Fuel is supplied to the engine by VAZ 2114 injectors installed in the intake pipe.

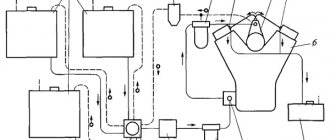

- Fuel supply system with distributed injection

- 1 – fitting for monitoring fuel pressure

- 2 – injector ramp

- 3 – bracket

- 4 – fuel pressure regulator

- 5 – electric fuel pump

- 6 – fuel filter

- 7 – fuel drain line

- 8 – fuel supply line

- 9 – nozzles

An electric fuel pump installed in the fuel tank supplies fuel through the main fuel filter and the fuel supply line to the VAZ 2115 injector ramp.

The Lada Samara 2 fuel pressure regulator maintains a constant pressure difference between the inlet pipe and the discharge line of the ramp. The fuel pressure supplied to the injectors is within 300±6 kPa when the engine is not running. Excess fuel beyond that required by the injectors is returned to the fuel tank through a separate drain line.

Before servicing fuel equipment, it is necessary to relieve the pressure in the fuel supply system of the VAZ 2114.

When disconnecting the fuel lines, do not allow the VAZ 2113 fuel to spill. To do this, wrap the ends of the tubes with a rag.

A whole complex of devices combined into one fuel system is responsible for supplying fuel to the VAZ 2114 engine. This article is dedicated to it, by studying which you will learn what the power supply system of the VAZ 2114 injector consists of, what is the principle of its operation, and what preventive measures must be taken in order for the system to work out its resource to the fullest.

The fuel supply system is the main artery of the car

PRINCIPLE OF OPERATION OF THE SYSTEM

The fuel system of the VAZ 2114, in comparison with foreign cars, is made quite simply, thanks to which a high level of its reliability and endurance has been achieved. The 2114 has an injector for injecting gasoline into the combustion chambers. The presence of an injector provides for a complex fuel dosing system, for which the ECU controller (electronic control unit) is responsible.

The VAZ 2114 fuel pump is driven electronically. The injection moment itself is calculated thanks to sensors that determine the location of the car’s crankshaft. When the fuel pump is turned on, the fuel is supplied through the transport system to the filters, where it is cleaned of impurities, and after the filters - to the fuel rail.

The fuel rail is the part of the intake manifold in which gasoline and gas are mixed in a ratio of 1 to 15 (an increase or decrease in the amount of gas can be adjusted manually, but the optimal gasoline consumption is observed precisely at the above ratio). Next, the mixture is supplied to the injectors, after which it enters the combustion chambers.

Features of the engine power system 11183 (1.6i)

Receiver

engine 11183 (1.6i) is made of plastic.

Engine Intake Module 11183 (1.6i):

1 — flange with an o-ring for fastening the throttle pipe; 2 - receiver with o-rings for connection to the inlet pipeline

Engine Fuel Module 11183 (1.6i):

1 — inlet pipe (for supplying fuel to the pressure regulator); 2 - outlet (discharge) pipe; 3 — module cover; 4 — fuel level indicator sensor; 5 - intake chamber; 6 — module cover guide

Fuel pump

combined with a fuel level indicator sensor and a fuel pressure regulator into a single unit -

a fuel module

(often called an electric fuel pump). Fuel from the pump (through the outlet pipe of the fuel module) enters the fuel filter. Purified gasoline is again supplied through the fuel line and through a tee to the inlet pipe of the fuel module, and then supplied to the fuel rail.

Engine fuel pressure regulator 11183 (1.6i):

1 — hole for dumping excess fuel; 2, 4 — sealing rings; 3 — holes for supplying fuel to the regulator; 5 — body; 6 - terminal for connecting the regulator to ground

Fuel rail for engine 11183 (1.6i) complete with injectors:

1 — diagnostic fitting; 2 - fuel rail; 3 — fitting for connecting to the fuel line; 4, 5, 6 and 7 - injectors

Excess fuel is released through the pressure regulator into the tank. The fuel pressure regulator is installed in the fuel module cover.

Engine power supply diagram 11183 (1.6i):

1 - nozzle; 2 - fuel rail; 3 — diagnostic fitting; 4 - adsorber; 5 - check valve; 6 — throttle assembly; 7 - gravity valve; 8 — safety (two-way) valve; 9 - separator; 10 — fuel line tubes connecting the fuel module to the fuel filter; 11 — fuel module; 12 — fuel filter; 13 - filler pipe; 14 — fuel tank; 15 — fuel line connecting the fuel module to the fuel rail; 16 — metal fuel pipe; 17 — connecting hose; 16 - fitting for connecting the fuel rail to the fuel line

Source

WHAT GASOLINE TO POUR IN THE VAZ-2114?

This topic has become overgrown with various conjectures and speculations, but we will try to put everything in its place.

The technical data sheet of the fourteenth indicates that the car engine requires AI-95 gasoline, and there is no reason not to trust the manufacturer’s recommendations.

Another thing is that many car owners, over their long driving experience, have accumulated rational doubts about the existence of any serious differences between 95 and 92 gasoline. Adding fuel to the fire was the recent statement by the chief engineer of the Moscow oil refinery, A. A. Abrosimov, that we do not make 95-grade gasoline in our country, and everything that is sold under its guise is either 92-grade or unknown fuel brought from somewhere.

As evidenced by reviews from VAZ 2114 owners who use exclusively 92-octane gasoline, there were no problems with the car during its service life due to fuel, and they see no point in using a more expensive analogue. However, the final decision about what to pour into the fourteenth is yours.

The process of replacing the fuel pump VAZ 2114

1

.

At the very beginning of the operation, disconnect the “-” terminal from the battery terminal. (For information on how to disconnect the terminal, read the article: “Replacing the battery on a VAZ”, point 1) 2

. Then lift the bottom cushion of the rear seat, looking for a tab that allows you to lift it.

3

. After your seat is reclined, look under it for the fuel pump hatch, which you will need to remove by unscrewing the two nuts that secure it.

Note!

The hatch is located almost in the very center, if you don’t find it, then perhaps it is hidden under soundproofing material, in which case try to find a cut, perhaps somewhere it has already been made in advance for easy access to the fuel pump, and if a cut is found If not, then carefully use a knife to cut off part of the soundproofing material in the exact place where the fuel pump is located to gain access to it! 4

. Next, take the block of wires with one hand and the connector with the other and, as a result, separate them from each other by bending the side clamp that secures them. (The fastening lock is indicated by an arrow)

5

. Next, unscrew the two nuts that secure the fuel line or fuel tubes (whichever is more convenient) to the pump, and after unscrewing, carefully disconnect these tubes from it.

6

. Now that the fuel pipes are disconnected, then take a wrench or an extension with a head in your hands, and use it to unscrew all the nuts that secure the fuel pump to the car body.

7

. When the nuts are unscrewed, carefully pry up the pressure ring with a screwdriver and then remove it and set it aside.

8

. Then remove the fuel pump from the car tank with both hands.

Note!

Remove the pump very carefully and always remember that the float, which is also attached to this pump, is located in the inside of the gas tank and therefore, after removing the fuel pump, turn it slightly on its side so that this float passes through! 9

. Finally, after removing the fuel pump, remove the rubber O-ring from all the studs.

Note!

Pay attention when the pump is removed so that nothing remains in the inside of the tank, if there is a storage cup left inside the tank, then remove it from there and install it either on the old one or (if it is in good condition) on the new one pump, or throw it away altogether! Installation:

Installation of a new pump occurs in the reverse order of removal.

COMPONENTS OF THE FUEL SYSTEM

The VAZ 2114 fuel system consists of the following main elements:

- Gas tank;

- Fuel pump;

- Gasoline filtration devices;

- Pipeline system;

- Fuel rail;

- Injectors;

- Waste disposal unit.

Fuel system diagram

Let's analyze each component separately.

GAS TANK

The VAZ 2114 gas tank is a container made of two equal metal parts. A neck is removed from the tank into which gasoline is poured. The neck is connected to the tank via a rubber pipe and clamps.

FUEL PUMP

The fuel pump is located directly in the tank. It has a fuel level sensor, which transmits information about the current amount of gasoline to the ECU. The gasoline pump is connected to a line through which gasoline is transported to the fuel rail. The fuel pump itself consists of several parts - coarse filters, wiring and an electric motor, which pumps fuel. As evidenced by reviews from owners of fourteenth cars, fuel pumps from the German company BOSCH have proven themselves to be the best.

FILTRATION DEVICE

The VAZ 2114 fuel injection system very much depends on the quality of the filter devices used. A bad filter will significantly reduce both the efficiency and the longevity of the entire system.

On the fourteenth, non-separable filters with a working element made of paper are installed. Such filters clog quite quickly, and they need to be changed at least once every 10-15 thousand kilometers.

FUEL RAIL

The fuel rail is located on the intake manifold housing. Its design consists of two parts, separated by a spring-loaded diaphragm. The first is the fuel one, in which the required level of gasoline pressure is set, the second is the air one, air is pumped into it, due to which the diaphragm compresses the fuel chamber and changes the pressure level in it.

Ramp

PIPING AND HOSES SYSTEM

To circulate gasoline from the gas tank to the injectors, the fourteenth uses steel fuel lines located on the bottom of the car. The VAZ 2114 fuel supply system also provides for a return pipeline through which excess gasoline from the injectors is returned back to the gas tank.

VAZ 2114 owners are advised to carefully monitor the condition of the fuel line in order to avoid gasoline leaks. Pipes should be checked regularly for deformation and corrosion.

How to determine if the fuel pump is not working

There are several situations in which the pump or its components can be at fault. This will definitely have to be checked. Otherwise, you can spend a lot of money buying and installing a new fuel pump, but in the end it turns out that the problem is completely different. 1

.

The engine will not start. This is not a clear sign of problems with the pump, but still. Therefore, first check the condition of the spark plugs, the presence of a spark, and the absence of traces of oil on them. Also check the electronic control unit. 2

.

Pressure inside the fuel system. If the pump is operating normally, it will create a pressure of 3.2 bar. Depending on the type of engine in your VAZ 2114, the characteristics may differ slightly: ➤ For a 1.5-liter engine, the optimal values are 285-325 kPa; ➤ For a 1.6-liter engine, these characteristics in optimal operating mode will range from 375 to 390 kPa. 3

.

There is no signal that is not sent to the pump. This happens when you turn the ignition key. During normal operation, the pump begins to vibrate slightly when turning the key. If this does not happen, be sure to check the wiring. 4

.

Troubles the power unit. This is also not an ideal sign of a fuel pump failure. But you still have to check. It is likely that the culprit in this situation will be the pump. 5

. The engine jerks. Moreover, this happens at low speeds or even at start. There are two possible reasons for the situation - a breakdown of the pump itself or a problem with the fuel pump grid, which will have to be replaced.

New and old coarse filter (mesh of the VAZ 2114 fuel pump)

Many people purchase the entire fuel module assembly at once, which includes a filter, sensor, float, intake chamber and the pump itself. Such a purchase will cost approximately 3,000 rubles. It is much more profitable and practical to buy a separate pump, which costs up to 1000 rubles. This is due to the fact that when the pump fails, the remaining elements almost always remain intact and are fully suitable for further use.

1

– fitting for checking the pressure in the power system;

2

– fuel rail;

3

– nozzles;

4

– fuel line;

5

– fuel tank;

6

– fuel pump module (in the fuel tank);

7

– fuel filter;

8

– tee.

Pressure in the fuel system of VAZ 2114

What exactly is a fuel pump? This is an element of the fuel system that allows fuel to pass through due to pressure. Therefore, if you take pressure measurements, you can get answers to many questions. Let's give an example of normal pressure readings when checking in certain modes.

How to measure the pressure in the fuel rail of a VAZ 2114

To work we need a “pressure gauge”. But not every pressure gauge is suitable, it all depends on the pressure limit that it can measure. In our case, we need a pressure gauge with a measurement limit of up to 7 atmospheres. If you have a pressure gauge measuring up to 17 atmospheres, then such a device will show incorrect data, because it has too much error at low pressure. In addition to the pressure gauge itself, we will need “plumbing flax”. We wind flax under the pressure gauge nozzle and put a hose with an internal diameter of 9 mm on it. Next, we tighten the whole thing with a clamp. Our device is ready for use.

1

.

Open the hood, turn off the ignition, find the fuel injector rail. 2

.

We unscrew the plug of the fitting for fuel pressure, then use a spool to unscrew the nipple that appears, carefully placing a container or rag, because gasoline will spray due to remaining fuel pressure. 3

. Place the pressure gauge hose over the fitting and secure it with a clamp.

| Check mode | Normal indicator |

| At idle | 2.5 atm |

| When ignited | from 3 atm |

| Without pressure regulator tube | 3.3 atm |

| When the drain is pinched | 7 atm |

| When you press the gas pedal | 3-2.5 atm |

We recommend measuring with a small range of atmospheres on a pressure gauge (up to 7 atm). This will reduce errors to a minimum. Having a pressure gauge at hand will allow you to significantly save on professional diagnostics. Contacts

The fuel pump includes three wiring: • Positive (positive); • Minus (negative); • Fuel level indicator. So, failure of the pump may occur due to a simple violation of the integrity of the wires. So if the pressure check shows normal, then we definitely examine the condition of the wiring. To check, you will need a 12V lamp, which is attached to the external connectors of the pump with positive and negative contacts. Turn the ignition key. If the lamp blinks, contact is present. In this case, you will have to check the condition of the internal contacts.

Motor

If the pressure and wiring are normal, let's try to check the serviceability of the motor. It is this element that is responsible for moving fuel through the system. To check it, you will need the same 12V lamp; • Attach it to any motor terminal; • Turn the ignition key; • If the lamp blinks, you will have to get rid of the motor and buy a new one.

Don't jump to conclusions.

Before checking, look at the condition of the terminals and motor wiring. Weight of the fuel pump

The contacts are fine, but the fuel level sensor may provide incorrect information. In this case, you definitely need to check the weight of the pump responsible for dispersing the fuel. It often turns out that after prolonged use or driving on difficult road sections, the mass simply loses its fastening strength. Accordingly, if the mass falls off, the pump will not be able to work. The mass is attached to the pump under the dashboard in the area of the hand brake. Therefore, when the driver turns on the handbrake, there is a possibility of hitting the ground contact, which is why it will fall off. Putting the mass back in place is not that difficult. The problem is caused by the path to it. You will have to: • Get to the bottom through the interior; • Remove the plastic under the handbrake; • Remove the floor covering; • Remove the grounding contacts; • Clean; • Attach it to the fuel pump as firmly as possible.

Relay

The fuel pump relay is located exactly where the ground is. Therefore, there should be no problems with the search. With an ideally working fuel supply system, when the ignition is turned on, the relay instantly creates pressure inside the system, and then turns off.

Fuse

All that remains is to check the condition of the fuse. This stage will make sure who the real culprit of the problems is - the pump itself or its fuse.

Where is the VAZ 2114 fuel pump located?

In all cars of the Samara family, this unit is located in the inside of the gas tank, and the gas tank is installed in the lower part of the car, popularly called the bottom, and this same gas tank is located in the rear of the car, that is, approximately somewhere under the rear seat cushion and therefore After reclining this pillow, it will be very easy to see the location of the fuel pump, in this case it is indicated by an arrow in the photo:

PREVENTION OF THE FUEL SYSTEM VAZ-2114

Prevention, as a rule, comes down to regular cleaning and, if necessary, replacing the fuel pump filter and the main fuel system filter.

Also once every 25-30 thousand km. It is necessary to clean the injectors, which is performed exclusively at a service station. There are two methods for cleaning injectors, neither of which require removing them:

- Ultrasonic cleaning;

- Cleaning with a special washing liquid.

The most effective and expensive is ultrasonic cleaning, which makes it possible to bring back to life even heavily worn nozzles.

For all types of vehicles, the timing of replacing the lubricating fluid of their power unit is established by the manufacturer's regulations. It is worth noting that the figures indicated in it are very approximate (approximately 12-15 thousand kilometers), however, it is impossible to correctly calculate the order of oil changes, since this is influenced by many factors. Unfortunately, the automaker does not always take most of them into account. Continue reading →

Engine diagram and structure

General view of the engine

Before we begin to consider the issue of the engine design and description of the characteristics, it is necessary to consider the design of the components and parts that are located directly in the main power unit and outside.

Diagram and design of the Samara-2 engine

1 – generator drive pulley; 2 – oil pump; 3 – timing belt; 4 – toothed pulley of the coolant pump; 5 – front cover of the timing mechanism drive; 6 – tension roller; 7 – camshaft toothed pulley; 8 – rear cover of the camshaft drive; 9 – camshaft oil seal; 10 – cylinder head cover; 11 – camshaft; 12 – front cover of camshaft bearings; 13 – pusher; 14 – valve guide; 15 – oil separator mesh for the crankcase ventilation system; 16 – exhaust valve; 17 – inlet valve; 18 – rear cover of camshaft bearings; 19 – fuel pump; 20 – housing of auxiliary units; 21 – ignition distributor sensor; 22 – outlet pipe of the cooling jacket; 23 – cylinder head; 24 – spark plug; 25 – crankcase ventilation hose; 26 – flywheel; 27 – crankshaft rear oil seal holder; 28 – rear crankshaft oil seal; 29 – cylinder block; 30 – oil pan; 31 – oil level indicator (oil dipstick); 32 – crankshaft; 33 – piston; 34 – connecting rod cover; 35 – connecting rod; 36 – crankshaft main bearing cover; 37 – front crankshaft oil seal; 38 – crankshaft toothed pulley.

WE RECOMMEND:

With the start of production of VAZ 2113, 2114 and 2115 cars, they used a carburetor-type engine with a volume of 1600 cubic centimeters. After long-term operation of this sample, several problems characteristic of the carburetor power system were identified. Namely: contamination of the jets, incorrect adjustment of the quality and quantity of fuel, unstable idle speed, etc. Therefore, it was decided to replace the type of power system with a more reliable one.

After the engineers chose which options to weed out and which to leave, the VAZ 2114 and 2115 with an injector engine were released. With the modification carried out, the engine design changed radically: power and speed increased, acceleration time to 100 km/h decreased. The engine size and number of valves remain the same. Let's look at what exactly the updated device contained, point by point.

Electrical equipment

On a VAZ 2114 car, such a concept as: a unified circuit of electrical appliances is simply absent. This is explained by the fact that from 1999 to 2011, the injector was modernized, incorporating more and more new components into its device that affect the final power and speed of the machine. In order to study how the electrical wiring diagram and its components work, you need to understand this individually, together with a specialist. The basis of any such system is a computer. The rest of the device may differ radically from each other, depending on the year of manufacture of the VAZ car.

Device

An injector engine consists of several main elements. As in any car, fuel comes from the tank through the fuel line. Along the way, the combustible mixture goes through several stages of purification: a fine filter and a coarse filter. There is no strainer, such as was located on the carburetor inlet.

In general, on a VAZ car with an injector engine, instead of carburetor throttle valves, a throttle assembly is used. Its circuit is directly connected to the adsorber of the electromagnetic valves. It is he who regulates the fuel supply to the injectors.

As far as everyone knows, the correct operation of the engine directly depended on the amount of combustible mixture. It was controlled by the volume of the primary and secondary carburetor chambers, and the jets. In the version with an injector, a combination of three valves is used: two-way, safety and gravity. It is they who control that there is no overflow of the spark plug, or, conversely, a lack of fuel in the combustion chamber.

Fuel pressure control

In order for the engine to produce normal power and have synchronous operation of the valves, a fuel pressure regulator is installed in front of the injectors. With increased or decreased pressure, the regulator is activated, ensuring further operation of the piston.

Well, the last element of the device is the nozzles. They regulate injection into the combustion chamber. Since fuel is supplied to the injectors under constant pressure, they almost never clog. That is why the service life of a VAZ 2114 engine with an injector, without outside intervention, is much longer than with a carburetor.

In the period from 1999 to 2011, VAZ 2114 models with an injector engine were produced in two versions, which differed in engine capacity: 1500 and 1600 cm/cc. Their design was slightly different, not the circuit itself, but some components not related to the fuel system.

COMPONENTS OF THE DEVICE

The VAZ 2114 fuel system includes:

- fuel mixture storage tank;

- gasoline pump;

- several types of filters;

- pipelines for transmitting flammable liquids;

- ramp with 4 nozzles;

- pressure regulator;

- cap on the tank neck.

The steel fuel tank serves as an object for storing fuel; it contains a high-pressure pump and a fuel availability indicator controller, which transmits a signal to the control panel. The pump has a coarse filter that prevents large particles of debris, rust and various impurities from entering the fuel system.

There is a fine filter near the tank; this unit guarantees thorough cleaning of the flammable liquid from the main line to the nozzles.

The injectors are placed on the fuel rail, which securely fastens them to the engine. Fuel injection is carried out using the system control unit. The pressure regulator controls the level of fluid injection between the inlet hose and the ramp line. The excess combustible mixture is returned back through the nozzles, along a separate tank drain line.

The temperature of the fluid that performs the reverse stroke increases by 6-14 degrees, this happens because the fuel circulates under the base of the machine and the blazing engine, and also rubs against the walls of the hose.

This circulation of the combustible mixture increases the temperature of the total liquid in the tank. Fuel vapors appear, which, according to a certain pattern, enter the fuel container and do not escape into the atmosphere; the fuel injection system ensures the safe capture of evaporation, destroying the vapors during engine operation.

Before carrying out repairs or preventative actions on the power system, it is important to reduce the pressure inside the unit. To prevent fuel spillage when removing the wires, it is important to secure the ends of the hose with microfiber.

The vehicles are equipped with a VAZ 2114 fuel supply system, which effectively supplies fuel at various inclinations of the vehicle, as well as when the liquid level in the tank is low.

WE RECOMMEND:

The fuel filter plays a rather important role in the car's power system. Regardless of which engine (diesel, carburetor or injection), or which car (domestic or foreign car), such a mechanism is installed on all fuel systems. Let's look at the principle of operation and design of the fuel filter, using the example of a VAZ 2114 car.

Features of the 2111 (1.5i) engine power system

Location of elements of the 2111 (1.5i) engine power supply system in the engine compartment:

1 - receiver; 2 — vacuum supply hose to the fuel pressure regulator; 3 — throttle assembly; 4 - fuel rail; 5 — fuel pressure regulator; 6 — air supply hose to the throttle valve; 7 - adsorber; 8 — air filter; 9, 10 and 11 — hoses of the crankcase ventilation system; 12 — throttle valve drive cable; 13 — diagnostic fitting

Purpose

The starting point where gasoline comes from is the gas tank. It is a 40-liter canister, which is absolutely sealed. If the car is used for a long time (about 5 - 10 years), then rust forms on the walls of the tank. Small parts of it are washed with gasoline and settle at the bottom. When driving over uneven surfaces, pieces of rust rise and enter the fuel system.

Considering that the cross-section of the jets is very small, in order to completely close them, a few particles of rust will be enough. So, to prevent this from happening, the car uses a fuel filter that retains all the debris from the tank.

Also, when the car is idle for a long time, gasoline vapors in the gas tank rise upward, and the watery part remains at the bottom. In this case, if you start the engine, gasoline will be supplied to the system along with water. Then, the VAZ 2114 fuel filter retains water and only allows gasoline fumes to pass through.

Of course, not one cleaning element does not last very long. This part constantly gets clogged and needs replacement very often. Fortunately, this part is not expensive, and any car owner can afford to buy it.

Device

Unlike the VAZ Classic, on the Lada 2114 model, fuel filters are installed on the highway, and not in the engine compartment. There are only two of them: fine cleaning and coarse cleaning. They differ in their structure, as well as in the quality of cleaning.

First, on the way from the gas tank to the carburetor, a coarse filter is installed. It is located on the pipe that comes out of the tank and leads into the engine. The cleaning element of such a filter is a mesh. Its purpose is to clean gasoline from large debris present in the tank. Since this mechanism is very simple in design, it does not need to be replaced, and it is enough to simply wash it with gasoline and put it back.

Further along the fuel line there is a fine filter. Its structure is already heavier. It consists of a plastic body with two pipes. The fuel enters one pipe and, after passing through the filter element, comes out of the second.

This type of filter is considered disposable. That is, it cannot be cleaned or repaired. If it gets clogged, the only solution is to replace the part with a new one. And changing this device is easy. First, loosen the clamp on the exhaust pipe. Then, remove the main hose from it and insert a new filter into it. This is done to prevent gasoline from leaking out.

The old fuel filter must be held in such a position that the outlet pipe faces upward. Next, loosen the second clamp and remove the old filter element. The fuel line hose coming from the gas tank should still face up. Once the old unit is removed, insert the hose into the inlet of the new cleaning element. That's it, the replacement is complete.

Symptoms of malfunction

Sooner or later, any fuel filter becomes clogged and needs to be replaced. But what are the characteristic symptoms that indicate that the filter element has worn out?

The first symptoms by which it can be determined that the mechanism requires replacement is a loss of engine power. When you press the gas pedal, the car will choke and jerk. It is worth knowing one detail that will distinguish this malfunction from others - at idle speed, the engine will operate stably.

If, when you press the gas pedal, the car not only jerks, but also stalls, then this means that it is time to change the filter, since such driving can have a detrimental effect on other components and mechanisms of the VAZ 2114 car.

The next degree of filter contamination is when the car begins to stall even at low speeds. At the same time, it is impossible to move uphill because there is not enough power. The last stage, which clearly indicates that the filter needs replacement, is when the car stalls immediately after starting, or does not start at all. But experts strongly recommend not to let the cleaning mechanism reach this state. If your car has the first symptoms, then replace the filters immediately, especially since they will not take a lot of money and time to install.

Signs of injector failure

In fact, there are quite a lot of reasons why injectors may not work well. And the most common symptoms are described below: • Difficulty starting the engine in any weather; • The engine is running unsteadily; • The engine stalls at idle; • High crankshaft rotation speed at idle speed; • Loss of power, poor response to the accelerator pedal; • When you press the gas, shocks or dips may appear; • High gasoline consumption; • If the nozzle is dirty or damaged, it should be replaced or cleaned. There is no point in repairing it. It should also be noted that today injectors cannot last even 100 thousand km.

Which injectors are better to install on a VAZ-2114

The VAZ-2114 model can be equipped with different injectors from different manufacturers. Depending on this, durability and their cost also differ. It is recommended to buy not domestic parts, but from other companies, for example, GM, BOSCH, SIEMENS

.

Also, the choice of injectors also depends on the working volume and the number of valves. For 16-valve engines, the performance of such parts will be different than for the 8-valve version. If the parts are selected incorrectly, then most likely, gas mileage will be higher or the car will lose power. If we talk about choice, then preference should be given to the BOSCH brand at number 0280158502

. This is the serial number that is suitable for an 8-valve engine with a volume of 1.5 liters.

Injectors fail not only because of their quality; their performance is largely affected by fuel that contains a lot of dirt or large fractions. Cleaning injectors at service stations will not be cheap. Therefore, if you do not check and clean it yourself, then you should think about whether it might be easier to buy new parts and replace them.

Removing the fuel rail and injectors on VAZ 2115 (2113, 2114) 8 cells. - video

WE RECOMMEND:

On VAZ 2108 cars, an emulsion, two-chamber Solex carburetor was installed, with a falling air flow. It was considered a factory option, and was most often found on this Lada model. Of course, over time it was changed to “Ozone” or “Daaz”. They did not have a particularly different device, but in some ways they differed from the standard one. We will look at this in this article.

Device

The carburetor of the VAZ 2108 car consists of two main parts - upper and lower. In each of them, there are some parts and mechanisms that are directly connected to each other. Let's look at the design of the standard Solex carburetor in more detail:

- Float chamber. It houses the jets, float and throttle valve;

- The first and second chambers, with a dosing device;

- Vehicle idle system;

- Transition system located in the second chamber;

- Econostat;

- Pneumatic economizer;

- Accelerator pump;

- Gasoline starting mechanism;

- EPHH;

- System providing crankcase ventilation;

- The mechanism that controls the dampers.

Description of the power system design

The vehicle's power system is designed to store fuel reserves, purify fuel and air from foreign impurities, and supply air and fuel to the engine cylinders.

The air entering the engine cylinders is cleaned of dust by an air filter. Air filter

installed in the engine compartment on three rubber supports. The filter element is replaceable and made of special paper. To prevent contaminated air from leaking into the intake tract, there is a sealing edging at the top of the element. To replace the filter element, the filter cover is removable. The purified air passes through the mass air flow sensor through the air duct to the throttle valve.

Throttle valve

regulates the amount of air entering the engine cylinders. The damper drive from the gas pedal is cable. The damper rotates on an axis in the housing (pipe). The throttle body is secured to the receiver flange with studs. The housing has a channel for coolant. The channel is connected to the cooling system by rubber hoses. Circulating coolant through the throttle body prevents the body's internal air cavities from freezing in the winter. The housing contains fittings for connection to the absorber and the engine crankcase ventilation system.

The throttle body, with the throttle position sensor and idle speed control installed on it, form the throttle assembly.

Throttle assembly:

1 - throttle valve drive sector; 2, 4 — fittings for connection to the engine cooling system; 3 — crankcase gas outlet fitting; 5 — throttle position sensor; 6 — idle speed regulator; 7 — fitting for connecting to the adsorber; 8 — throttle valve; 9 — throttle body pipe

Principle of operation

On the Lada 2108, different engines were installed, from 1100 cubic meters to 1500. At the same time, the carburetor design did not change at all. Enlarged jet holes helped adjust the fuel supply for a more powerful engine.

The operating principle is quite complex. Gasoline passes through a filter at the carburetor inlet. There is also a valve that prevents the amount of gasoline in the chamber from decreasing.

From the chambers, gasoline flows through jets into wells, where it mixes with oxygen and forms a flammable mixture. Some of the gasoline is taken by the idle jet, also mixing it with air. The rest of the mixture is injected under the valve. At the place where this injection occurs, two screws are installed - the quality of the fuel and its quantity. Thanks to them, you can adjust the number of engine revolutions and the supply of gasoline. The VAZ 2108 carburetor is adjusted using a flat-head screwdriver.

The economizer serves to add fuel to the combustion chamber when the throttle valves are fully opened.

The econostat is also responsible for the additional supply of gasoline, but, unlike the economizer, it passes it through the nozzle. The econostat starts working when the engine reaches maximum power.

The accelerator pump in Solex carburetors serves for atomized injection of fuel into the float chamber. It is activated when you sharply press the gas pedal, that is, during acceleration. Its device also provides for stopping the fuel when the gas pedal is released. This will protect the mixture in the float chamber from excessive air leaks.

Acceleration pump nozzle

A starting device is installed in order to increase the amount of gasoline supplied to the float chamber. Mainly used to start the engine “cold”. Increasing or decreasing the fuel supply is carried out manually, using a choke.

After the mixture is ready, it is fed into the combustion chamber through the intake manifold opening. Since the Solex carburetor was installed on all modifications of the VAZ 2108 engine, the difference between them can only be in the size of the manifold hole. Therefore, be sure to pay attention to the diameter of the hole and the size of the gasket. This will be useful to you if you carry out repairs.

Problems and repairs

Very often, Solex carburetors encounter a problem such as clogging of the inlet hole in the first chamber. This is due to the fact that after long-term operation of the engine, carbon particles appear on the cylinder walls, which enter the chamber along with the air entering the carburetor. Repairing this problem is quite simple. In order to clean the holes and chambers from carbon deposits, use a special liquid that is sold in every Automotive store. It eats away carbon particles and cleans the carburetor. If such a breakdown caught you on the road, and you did not have a cylinder with such a liquid at hand, then the following scheme of actions will help you:

- Without turning on the ignition, pull the choke lever towards you until it stops;

- Start the engine;

- Gradually and smoothly release the choke, and when you feel that the car is about to stall, press the gas pedal all the way. You need to provoke the opening of the second chamber, and then the carbon particles will fly out of the hole under high pressure.

Remember that this method will relieve you of the problem for a while. To completely solve it, contact a service station, where the carburetor will be repaired.

Another weak point of Solex carburetors is the small hole in the idle jet. This is fraught with the fact that even a small speck can clog the hole, and the car will stall at idle. In such a situation, no repair is required. Simply remove the jet and blow it out thoroughly.

The third problem, which very often occurs on carburetors of VAZ 2108 cars, is wear of the economizer gasket. At the same time, the engine's idle speed will not be stable, and the exhaust gases will turn black. Repair is carried out by replacing the gasket.

There are rarely cases when the amount of carbon deposits entering the chamber is very large. This mainly happens to those cars that have not undergone major repairs in a timely manner. Since the previously described scheme will not help you get to the nearest service station, you need to act more radically. Experts, in this case, recommend disconnecting the breather from the carburetor, directing its flow downward, using a long hose. This will help you somehow get to the station where repairs can be carried out.

Remember to periodically clean the Breather

Don't forget that the carburetor must be adjusted correctly. The VAZ 2108 carburetor is adjusted as follows: tighten the quality screw and the quantity screw until it stops, turning them clockwise with a screwdriver. Next, unscrew the quantity screw by one and a half turns, and the quality screw by 3.5. This is a mixture adjustment with minimal spark plug wear. If the spark plugs are worn out enough, add 1 - 1.5 turns for quality. With normal settings, the Solex should provide the engine with 800 - 900 rpm at idle. Under such conditions, repairs will very rarely be necessary.