed limit : for hard ones - no higher than 80 km/h, for soft ones - no more than 50 km/h. Use such equipment only in emergency situations to increase cross-country ability. Homemade hooks (mordovkas, anti-skid belts, anti-slip tapes) are suitable for any car - Gazelle, truck, tractor, UAZ, VAZ, Niva and others. Rate the author

How to do it yourself, the main stages of work

First you need to cut four pieces of chain to the appropriate length. To do this, measure the required size and cut it with a grinder.

We recommend: Wood lathe based on an electric drill

And after that, you will need to thread straps with a lock into the prepared sections of the metal chain (in the first and last link). Four pieces of chain will require eight straps.

And in the end we get ready-made “elements” - now you just need to install them on the wheels. No one should have any problems with this.

Such “shoes” are unlikely to be suitable for a long drive, but if you need to go out for a short time, then homemade chains will do just fine. Moreover, the cost of materials is cheap. For details on how to make snow chains on car wheels in 15 minutes, watch the video on the website.

Antibux from old tires

The simplest alternative to anti-traction chains is homemade snow bracelets made from old tires. Outdated rubber is put on the tire, creating a kind of “shoe” for the wheel.

Anti-skid bracelets made from an old tire

The materials can be taken free of charge at any tire shop. You need to choose the same tire diameter as the wheel, or a size larger. You will get a simple and budget version of anti-bux. You will also need a grinder or jigsaw.

To make anti-skid bracelets from an old tire, you need to cut out pieces of rubber along its entire circumference, having previously marked the cut points with chalk. It should look like a gear.

The next step is to cut off the excess material along the inner diameter of the tire so that the “shoe” fits freely on the wheel.

Bracelets or chains: what to choose

Metal chain structures provide better maneuverability and controllability compared to bracelets, are safer and more durable, and allow you to cover long distances. The disadvantages of snow chains are:

- the need to install them on tires immediately before a trip or storming an obstacle;

- labor-intensive installation on a stuck car (requiring the wheel to be lifted off the road surface);

- maximum speed limit (40 km/h);

- inapplicability for hard coatings;

- production of each model for a specific wheel size;

- price;

- weight.

Anti-traction bracelets can be worn on the drive wheels of cars with any type of drive. Such products will be a profitable purchase, because among their main advantages:

- simple installation;

- the ability to quickly install on wheels in an already existing extreme situation;

- variable length, which allows the bracelets to be used on tires and wheels of different sizes;

- compactness and light weight;

- small price.

Among the disadvantages is the need to constantly monitor the tightening and position of devices relative to shock absorbers, brake hoses and calipers. On some vehicle models, lugs are not applicable due to the risk of damage to chassis or brake system components. There may also be problems with installation on wheels with stamped rims. When driving, the loads on tires, suspension and transmission are high when compared to chains. Therefore, the travel distance recommended by manufacturers is no more than 1 km. The remaining pros and cons are related to the material of manufacture, design and quality of each specific product.

The choice of devices depends on the purpose of use. The bracelets are effective on light off-road conditions and are useful for drivers who rarely need to increase the vehicle's cross-country ability. Feedback from owners who conducted comparative tests of anti-skid bracelets became the basis for the presented rating.

Leopard Master

The review concludes with Russian products. The company's product range includes more than a dozen offerings. Positive reviews of anti-skid bracelets for wheels were received based on the results of operation and comparative tests.

Leopard Master

The presented products for SUVs and trucks are wear-resistant and durable, they have a reliable connection of links and slings through steel plates with a pendulum clamp 4 mm thick. Bolt fixation is not used. The chain segments are spaced apart at a greater distance than in other devices. The special design made it possible to distribute the links on the tread more evenly, which increased comfort and safety when driving.

Bracelets with a metal part (chain and buckle) of 400 mm and a strap of 700 mm can cover wheels with tires from 225/60 to 275/90. The cross-sectional diameter of the chain links is 6 mm. Maximum load – 1200 kg.

Airline ACB-P 900

The Russian company Airline has been developing and producing automobile accessories since 2006. The company offers to choose the appropriate model and configuration from more than a dozen products.

Airline ACB-P 900

These car bracelets are intended for passenger cars with a tire profile width of 165–205 mm. The devices increase the vehicle's cross-country ability when overcoming light off-road conditions, slippery slopes, snowy sections of the road, and ruts.

The product is sold in a bag containing 2-6 bracelets, a hook for installation and instructions for use. The length of each bracelet is 850 mm. The lock is a spring clamp made of silumin alloy. Chains are made of galvanized steel.

You can purchase it for 900–2200 rubles, depending on the number of devices in the set. They have earned popularity among customers due to their good workmanship and low price.

"Promstrop"

from Yaroslavl opens the top three in the top ranking of the best manufacturers of anti-skid bracelets. The company has been supplying lifting equipment and auto accessories since 2007. The catalog contains several dozen models of chains and bracelets for trucks and passenger vehicles.

"Promstrop"

Belt chain options are designed for wheels with rims from R14 to R21. The slings have a width of 35 and 50 mm, the thickness of the links is 6 and 8 mm.

Prices start from 1300 rubles per pair. Reviews from car owners are positive. Anti-slip bracelets really help when overcoming slippery sections of the road, shallow holes and ruts. On severe off-road conditions it is better to use chains.

TPLUS 4WD R16-R21

Product of the Ufa company Tplus, which produces slings and accessories for them, belts, cables and other textile products. These anti-skid bracelets are suitable for all types of alloy wheels from R16 to R21. On stamped discs, it is recommended to use pads under the tapes to protect against chafing on sharp edges.

TPLUS 4WD R16-R21

Structurally, it is analogous to the products of the previous position. The bolts connecting the chains and tapes are of high strength class 12.9, made in Germany. The manufacturer's warranty period is 1 year.

A pair of lugs that have proven themselves on GAZelle and classmates will cost 1,400 rubles.

AvtoDelo R12-R15

Products of a Russian company that produces auto accessories, professional tools and equipment for auto repair. Traction control devices are used on wheels with rim diameters R12–R15 and tire sizes 185/55–255/55.

AvtoDelo R12-R15

The devices are externally similar to LIM, BP 005. Length and width – 1030x25 mm. The diameter of the links is 5 mm. The weight of a set of 4 pieces in a fabric bag is 1.61 kg.

The price of anti-slip bracelets for car wheels is 1800–1900 rubles. Buyers are satisfied with the price-quality ratio.

Alternative solutions

The thoughts of folk craftsmen do not stand still - and now they are offering an alternative solution: anti-slip bracelets . In principle, these are the same homemade metal chains for wheels, only with the difference in the absence of longitudinal elements . The advantages of bracelets are:

- ease of manufacture;

- quick installation;

- high reliability and efficiency.

So, what is needed for production:

- rubber mounting element for the VAZ muffler;

- metal chain with a diameter of at least 6 mm.

Tires with a width of 195 and 205 mm will require about 4 meters of chain. As you can see, the costs are minimal and you only need to cut the material to the required length. Another alternative option is kits for making DIY wheel bracelets using chains, which are quite affordable and of good quality (with the exception of Chinese ones).

The set consists of:

- chain blanks;

- fastening accessories;

- sling;

- clamping mechanism.

The kit is very easy to use and does not take up much space. An important plus is the possibility of use on cars with disc brakes . Judging by the reviews, owners of expensive SUVs do not hesitate to use it, which once again speaks of the practicality of the device.

Installation of bracelets on wheels, mounting options

Installing bracelets on wheels is not a particular problem. There are several mounting options you need to be aware of. The difference between them is quite significant:

- The first option is to install bracelets only on the rear wheels. This method is especially relevant for cars with front-wheel drive.

- The second option is to install only on the front wheels. Accordingly, it is most effective for cars with rear-wheel drive.

- The third method is to install on all 4 wheels. The most reliable and safe option, guaranteeing maximum grip on the road.

The main rule, regardless of the fastening method, is an even distribution of bracelets. That is, if you attach a total of 3 belts to a wheel, then this must be done at an equal distance from each other. Only this method will minimize rubber wear and achieve precise anti-skid performance.

Things to remember

The use of anti-slip chains is prohibited when driving on hard-surfaced roads (concrete, asphalt). In conditions of loose snow or soil, it is recommended to maintain a speed of 10-20 km/h. Wheel slip must not be allowed.

After installing the anti-slip device, after driving the first 100 meters, you should stop and check the reliability of its fixation, as well as the tension around the entire perimeter. A poorly tensioned chain can cause damage to suspension and steering components.

Sources

- https://carnovato.ru/cepi-protivoskolzheniya-svoimi-rukami/

- https://remontautomobilya.ru/cepi-protivoskolzheniya-svoimi-rukami-poshagovaya-instrukciya.html

- https://autostadt.su/tsepi-protivoskolzheniya-svoimi-rukami/

- https://autoclub.su/samodelnye-cepi-na-kolesa/

- https://sdelairukami.ru/kak-sdelat-tsepi-protivoskolzheniya-na-kolesa-za-15-minut/

- https://avtoshark.com/article/ratings/accessories/rejting-brasletov-protivoskolzheniya/

- https://zen-Top.ru/top-cepej-protivoskolzhenija/