LADA Kalina has been produced since 2003, when the first copies rolled off the assembly line. Before this, prototypes of future production models were repeatedly tested.

The process of creating the model itself turned out to be quite difficult and lengthy.

The first developments began back in 1999 and lasted until 2003.

During its existence, the model has undergone repeated updates. There were four in total:

- 1.4 liter engine, 16 valve mechanism, Euro standardization – 3, 4;

- 1.6-liter engine, 16-valve mechanism, Euro standardization – 3, 4 (production started in December 2009);

- 1.6-liter engine, 8-valve mechanism, Euro standardization – 2, 3 (subject to the “Basic” package);

- 1.6-liter engine, 8-valve mechanism, Euro 4 standardization (Lux+ package from November 2011).

Despite the many positive aspects of the car and the brand as a whole, it is necessary to highlight a number of weak points. These are: fuel system, exhaust gas recirculation system.

After a run of 80-100 thousand km, the metal housing of the exhaust manifold begins to crack at the seams. Flange connections are torn away from their seats. This does not take into account the fact that the catalyst itself needs to be changed due to burnout of internal parts due to systematic contact with a hot flame flow. The average gas temperature reaches 600℃.

Removing and replacing the catalyst on Kalina 8 valves

Replacing the catalyst on Kalina 8 valves involves work both in the engine compartment and under the bottom of the car.

- Initially, we provide ourselves with access to the exhaust manifold housing, move the high-voltage wires to the sides, and remove the plastic cover covering the motor at the top. Our collector itself is located at the front of the engine, if you look at it while standing in front of the car. When carrying out dismantling work, there is no need to drain the coolant.

- Using socket wrenches, unscrew the fastenings of the catalyst body. We do not remove it from its seat.

- At this stage, the work in the engine compartment is completed; it is necessary to lift the car on an electric lift for further dismantling.

- We need to unscrew the flange connections at the junction of the corrugated pipe and the back of the catalyst.

- Carry out a similar procedure in the resonator area.

- Now, piece by piece, remove the products from under the car and place them on the work surface for repairs.

Replacing the Lada Kalina catalyst begins with the fact that the owner of the technical device needs to decide on the further choice of part: a new standard catalyst or a “spider”. Considering the short lifespan of factory equipment, the second option would be the most practical. The catalyst is also often replaced with a flame arrester; Kalina accepts this alternative well. But in this article we will not consider this issue.

Replacing the catalyst on Kalina: what do you need to know about the spider?

Let's look at how the Kalina car, replacing the catalyst and a device called a “spider” are connected below.

Many owners of technical equipment often complain that the stock version of the engine, tuned for Euro 3 firmware, by default “eats” 10-12% of the total power of the power unit. Part of the power is taken away by the exhaust gas removal system. This is not to the liking of many owners. You can restore justice by returning the required 10% of power by installing the so-called “spider” - a modified version of the exhaust manifold.

Replacing the Lada Kalina catalyst: types of spiders

The Lada Kalina catalyst is replaced with one of two spider options: 4/1 and 4/2/1.

The main difference between these options is that the first option involves attaching four pipes to one main pipe, which is supplied to the catalyst. The second option is somewhat modernized and provides the possibility of connecting four pipes into two, then into one. Both versions of the spider have no filling inside, only a solid cavity. In a standard catalyst, the specified filling allows the engine to comply with Euro 3 standards and higher, but at the same time, the filling suffocates the engine, taking away power. Replacing the catalyst on Kalina 16 valves with a 4-1 spider system is the most ideal option. Power characteristics allow this to be done.

Depending on the type of spider, it is necessary to select the technical characteristics of the motor. It should be high-speed and forced. To ensure normal purging of the cylinders, more than 6500 rpm is required.

Replacing the catalyst with a spider on Kalina with an 8-valve system is carried out subject to the installation of a 4-2-1 type product. This design allows you to achieve maximum effect even at medium speeds. For this, no modifications to the Kalina power unit are needed, as in the version with a 16-valve mechanism.

Firmware for EURO2 and snag – what does this mean?

As I wrote above, the second oxygen sensor (lower lambda) controls harmful emissions. Their number is now strictly regulated by European standards, which are called “EURO”; I will not talk about EURO “0-1” now; we are interested in the second generation.

So, what is EURO2? It was introduced a long time ago, namely in 1996. AT that time, the cars received an innovative system, namely a catalyst. As we all know, over time it can become clogged, and the fuel then was not the same as now, it had a lot of sulfur, which contributed to the honeycombs clogging much faster, and as you and I know, the car began to choke itself. Then the engineers installed an oxygen sensor, there was only one, and it was needed to capture CO2 in the chamber in front of the catalytic converter.

If the CO2 level increased, this indirectly indicated that the catalyst was clogged (that is, a backpressure effect was manifested); the sensor sent this information to the ECU and the ignition was adjusted, namely, a decrease in the supply of the fuel mixture. Thus, the power dropped significantly, the car did not drive and the owner “willy-nilly” had to go to a service station and change this spare part.

BUT, as you and I know, the price tag is, to put it mildly, HIGH, so many owners simply removed these honeycombs and the POWER RESTORED!

But how? YES, everything is simple, the CO2 level in the chamber in front of the neutralizer dropped significantly, the oxygen sensor recorded this (that everything is in order) and the car drove cheerfully and without constraint. This suited everyone, BUT NOT ECOLOGISTS! Therefore, they introduced the EURO3 standard (now the EURO5 standard already exists). What has changed is that a second oxygen sensor (lower lambda) just appeared behind the catalyst. The principle of operation here is this: the first lambda (before the filter) records the level of harmful substances, the second (after it) should record a much lower level, because the harmful substances have decomposed.

If you remove the catalyst cells, then both sensors will record the same values (“the second one” supplies information to the ECU), thus, CHECK ENGINE will light up, the power will drop, and the car will not drive. Now this doesn't solve the problem.

What is done with firmware for EURO2? The firmware in the ECU is changed, instead of EURO3.4 standards, EURO2 standards are installed. The essence of all these actions is banal - we simply turn off the second lower lambda (only the upper one remains), the car begins to drive as expected, without underestimating the power.

But such interventions in the firmware are not entirely good. The whole point is that they don’t produce them themselves, okay, the second “lambda” is simply turned off, that is, they simply adjust the readings. Or maybe this programmer will want to put some incomprehensible algorithms into the ECU, the engine will definitely not benefit from this. You need to be very careful here.

Therefore, we found a second solution, and I think it is more correct - installing a blende. What is a snag - essentially it is a “spacer” in front of the second oxygen sensor, it seems to move it a greater distance from the exhaust gases, it detects more oxygen and starts working normally.

Now there are several options for deception:

- Empty. It's just a tube with a very thin hole at the end (the part that screws into the muffler), and an oxygen sensor is screwed into the other side. A limited amount of harmful substances from the exhaust passes through it, there are no excesses and therefore CHECK does not burn.

- With a mini catalyst inside. That is, right in the “spacer” there are, as it were, mini honeycombs, which also clean the exhaust precisely to record normal values.

- Angular. These are both of the types described above, only they are made at an angle of 90 degrees; they are needed for difficult places.

The advantages of the decoy are that you don’t need to go into the ECU and change the standard firmware, as well as the price (knocked out the cells, screwed on the decoy and that’s it, you can spend 3,000 - 5,000 rubles).

Lada Kalina: catalyst replacement - final stages

The final phase of installing the spider on the Lada Kalina occurs as follows:

- We weld the standard mount for the oxygen sensor onto the spider.

- We install the new spider in its regular place and start it through the opening in the lower part of the engine.

- Next, the system is assembled from a corrugated intake pipe. We cut out the length we need in order to connect the spider and the resonator together. If you plan to completely replace the system, then forward flow will follow, without the remaining parts of the exhaust system.

- We connect the flange connections to each other.

- We connect the lambda probe with long wires to connect to the ECU.

We lower the car, screw on the manifold housing, and start the engine.

The final stage: we rewrite the data in the engine ECU about the firmware version. This will allow the computer to understand the new exhaust system as stock. There will be no error identification on the instrument panel.

Sale of spare parts and repair of muffler in St. Petersburg tel.: +7 (812) 336-43-32

Catalyst (catalytic converter) - is a metal body (in the form of a “can”), coated on the inside with a layer of refractory material in the form of numerous honeycombs.

The main symptoms of malfunction of this element are: a decrease in engine power and, as a consequence, the dynamic capabilities of the car; the “Check Engine” sign turns on (engine ECU error: “low catalyst efficiency”). Possible breakdowns may include blockage of the cells or their melting, or melting or rupture of the wires of the oxygen level sensors. Unfortunately, catalysts cannot be repaired in any way; for this reason, it is almost always necessary to remove it from the system and install a blende in its place. It is possible to replace the catalyst, but the high cost of this element repels almost everyone.

Almost all modern electronic engine control systems are equipped with numerous detectors that monitor the composition of the fuel mixture. Oxygen detectors (lambda probes) always operate in tandem with a catalyst, and two sensors are usually installed in the system:

The first of them is mounted in front of the “catalyst can”; its task is to change the fuel supply depending on conditions and send a signal to the engine ECU; The second lambda probe is inserted into the system after the catalyst and serves to determine the qualitative composition of the combustion products of the fuel mixture. If a catalyst is excluded from such a gas exhaust system, then the content of toxic elements in the combustion products of the fuel mixture will be higher than normal, and the diagnostic sensor will give a signal about excess CO in the exhaust tract. The engine ECU will receive the signal and inform the driver about the error - after the catalyst is ejected from the gas exhaust system, the Check Engine light will turn on on the instrument panel.

Maintenance instructions

Preventative washing of the catalyst with Hi-Gear and the like is done by emptying the bottle directly into the gas tank immediately before refueling the car. No further action is required on the part of the motorist - while driving, the ceramic honeycombs of the element are cleaned independently, and dirt flies out through the exhaust tract.

To clean or rinse a clogged neutralizer with your own hands, you will have to dismantle it. Drive the car into an inspection ditch, turn off the lambda probes in the car and unscrew the clamps holding the unit to the exhaust pipe or exhaust manifold. Then follow this algorithm:

- Thoroughly blow out the catalyst on both sides with a compressor, pumping up a pressure of 7–9 bar.

- Fill the ceramic honeycomb with ABRO carburetor spray foam. Pour the product through both pipes.

- Wrap the neutralizer with a rag and wait 20 minutes.

- Thoroughly rinse the internal mesh of the element under hot water pressure and blow it with a compressor.

- Repeat the operation again, dry the catalyst and make sure that the ceramic honeycomb is visible through. Reinstall the unit on the vehicle.

If you can't clean the catalytic converter with spray foam, you have nothing left to lose. Soak the element in kerosene or diesel fuel and leave for 12–24 hours. To be sure, diesel fuel can be diluted with a small amount of acetone or solvent 646 (ratio approximately 4:1). After a day, perform the cleaning procedure with an aerosol cleaner as described above.

Mechanical cleaning is carried out with fine sandpaper with periodic blowing with a compressor. The outer meshes are cleaned carefully, with slight pressure, so that the fragile ceramics do not crack. It will not be possible to remove carbon deposits from internal cavities using this method.

Often, instead of washing, car enthusiasts pierce contaminated honeycombs with a metal object to free the passage for flue gases. It is permissible to use such extreme measures only in one case - you have tried all flushing means and have not been successful.

Please note: driving with a broken catalyst not only harms the environment, but also costs you money: the lambda probe “sees” untreated exhaust gases, and the controller switches to emergency mode with increased fuel consumption. To solve the problem, you need to install a fake oxygen sensor, which leads to additional costs

https://youtube.com/watch?v=TOTqHFrimnI

Replacing the Catalyst on Kalina 8 Valves

But high-class auto repair shops have figured out how to deceive the engine ECU - we will reflash the engine ECU, excluding the second lambda probe from the circuit. The electronics “believes” that there is no second detector in the exhaust system, so it does not expect any readings from it, and the engine operates as usual. With the “bleeder” (installed after removing the catalyst), the consumption of the fuel mixture remains the same as before with the catalytic converter.

If the catalyst is excluded from the gas exhaust system on a gasoline engine, the combustion products of the fuel mixture will act as an unextinguished flame and lead to failure of parts of the gas exhaust system (resonator, muffler). To increase the service life of the gas exhaust system, it is necessary to install a flame arrester in it. If there is such a possibility, then you can replace the catalyst with a flame arrester in the same place. If the catalyst is simply thrown out of the system, the engine ECU will display the error “insufficient catalyst efficiency p0420”. To prevent this from happening, either a decoy is installed, or the engine ECU is fully re-flashed to operate within Euro2. The more modern and complex the car, the more complex the methods for testing and monitoring the efficiency of the catalyst, so the use of decoys in terms of the significance of the result comes to naught. For example, as catalyst performance decreases, the engine ECU can change the mixture composition to reduce catalyst wear.

When removing a particulate filter on a diesel engine, you must programmatically disable the use of the particulate filter in the engine ECU - make changes to the firmware. This allows you to further significantly improve the dynamic performance of the engine. The presence in the service station of specialists with the necessary qualifications, modern equipment, as well as firmware from global manufacturers of various car brands with the necessary modifications allow us to fully remove the particulate filter on almost any diesel engine.

The exhaust system of all modern cars contains a device to reduce the toxicity of exhaust gases - a catalytic converter. Let's consider its design and possible malfunctions.

LADA > 4×4

LADA > Granta

Renault > Duster

Toyota > Camry

Nissan > X-Trail

LADA > Priora

Catalytic converters began to be used back in the last century to reduce the toxicity of exhaust gases from spark-ignition automobile engines.

Errors and malfunctions, sensor maintenance

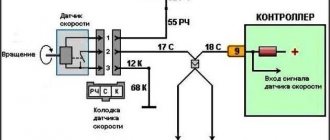

To check the heater circuit, you need to turn off the ignition, disconnect the harness connector from the controller and check contact X1/C4 by connecting it to the vehicle's on-board network. If a short circuit does not occur, then the controller is faulty. If there is, you need to disconnect the UDC block and check the closure of its contact D. If present, you need to check the wiring harness; if not, the UDC has failed.

When the harness, block or plug of the lambda probe is damaged, the only solution is to replace it. The oxygen sensor must be in contact with ambient air. For this purpose, special gaps are made between the probe wires, which can be easily damaged if repairs are undertaken.

Monitor the condition of the sealing pad on the outer surface of the sensor and prevent it from being damaged. To remove the lambda, turn off the ignition, disconnect the wiring harness from the probe, and carefully unscrew the device itself using a 22mm wrench. The procedure for installing a new sensor is described in the next section. The new lambda requires careful handling during installation to avoid contamination and damage.

The Check Engine on the dashboard may not light up, but if you notice increased fuel consumption and unstable engine operation, or that the engine is not reaching its maximum power, this is an indicator of failure of the UDC. If the Check Engine lights up, the ECU averages the engine settings, and it will no longer be possible to use it to its full potential - you need to go to a service center for diagnostics.

Catalytic converter for Lada Priora

For proper operation of the system, oxygen sensors (lambda probes) are installed in front of the catalytic unit and immediately behind it. The sensor located before the neutralizer is called control, and the one installed after is called diagnostic.

In world practice, a different arrangement of the catalytic converter is used. This scheme with the location of the barrel of the catalytic converter under the bottom of the car appeared at the dawn of the use of this method of reducing exhaust gas toxicity and is still used, for example, on Renault cars with Euro-4 and even Euro-5 standards.

Exhaust system Lada 4×4

The catalytic converter is considered a reliable design element of a modern car, and manufacturers do not provide regulations for its replacement. That is, in their opinion, the service life of the collector or element under the bottom of the car should be equal to the service life of the entire car. However, practice has shown that catalytic converters do not always serve flawlessly.

What could happen to her trawler?

The first malfunction of the active element of the catalytic collector is its melting, which manifests itself in the form of honeycomb sintering and leads to difficult passage of exhaust gases. This usually happens after the gas temperature threshold of 900 degrees is exceeded.

How to repair a muffler

If your car's muffler requires repair or complete replacement, it is not recommended to do this work yourself, since there is a high risk that you will only worsen the condition of the exhaust system, and possibly the entire vehicle as a whole. In order to prevent such a situation, contact only specialized car services. In our car service center, qualified specialists with the necessary competence in the field of working with exhaust systems will competently diagnose the exhaust system of your car, and, if necessary, repair or install a new muffler in the shortest possible time.

If you encounter any malfunction in the exhaust system and you need to diagnose it, repair it or replace the muffler, then our salon specialists will be happy to help you with this, since we carry out all types of this work!

When developing most modern cars, technical solutions are widely used in their design, the main task of which is to ensure maximum comfort for the driver and passengers of the vehicle. In addition, a car that comes off the assembly line today simply must be environmentally friendly: it pollutes the air minimally and creates a low level of noise when driving. Environmental standards are especially strict in Europe and the United States, but Russia is gradually moving in the same direction.

Reducing the amount of harmful exhaust into the atmosphere and the noise level of the machine is achieved through the design of the exhaust system and the operation of the catalyst, whose task is to neutralize the main toxic gases generated during engine operation. This is a necessary part of any car; in the West, a car cannot be operated without a catalyst, but in Russia the situation is somewhat different. The fact is that the catalyst is quite expensive (precious metals are used in its design), therefore, after the end of the service life of this element, various cheaper alternatives are sought for it.

One of the most common ways to replace a catalyst is to install a flame arrester in the vehicle's exhaust system. Currently, you can easily find a flame arrester for any type of engine; many well-known foreign and domestic manufacturers of automobile parts are engaged in their production. The most common is the so-called universal flame arrester; they are manufactured by such well-known brands as “Platinik”, “Asmet”, “Ferroz” (Poland), “Asso” (Italy), “Simons” (Finland), “Walker”, “ Universal" (Estonia), "Marmittesara" (Italy).

Catalytic converter

A much more insidious defect is when ceramic particles begin to crumble from the surface of the honeycomb. The cause of destruction of ceramics is most often low-quality fuel, which burns out during the exhaust stroke. Moreover, crumbling begins in the hottest zone, on the edges of the honeycombs located closer to the engine.

When the engine operates at different modes, some of the exhaust gases may be thrown back into the engine cylinders. Ceramic dust, which is an abrasive and gets into the cylinder with the gas flow, will quickly damage the piston group and lead to scoring on the cylinder walls.

However, this phenomenon is not dangerous for all engines. We won’t even talk about models in which the neutralizer, contrary to global trends, is fixed under the bottom of the car, and therefore harmful particles would have to travel almost a meter “against the flow.” Some manufacturers, thanks to the use of correct design solutions, avoided these problems or managed to eliminate them in a timely manner.

How's the warranty?

Against the background of such an attitude towards the consumer, the position taken by the Kia concern causes a sharply negative attitude. Until the beginning of 2016, in the service book of cars of this brand there was an inscription that the warranty for the catalytic converter extends up to 1 (!) thousand kilometers. Roughly speaking, two refuelings, and then “bad Russian gasoline” can damage the catalytic converter, but the company is no longer responsible for this. However, since 2016, the warranty for the catalytic converter has been extended to 150 thousand km.

In the author's opinion, the warranty on the catalytic converter should be at least as long as that on the car.

Now let’s take a closer look at what a car owner should and shouldn’t do to ensure that the neutralizer serves a long and happy life.

Causes of catalytic converter failure:

- Poor quality fuel - most often with a low octane number. The engine management system switches to late ignition. This causes the mixture to burn out at the outlet and an increase in the temperature of the exhaust gases.

- Incorrect operation of the ignition system (misfire). Fuel that is not burned in one cylinder is immediately ignited and burns in the neutralizer.

- Mechanical damage to the catalytic converter. Increased vibration of the power unit and impacts on the catalyst lead to crumbling of the ceramic block.

- Thermal shock. Instantaneous cooling of a hot neutralizer when overcoming a puddle, for example, can cause cracks in the ceramic element.

- Incorrect air-fuel mixture, caused, for example, by a faulty oxygen sensor. Leaky, leaking injectors will cause the same effect.

- Adding additives to gasoline. Cocktails from unverified manufacturers or a concentration imbalance may increase the exhaust combustion temperature.

- The newest engine designs with minimal toxicity are programmed to quickly warm up the converter. In cold conditions, to speed up warm-up, the engine control units initially over-enrich the mixture, which burns out on the surface of the converter.

- There have been blatant design defects in the neutralizer throughout history. For example, Suzuki carried out a recall campaign to completely replace converters on SX4 cars.

From personal experience

Second half of the nineties. I worked as a fleet manager for a commercial company. The boss calls and says: We will sell Karina (Toyota Carina E). Go to the car wash and let your engine shine like...

What causes catalytic converter failure?

Catalytic converters, which can be purchased on the website autocatalystmarket.com in Russia, have a limited service life (100-150 thousand kilometers). Over time, the internal cellular structure of the ceramic device is destroyed, and the coating with precious metals (platinum, palladium, rhodium) is depleted, as a result of which the neutralizer is no longer able to perform its function.

Malfunctioning catalytic converters

occur for various reasons:

- use of low-quality fuel with foreign impurities;

- faulty ignition or fuel supply system;

- the entry of a large amount of motor oil into the engine, due to which the fuel does not completely burn out, and soot gets into the catalyst and clogs its honeycombs;

- mechanical shocks, due to which the ceramic base of the devices is destroyed.

Regardless of the reasons for the failure of the catalyst, removing the faulty device is considered the only correct solution. But not every car owner plans to buy and install a new converter due to the high cost of such units, while continuing to drive a car without a filter device. What are the pros and cons of such a solution?

Toyota Carina E

In general, it burned and stopped. I returned to the car, opened the hood, opened the distributor cap, and there was a swamp. He wiped away the moisture, dried it and finally made it to the office. Now answer the question: where do you think the fuel burned?

What if it’s the end?

Not everyone can or will want to replace a failed catalytic converter on an out-of-warranty car with an original one. Before _

rogo it. What are the options for the development of events?

- Just knock the filling out of the neutralizer. This requires reflashing the control unit so that it “turns a blind eye” to the signal from the second oxygen sensor, or installing a mechanical or electronic switch. The mechanical one is a bushing in which a piece of the catalytic converter is fixed, and the electronic one simply simulates the correct signal from the oxygen sensor.

- Knock out the filling and install a flame arrester in its place. It consists of several chambers with holes that serve to reduce the temperature and pressure of gases. This somewhat reduces noise and facilitates the operation of other elements of the exhaust system. The “brains” of the car must be deceived, as described above.

- Install a universal repair catalytic converter instead of the ceramic block. Most often on a metal rather than ceramic base. The degree of cleaning will be slightly lower, but you will not feel like “pests”.

Tell us, how did you communicate with the “monster under the bottom” - the catalytic converter: does it work, was cut out, replaced?

You can get acquainted with the “illness histories” of cars of past generations by following the link.

Device

The lambda probe consists of the following elements:

- Ceramic insulator.

- Rings and cuffs (serve for high-quality sealing).

- Tip with drilled hole.

- Protective shield (also has a hole for exhaust gases).

- Spirals (it is placed in a separate tank).

- Conductive contact.

- Postings.

All this is enclosed in a metal heat-resistant case. The Kalina oxygen sensor is attached to the exhaust manifold using a threaded connection.

Note that the technical characteristics of the lambda probe do not allow measurements to be taken at temperatures below 250 degrees Celsius. In order for the Kalina oxygen sensor to show the correct values, its ceramic tip must warm up to operating temperatures. These are considered values of 300-400 degrees Celsius. But how does the element work when starting a car “cold”? In this case, the control unit uses average lambda values that come from other sensors (crankshaft speed and coolant temperature). A little more fuel is burned in the cylinders than required by the standards. But as soon as the temperature in the exhaust manifold reaches three hundred degrees, the fuel to oxygen ratio will return to normal and will be 1:14.7.