An injector (in the everyday life of mechanics and car enthusiasts, this part is often called an injector) is a key element of a modern diesel engine. Its main purpose is to efficiently supply fuel to the combustion chamber, having previously dosed and atomized the required volume. Taking into account the rather difficult operating conditions of diesel engines (high temperature and pressure), the performance of the entire power unit largely depends on the quality of manufacture of the injector components and the perfection of the design. To monitor the health of the engine, you must first understand the design and operating principle of a diesel engine injector. Together with the engine service center specialists, we will try to consider the main points, classification and differences in the design of injectors.

Purpose

The presence of fuel injectors in the design of the power unit is typical not only for diesel, but also for gasoline engines. This is due to the operating principle of the installation, which provides an effective system of direct fuel injection into the combustion chambers. The fuel-air mixture is ignited under high pressure. In practice, the operating efficiency of diesel injectors is much higher than that of similar gasoline injectors.

It is logical to assume that high efficiency of an engine running on diesel fuel is possible only with the use of high-quality components capable of ensuring timely preparation and supply of the fuel mixture inside the combustion chamber. Here are the main tasks that the injector performs:

- Direct injection of diesel fuel into the combustion chamber.

- Dosage of the required volume of fuel, which allows you to provide the specified power of the power unit.

- Fuel atomization, which guarantees more efficient and complete combustion of the mixture.

- System tightness.

Symptoms of malfunction

If the injector distributes fuel unevenly in the combustion chamber, the following symptoms are observed:

- deterioration of dynamic characteristics;

- a knock from the engine compartment, which can be confused with the knock of a connecting rod;

- engine tripping due to malfunction of any of the cylinders.

Excessive wear on the injector is indicated by:

- blue smoke while driving;

- exhaust too black;

- increased vibration and engine noise.

During a visual inspection, you can see diesel fuel leaks near the faulty injectors. There may also be a fuel smell that gets worse after stopping. Problems require urgent intervention, as fuel ignition and a fire in the engine compartment are possible.

Design of diesel injectors

Today, diesel car manufacturers actively use an impressive number of injectors that differ in design and operating principle. Despite a number of differences, each of the devices consists of the same parts and elements. These include:

- The housing where the main parts and elements of the unit are located.

- Needle-shaped sprayer. This element is responsible for the distribution of fuel in the engine space above the piston.

- Plunger. A metal rod that, due to movement inside the housing, creates the required level of pressure.

- A locking spring responsible for fixing the needle in the working position.

- Connector for supplying fuel to a diesel injector.

- A control valve that allows you to effectively solve two problems at once - dose the fuel mixture and set the regularity of injection into the combustion chamber.

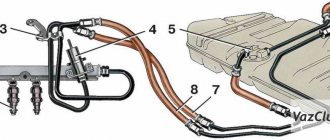

- Fuel purification filter. A key element of the overall cleaning system in a diesel power unit.

- Return outlet fitting. Responsible for removing any remaining fuel from the injector that did not enter the combustion chamber.

When producing injectors, manufacturers must provide an electronic control unit. It includes automatic sensors and monitoring devices that continuously monitor the processes occurring in the device and ensure the efficient operation of the injector and the power unit as a whole.

or call back 7 (921) 932-25-54

Mechanical nozzles: design and principle of operation

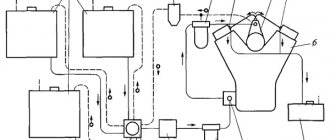

The diesel engine fuel supply system with mechanically controlled injectors is one of the varieties found in modern cars. The high-pressure fuel pump receives fuel from the tank; due to the operation of the booster pump, the necessary pressure is created, which pumps the mixture through the fuel lines.

The high pressure pump is responsible for distributing and forcing the fuel mixture into the lines that lead to the mechanical injector. It opens to inject a portion of fuel into the cylinders under pressure. After the pressure decreases, the mechanism closes. A simple mechanical injector has a simplified design: a body, an atomizer, a needle and one spring. The locking needle moves freely along the guide channel. The nozzle is tightly closed at the moment when the injection pump does not create working pressure. In the lower part, the needle rests on the conical seal of the atomizer, and the pressure is carried out by a spring attached to the top of the device.

The atomizer is one of the key elements in the design of a mechanical injector. It may have a different number of holes and differ in the way the volume of fuel into the combustion chambers is adjusted. In simple diesel engines with a split combustion chamber, the nozzle usually has one hole and a needle. More advanced power units with a direct fuel injection system are equipped with injectors with several spray holes - from 2 to 6, depending on the car model.

The method and intensity of supply of the fuel mixture are directly related to the design of the atomizer, because There are two options for working:

- Channel closure.

- Covered volume.

The first type assumes that the fuel supply is stopped by blocking each hole with the nozzle needle. In the second case, the needle does not block the hole, but the chamber formed in the lower part of the atomizer. Under the influence of pressure pumped by the fuel pump, the needle rises, and the fuel penetrates into the housing under the resulting step. At the moment when the pressure of the incoming fuel becomes higher than the initial force of the pressing spring, the needle begins to move upward, opening the nozzle channel. Fuel under pressure passes through this section and is sprayed into the combustion chamber in the form of a torch.

After this, part of the fuel supplied by the injection pump enters the combustion chamber. The pressure on the needle step decreases, the spring forces return it to its original working position and block the channel. This eliminates the flow of diesel fuel into the atomizer.

Historical excursion

At the stage of the advent of internal combustion engines, Rudolf Diesel planned to use coal dust blown through a nozzle with compressed air as fuel. When burning coal, little heat was produced per unit mass, which forced the scientist to switch to higher-calorie fuel. Gasoline could not be used due to its explosiveness. Preference was given to kerosene.

In 1894, Rudolf Diesel managed to successfully start an engine that was supplied with fuel using a nozzle. A pneumatic compressor was used to carry out the injection. The pressure it created exceeded the force generated inside the cylinder. Because of this, this type of engine is called a compressor diesel engine.

Hydraulic fuel injection appeared a little later. It is used to this day, constantly being improved. The inventor of this method of fuel supply is the French engineer Sabate. He also suggested doing multiple injections. By supplying diesel fuel in several stages, it is possible to obtain more useful energy from a unit of fuel.

In 1899, Arshaulov designed a diesel engine with a high-pressure fuel pump, paired with a compressorless nozzle. This technical solution turned out to be successful, which is why diesel engines with fuel injection pumps are still used today.

The most modern diesel power systems have computer controlled nozzles and adapt to the operating mode of the engine. Depending on the type of combustion chamber, variations in fuel supply are possible. To ensure stable operation of diesel engines of various types of mixture formation, multi-hole and pin nozzles appeared.

Electromechanical injectors

Subsequently, the production of fuel supply systems for diesel engines only improved, which led to the appearance on the market of injectors in which the fuel mixture is supplied to the combustion chamber due to a combined electromechanical effect. The difference is that in such an injector the injector needle moves not under the influence of pressure from the injection pump, but due to a controlled solenoid valve. This element is controlled by the engine's electronic control unit, so without a corresponding signal, the fuel mixture cannot enter the nozzle.

The ECU is a key element of the distribution system, which is responsible for the timing and duration of fuel injection into the combustion chamber. It is the control unit that doses the amount of fuel by supplying a certain number of pulses to the valve. The operating parameters of the pulses depend on the crankshaft speed, operating mode and temperature of the power unit and other initial parameters.

For example, in a Common Rail fuel supply system, an electromechanical type injector is capable of supplying a fuel mixture through several separate pulses. In one cycle, diesel fuel is injected into the combustion chamber up to 7 times. This mode of operation of the diesel injector made it possible to significantly increase the injection pressure and improve the efficiency of the system. Due to the fact that fuel is supplied in doses, the gas pressure on the piston changes smoothly. The mixture is distributed more evenly throughout the engine cylinders, is better atomized and burns more efficiently.

Thanks to this approach, manufacturers were able to completely redistribute the task of controlling injection from a traditional injection pump to an improved ECU. The electronically controlled injection system works more smoothly and accurately, making the diesel power unit more economical, environmentally friendly (fuel burns better) and at the same time powerful. The degree of vibration and noise during operation has decreased, and the overall service life of the motor has become much longer.

Injector with two springs

The efficiency of fuel supply and subsequent fuel combustion in diesel cylinders can be influenced by changing various characteristics of the injector, such as the structure and number of nozzle channels, spring force, etc. One of the design solutions was the introduction of a special needle lift sensor into the injector device. This rise is taken into account by special electronic control units that interact with the injection pump.

Another round of development was diesel injectors with two springs. The design of such injectors is more complex, but the result is greater flexibility in the fuel supply process. The combustion of the working mixture becomes softer, the diesel engine runs quieter.

A special feature of the operation of these injectors is a two-stage needle lift. It turns out that the fuel pumped by the injection pump first exceeds the pressure force of the resistance of one spring, and then the other. In idle mode and with light loads on the engine, injection is carried out only through the first stage, supplying a small amount of diesel fuel to the engine. When the engine reaches load mode, the pressure of the fuel pumped into the injection pump increases, and the fuel is supplied in two metered portions. The first injection is a small volume (1/5 of the total amount), and then the main one (about 80% of diesel fuel). The difference in injection pressure for opening the first and second stages is not particularly large, which ensures smooth fuel supply.

This approach made it possible to increase the uniformity, efficiency and completeness of combustion of the mixture. The diesel engine began to consume less fuel, and the amount of toxic impurities in the exhaust gases decreased. Diesel injectors with two springs were actively used on units with direct fuel injection until the advent of power systems called Common Rail.

Operating principle of an injector pump

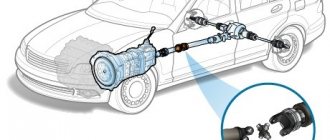

A diesel pump injector is a special type of power unit power system that does not have a fuel injection pump. The principle of operation is that the low pressure pump at the first stage supplies fuel directly to the injector, which has a plunger pair to create the required operating pressure. Subsequently, this element is brought into action due to the direct action of the camshaft cams. This fuel injection system provides more efficient atomization by creating increased pressure.

As designers and mechanics note, the absence of a high-pressure fuel pump did not worsen the performance of the diesel engine. On the contrary, the power unit has become more compact, and part of its power is no longer spent on the constant rotation of the injection pump. Unit injector injectors deliver fuel in just two pulses thanks to an advanced electric valve.

The general operating principle of such a mechanism is similar to a mechanical injector with two springs. First, the injection is carried out, and then the main portion of fuel enters the cylinder. The system selects the starting point of injection as accurately as possible and doses fuel more efficiently. This ensures economical fuel consumption, quiet and smooth operation of the power unit. The content of toxic gases in the exhaust is noticeably lower, because the fuel mixture burns almost completely.

The only disadvantage of such a system seems to be the direct dependence of the injection pressure on the crankshaft speed. Experts note high requirements for the quality of motor oil, the complexity of the design, the impossibility of self-repair and difficulties with maintenance. Accordingly, the price of the motor and the cost of its maintenance increase.

Why should you have your injectors repaired by professionals?

As you can see, the fuel injection system in a diesel engine is a complex mechanism, each detail of which is important. That is why we recommend not to experiment, but to entrust the repair of injectors to experienced specialists. Our service center has diagnostic and repair equipment that allows you to troubleshoot problems with the diesel engine of any car, regardless of the year of manufacture and configuration. The work is carried out within 1 day, using original components from manufacturers.