On a car like Lanos, replacing the fuel pump grid is not particularly difficult. Therefore, if the time has come to replace this part on your car or characteristic symptoms of a clogged mesh appear, then you can safely get to work. The work will take about two hours at a leisurely pace.

Lanos: replacing the fuel pump mesh is done in a garage, you don’t need to go to a service station for such a simple job, you don’t need rare tools either. Before describing the replacement process, it is worth saying that the fuel pump mesh is located in the gas tank, specifically in the fuel pump glass. The purpose of the mesh is to filter the incoming gasoline into the fuel pump, and, consequently, into the engine. It traps debris and other dirt that somehow got into the gas tank.

Replacing the mesh on the fuel pump is recommended every 30 thousand km. But, if you give statistics, then one part of car owners changes it almost every 10 thousand km, while another, no less, part drives 50 thousand or more, without replacement. Then a logical question arises: when should it be changed?

As already mentioned, the task of this mesh is to trap debris that gets into the gas tank. Based on this, we can say that if you often have to fill gasoline from cans and other containers, then it is advisable to change the mesh every 10 thousand km. In cans, especially old ones, there is often all sorts of debris floating at the bottom that cannot be completely cleaned out due to the shape of the neck, so it turns out that some of the debris with the fuel always ends up in the gas tank. In such a situation, the grid quickly becomes clogged and problems begin.

If you always refuel at the same gas station, and you know that the gasoline there is clean and of high quality, based on previous inspections of the grid, then you can safely cross the threshold of 30 thousand km. After 35-40 thousand, it is advisable to carry out an inspection and look at the condition of the mesh; if it is dirty, then it is worth replacing. It is worth adding that the mesh does not need to be changed if it has noticeably darkened and become dark yellow, and not white, as it was originally. The main thing is that there is no dirt on it. It loses color because of gasoline.

If the mesh is clogged, it greatly complicates the fuel pump's suction. This situation cannot but affect the behavior of the car. The main symptoms include:

- After turning on the ignition, the fuel pump pumps longer than usual;

- Poor cold start. The car starts only the second or third time;

- While driving, when you sharply press the gas, the car begins to twitch and or “stupid”;

- Loss of power. When accelerating, there is a feeling that there is less horsepower in the engine;

- In particularly advanced cases, the idle speed will drop, until the engine stops working.

Before starting all work, remove the fuel pressure in the system. To do this, you need to pull out the fuel pump relay from the fuse block. If you stand opposite the car, the relay is located at the very bottom of the block, on the right. When the relay is removed, you need to start the car. The engine will start and stall after a few seconds, which means that the pressure in the fuel line has dropped.

Now we move on to removing the rear sofa. Lifting the rear sofa on both sides you can see the brackets. You need to pull these two brackets towards yourself so that the sofa moves forward a little. Two bolts will become visible between the back and the sofa. We unscrew them with a head 12. Now the sofa can be completely removed.

Under the seat, on the right, we see a black plastic circle, it needs to be removed. Under this black cover there are hoses and a fuel pump connector that need to be disconnected. There is a lock on the chip; you need to move it towards the fuel hoses, then the chip can be removed without any problems. The hoses are removed by squeezing the clamps on the sides.

Next, using a hammer and a flathead screwdriver, you need to remove the retaining ring. This is done like this: the tip of the screwdriver must be inserted into the engagement of the ring and lightly hit the screwdriver with a hammer. After a few taps, the ring will come out of place. Now you can pull out the fuel pump glass. You need to pull it out slowly so that all the gasoline has time to drain into the tank.

When the glass is in your hand, you need to remove the locking chip that holds the float mechanism and then remove the float itself. Now you need to remove the fuel pump module from the glass. The module is fixed in the glass using three latches. Using a flat-head screwdriver, carefully pry up the latches one at a time. When the module is removed from the latches, we pull out the chip with the wires.

To pull the module itself out of the flask you will need some kind of hook. Such a hook can be made, for example, from a bicycle spoke or a welding electrode. We hook the module to the bottom part with a hook and slowly pull it out. When the module is removed, we proceed to removing the mesh.

Before removing the mesh, you need to remove the small retaining ring at the very bottom of the module. After this, the mesh can be removed without problems. We install a new mesh in its place and secure it with a locking ring. This is how the fuel pump mesh is replaced on a Lanos car. You can assemble everything in reverse order. It is important when installing the module back not to use force; it should fit in with a slight tension, but not rest in any way.

Cleaning the injectors

Cleaning and washing the engine injectors, as well as replacing the fuel pump mesh on a Chevrolet Lanos, is necessary every 30,000-35,000 mileage (and with the current quality of gasoline, even more often). There are several washing options:

- Flushing the injector with specialized fuel additives is the easiest and most affordable cleaning option, but also the most questionable. These additives become effective when regularly added to gasoline;

- Cleaning without removing from the engine

- instead of the factory power supply system, a unit is connected to the injectors that supplies a special cleaning solvent, the engine runs on it for 20-30 minutes. The efficiency of this method is very high; all deposits are removed from the injectors without leaving any residue; - Cleaning on an ultrasonic stand

is considered the most effective way of washing and cleaning. The advantage is that there is no need for an expensive solvent, but you have to remove the injectors from the engine; - * We also recommend reading the article “How to wash injector nozzles.” Everything is explained there in detail.

There are also ways to wash it yourself; with the right approach, it will be no less effective, but we’ll talk about that separately.

Design and types of fuel level sensors

The fuel level sensor on Lanos cars is located directly in the gas tank. This device is a potentiometric device or variable resistor, which has a number of advantages:

- Simplicity of design

- Reading accuracy

- Reliability

- Low cost

Among the disadvantages, it can be noted that due to the simplicity of the design, the device tends to wear out during operation. This wear is especially accelerated when the driver adheres to the refueling method when the gas tank is completely empty. To understand why the device fails, let’s look at its design.

A potentiometric device consists of a group of contacts, some of which are movable. Due to this mobility of contacts, the filling of the gas tank with fuel is determined. When the moving contact (slider) moves, it rubs against a fixed scale, consisting of conductive marks made of resistive material. During the friction process, the fixed scale wears out, which causes malfunctions such as incorrect readings or a complete malfunction of the fuel gauge on the Lanos instrument panel. The photo below shows the design of a potentiometric fuel level sensor, which is used on Chevrolet and Daewoo Lanos cars. Such sensors are called lever sensors, but there are other types of such devices.

FLS on cars, installed directly in the gas tank, are of the following types:

- Lever or float

- Tubular

The principle of operation of both types of sensors is the same, and it is based on the fact that the float connected to the moving contact of the sensor takes the corresponding position on the fixed contacts. As the gas tank empties, the position of the float decreases, which means that the moving contact moves along a fixed scale. The amount of fuel in the tank is measured due to the fact that an electric current flows through fixed contacts. By changing its position with the moving contact, the resistance increases or decreases, on the basis of which the level of gasoline in the container is determined.

If a lever sensor is a block consisting of a fixed resistive scale and a moving contact connected to a float, then a tubular sensor is a separate container. This container is presented in the form of a tube, which is filled with gasoline. Inside the tube there is a float that changes its position depending on the fuel level in the tank. The float is connected to a movable contact that moves along a fixed resistive scale. The advantage of a tubular sensor is that it is possible to determine the amount of fuel in the tank more accurately than when using lever devices.

This is interesting! The disadvantage of a tubular fuel level sensor is that it is not suitable for use in all cars, which depends on the geometric parameters of the tank.

Lanos cars with nameplates from various Chevrolet, ZAZ and Daewoo factories, as well as Sens and Chance, use lever-type fuel level sensors. They are located directly inside the gas tank, and they are attached to the fuel pump module.

How it works and what the device consists of on Daewoo and Chevrolet Lanos

To understand the principle of operation, you need to understand the design of the catalytic converter on Lanos.

Inside the cylindrical barrel there is an appropriate amount of noble metals, which are tasked with filtering exhaust gases. Inside the device consists of small meshes, which are also called honeycombs. These meshes are made of a ceramic or metal base using expensive non-ferrous metals. The honeycomb is opened from above using a platinum-iridium alloy. A special sensor is installed in front of the converter, the existence of which everyone has probably heard of - this is a lambda probe or an oxygen pressure sensor. He is responsible for recording and analyzing the level of gas contamination before the device. If the cells are clogged, clogged or destroyed, then the CO2 level accordingly increases, which is recorded by the sensor. It sends a signal to the ECU and the Check Engine light comes on. This is interesting! The reason for the high cost of the catalyst lies precisely in the presence of non-ferrous metals (platinum and iridium) inside the device.

If gold is present in the composition, it is in very small quantities. The device starts working only after warming up, so for the first 3-5 minutes after starting the engine, the exhaust gases are not filtered by the neutralizer, from which you can hear the corresponding smell of acetone. As soon as the device heats up to a temperature of 600 degrees or higher, an oxidation reaction begins to occur. In the process of this reaction, harmful substances from the operation of the Lanos engine are burned, and low-harm substances - nitrogen and carbon dioxide - are already released into the atmosphere. A normal reaction to reduce harmful substances occurs when the neutralizer is heated to a temperature above 750 degrees.

This is interesting!

On new models of Lanos and Chance, converters began to be installed directly at the outlet of the exhaust manifold. This is done to quickly warm up the device, so the neutralizer starts working immediately after starting the engine.

When to change the fuel pump mesh Lanos, Sense and Chance

Any filter becomes dirty over time, and this also applies to the mesh installed at the inlet of the gas pump. When the element becomes clogged, there is a decrease in its throughput, resulting in a decrease in the amount of intake fuel. Reduced gasoline absorption has a negative effect not only on the fuel pump itself, but also on the functioning of the engine. A clogged mesh of the Lanos suction device leads to the following consequences:

- The load on the pump electric motor increases, causing it to heat up more. This reduces the service life of the device

- The absorption of the amount of fuel decreases, which ultimately leads to a decrease in the quality of cooling of the pump electric motor.

- The pressure in the fuel line decreases, which negatively affects the functioning of the internal combustion engine

The main signs of a clogged fuel pump filter on Lanos are:

- Problem starting the engine due to low pressure in the fuel line

- The engine does not start at all if the filter is heavily clogged

- When the car moves, jerking and jerking appears, indicating problems with the fuel supply

If the above symptoms occur on Lanos, it is necessary to resort to replacing the part. Every driver can cope with this, but the biggest drawback of the process of replacing the fuel pump grid on Lanos is that this will require dismantling the entire module.

This is interesting!

Some drivers prefer to clean it instead of replacing the mesh. This is not a rational approach to such an event, since it is impossible to clean the element to perfect condition. However, this method is suitable when the engine does not start due to a clogged filter mesh, but you still need to get home or to a car service center.

Instructions for replacing the fuel pump mesh on Chevrolet, ZAZ and Daewoo Lanos, Sens and Chance

It should be noted right away that the resource of this filter element ranges from 50 to 100 thousand kilometers. It all depends on the quality of the gasoline being poured into the tank, but you can refuel once unsuccessfully and, at best, end up having to replace the filter, and in the worst case, you will have to change the fuel pump.

Next, we’ll look at how to replace the Lanos fuel pump mesh yourself, and what you’ll need for this. When carrying out the work, you will need a minimum set of tools, consisting of a flat or slotted screwdriver, steel wire and a hair dryer. To replace the mesh, you will need to remove the entire fuel pump module. How to do this yourself is described in detail in the material on removing the gas tank or instructions for replacing the Lanos fuel pump. The process of dismantling the fuel pump assembly with the mesh must begin by disconnecting the negative terminal of the battery.

After the fuel pump module assembly is removed from the mounting hole of the tank, we proceed to further steps to replace the strainer:

- After removing the pump, there will be some fuel left in it, which can be drained back into the tank or container by turning it upside down

- We place the entire mechanism assembly on a clean cloth or newspaper, and proceed to replacing the mesh

- The first step is to dismantle the float, for which the plastic clip in the shape of the letter “C” is removed. To remove the clip, you need to squeeze it and remove it from its seat.

- To get to the fuel pump coarse filter, you should remove the top cover of the plastic flask. It is attached using three protruding slots, which you need to press with a screwdriver.

- Before removing the top cap of the flask, you need to disconnect the power supply connector for the fuel level sensor. This sensor is attached to the outer flask (also called a glass)

- Next, we move on to dismantling the inner flask with the fuel pump, since the mesh is attached specifically to it. You can dismantle the inner flask using strong steel wire, from which you need to make a hook. An example of such a hook is shown in the photo below.

- The hook is needed to dismantle the inner flask (with the fuel pump), to which the mesh is attached. This flask is fixed using an internal protrusion along the circumference on the outer flask. The photo below shows a protrusion in the inner part of the outer flask, through which the fuel pump bracket with filter is fixed

- To simplify the process of dismantling the inner flask, it is necessary to heat the walls of the outer bowl with a hairdryer. This will lead to its expansion, which will allow you to easily and quickly remove the flask (it is important not to overdo it with a hairdryer)

- Using a hook, you need to hook onto the plastic protrusion on the inner flask and pull towards you (moderately). To increase the effectiveness of actions, efforts should be made alternately at several points. As a result, the inner flask with the fuel pump and the mesh located at the bottom is removed

- It is this mesh that needs to be replaced, having previously assessed its condition

- In 100% of cases, the inside of the outer flask will have contaminants that should be removed

- Let's start removing the mesh, for which you first need to remove the locking ring (washer) by prying it off with a screwdriver

- The old filter is removed, replaced by a new one, and secured with a retaining ring. It is recommended to purchase a new ring, since when it is removed, the quality of fixation has significantly decreased. If you install an old ring, there is a high probability that the mesh may come loose during use.

- We install the Lanos gas tank mesh in place and carry out the assembly in the reverse order

The procedure for replacing the gas tank mesh is not difficult, but it is very responsible, since the work is carried out with parts that are coated with highly flammable substances.

After assembling and installing the fuel pump with the new element in place, you can put the negative terminal on the battery and turn on the ignition. When the pump pumps gasoline and turns off, you can start the engine. This completes the process of replacing the fuel pump mesh.

This is interesting! Two types of fuel pump modules TA and TG were installed on Lanos. The principle of replacing the mesh on TG type devices is discussed above. Blocks of the TA type differ in that the mesh on them is located on the outside. You can read more about the differences between the modules here.

Where is the relay located?

The part on cars is installed mainly together with all the fuses, but in some brands of cars there is also a different arrangement of devices. In cars with an injector, the relays can be located both under the hood and under the instrument panel. Most often, the fuel pump relay is located in the following places:

- Near the ABS blocks.

- Near the fuel injection control unit.

- Under the dashboard. Most often it is installed on the passenger side under the dashboard.

Since the fuel pump relay ensures the supply of fuel, it is sometimes worth diagnosing the part so that an unpleasant breakdown does not cause a premature end to the trip.

What fuel pressure in the rail should be

Normal pressure is considered to be 2.5 atmospheres at idle. When gas is added, the pressure briefly increases to 3-3.2 atmospheres - this is a kind of imitation of an accelerator pump, like on a carburetor. These indicators are influenced by several factors:

- rail pressure regulator;

- fuel pump performance.

If the fuel pump does not provide the proper pressure, then there will be no pressure in the ramp. But within certain limits, the ECU will be able to compensate for this by increasing the injection time. But at low pressure, the accelerator pump imitation will not work, which will lead to failures.

A working fuel pump gives a pressure of about 5-7 atmospheres. But then how does 2.5-3 stay on the ramp? It's simple - the pressure regulator in the fuel rail is responsible for this. This is a small bypass valve, which is located on the rack, in the area of the fourth cylinder. Structurally, the pressure regulator is made in the form of a spring-loaded valve, which is also connected to a vacuum membrane.

You've probably seen that the rail pressure regulator is connected by a thin tube to the intake manifold. If it is disconnected from the manifold, it will maintain pressure due to the spring, and it will be equal to 3-3.2 atmospheres. And when the vacuum tube is connected, not only the spring, but also the membrane acts on the valve stem. Thus, the regulator has the ability to further adjust the fuel pressure in the rail due to changes in the vacuum in the manifold.

Replacing the fine fuel filter

To replace the fine fuel filter on a Chevrolet Lanos, it is recommended to follow the step-by-step instructions presented below.

Open the hood and find the fuse and relay box.

Remove the cover from the relay and fuse box.

- Start the engine.

- Wait until the engine stalls.

- Rotate the crankshaft of the power unit several times with the starter.

- Press the lock and remove one of the fuel lines from the filter pipe.

To prevent fuel leakage, it is recommended to place a plug on the fuel filter pipe. An alternative way to solve the problem of spilled gasoline is to drain the fuel from the consumable into a container, for example, a bottle.

Disconnect the second fuel line.

Install a new consumable, taking into account the direction of fuel flow.

Check for gasoline leaks.

Replacing the filter (mesh) of the Chevrolet Lanos fuel pump

Why is it important to remember that timely replacement of Chevrolet fuel filters is, first of all, the key to long-term operation of the car engine. After all, it’s no secret that the quality of Russian gasoline leaves much to be desired. According to the Chevrolet Lanos maintenance regulations, the fine fuel filter must be changed every 15 thousand km. mileage But the regulations are silent about the fuel pump filter, so make it a rule to replace it once a year, since various particles that are in the fuel eventually clog the filter mesh, which makes it difficult for gasoline to pass through it, and as a result, interruptions in engine operation.

Selecting a fuel pump strainer for Lanos, Sens and Chance and its features

Before you start replacing the fuel pump strainer on Lanos, Sense and Chance, you must first purchase the part. Meshes for fuel pumps for Lanos are produced by different manufacturers. Before deciding on the manufacturer, you need to find out what diameter of the filter element you need to buy. Fuel pump screens for Lanos are available in different diameters: 11 mm and 22 mm. How they differ, and how to understand what diameter filter element to buy for a gas pump, we will find out further.

- New 11 mm mesh - designed for Lanos and Sens cars from 2003

- Old-style mesh 22 mm - for Sens and Lanos cars until 2002

These parameters need to be taken into account, since during the replacement process it may turn out that you bought the mesh of the wrong size, and it will need to be changed. Which manufacturer is the best product to buy? Today, the products in question are produced by the following companies:

- FSO is a Polish manufacturer characterized by the production of reliable and affordable spare parts. Part number for the fuel pump for Lanos is 96350589

- ICRBI is a Chinese manufacturer that produces spare parts of no worse quality than FSO. Part number 13042081

The price of the spare part in question is not so high as to save on it and sacrifice the quality of the engine. As a result, it should be noted that the procedure for replacing the mesh takes a little time, and most importantly, you can do it yourself.

Replacing the fuel pump mesh with your own hands

Let's start with the fact that in some cases, many car enthusiasts decide to clean the fuel pump mesh, especially when a new filter is difficult to find on the open market. Note that after cleaning the fuel pump screen, it is possible to remove a significant part of the contaminants, although the optimal way remains to replace the fuel pump screen with a new one. The fact is that it will not be possible to completely remove dirt. Also, cleaning is often impractical, since the cost of a new fuel pump mesh is usually quite affordable (about 2 USD for meshes for VAZ family cars);

Chevrolet car repair manuals and tips

I've been wanting to replace the strainer in the fuel pump for a long time. Once I tried to open it (as I had a problem with the exhaust, there was an entry in the BZ) but it didn’t work. So the day came when I managed to open the pump and change the filter. The mesh cost 100 rubles.

Two hooks from the electrode are visible hereFirst, we open the top cover of the flask; it doesn’t give much of a view, but we try to open nothing. We insert one hook into the inside of the flask, we hook this hook to something, and slowly pull with force, as soon as it moves a little we change the position, when we walk around in a circle, the inner part rises a little; a second hook will be needed in order to reach the inner part of the flask without distortions. You also need to disconnect the wire connector, otherwise it won’t allow you to disassemble it completely. And when everything works out, you can rejoice, since this is the most difficult stage when replacing the mesh in the fuel pump.

Old and new mesh

I also removed the pump motor itself from its housing.

Replacing the mesh filter

Replacement filter mesh is shown below.

- Relieve pressure.

- Unscrew the seat fastening.

- Remove the back row.

- Remove the upholstery.

- Open the hatch.

- Remove the glass and disassemble it.

- Change the filter mesh.

- Assemble the module and return it to the car.

Causes of fuel pump failure

If the Lanos car engine does not start, then do not rush to conclusions. Even the absence of a characteristic sound in the area of the fuel tank does not mean that the device is faulty. One of the important elements in a car is the crankshaft position sensor. If it is not working properly, then the engine will not be able to start. When the ECU does not receive data from the DPKV, no power will be supplied to the electric pump. The driver may think that the fuel pump is faulty and resort to replacing it, but after successfully completing this procedure the effect when starting the engine will be identical

That is why it is important to first establish the exact cause of the malfunction, and only then resort to eliminating it.

One of the reasons for fuel pump failure is the use of low-quality fuel. That is why it is recommended to refuel only at gas stations that have the appropriate certificates. In addition to contaminants in gasoline, which cause the device to fail, driving a car with an empty tank can reduce the service life of the electric fuel pump on Lanos. Many drivers drive their car until the indicator on the instrument panel lights up. However, it is not recommended to drive a car with a half-empty gas tank, because fuel is the coolant of the pump.

When entering steep turns, the fuel is displaced to one side of the tank, so the pump does not have access to it for a certain period of time, as a result of which it sucks in air. As a result, accelerated overheating of the windings occurs, and as a result, failure of the part. The issue of driving a car with HBO is especially relevant. If your car has an LPG system, then the gasoline tank must be at least ½ full. If you neglect this fact and drive a car with an empty gas tank, the consequences will be sad for the gas pump. The consequences of driving with an empty gas tank are shown in the photo below.

This is interesting! The service life of the fuel pump depends on many factors. If you use high-quality fuel and timely replace the fuel pump mesh, the original device will last at least 200 thousand kilometers.

Preliminary checks of the fuse, relay, crankshaft position sensor, and pressure in the fuel rail will help you verify that the fuel pump is faulty on a Lanos car. And although it is easier for many to immediately remove the fuel module and check the serviceability of the fuel pump, it is recommended to perform one more preliminary procedure - measure the voltage on the chip connected to the module. To do this, you need to use a multimeter, connect the probes to the contacts on the chip, and turn on the ignition. After making sure that there is 12V voltage at the contacts, you can begin to remove the module and replace the fuel pump on the Lanos.

This is interesting!Sometimes a fuel pump malfunction can be associated with a decrease in the quality of contacts.

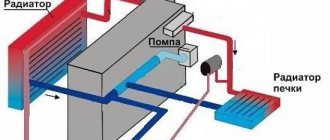

Fuel system composition

A standard injection system, the heart of which is four injectors, which are solenoid valves. The injectors operate using a control unit containing special firmware. Firmware is a program that monitors a lot of data about engine operation, and systems operate on their basis. To change the engine power, it is enough to change the opening time of the injectors. Accordingly, fuel consumption will also change.

The fuel rail to which the injectors are connected is under a certain pressure when the engine is running. This pressure is created using an electric fuel pump installed directly in the fuel tank of the car. True, there is a pressure regulator between the ramp and the fuel line. If it were not there, then the pressure in the ramp would constantly change, but due to the regulator it remains constant.

The fuel pump on Lanos, especially the original one, is not a cheap part, so before condemning it, you need to check the power circuits going to it. So, guess one: the pump is alive and well, the problem is in the power supply. Let's consider the classic sequence of checking the fuel pump for an open circuit.

Checking the fuel pump fuse - useful advice

Let's start with where the fuel pump fuse EF16 and relay K9 are located, which switches the power circuit from the battery to the fuel pump.

Now I will tell you one piece of advice that applies to all fuses in general, and which can save a lot of nerves and money in the future. And here's my advice - don't believe your eyes! If you have a spare fuse, then it is better to install it, and here's why: it happens that the fuse does not burn out , but simply cracks when you take out the fuse - visually it is intact and even rings, but when you insert it back, the legs move apart sides and contact disappears! If you have a multimeter, then you can ring the fuse without removing it from the block: on the sides of the fuse there is access to the terminals. My next piece of advice is to pay attention to the terminals and the plastic around them - poor contact may be between the terminal and the fuse leg. In my case, the fuse turned out to be intact, the next step is to check the fuel pump relay.

How to check the fuel pump relay

What can happen to the relay in principle, due to which it will stop switching the power circuit (from the battery): the contacts inside the relay may burn due to sparking, secondly: poor contact between the terminals and legs of the relay and the third thing that will need to be checked - voltage level on the control circuit (voltage that causes the relay contacts to attract). The picture above shows the principle of operation of the relay, the picture below shows the relay contact numbers and the electrical diagram.

The easiest way is to find the same relay in the relay block, for example, the radiator fan switching relay and swap it, while first inspecting the relay legs and terminals for carbon deposits, and also checking whether the seats for the terminals have melted. After you swap the relay, of course, you will need to check whether the fuel pump is working by turning the key in the ignition. If the result is negative, you need to measure the control voltage with a multimeter: remove the fuel pump relay, turn the ignition key and check the voltage between terminals 85 and 86. Automotive relays of this type operate at a voltage value of 7 V or more.

If you don’t have a multimeter, you can do it simpler: insert a jumper between power terminals 30 and 87, thereby eliminating the presence of a relay in principle. After this, sit in the passenger compartment and turn the key in the ignition. In my case, the fuel pump did not work. Then I proceeded to the second stage of testing - the fuel pump itself.

Filter at the inlet of the fuel pump - purpose

It is clear that the main purpose of the filter is to retain various contaminants. The mesh on the Lanos fuel pump (popularly also called a diaper) is a filter element for rough cleaning of fuel. It serves to prevent contaminants from entering the fuel pump.

The absence of a mesh will lead to accelerated failure of the pump. That is why a mesh is installed at the entrance to the gasoline pump to prevent large and medium-sized contaminants from entering the electrical mechanism. After the fuel pump there is another filter, which is designed to clean the gasoline pumped from the tank to the fuel rail. The absence of this filter will lead to accelerated clogging of the injectors and a decrease in their performance.

https://youtube.com/watch?v=TarJAPHLA3U%3F

Checking the fuel pump directly

Having suffered a fair amount, it’s time to suffer even more... To gain access to the fuel pump cover, you need to “pull” the rear sofa: it is attached in two places to the floor (seen in the photo above), approximately in those places you need to pull. We removed the sofa - we unscrew the cover with a screwdriver and see the fuel pump connector (in the photo above on the right). To check the fuel pump directly, excluding all other elements of the car's electrical wiring, you need to apply voltage to the fuel pump directly from the battery. To do this, you first need to find which contacts in connector C901 are responsible for powering the fuel pump.

The picture above shows a connector (or, as people say, a chip) of a fuel pump (view from the pins). I didn’t remove the fuel pump from the gas tank, I just used a long wire to connect it to the battery. The fuel pump turned out to be alive!

Having experienced some bewilderment in connection with the diagnostic information received (the pump is working, the fuse is working, the relay is working - all the obvious participants in the circuit are working!), I decided to use a tester to check the voltage on the second half of the fuel pump connector (C901), coming from the bowels of the car. There was tension on him! That is, voltage was supplied to the fuel pump, the fuel pump was working, but did not work! How is this possible, you ask?

Why this situation has arisen and what transient contact resistance is, I will tell you in the next part of my adventures as a car enthusiast: Lanos (Lanos 1.5) will not start, part 2: the “Check” does not light up, the fuel pump or “C301 connector” does not hum