Most Lada Priora cars were equipped with electric power steering from the factory, produced by Avtoelektronika Kaluga. It is these EURs that are considered quite reliable and rarely fail. For comparison, problems with amplifiers produced in Makhachkala are much more common.

If for any reason you need to replace the EUR or simply remove it from the car, you can perform this repair yourself. For this procedure we will need a tool such as:

- 8 and 13 mm head - preferably deep

- ratchet or wrench

- extension

- hammer

- chisel

How to remove the EUR on a Priora with your own hands

In fact, the electric power steering can be removed without any problems, you just have to remove quite a lot of parts first. Namely, you will need to do the following:

After that, using an 8 mm socket and a ratchet, unscrew and remove the contact group.

We remove it from the shaft completely so that it does not interfere.

Now you need to disconnect all the power wires from the power steering control unit, which are clearly shown in the photo below.

Each of the plugs has its own lock, so be sure to first look at the design of the lock so as not to damage it when removing it. When you have dealt with the wires, you need to unscrew the coupling bolt at the fastening of the driveshaft with the steering rack.

Using a chisel and a hammer, we slightly expand the coupling “collar” of the cardan shaft. Then you can begin to unscrew the nuts securing the EUR to the body. Two nuts are located at the front.

And two from the bottom.

Of course, when unscrewing the last fastening nuts, it is necessary to hold the EUR so that it does not fall. Next, we pull it off the steering rack shaft and remove it completely. If necessary, we replace it with a new one. This mechanism is installed in the reverse order and we connect all the necessary wires to their places.

Design and circuit of electric power steering Lada Priora

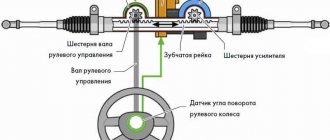

Steering elements of Lada Priora:

1 — right steering rod assembly; 2 — right steering gear support; 3 — steering gear support bracket; 4 — intermediate cardan shaft; 5 — electric amplifier; 6 — steering wheel; 7 — steering column pipe; 8 — left steering gear support; 9 — steering mechanism; 10 — left steering rod assembly

Steering column with electric power steering Priora:

1 - input shaft; 2 - column pipe; 3 — column bracket; 4 — electric amplifier; 5 — electric amplifier control unit; 6 — steering column tilt adjustment lever; 7 — tie rod; 8 — rear bracket for electric amplifier; 9 - spring; 10 — output shaft; 11 — bolt-axle; 12 — front bracket for electric power steering; 13 — power connector of the control unit; 14 — control connector of the control unit; 15 - nut.

Price for the new EUR Priora

Recently, prices for electric amplifiers have risen so much that not everyone can afford even a used option. For example, a new EUR produced by Kaluga on Priora can be purchased at a price of 23,0000 rubles, while a few years ago the price was half as much.

As for used options, used EURs are sold at scrapyards for 10 to 12 thousand rubles.

On the Lada Priora, a device such as electric power steering is offered as a standard feature as a comfort feature. It is this device that we will talk about in this article. We invite you to find out what malfunctions the car owner of this car may encounter and how to replace the unit yourself.

The role of the electric power steering in the steering of the VAZ 2170 Priora

It's no secret that the electric control method plays an important role in ensuring safety while driving. EUR or power steering of Priora performs the option of reducing the level of load on the steering wheel while turning it. The key advantage of using such an EUR device on the Priora is comfort when moving as a result of improved feedback between the steering wheel and wheels.

The electric amplifier is a more modern and improved unit, which is not only easier to use, but also does not require the introduction of additional highways to ensure operation. In addition, this device does not take power from the power unit. The main advantage of the EUR is that it does not require frequent maintenance and fluid monitoring, unlike power steering.

But it should be noted that such a system has several disadvantages, one of them is rather weak feedback between the road surface and the control system. As a result, it may become difficult to drive in snow. Unlike Prior, foreign cars are equipped with additional mechanisms and units for blocking and stabilization, so the method of controlling the electric power steering in the domestic version is less reliable. In addition, in practice, a faulty electric booster with poor traction is a fairly common occurrence.

Priora steering rack malfunctions

Problems with the functioning of the steering rack can be different. To identify them, it is not necessary to have a wealth of special knowledge; it is enough to periodically inspect the mechanism.

Large steering play

If you turn off the engine and actively turn the steering wheel, there should be no extraneous sounds. When not only suspicious noises appear, but also play is observed, the cause of the problem may be a weakened spool stop or insufficient elasticity of the torsion bar. The steering wheel may play due to severe wear of the silent blocks on which the steering rack is fixed. The same problem occurs when the angle of contact between the teeth and the screw is incorrect, or the curvature of the crankcase or shaft is caused by damage or the stroke of a screw-type bearing. To determine the malfunction, you will need to diagnose the rack bushing, steering rod joints and teeth.

The appearance of knocking and heaviness when turning the steering wheel

The steering wheel becomes heavy due to a soured cardan, but most often it is the knocking that occurs. There are a number of characteristic reasons for this phenomenon:

- noise occurs during the movement of the vertical bearing shaft;

- excessive wear of joints and crankcase;

- exhaustion of the life of a screw bearing, bushing or teeth;

- crooked shaft or crankcase, as a result the screw contacts the teeth with an offset angle;

- wear of silent blocks;

- loose rack fastening;

- steering wheel play.

In any case, you will need to carry out diagnostics, and if malfunctions are identified, you will need to dismantle and repair the Priora steering rack with replacement of worn elements.

Worn steering shaft center tooth

Wear of the mechanism with teeth occurs quite often. The main purpose of the steering shaft is to convert rotational motion into translational motion. Most cars are characterized by the exhaustion of the resource of the central teeth. The reason is simple: movement in city traffic is determined by driving in a straight line with slight deviations of the trajectory to the left or right.

To determine the malfunction, you need to swing the steering wheel to the sides from the middle position. If knocking noises are heard, it is better to carry out further diagnostics at a service station. If the central tooth is worn excessively, the entire shaft must be replaced.

Common faults and solutions

Many prior drivers encounter device breakdowns, in particular, we are talking about a malfunction of the control unit. If the system control unit does not work correctly or is faulty, a corresponding error will appear on the on-board computer display. Having deciphered it, you can understand that the computer reports a failure of the EUR connection, which in most cases indicates the presence of problems in soldering. In particular, we are talking about the connection point between the amplifier board and the controller.

This malfunction can be solved either by replacing the system at the dealer, if the car is under warranty, or by repair. If you do not have experience in chip tuning or working with electronic devices, then solving such a malfunction should be entrusted to professionals. Of course, in order to accurately make a “diagnosis”, you will need to conduct computer diagnostics.

It often happens that the speed sensor malfunctions, which again contributes to the appearance of an error on the on-board computer. This type of malfunction can be solved by reprogramming the device or replacing the wires in the places where the regulator connects to the controller. If the regulator itself is not working, then it will have to be replaced (the author of the video is Alexey a-skorp).

Too low a voltage level in the car's on-board network is also a common problem. In this case, it is necessary first of all to pay attention to diagnosing the generator device or wiring. Use a tester to check. In any case, if problems are detected in the operation of the system, it is necessary to repair the steering rack yourself. Operating a car with a non-functional ESD is not allowed until the problem is completely eliminated.

How to determine mechanical damage to the EUR and steering mechanisms?

Mechanical diagnostics are carried out if it is not normal, but the on-board computer does not generate errors. To check for mechanical damage, you need to turn the steering wheel left and right as much as possible, while the engine must be running. It should be noted that when turning the steering wheel, the vehicle must remain in one place.

If you notice that when turning the steering wheel you need to apply more force than usual, this may indicate a failure of parts or components of the amplifier. But this may also indicate a breakdown of other elements of the steering system (a video about diagnosing power steering using a paper clip is presented below, the author of the video is Gosha Vakhromeev).

To accurately identify what caused the problem, you will need to conduct a more thorough diagnosis. To do this, the vehicle first needs to be driven onto a lift and raised, while carefully checking all the elements of the chassis for operability. Racks, tie rods, etc. must be checked. This procedure can be carried out without any problems at any service station or on your own, but only if you have a lift and certain diagnostic skills. There is a possibility that repair of the EUR is not required, since it itself is operational, but repair of other elements is required.

To prevent the occurrence of malfunctions associated with the electric amplifier, it is necessary to clean the system, as well as contact nodes, from time to time. To carry out service yourself, you will need to remove your EUR, completely disassemble it, clean it and put it back. We will tell you more about this below.

Design and operating features of power steering and power steering

To make steering easier to turn and increase comfort, either hydraulic or electric power steering can be used. Both amplifiers have both pros and cons.

Power steering device

Structurally, power steering is a system of high and low pressure hoses containing oil driven by a pump. Power steering fluid must be poured into the reservoir near the pump. It only works when the engine is running. The driver turns the steering wheel, and at this time the fluid flows through the distributor under pressure created by the pump to the steering mechanism. It enters the working cylinder, puts pressure on the piston, which begins to move, and facilitates the rotation of the steering wheel. When moving in a straight line, the liquid flows back into the system reservoir.

Power steering diagram

Advantages and disadvantages of power steering

In the case of a hydraulic booster, the main disadvantage is the bulkiness of the entire system. But it is cheaper to produce and maintain, and this affects the price of the car. At the moment, power steering is found mainly on budget class cars, which include Priora. An amplifier of this type is also installed on expensive, powerful SUVs. This is explained by the fact that the power steering is capable of transmitting greater torque transmission power to the steering. In this regard, it outperforms an electric booster, but there are still more disadvantages:

- In a car equipped with a hydraulic booster, it is not recommended to hold the steering wheel in the extreme right or left position for more than 5 seconds. Otherwise, the oil in the power steering on the Priora begins to heat up, which can lead to system failure.

- The mechanism requires constant monitoring of the oil level, inspection and replacement of drives, hoses, and pump.

- The pump depends on the operation of the engine, which means it takes a certain percentage of power from the power plant. If the power steering does not work when driving in a straight line, this percentage of power is wasted.

- Such a system does not imply setting operating modes depending on the speed of movement or the angle of rotation of the steering wheel.

- At low speeds, the steering mechanism provides good sensitivity, but at high speeds it becomes less pronounced.

Engineers compensate for the last drawback by using a steering rack with a variable gear ratio. Power steering has already become an outdated system; designers are no longer involved in improving it.

Electric amplifier design

The design of the EUR is simpler than that of the power steering. It consists of an ECU, a torque sensor, a steering angle sensor and an electric motor. There are no hoses or fluids here. The electric motor is mounted directly on the steering rack itself, and torque is transmitted to it via a torsion shaft built into the steering mechanism system.

In the case of power steering, the force is facilitated by liquid, and in the electric booster the current is responsible for this. When the driver turns the steering wheel, force is transmitted to the steering rack. At this time, the torque sensor transmits data to the electronic control unit. The controller calculates how much current needs to be sent to the electric motor to optimally facilitate steering rotation. Since the force must be uniform, the speed of movement and the angle of rotation of the steering wheel are taken into account.

If the steering wheel rotates without the vehicle moving or at low speed, as when parking, the electric motor receives maximum current and the steering wheel turns easily. When driving at medium and high speeds, such force is no longer required, and the controller supplies a lower current.

Pros and cons of EUR

The electric booster is a more modern system with high potential for modernization. It is not without its shortcomings, but there are fewer of them than the power steering:

- high price,

- The electric motor cannot provide high power, so it is installed only on passenger cars.

The disadvantages are leveled out, since the design of the electric amplifier is constantly being improved.

The EUR for the Priora has many advantages. The system is easy to maintain due to its simple design. The only part that requires inspection is the rolling bearing. The ESD mechanism has more compact dimensions and can be installed on the steering shaft in the cabin, freeing up space in the engine compartment. Due to this, the durability of the structure increases, since there is no exposure to temperature changes and high humidity.

The electric booster does not take power away from the engine, which saves fuel. The drive only operates when the steering wheel is turned. The ECU is responsible for the operation of the amplifier, with the help of which you can adjust the operating mode of the EUR, taking into account the operating conditions of the vehicle. The electric booster is not afraid of extreme steering positions. Driving at high speed makes the steering wheel with ESD more sensitive.

Removing and installing EUR at home

In order to remove the device from the car, you will need to prepare in advance everything that may be useful to you in the process. In particular, we are talking about flat-head and Phillips-head screwdrivers, as well as a set of socket wrenches.

So, how does the procedure for removing and installing the electric amplifier take place:

- First of all, you need to turn off the power to the on-board network; to do this, disconnect the negative terminal from the battery. Then dismantle the steering wheel by first removing the plastic cover under it and on the control panel. The steering wheel is dismantled in accordance with the service book for the car.

- Using a Phillips screwdriver, you need to unscrew the four bolts that secure the decorative trim on the steering panel.

- Having done this, you will be able to see the wiring pads - they need to be disconnected from the steering column switch, and the slip ring is also disconnected.

- Using a size 8 wrench, you need to unscrew the screw that secures the wire blocks that run from the ignition switch.

- Next, you need to press on the plastic fixing elements and disconnect the pads with wires at the top and bottom of the column itself.

- In the place where the electric power steering wheel is attached to the column itself, you will need to dismantle the so-called plastic curtain; to do this, disconnect the clamps.

- Using a socket wrench, you need to slightly loosen the nuts that secure the assembly to the bottom of the column.

After completing these steps, the amplifier itself is removed - it is dismantled along with the intermediate shaft. But in order to make it more convenient for you to clean the assembly and then perform the installation in reverse order, it is advisable to disconnect these components from each other in advance. To do this, use a 13mm wrench to unscrew the screw securing the universal joints to the shaft itself. Then you will need to unscrew the two fixing nuts at the ends, after which the steering column itself can be removed.

Then you will need to remove the screw and remove the cardan from the splined pulley of the unit. To make the reinstallation procedure more convenient after removal, it is advisable to make sure that all marks match. We are talking about marks on the protective cover, pulley, and also the starter cover. Cleaning the contact group mechanism and other elements of the system must be done carefully so that all components remain intact and undamaged. If you turn to specialists for help in this matter, the cleaning procedure will cost you on average about 30-50 dollars, depending on the region.

For several years now, there have been heated debates and “spears breaking” regarding the Prior’s electric power steering on the pages of the Internet and periodicals. This is largely due to the fact that a number of owners of this, the most popular model of the domestic automobile industry, under the influence of a number of publications, have formed the opinion that the electric power steering (EPS) on the VAZ 2170, 2171 and even 2172 models poses a certain danger for drivers.

In this regard, it is worth understanding what this electrical control unit is, what its installation has brought to motorists, and what measures should be taken if there are suspicions about its malfunction.

It should be said that according to experts, including experienced car enthusiasts, thanks to the presence of an electric booster, driving the Priora has become much easier, this is especially noticeable at low speeds. Some drivers, accustomed to tighter steering forces, even feel that the steering has become too easy.

However, already from a speed of 80 km/h, the force on the steering wheel begins to increase, and from 100 km/h the assistance of the amplifier stops altogether. In addition, it was noticed that when turning quickly, the steering arm seemed to become shorter, although this feeling should be considered subjective - in practice, turning the steering wheel from lock to lock remained the same. I would especially like to note that anyone who has managed to get acquainted with this useful unit is unlikely to consciously express a desire to abandon it.

Of course, the topic of the reliability of the EUR on the Prior deserves special mention. Indeed, several years ago there were quite a lot of complaints about the occurrence of various malfunctions and it came to the point that a significant number of cars were recalled through official dealers to manufacturing plants.

However, those car enthusiasts who are seriously interested in this topic can, with some desire, find an investigation by the magazine “Behind the Wheel”, from which it becomes clear that the scandal three years ago was associated with an attempt by the Kaluga company to replace an expensive German microcircuit in one of the EUR units with a homemade electronic assembly.

This “innovative” solution led to cases of spontaneous turning of the steering wheel to the side. Let’s immediately make a reservation that “the comrades were corrected in a timely manner” and now under the hoods of all Priors there are modified and completely reliable (according to modern statistics) units.

Of course, with all the reliability of the Prior's EUR, it cannot be said that it never fails, and if suspicion arises, it is strongly recommended to perform certain actions. First of all, you should turn the car's wheels two or three times, both with the engine idle and with the engine running.

With the electric power steering operating normally, you will feel a noticeable difference (with the engine running, the electric power steering will significantly reduce the steering effort). We should not forget about the possibility of a built-in control system, a competent analysis of the codes of which can greatly facilitate diagnostics and understand why the electric amplifier is not working at the moment and whether in this case it is necessary to replace one of the sensors or, more seriously, you need to change the main control unit of the power steering unit .

As for the repair of the EUR control unit, today it is not possible to restore its serviceability on your own and it must be replaced entirely, assembled. At the same time, it is better to entrust this procedure to specialists (management, after all). If the warranty has already expired, then the price of a new unit is about 10 thousand rubles, and the cost of work is 1 thousand. rubles

If you have become the proud owner of a LADA Priora, then from time to time you will have to drive it into the garage and modify something with your own hands. A frequent breakdown is the electric power steering of the Priora, the problem here is the dampness of the structure. Namely, the replacement of an expensive German electrical circuit with a domestic one, which, of course, has been modified, but failures do occur.

Before you start repairing the Priora's electric power steering, you should figure out what's broken. First you need to find out under what conditions the EUR failed. There could be several reasons why it failed:

- after charging the battery;

- when turning the steering wheel at a large angle;

- in car parking mode;

- when driving over 110 km/h.

Comments and reviews

Periodically, after replacing the ignition switch, the power steering began to turn off at low speeds. Especially when you turn around. Car Lada Priora 16 cl. 2011 mileage 80000.

Good evening) I need advice) EUR Kalina is not working) the power supply has checked everything is normal) the speed sensor is working) the tachometer is working) the rotor sensor is missing) I connected the scanner) two errors) 1011 incorrect DPR sequence and 1044 engine speed signal circuit no signal) I turn the steering wheel) on the scanner, phases A and B change values) but phase C does not) I WOULD BE GRATEFUL FOR CONSULTATION

The light on the dashboard came on, there was a squeak somewhere and the steering wheel turned hard, I have a Priora with electric power steering, pr. 100,000t.

The electric power steering light on the dashboard is on, so it doesn't work, maybe there are some fuses.

Electric power steering intermittently fails

Hello Sergey, I bought an EUR from Priora, installed it on a VAZ2114, connected it through the instrument panel, the steering wheel turns jerkily! Maybe you need to connect through the brain. I have an injector with brains.

EUR Priora does not work, the error suddenly came on

When you turn the steering wheel left to right, the power steering is turned off.

Good afternoon) It all started trivially with reviews and reviews, according to which the finalization of such a plan is simply a “fairy tale!”) Afterwards we experienced this miracle of technology from personal experience! Details.

The unit was purchased from a 2012 Priora

(mileage 12,000 km).

It came with an adjustable shaft

, excellent condition. Will go for further improvements!

The hardest part was finding the wiring. In the end, they cut it out of the under-panel “braid” from the viburnum fret =) Ready-made versions are also sold (in the photo on the right).

In my case, the option from the store is not suitable, all the harnesses were redone, the power part of the wiring was moved to the engine compartment and located next to the battery. You only need connectors to the amplifier control unit and power wires (“+” and “-“).

About the plate and preparation of the intermediate shaft.

1)Adapter plate.

There are two options: - finished steel with a coating (buy in a store) - a drawing is available online which you can make yourself, or have it made to order.

Initially, I was confused by the comment on the drawing: “...for a VAZ 2110-2112 with an old instrument panel.” What about the Euro panel? Most likely, this plate is completely universal and in order to eliminate unnecessary gaps (between the panel and the steering column casing), you will have to adjust the outer mounting studs individually to the location... In fact, this is so! I didn’t make it to order because it’s cheaper to buy ready-made (Even taking into account delivery). Material: steel 5 mm, galvanic coating. There are no spacer rings included in the kit (needed to maintain the up-down adjustment of the steering column).

2) Intermediate shaft.

Made on the basis of a priority one with two cardan shafts. Subjects:

The original one is hollow at the base; a piece was cut off from it to lengthen it. The inside of the tube was machined at both ends. It was not possible to insert the part from the prior shaft any other way; the diameter is larger than the internal hole in the tube.

You need to act carefully near the crosspiece; you must not overheat the part! Otherwise, the rubber sealing the hinge joint will “float”. Finished product)

If desired, you can make any length. In the installed version with the adjusting bolt tightened, the result is slightly more than 26 cm, i.e. the middle of the possible tolerance. 3) Shred the plastic.

I don’t remember exactly how it worked out for others, but for me the EUR specifically hit the plastic. It seems that I didn’t see this in the reports, so I didn’t initially think about sawing the panel... Let’s act)

As I wrote at the beginning, there were no spacers included in the kit, and after trying it on, it turned out that they were not needed. I put three washers on the front studs (wide, about 1-1.5mm thick). Two were enough, but this resulted in a small gap between the body and the engine (when adjusted as high as possible)

5) EUR, rejoice at the finish!

6) The connection was made according to the factory diagram.

Purpose of terminals of EMUR blocks:

Battery problems

Based on this, we can draw the first conclusions about the cause of the breakdown. A common cause of malfunction is low voltage in the on-board network. The fact is that for the amplifier to function, a supply voltage of 13.5V is required.

First of all, we test the battery, if everything is fine with it, then we’ll look into it further. The problem may have occurred when you removed the battery for charging. To make the electric booster work again, turn the wheels to the extreme position and back 5-6 times, very often this is enough to resume operation.

Diagnostics

First of all, it should be noted that a breakdown that occurs with the EUR is determined by the indication on the instrument panel. It has a light bulb with a schematic representation of a steering wheel and an exclamation mark.

Normally, after starting the engine, it lights up for a couple of seconds and then, after self-diagnosis performed by the ECU, goes out when no faults are detected. But when a problem is detected, the indication does not turn off.

Do not forget that the electric amplifier controller communicates peripherally with the vehicle's ECU. Therefore, it is better to identify this kind of breakdown at a service station using a computer.

However, individual devices are currently available for sale to test the functionality of certain electronic components. They are easy to use and are quite inexpensive - up to 1.3 thousand rubles.

Thus, an individual scanner allows you to find out what happened to the car. It should be connected to the ECU - the latter will generate error codes. All related to ESD malfunctions begin with “C”. In particular, C1013 signals that the voltage in the on-board system is too low - this means that it is not enough for the amplifier to operate normally.

According to experts, the most common problems are the following:

- breakage, burning or short circuit of the wires supplying the EUR (they are red and black, have a larger cross-section than the others, and are also included in a separate connector);

- fuse blown;

- low voltage.

In the latter case, you need to check both the battery and the generator.

Wiring fault

In the case when the battery is in order, we look at the wiring; weather conditions, frost, rain or heat may be associated factors. If the electric power steering on a Priora turns off when weather conditions change, then this is a clear sign of a wiring fault. Check the soldering and insulation of the winding; a short circuit may occur.

The Priora's electric power steering does not work all the time. The maximum load on the electric motor occurs at low or no speed, and the minimum at high speed. So, in the Priora, at a speed of 110 km/h, the electric booster is completely turned off. At the same time, feedback to the steering wheel becomes maximum. Electric power steering "Kalina" turns off already at 60 km/h.

Chip errors

When a situation is observed that the wheels turn on their own, the reason is the electronic filling of the Priora electric power steering control unit. As mentioned above, quality was sacrificed for the sake of economy. Now the situation with this seems to have improved and everything has been finalized, but if suddenly you feel that the steering wheel is starting to move by itself, go for repairs.

If, along with the electric power steering, the speedometer also fails, then you need to look at the speed sensor. It was either simply dirty or broken. The same applies to the torque sensor installed on the amplifier. Clean them well and check their functionality.

Don’t forget to reset errors on the on-board computer; this can be done in several ways.

- Remove the terminal from the battery, wait a few seconds and put it back, the error should go away.

- Using a computer, the corresponding software can be found on the Internet.

Fuse box location

If you suspect that a fuse has blown and you want to check it, then the question arises: where is the Priora electric power steering fuse located? The control mounting block is located to the left of the steering wheel. Its opening scheme is simple. All you need to do is turn the three latches 90˚ and remove the cover, as shown in the photo, and you get to the brain stuffing of the car.

Here you can check and replace the failed fuse, then close the lid by pressing it tightly and snapping the three latches back 90˚ in the opposite direction.

Bottom line

You can carry out diagnostics and minor repairs to the Priora's electric power steering with your own hands. To do this, it is enough to determine what caused the failure and fix the problem, following our advice. It is better to entrust a complete replacement of the electric amplifier to professionals.

In VAZ Priora cars, the electric power steering performs the function of making the vehicle easier to control. With the help of the ESD, the driver can easily turn the steering wheel with one hand. What malfunctions are typical for the amplifier and how to replace the EUR in a garage - we will talk about this below.

Possible malfunctions: signs and causes

In what cases is the steering rack, power steering and power steering disassembled and repaired, what is the diagram, what functions does the torque sensor perform?

First, let's look at the main malfunctions of the system, why it does not work and how to fix them:

- Incorrect operation or breakdown of the control unit is one of the most difficult reasons for the inoperability of the EUR and power steering in the Lada Priora. If such a problem occurs, a corresponding error message will appear on the on-board computer screen. If you decipher it, you will find out that the computer has detected that the control module is inoperable. Such problems are usually associated with soldering problems. Most likely, the reason is a lack of connection or poor contact between the amplifier circuit and the controller. Such a malfunction can be solved by repair, that is, re-soldering, or replacement if we are talking about a car under warranty. You can find out more accurately about problems by conducting computer diagnostics.

- Failure of the speed controller. If the speed sensor breaks down, the electric booster turns off spontaneously or does not work at all, and an error message about inoperability will appear on the computer display. In this case, you can try to reconfigure the device or change damaged sections of the electrical circuit at the junction of the sensor and the control unit. Sometimes the reason lies in poor contact of the sensor with the on-board network, then the connector will simply need to be corrected. If the malfunction is associated with a non-functioning sensor, the device must be removed and replaced.

- The steering wheel turns with great difficulty. First of all, the reason should be sought in the lack of lubrication. If there is little oil in the system, the steering wheel will be difficult to turn, and uncharacteristic noise or creaking may be heard during rotation. Check the lubricant level and add oil if necessary.

- Prolonged operation of the electric booster without lubrication can lead to pump failure. The malfunction is accompanied by sounds uncharacteristic of the operation of the EUR, as well as difficult rotation of the steering wheel. If the pump can be repaired, then you can consider yourself lucky, but if it can’t, then the device will have to be replaced.

- Malfunctions in the operation of the electric amplifier can also be caused by reduced voltage in the machine's electrical network. If the voltage in the on-board network really jumps, then you should initially check the generator and the electrical circuit for its connection. For diagnostics, it is recommended to use a multimeter or voltmeter (video author - Alexander Loginov).

FakeHeader

Comments 108

I have this problem on my Priora. In short, I go to work, get into the car, start it, warm it up, start to move away and the EUR turns off, and only by the end of the evening it doesn’t seem to work for me. I decided to check the charging and this is what happened: with the engine running 13.9, with a stove 13.7, with dimensions and a stove 13.5, with low beam and with a stove and dimensions 13.3 and all together and the high beam in general 13, I think that’s why the EUR turns off because it doesn’t have enough power, I think There's something wrong with my generator, who knows?

Technical characteristics of the electric power steering: - rated supply voltage 13.5V; — maximum current consumption no more than 55A; — current consumption in the absence of torque on the input shaft is no more than 0.5A; — maximum compensating torque (at a shaft rotation speed of up to 360 degrees/sec., vehicle speed 0 km/h, load torque on the output shaft 35 Nm) — 24 Nm (12.9 kgf at R steering wheel = 190 mm), which corresponds to the control force on the steering wheel driver 6Nm (3.2kgf at Rsteering wheel = 190mm); — the moment of resistance to shaft rotation when the EMUR is not working is no more than 0.8 Nm; — total weight no more than 9.3 kg; — operating temperature range -40…+65С; — operating supply voltage range 10.8…15V.

Didn't you read the errors with a scanner? There are a lot of codes for eur.

Temporal parameters of the light code: duration of the initial pause – 2 seconds; long signal duration – 2 seconds; short signal duration – 0.5 seconds; the duration of the pause between signals is 0.5 seconds; Pause duration between codes – 2 seconds

Code decoding 1 long 1 short System OK 1 long 2 short No engine speed signal 1 long 3 short Malfunction of torque sensor 1 long 4 short Malfunction of engine EMUR 1 long 5 short Malfunction of steering shaft position sensor 1 long 6 short Malfunction of engine rotor position sensor EMUR 1 long 7 short Malfunction of the vehicle's electrical system (below 10V or greater than 18V) 1 long 8 short Malfunction of the EMUR control unit 1 long 9 short Malfunction of the vehicle speed sensor

Description of EMUR fault codes read from internal memory using a special scanner.

C1011 Vehicle engine speed signal circuit, no signal C1012 Vehicle speed sensor signal circuit, no signal C1013 Vehicle on-board voltage below the minimum threshold C1014 Voltage at the ignition switch below the minimum threshold C1021 Voltage of the main terminal of the torque sensor C1022 Voltage of the control terminal of the torque sensor C1023 Incorrect signal of the main and /or torque sensor control terminal C1024 Torque sensor, no signal C1031 Steering shaft position sensor, main signal circuit fault, or out of range C1032 Steering shaft position sensor, control signal circuit fault, or out of range C1033 Steering shaft position sensor, no power C1041 Engine Rotor Position Sensor, Phase A Circuit Malfunction or Out of Range C1042 Engine Rotor Position Sensor, Phase B Circuit Malfunction or Out of Range C1043 Engine Rotor Position Sensor, Phase C Circuit Malfunction or Out of Range C1044 Engine Rotor Position Sensor Sequence Incorrect C1045 Motor rotor position sensor, lack of power C1050 Short to ground in power circuits C1051 Motor, excess current through phase winding A C1052 Motor, excess current through phase winding B C1053 Motor, excess current through phase winding C C1054 Motor, open phase windings C1055 Motor, open circuit of phase winding A C1056 Motor, open circuit of phase winding B C1057 Motor, open circuit of phase winding C C1058 Motor, short circuit of phase windings C1059 Short circuit of motor phase A winding C1060 Short circuit of motor phase B winding C1061 Short circuit of motor phase C winding C1070 Fault not recognized C1 071 Control unit, RAM error of the electronic unit C1072 Control unit, ROM error of the electronic unit C1073 Control unit, error EEPROM of the electronic unit C1074 Relay of the electronic unit C1075 Control unit, excess temperature of the radiator C1076 Supply voltage of the ECU elements is below the minimum threshold C1077 Voltage on the power capacitors is below the minimum threshold C1078 Charging time power capacitors C1079 The current of one of the phase windings is above the maximum threshold C1080 Breakdown of at least one of the upper power transistors

Methods for determining mechanical damage to electric power steering and steering mechanisms

Mechanical damage is checked only when the EUR as a whole is not functioning correctly, but there are no errors on the on-board computer display. To diagnose mechanical breakdowns, turn the steering wheel in different directions until it stops while the engine is running. Of course, the car must be in one place. If you have to exert significantly more force than usual when turning the steering wheel, this indicates a malfunction in the system and a breakdown of one of the components. The same problem may indicate a failure of other components of the steering system.

To more accurately identify problems, a thorough performance check should be carried out. You will need to drive your Lada Priora onto an overpass, pit or lift, and then carefully diagnose all components of the chassis. It is necessary to check the racks, steering rods and other components, since there is a possibility that the amplifier itself is working, and the signs of malfunction are associated with other problems. To service an electric amplifier at home, you will have to completely disassemble the system, clean its components and put it back together.

Pinout diagram and designations of EUR contacts

Electric power steering

This device increases the force that is transmitted in the steering system. Simply put, you can turn the steering wheel with two fingers. Previously, VAZ models were equipped with hydraulic boosters (power steering), but starting with the Lada Kalina they were abandoned.

The EUR was developed. In terms of force transmission power, power steering is preferable, however, it has many disadvantages:

- Engine power take-off.

- Constant monitoring of the level in the tank is necessary.

- Checking oil lines.

The electric amplifier is devoid of all these disadvantages. And it is even easier to repair than power steering. But it also has its own faults.

EUR device

Main components of an electric amplifier:

- Mechanical part.

- Electrical component.

- Electronic control unit (ECU) with peripherals.

The mechanical part includes the actual steering parts, connecting parts and mounting hardware. That is, the input and output shafts, bracket, nuts, bolts, studs and springs. Well, there’s also an adjustment lever for changing the angle of the steering wheel.

Electric, actually the amplifier motor itself. The most vulnerable is the electronic component. ECU and connectors with sensors.

Self-removal and installation of the amplifier

You can do the procedure for dismantling and installing a new electric amplifier yourself, but for this you will need to prepare all the tools. To complete the job, you will need two screwdrivers - one with a flat head and the other with a Phillips head. You will also need a set of socket wrenches.

How to complete the DIY removal and installation task:

- Before performing work, you will need to turn off the power to the on-board network of your Priora. To do this, turn off the ignition, then open the hood and disconnect the battery from power. After this, you will need to remove the steering wheel, but first remove the plastic trim located under the steering wheel and under the dashboard. The casing is attached to several bolts; they must be unscrewed and set aside. Removing the steering wheel is carried out taking into account the recommendations described in the service manual.

- When the trim is removed along with the steering wheel, you will see the connectors of the steering column switches to which the wires are connected. These plugs will need to be disconnected. The contact ring must also be dismantled.

- Using a 8-mm wrench, you will need to unscrew the bolt that secures the connector with the wires from the ignition switch. Set the bolt aside so you don't lose it.

- Once these steps are completed, press down on the plastic fasteners and disconnect the wiring connectors at the top and bottom of the steering column.

- Having done this, you will see a plastic curtain in the place where the electric amplifier is fixed directly to the speaker. You will need to remove it, which will also require you to remove the fasteners.

- Using a socket wrench, you will need to slightly loosen the nuts that secure the amplifier to the bottom of the speaker. Just loosen it, not twist it. When the nuts are loosened, you need to remove the electric amplifier from its seat; its removal is carried out with the intermediate shaft. But we recommend that you still disconnect the amplifier from the shaft; this will allow you to quickly clean the EUR and simplify the installation procedure. To disconnect the shaft, you will need to unscrew the screw that secures the universal joint to the shaft using a 13mm wrench. Having done this, you will also need to unscrew the two nuts located on the end parts, after which the entire steering column must be removed.

- Then you will need to remove the bolt and cardan from the splined pulley of the mechanism. In this case, pay attention to the labels - during further installation they must match in any case. The marks are located on the protective cover, pulley and starter mechanism cover. Now you can clean the electric booster and other system components or replace the failed EUR with a new one. The assembly procedure is carried out in reverse order.