Catalyst replacement inserts for VAZ cars are products designed to replace a failed catalytic converter, which is equipped with VAZ 2110-12, Priora, Kalina cars. The main purpose of these inserts is an inexpensive alternative to a rather expensive cat-manifold, which is not designed for a significant increase in engine power. But at the same time, it is still possible to get some results in terms of car dynamics.

As you know, the standard catalyst for a VAZ car consists of a housing containing a porous material similar to a honeycomb. During operation, due to carbon deposits formed, the honeycombs become clogged and throughput decreases, and engine efficiency decreases.

There are three options to solve this problem:

- installation of a new cat-collector, which is very expensive (5000-6000 rubles),

- removal of porous material from the old cat-collector, after which only the outer shell remains (a ringing sound may appear, as the body begins to vibrate at certain speeds),

- installation of the Stingersport catalyst replacement insert.Â

Catalyst replacement inserts are divided into 8 and 16 valve valves (according to engine type) and into inserts with one hole for the DC (oxygen sensor) and inserts with two holes for the DC. When ordering an insert for replacing the catalyst, it is advisable to see for yourself in the number of oxygen sensors.

Catalyst replacement inserts for VAZ cars are products designed to replace a failed catalytic converter, which is equipped with VAZ 2110-12, Priora, Kalina cars. The main purpose of these inserts is an inexpensive alternative to a rather expensive cat-manifold, which is not designed for a significant increase in engine power. But at the same time, it is still possible to get some results in terms of car dynamics.

Catalyst heating: features

In some cases, the catalyst becomes very hot, turns red and begins to glow. This is due to incompletely burned fuel entering the catalytic analyzer. It begins to burn right in the device. The reason for this may be the following phenomena.

- The mixture does not ignite in the cylinder.

- The membrane maintaining fuel pressure has burst.

- The injectors are filled with a combustible mixture.

Due to the strong heating of the catalyst, the car loses its power, you can hear the engine starting to stall, and thick acrid smoke comes out of the engine compartment. To repair a car, you need the help of car service specialists. How to replace the catalyst?

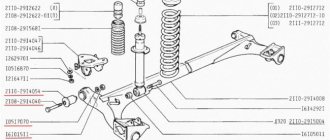

The part is attached to the resonator through a flange connection with two bolts. The downpipe holds the catalyst with a spring-loaded flange and two flares. A metal-asbestos ring is installed between them. Thanks to this connection, vibration does not transfer from the engine to the exhaust system.

During replacement, it is not necessary to look for new bolts and new springs. They only need to be replaced if they were damaged during disassembly.

A new ring must be installed. Penetrating gases can penetrate through the old one, which will damage the flaring of the catalyst. After installing the new catalyst, lightly screw in the mounting bolts. Full tightening begins with the bracket securing the resonator.

What part in a car is called a spider?

Spiders. Most of the exhaust losses occur in the exhaust manifold. In sports and tuning, the standard one is replaced with the so-called “spider” - it differs in the shape and order of connection of the exhaust pipes with the exhaust windows. “Spiders” are “short” and “long” (two U). If we take a 4-cylinder engine, then the pipe diagram for the “long” one is built according to the formula 4->2->1, and for the “short” one 4->1. The “long” spider has a 2->1 coupling, while the “short” one has a more complex geometry. The 4->1 manifold provides additional power only in a very narrow rev range, beyond 6000 rpm, and is usually used for highly boosted engines with wide-phase camshafts, that is, sports cars. 4->2->1 manifolds are suitable for amateur tuning, as they provide a certain increase in power and torque over a fairly wide speed range. Adding power gives about 5-7% for VAZ engines. In a direct-flow system, intermediate straight pipes of increased diameter and resonators of reduced resistance are also used. Instead of rigid connections, “corrugations” (bellows) or ball joints are often installed. The latter do not create parasitic resonance frequencies, but are short-lived. But the “corrugations” soften shocks during startup and a sharp increase in power.

All these parts are not difficult to install yourself, if only you had a lift or a pit, a tool, dexterous hands and a clear head. But it’s better to entrust the work to a service: considering the price of the parts, installation is cheap, and also requires an angle grinder, welding and a pipe bender. And you shouldn't lose the warranty. The movement of exhaust gases in the exhaust pipe is an oscillatory process that can be experimentally coordinated with the oscillatory process of movement of the combustible mixture in the suction tract in such a way as to improve the cleaning of the cylinder from exhaust gases and its filling with a fresh mixture. The pressure in the exhaust pipe is subject to sharp fluctuations throughout the entire exhaust period. At the first moment after the opening of the exhaust valve, combustion products rush into the exhaust pipe at a very high speed, exceeding the speed of sound. The rapid removal of 50% of combustion products entails the formation of a vacuum in the cylinder, which can reach up to 0.5 kgf/cm2. In the same way, periods of low pressure are formed in the exhaust pipe.

Experiments with exhaust pipes have proven that the length of the pipe does not affect the efficiency of cleaning the cylinder in the first stage of the exhaust process, but with increasing pipe length, within certain limits, the duration of the period during which the vacuum is maintained increases. With a change in rotation speed, the period of low pressure in the exhaust system not only changes in duration and magnitude of the vacuum, but also shifts along the angle of rotation of the crankshaft. Therefore, each engine operating mode corresponds to a certain optimal length of the exhaust pipe. There are two processes in the exhaust system of an internal combustion engine. The first is the gas flow through the pipes, damped to one degree or another. The second is the propagation of shock waves (sound) in a gaseous environment. Both processes affect the cylinder filling ratio. In the first case: high resistance to gas flow (plug the exhaust pipe!) will cause a decrease in the quality of purging and loss of power. It is absolutely clear that the shorter and larger the diameter of the pipe, the lower its flow resistance. In real life, for a one and a half liter engine operating at speeds no higher than 8000, a diameter of 45 - 50 mm with a length of 3 - 3.5 meters is sufficient. A further increase in diameter does not cause a significant decrease in dynamic resistance. It is further clear that if a reflector, called a resonator, is built in the exhaust system at a certain distance from the valve, then at certain speeds the purging of the cylinders will improve, which will increase the engine torque. This phenomenon is called "tuned exhaust" and is used to adjust the torque curve. If the task is to increase power, as for a sports engine

Source

How to repair the exhaust system

Repair of exhaust system parts is done only if holes from mechanical impact have been discovered. If the pipe breaks and the tank burns out, it is necessary to completely replace the parts. Their warranty period has expired. It must be said that metal expansion joints are changed in any case, regardless of the condition of the exhaust system.

Due to the fact that the catalyst is very expensive, amateurs weld a stronger instead. The catalyst is cut off, leaving only the connecting flanges together with the flaring. A stronger is welded into the vacant space. This part costs much less than the catalyst. However, the stronger is not able to burn the remaining gasoline. For this reason, it can only be mounted on a car equipped with a lambda probe. After installing the stronger, gasoline consumption increases by approximately 10%.

Cars equipped with engines with 16 valves often have two metal expansion joints attached to the “pants”. The size of such corrugation does not exceed 50 mm. The cost of such a receiving pipe is incredibly high. The industry does not produce metal expansion joints of this size. The only solution is to insert a corrugation measuring 100 mm and then adjust the length. Welding is done end-to-end with the “pants” and the gasket flange.

Manifold dismantling procedure - step-by-step instructions

The dismantling process itself is not so complicated; access to some nuts is difficult, so it is advisable to carry out the work on a lift or in an inspection pit. The algorithm of actions for the injection VAZ-2114 in this case looks like this:

- Remove the negative terminal from the battery or turn off the mains switch.

Remove the terminal from the battery

Drain the coolant from the system

Removing the fuel pipes

Search under the hood chapter 1. network spider

Disabling the throttle position sensor

Disconnect the muffler exhaust pipe from the manifold

- Which spider insert to choose instead of a catalyst from 2022

Dismantling the exhaust manifold mountings

Removing the exhaust manifold

Replacement of gaskets and installation of manifold

After dismantling the manifold, it is rarely possible to remove the gasket intact. It changes in any case, but parts of the destroyed gasket will definitely remain on the mating plane on the head side and on the manifold side. They must be carefully removed.

Changing the manifold gasket

Also, when installing new exhaust manifold gaskets, it is not recommended to use sealants. They can be of different quality, and during crimping they can form particles that get into the crankcase, which is extremely undesirable.

Independent production and installation of a flame arrester

Most auto-tuning workshops have found an alternative version of the catalyst. A flame arrester is installed instead. It can be easily made even in the garage. Auto mechanic services are not required. The main function of a flame arrester is to extinguish the fire escaping from the collector.

This flame has a very high temperature, so one of the muffler parts may burn out. If you weld an ordinary straight pipe instead of a catalyst, removing the internal parts located in the body of the catalyst, the exhaust system will quickly become unusable.

It will simply burst and burn out, and you will have to completely replace it. A flame arrester comes to the rescue, which has properties similar to those of the catalyst. It does not interfere with the movement of flows and is much cheaper than a catalyst. You can buy such a flame arrester at auto parts stores. But sometimes they are not on sale. Therefore, the part is often made by hand. To work you must have:

- metal pipes;

- steel brushes;

- welding machine.

Pipes must have specific diameters. One should match the size of the exhaust system, the other should be slightly larger. Six-millimeter holes are made in the first pipe with a diameter corresponding to the diameter of the leading system pipe. They are drilled along the entire circumference and length. It is then inserted into a pipe with a larger diameter and, after centering, welded at one end.

Using brushes, the pipes are stretched and then pushed inside. They are compacted with a steel rod. This operation is done until the entire free space of a larger diameter pipe is filled with brushes. When the operation using brushes is completed, the free end of the pipe is welded, the edges are first bent.

The result was a ready-made flame arrester, made independently. This part can be mounted on a car instead of a catalyst. A vehicle equipped with a flame arrester will run perfectly and quietly.

Selecting the appropriate modification

Part installed on the machine

When choosing a “spider” for a Priora, two options are most often considered - 4-1 or modification 4-2-1. It all depends on what final result we want to get. The 4-1 manifold produces an optimal increase in power in a fairly narrow rpm range. It has four pipes from the valves connected into one without transitions. Collectors are available with both short and long pipes. Modification 4-1 is suitable for engines with high afterburner, speed range from 6 to 10 thousand per minute. Typically, these “spiders” are installed on engines with camshafts with a phase of more than 285 degrees.

Exhaust manifold for VAZ 2114

Spider 4-2-1 is a part in which four pipes from the cylinders are connected first in pairs, and then into one common pipe. It gives a less significant increase, but over a wider rpm range. These parts are installed on medium-boosted engines. It is believed that short versions of the 4-2-1 model are effective at revolutions above 4500 per minute, and long ones at average speeds from two and a half to four thousand per minute.

The 2-2 “spider” configuration, when four pipes turn into two in pairs, each of which has a separate outlet, (you get two outputs) is practically not found in mass production. However, amateur welders perform modifications for themselves, as shown in the photo. Such work was carried out by autogen and camping, for which pipe blanks were cut and adjusted using angles. Some believe that this 2-2 “spider” configuration does not provide the ability to connect a lambda, so its use is not always justified.

There is no single scheme for selecting a 2-1 spider or another for a Priora car, since the choice of modification is made mainly during testing on a bench. But there is a formula for the length of the primary pipe (the distance from the valve to the end of the primary pipe) which is the following:

L = A x C x DxD / 1400 (constant) x BxB, where

Variable

Meaning

VAZ, remove the catalyst, install spider 4-1, high consumption, cleaning the air flow sensor, oil in the air duct

The resulting length must be multiplied by integers. The total length of the pipes from the connection to the valve on the Priora is approximately (!) determined by the formula (regardless of the 2-1/4-1 modification):

M = 2159 x (K+180)/T - P, where

K is the opening size of the exhaust channel in degrees before BDC, along the crankshaft;

T is the required engine speed for which the car is tuned;

P is the length of the outlet channel.

After the car owner has decided on the required “spider” model, he needs to purchase a muffler, a resonator (direct-flow, sports), a graphite ring and an oxygen sensor adjusted to the length to carry out the work. Models 4-2-1, offered in stores for the Priora car, have a nut for the oxygen sensor, so installing it will be quite easy. If the spider does not have a built-in sensor, then after installing it you will need to replace the firmware on the ECU.

Replacing the catalyst on a VAZ 2110

When should you change the catalyst? 1) If the catalyst is severely clogged, which is accompanied by: • Loss of vehicle power. • Also, if the catalyst is clogged, the tachometer needle may simply float at idle.

2) After the catalyst becomes clogged, over time it begins to collapse, and therefore various sounds will appear inside the catalyst itself, such as: • Rumble. • Or just its humming.

What can cause a catalytic converter to fail? 1) The main reason is low-quality fuel, especially if your car has a catalyst installed, then you are strictly prohibited from using leaded gasoline for the engine, as its use can lead to destruction of the catalyst.

2) The catalyst may also fail if a malfunction occurs in the ignition system.

Popular myths

Varieties

Some people deliberately get rid of the catalyst, others deliberately ignore the clogged unit. All this caused the spread of myths.

- By removing it, the engine gains power. A misconception that arose for unknown reasons.

- The engine cannot “breathe” normally due to the catalyst. Absurd. It functions quite well if the cat itself is in working order.

- A clogged element ensures a more environmentally friendly ride. Another myth, the origin of which can only be guessed at. Rather, on the contrary, a clogged device harms nature and your car even more.

Therefore, monitor the condition of the catalyst on the VAZ 2114, check its functional condition, and if necessary, replace it with a new one or replace it with a flame arrester. Both options have shown their effectiveness.

How to replace the catalyst on a VAZ 2110-VAZ 2112?

Removal: 1) First, unscrew the two nuts of the bolts that secure the catalyst to the resonator, holding the bolt from turning with one spanner, and with the other at the same time, unscrew the nut securing this bolt.

2) Next, move to the two bolts that secure the catalyst to the exhaust pipe of the car, and then completely unscrew them.

Note! When you unscrew the last bolt, hold the catalyst itself with your hand to prevent it from falling!

3) And to complete the operation, remove both bolts, along with two springs.

Note! Be sure to replace all cracked or deformed springs with new ones!

Installation: 1) First, install two springs on the bolts that secure the catalyst to the exhaust pipe of the car.

2) Next, attach the edge of the new catalyst to the exhaust pipe of the car, and then tighten the two retaining bolts with springs.

3) And to complete the operation, using two spanners, tighten the two nuts of the bolts that secure the catalyst to the car’s resonator.

Important! It is best to carry out the work of removing the catalyst on a cold engine, or wearing gloves, because when the engine runs for a long time, the catalyst heats up to very high temperatures, about 600 ° C!

I removed the catalyst, and this is what changed the car's behavior

Hello everyone, today we’ll talk about what happens if you remove the catalyst and whether it’s worth doing. At the end of the article there is a life hack on how to make money on forced repairs.

Owners of used cars are often faced with the need to remove the catalyst.

There is a slight danger if you approach the issue illiterately, you can get problems with the motor.

An example of a clogged catalyst. Photos from open sources

A catalyst is a device located in the exhaust system and is needed to purify exhaust gases. In this device, using chemical reactions, harmful substances are neutralized from exhaust gases, thereby bringing the exhaust gases into compliance with environmental standards.

Its interior is shaped like a honeycomb, made of ceramic and coated with catalyst substances such as platinum and palladium. It is because of this that it has a high cost.

Over time, the efficiency of the catalyst decreases, and the honeycombs in it may become clogged with deposits or burn out. If the car is not new, then in our conditions it is easier to remove it.

Since installing a new catalyst is quite expensive, and unreasonably expensive on a used car, the catalyst is often removed, a flame arrester is installed instead, and in some cars an electronic decoy may be required.

The problem is that if you do this incorrectly, the check engine light may come on, the car may not operate stably, and increased fuel consumption will occur.

It is best to additionally update the engine software to operate without a catalyst, in other words, “reflash”.

They usually don’t give a 100% guarantee; it all depends on the experience of the servicemen.

Flame arrestors of various types

Signs of a malfunctioning catalyst:

- First of all, this is a loss of power, the car accelerates poorly, traction is lost, difficulties appear when overtaking and when climbing hills

- Increased fuel consumption

- Unpleasant exhaust smell, very similar to the smell of rotten eggs

- Difficulty starting the engine

In my case, after a service check, a verdict was made: the catalyst began to burn out and crumble.

After weighing all the pros and cons, taking into account that my car is far from new, I decided to remove the catalyst, install a flame arrester and install an electronic snag, otherwise the engine malfunction light would have come on.

In progress

As a result, everything returned to normal, the car became easier to accelerate, the engine began to run smoother, and fuel consumption dropped. There have been no negative aspects yet.

A badly melted catalyst on my friend's car

About the opportunity to make money: when I began to look for the cause of the malfunction and read about catalysts, I began to come across an advertisement that we would remove the catalyst for free and I wondered what the benefits of the service were. Here's what I learned: the service removes the catalyst, keeping it for itself, welds you just a piece of pipe, and delivers the catalyst to acceptance. So, they accept used catalysts for 5-10 thousand rubles, and the cost of the pipe for service is negligible, and that’s how they make money. What I did was, first I bought a flame arrester (and not just a piece of pipe), it cost about 2000 rubles, plus I paid for installing it instead of the catalyst. Then I went and handed over my old catalyst for acceptance. As a result, I not only received a free replacement, but also remained in the black.

SYMPTOMS OF MALFUNCTION

Over time, this mechanism becomes unusable and requires repair or replacement. Typically, a VAZ 2114 catalyst can operate for about 150 - 200 thousand kilometers. After this, the filler becomes so clogged that exhaust gases cannot penetrate through them. You can determine that this mechanism is faulty by a number of characteristic symptoms.

The first thing that becomes noticeable, even when the catalyst is working, but already in its critical condition, is a sharp deterioration in dynamics. For example, acceleration to 100 km/h, instead of 13 seconds, will take 17 - 20, and the free wheeling will practically disappear.

The second sign is unstable idle speed. Due to the fact that the purifier will be practically clogged, some of the exhaust gases will return to the combustion chamber. Since the engine does not generate pressure at idle speed, the reverse flow of gases will simply “choke” it.

The third sign is deterioration in engine starting. Since exhaust gases will not exit through the exhaust pipe, they will remain in the system even when the car is not running. Therefore, when you try to start the engine, the gases will mix with fuel fumes, and a fire will not occur.

And the last, fourth sign is a distinct smell of sulfur in the car interior. Since the exhaust gas removal mechanism passes through the entire car, if it is clogged, gases will penetrate into the ventilation cracks, polluting the interior of the car.

Catalytic converter VAZ 2110, Bogdan. Features and replacement

Adjusting the valves of the VAZ 2110 is an important process that must be carried out by a professional. Let's look at the problem that can arise if the adjustment is incorrect. There can be many consequences:

- the full operation of the valve clearances is disrupted;

- the bearings on the camshaft wear out faster;

- the elasticity index deteriorates and, as a result, the valve spring breaks;

- they freeze;

- The drive gear pulley on the camshaft wears out.

Caps that reflect oil, valve stems and bushing guides also quickly fail. Scale and carbon deposits accumulate on the valves, which is due to the long exhaustion of the installed engine life. As a result, most of the structural elements become unusable. A common option is if the owner violates the basic rules of engine operation, allows the use of incorrect, used oil and irregular replacement. Fueling a car with low-quality gasoline, which contains a large amount of resins that settle on the surface of the valve stems, has a negative effect. If the engine runs for a long time at high speeds, this also causes a breakdown.

As you know, the internal combustion engine of a car emits carbon dioxide, water, carbon monoxide, nitrogen monoxide and hydrocarbons during its operation. All of these gases, with the exception of the first two, are quite poisonous and dangerous to the environment.

In order to somehow reduce the harmful effects of these substances on the external environment, a device called a catalyst was invented. It decomposes these toxic substances into safer ones for health.

A modern car catalyst in combination with a feedback system (lambda probe) can reduce emissions of harmful substances by up to 90%. Even precious metals such as rhodium, platinum, palladium are used in the chemical reactions of this device. This is what explains its high cost.

The reason for the failure of the neutralizer may be the operation of the car on leaded gasoline or interruptions in the ignition system.

If you are ready to spend a tidy sum on a new catalyst for 2110, then see below the illustrated instructions for replacing it on a car.

Standard "glushak" - what's bad?

Actually, we’re starting to get to the most interesting part, what’s wrong with the standard system? Why does it urgently need to be replaced (I think all tuners do this)?

To begin with, what is formula 4-1 - these are four pipes (from each cylinder) that are connected at one point (pipe) and then the whole thing goes into the main path through the catalyst, resonators, etc.

NOW WHY IS SHE NOT DEVELOPED? As a rule, to please engineers, environmentalists and others, the manufacturer makes short pipes from the engine cylinders, which are immediately connected into one. Why is this bad? YES because the distance to neighboring pipes is very short. During exhaust, a certain wave is formed, which should remove gases into the main exhaust - BUT this wave also enters adjacent pipes and cylinders, thereby inhibiting the removal of gases. The situation is aggravated by the presence of a catalyst (because it is a filter and creates additional resistance), the presence of advanced resonators (sound is damped well, but gas removal is worse) and the diameter of the pipe (often made thin, within reason of course).

To put it in simple words, the engine seems to be strangling itself, that is, this is the UNDEVELOPMENT of the gas exhaust system. The engine must “breathe” (discharge waste freely), thereby increasing the power.

How to replace?

- Raise your vehicle to a comfortable height for working from below.

- Secure the nuts using wrenches.

- Unscrew the bolts, holding the nuts securing the resonator to the converter and remove the spring washers with the bolts.

- Do the same with the nuts securing the converter to the exhaust pipe.

- Now you can carefully remove the catalytic converter from the car.

- The new catalyst is installed in the reverse order of removal.