After starting the engine of a VAZ 2108, 2109, 21099 car, the oil pressure warning lamp on the instrument panel lights up, or when the car is moving, the pressure lamp lights up suddenly. The reasons for this situation in the operation of a carburetor engine are both a malfunction of the engine itself and a malfunction of electrical equipment.

The engine oil pressure indicator light is on (reasons)

1. The tip of the wire fell off the output of the oil pressure sensor in the cylinder head.

Check if this is true and fix the problem.

2. The engine oil pressure sensor itself is faulty, or its electrical circuit is faulty.

Turn on the ignition, remove the wire from the oil pressure sensor and touch it to the vehicle ground (engine, body...). If the light goes out, the sensor is faulty; if not, its electrical circuit is faulty. Or, for greater accuracy, check the pressure in the lubrication system using a pressure gauge.

3. Low oil level in the engine crankcase.

Let the engine sit for 15 minutes, then check the level by pulling out the dipstick. Add oil if necessary.

4. Low engine idle speed.

When the crankshaft speed drops below 650 rpm, the oil pressure warning light may blink or clearly illuminate. Adjust idle speed. The norm is 750-850 rpm.

5. Engine oil pump is faulty.

6. Engine oil filter is faulty.

7. The oil intake of the oil pump in the engine sump is dirty.

Remove the pan and clean the oil intake.

Five more articles on the site on VAZ car engines

The owner of the Nine will most likely find out that there is a VAZ 2109 oil pressure sensor and an oil level sensor in the engine compartment when the indicator on the instrument panel lights up red, indicating that there are problems with the oil pressure level. And then many questions immediately arise, including what kind of oil should be poured into the system, whether its volume is sufficient, but most importantly, whether this small device has deteriorated. Let's take a closer look at what an oil pressure controller is, what its operating principle is, and how accurately its performance can be determined.

Oil pressure sensor for VAZ 2109

The owner of the Nine will most likely find out that there is a VAZ 2109 oil pressure sensor and an oil level sensor in the engine compartment when the indicator on the instrument panel lights up red, indicating that there are problems with the oil pressure level. And then many questions immediately arise, including what kind of oil should be poured into the system, whether its volume is sufficient, but most importantly, whether this small device has deteriorated. Let's take a closer look at what an oil pressure controller is, what its operating principle is, and how accurately its performance can be determined.

Sensor design and operating pressure check

To determine whether a device is functional, you need to understand how it works. It is also useful to know how the controller and the VAZ engine, or rather its lubrication system, interact with each other. The sensor is mounted on the cylinder head on the side on which the carburetor is located. Next to the controller there is a VAZ oil filter.

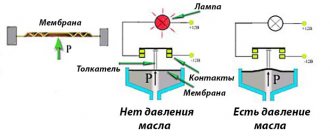

The design of the oil pressure controller is very simple. It consists of a housing, a built-in control and measuring elastic membrane and a transmission mechanism. The principle of operation of the device in question is also quite simple. Engine oil for VAZ, located in the lubrication system, acts on the membrane during engine operation.

The latter is deformed by an amount corresponding to the oil pressure. Vibrations of the elastic “partition”, which make or break the contacts of the electrical circuit, are transmitted to the rheostat through the mechanism mentioned above. In turn, changing the resistance of the rheostat affects the indicator readings on the car’s dashboard.

Checking the operating oil pressure using the crankshaft is used, as a rule, in cases where the indicator begins to signal a drop in pressure in the lubrication system away from the service station, and the driver does not have a pressure gauge at hand.

Before checking, you must make sure that the oil level in the system and the corresponding VAZ 2109 filter are in order. If the level is insufficient, the oil will have to be filled to the nominal level. Then you can proceed directly to checking the health of the sensor. For this purpose, it is unscrewed from the socket.

With the lubrication system open, the crankshaft of the machine is turned manually (without turning on the engine). If at the same time the hole into which the oil pressure controller was screwed begins to fill, then the pressure is normal. The indicator that continues to light indicates that the sensor has failed.

In this case, the device should be carefully inspected for defects. If there is no damage, it must be washed with gasoline (diesel) and installed in its original place. If the light continues to light after this, the sensor will have to be replaced.

EMERGENCY MEASURES

So, the oil pressure light on the dashboard came on while driving. As already noted, you should immediately stop and turn off the engine. Since while on the road there is no way to accurately determine the cause of the problem, the only diagnostic method is a visual inspection.

After stopping the engine:

Depending on the results of the inspection and level check, we take further actions. If a slight leak is detected, and the dipstick shows the amount of lubricant below o, you can continue moving to the repair site, but first replenish the oil loss and check whether the warning lamp lights up. To top up, you should use the same lubricant that was filled in (it is not for nothing that it is recommended to always carry oil with you for topping up) or purchase a similar one. During the movement, you should stop periodically and replenish the level.

We do the same in the case when no leaks are detected, but the level is below normal. We just add lubricant, make sure that the control light does not light up and continue on our way, periodically stopping and checking the dipstick. If there are no leaks and the oil level is normal, it is possible that the pressure sensor is acting up. Restarting the engine after a short pause (the time it will take to inspect the engine and assess the amount of lubricant) will help verify this.

If the lamp lights up even when you restart it, it is better not to experiment, but to call for help to transport the car to the repair site. It is strictly forbidden to operate the machine if the dipstick shows a level higher than normal or if there is a foamy whitish coating on it - emulsion (you can additionally check for the presence of emulsion on the oil filler cap).

This indicates that other technical fluids, such as antifreeze or fuel, are leaking into the pan. An excessive level of oil (liquid mixture) in the pan has a strong negative effect, as does its lack.

The problem is diagnosed by the non-characteristic color of engine oil and smoke from the exhaust pipe.

These are all the measures that can be taken in an emergency situation - when the lamp lights up while driving and there is no necessary equipment and tools for a more detailed search for the cause.

Checking the pressure controller using a pressure gauge

The second method is more accurate and involves the use of special devices. Note that this method can also test the bypass valve at the same time. The preheated engine, into which the required volume of oil is poured, is turned off. The sensor removed from the engine is screwed into the pressure gauge. In place of the sensor, screw the adapter of the monitoring pressure gauge.

As a result of these connections, the pressure gauge and sensor should form a single circuit that records the impulse from the lubrication system to the indicator. Next, start the engine, its speed is gradually increased until the pressure gauge shows a value of 1.2-1.6 bar. If the sensor is working properly, the LED goes out. If it continues to light, it means the controller has failed.

If the oil pressure indicator is lit when the sensor is operational, it indicates that the cause of the problem is most likely something else. As practice shows, most often this situation can indicate either wear of the crankshaft bearings or a breakdown of the bypass valve. If we are talking about a technically faulty sensor, it is better to replace it with a new one.

Possible reasons for VAZ 2106, 2108, ZMZ 406, 405

But there are also reasons that may appear on specific cars, since there is another factor that influences the occurrence of the problem - the design features of the engine.

For example, on carburetor engines of the same VAZ-2106 or 2108, fuel can penetrate into the sump through the fuel pump. This unit on such engines is mechanically driven by a timing belt.

And due to damage to the pump membranes, fuel will penetrate inside the engine and mix with the oil, diluting it and increasing the level.

But on the ZMZ-406 engine, the cause of the pressure drop, in addition to those described, may be damage to the oil pump drive. Because of this, the unit simply will not function normally, which will affect the performance of the lubrication system.

Mechanical breakdowns inside the engine should not be discounted, as a result of which the operation of the lubrication system is affected. For example, a break in the timing chain tensioner shoe, for example, on the same VAZ-2106, will lead to the torn part starting to hit adjacent surfaces, knocking out small pieces of metal.

The chips formed as a result of such a breakdown will enter the lubrication system, and then settle in the filter, leading to a drop in pressure in it.

Or on the same ZMZ-405, the pump is driven through an intermediate shaft, which is driven by a timing chain. If the sprocket of this shaft breaks (it can rotate separately from it), the pump will stop working.

And there are enough such nuances. But in any case, without eliminating the cause of the malfunction, you should not use the car, so as not to end up with expensive repairs later.

We recommend watching:

- How much does the body of a Cossack weigh?

- VAZ 21103 oil pressure victory

- Installation of connecting rod bearings VAZ 2106

- I checked the inserts, what is it?

- What does it mean to turn the liners in the engine?

- Oil pressure reducing valve VAZ 2112

Oil pressure sensor VAZ 2109

The oil pressure sensor is very important - it informs you that there is oil in the engine lubrication system and the oil pump creates pressure in the oil lines. When the engine is running, the oil pressure light comes on on the instrument panel for two reasons: 1) There is no oil in the engine or the oil pump is faulty 2) Malfunction of the oil pressure sensor How can there be no oil in the VAZ 2109 engine? Here are a couple of popular reasons. Reason one: the engine sump is broken and oil spills onto the road. An experienced driver always pays attention to whether there is any leakage of any operating fluid under his car. Anything can leak: antifreeze, brake fluid, gearbox oil, engine oil, gasoline. Therefore, the habit of looking to see if there is anything under the car can help you find a fault in time and protect the driving process. Reason two: the engine takes oil. That is, when the engine is running, the oil partially burns in the cylinders. This is usually indicated by black smoke coming from the car's exhaust pipe. And if you don’t add it in time, there may be no oil left in the crankcase. Therefore, if you ignore the oil pressure light when the engine is running, in a couple of minutes the unlubricated pistons will jam in the cylinders and you will have to do a major overhaul of the engine.

Oil pressure warning light

If you are convinced that there is oil in the engine, but the light is still on when the engine is running, then the oil pump may have failed. To check it with the engine not running, use a 17 key to unscrew the oil pressure sensor from the engine. We ask someone to look into its mounting hole and, without starting the car, we work with the starter a couple of times. Oil should flow out of the hole under the pressure sensor. If the oil does not flow out, then the oil pump is faulty. And if oil flows, then the oil pump is working, and the reason is in the sensor.

We buy a new one and put it in place of the old one. We connect the chip and start the engine - the light should go out.

Extinguished emergency oil pressure light

Source

Recommendations

Comments 13

thanks, fixed the problem. The problem is that the oil pressure sensor did not work. Where the timing belt cover is located nearby, the wire from the oil pressure sensor broke. I took a piece of wire about half a meter, soldered it, soldered the terminal again, and connected it to the sensor. I connected the battery terminal, turned the key and STOP and OIL lights up on the dashboard. Thanks for the advice and for the picture of the diagrams

Well, I roughly described the problems to you. If you need a book by email, I’ll send it to you in PDF format, you need Adobe Reader to open it.

ok, send me the book... just in case

Hello. I have the same problem, I have a VAZ 21083, with a low instrument panel, when I turn the key with one push (the stop light does not light, the oil light does not light up), the battery lights up. How to fix the problem? can you help me suggest a diagram? I changed all the light bulbs to new ones, treated them with a bucket, same problem. Thank you

Was everything on fire before? If yes, then look first at connecting the wire to the oil pressure sensor on the engine. A possible second option in this case may be that fuse F16 (15A) has blown in the mounting block from the VAZ-2114 (2115) or No. 5 (8A) in the old VAZ Fuse Box, but the following devices will not work: Turn indicators and relays turn signal and hazard warning light switch (in turn signal mode). Turn signal indicator lamp. Rear lights (reversing lamps). Gearmotor and windshield wiper activation relay. Generator excitation winding (when starting the engine). Indicator lamp for low brake fluid level. Oil pressure drop warning lamp. Carburetor air damper warning lamp. Indicator lamp for turning on the parking brake. "STOP" light display lamp. Coolant temperature gauge. Fuel level indicator with reserve indicator lamp. Voltmeter. Well, if all the devices listed above work, except for the control lamps you listed, then look at the wire connections on the block suitable for the instrument panel and at the output from the safety block. And the best option is to find a good electrician, even if you have to pay money. If you have an email, write the address and I’ll send you the wiring diagrams from number nine.

There were no problems with the electrics before, everything worked perfectly. everything works except stop and engine oil pressure. The entire fuse box is working, the fuses are intact and not blown, recently replaced with new ones. The relay also works. There seems to be something wrong with the instrument panel. I disconnected the cable from the engine, then from the dashboard, cleaned it, treated it with a bucket, and replaced the lamps. I tried to insert the key into the ignition, and turned it over with one push. does not burn. ok I'll give you my email. thanks for the advice. I'll contact an electrician. thanks for the advice. I'll try to figure it out. I have an old-style eight, low panel

Thanks for the response, I removed it and found a burnt track there, a broken wire, it was all oxidized. I cleaned everything, I haven’t soldered it yet. I think that was the problem after all!)

hi, how do I understand (additional leg) I’m new to this business, my Akum lamp is constantly on, although it charges everything normally, and when I pull out the handbrake, my brake light comes on and the brake fluid level lights up, what a joke, how do I remove it in a VAZ 2108 low ponel?

I thought about my problem for a very long time, because when I turned on the ignition, instead of the battery, the indicator for closing the throttle air damper came on. In the 4th photo, an additional leg is clearly visible (it is screwed to the board with a bolt). There was also a problem with suction, when the handle was pulled out the low brake level indicator came on - this problem was solved by rearranging the wires, but before that I smoked electrical circuits from the VAZ-2109 for a very long time, everything was solved by the so-called poke method. There is also a problem with the emergency lights and the handbrake lights up instead of a triangle. It is possible that the wires in the terminal blocks are mixed up, this could be if the wiring or instrument panel was changed in the car (there may be different circuit boards on the instrument panels). For example, I have Hungarian, maybe the USSR or some other country. But the surest option is to find a competent electrician. Good luck on the roads and in solving your problem.

I bought the car already with such a tidy. So try searching on the Internet. On the ProSport website I saw tens and fourteens. You can also look at the Tuningsport website.

Where can I buy such an overlay?

Which one? On a low panel or on instruments?

Device

The device in question may schematically look like this:

Main elements of the oil pressure sensor:

- frame;

- wire connection location;

- thread for fixation in the cylinder block;

- diaphragm;

- a spring that resists deformation of the diaphragm;

- positive and negative contacts.

The oil pressure sensor is located on the left side on the back of the engine. This makes it fairly easy to diagnose or replace.

Oil pump

A gear pump with an oil receiver and a pressure reducing valve in the cover is installed in the engine crankcase. The pump is attached to the cylinder block with two bolts.

Gears are installed in the pump housing: the drive gear is stationary on the pump shaft and the driven gear is free on an axis pressed into the housing. The pump is driven by a chain transmission from the crankshaft sprocket to the auxiliary drive shaft sprocket, which is installed in the cylinder block in steel-aluminum bushings. The roller has a helical gear that meshes with the drive gear of the oil pump and ignition distributor, which rotates in a cermet bushing. On the latest car models, the drive shaft of auxiliary units is also installed in metal-ceramic bushings.

Principle of operation

While the engine is running, the oil pump drives oil with the necessary force along a special oil line into which the sensor is built. Having high pressure, the oil presses on the diaphragm in the sensor and displaces it, thereby opening the contacts. At the same time, the indicator on the dashboard goes out.

If there is insufficient pressure, the sensor diaphragm does not move and, accordingly, the contacts do not open. In this case, the indicator lights up and the driver learns about the malfunction.

The VAZ 2109 oil pressure sensor has an electronic emergency operating principle. That is, it is more like an oil level sensor. It transmits information only about sufficient or insufficient level and pressure, without conveying their exact value. This feature distinguishes it from another type of sensor - a mechanical one, which is capable of indicating the degree of pressure created in the engine crankcase.

Design

Oil pump VAZ 2109

Today there are three types of pumps:

- 2-gear pumps, in which one gear is connected to a shaft, which starts working from the intermediate or camshaft of the VAZ. This pump is installed inside a sump located in the lower area of the cylinder block. Typically, the rotation speed of the element is ½ the rotation speed of the motor.

- A gerotor pump has a rotating small gear inside an outer gear. This pump is located in the lower area of the motor in the sump.

Old style oil pump

The internal pump is often installed on the front cover of the engine. It begins to function from the crankshaft. Structurally, such a mechanism is similar to a gerotor mechanism, but in this situation it replaces the front damper of the engine. As a result, it is possible to generate higher oil flow with higher pressure.

Reasons for the indicator light and diagnostic methods

A sufficiently experienced car owner can independently diagnose or repair this system. Otherwise, it is recommended to contact a service center for help.

Sensor malfunction

To check the serviceability of the sensor, it is necessary to perform a number of operations:

- Turn the ignition key to the first position (turn on the ignition).

- Make sure the pressure indicator lights up.

- Open the engine compartment and disconnect the sensor wire.

- Make sure the indicator is not lit.

- Attach the bare end of the wire to ground, for example to the engine housing.

- The indicator on the dashboard should light up. If so, the wire is OK and the cause of the malfunction lies in the sensor.

The manufacturer does not recommend disassembling or repairing the sensor. It needs to be replaced.

Violation of the integrity of electrical wiring

Due to large temperature changes, ingress of fuels and lubricants, natural drying or mechanical damage in the engine compartment, electrical wiring is a vulnerable part of the vehicle's electrical systems.

Checking its integrity can be visual, by inspecting visible parts, or using a multimeter to check the conductivity and resistance of the wire.

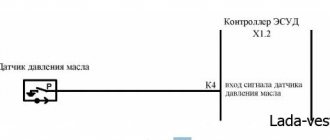

This check is carried out strictly in accordance with the electrical diagram of the VAZ 2109 car.

Low engine oil level

During the operation of the vehicle, minor consumption of engine oil is allowed. Checking its level should be done using a special dipstick with the engine cold or not running for more than 10 minutes.

It is necessary to check its level using the dipstick and, if necessary, top up. The indicator is then rechecked with the engine running.

Low oil levels can also be caused by oil leaks.

Engine wear

Engine operation involves constantly rubbing metal surfaces. No matter how well they are lubricated, wear is inevitable.

In internal combustion engine elements such as the piston group and the timing mechanism (gas distribution mechanism), there are special oil channels. Through them, the most inaccessible rubbing surfaces are lubricated. Due to prolonged use of the vehicle and engine wear, the sealing of the channels is lost and the oil pressure drops. To eliminate this problem, you need to completely disassemble the internal combustion engine and overhaul it.

Oil pump drive

The oil pump drive is a part that needs to be discussed separately. The fact is that the duration of operation of the entire motor depends on it. The drive part of the oil pump itself consists of several parts:

- parasitic shaft;

- intermediate gear;

- small shaft;

- big shaft

The drive is considered a simple part of the pump, but the gear splines quickly wear out during operation.

Most cases of oil pump failure are associated with a breakdown of the drive, or more precisely, with wear of the gear splines. Most often, the splines “lick off” when starting the car in winter; in this case, the engine cannot be started again.

Gear wear is an irreversible process during long-term operation of the machine. If the gear teeth begin to slip, the pressure in the oil system will be below operating pressure. Accordingly, the engine will not receive the amount of lubricant that it needs for normal operation.

How to replace the pump drive

Replacing the drive gear is not an easy procedure, but after careful preparation, you can remove the drive and repair it:

- Remove the car's ignition distributor.

- To remove the intermediate gear, you will need a special puller. However, you can get by with a simple wooden stick with a diameter of about 9–10 mm. The stick needs to be hammered into the gear and then rotated clockwise. The gear will then easily come out.

- Install a new one in place of the worn gear using a regular stick.

- Replace the ignition distributor.

Video: replacing the oil pump drive mechanism

What is a “hog” and where is it located?

The VAZ 2106 mechanisms include a shaft, which is called the “hog” (or “pig”). The shaft itself drives the car's oil pump, as well as the gasoline pump and sensors. Therefore, if the “hog” suddenly fails, then the machine ceases to function normally.

The intermediate shaft is located in the engine compartment of the VAZ 2106 on the front side of the cylinder block. On the “six” the “hog” is started using a chain drive. This shaft has an extremely simple structure - only two necks. However, if the bushings on the journals are heavily worn, the operation of the oil pump and other mechanisms will be difficult. Therefore, when checking the pump, they usually look at the operation of the “hog”.

The shaft, called the “hog”, is mounted in front of the cylinder head

You can work with the oil pump on the VAZ 2106 yourself in the garage. The main feature of domestic “sixes” is precisely their unpretentious maintenance and simplicity of design. You can repair the oil pump and adjust the pressure in the system yourself, since there are no special requirements for this procedure.

Does the VAZ-2109 oil pressure sensor work?

To determine if it is correct, you need to check the engine oil level. To do this, you need to open the hood and pull out the dipstick. In order to check more accurately, you need to do this:

- drive into a pit and remove the protection;

- get close to the sensor;

- turn on the ignition;

- disconnect the power cord;

- Use a voltmeter to measure the voltage between the block and ground. It should show 12 volts.

If there is no voltage, then there may be a problem in the contact or a broken wire.

Third-party liquids in the pan

As for the increased oil level, it is not necessary to check the lubrication system, since the reason for the lamp to operate is the ingress of technical fluids into the pan. And here it is necessary to establish where they are leaking from and eliminate the damage.

If instead of oil an emulsion of asphalt or another color is found, this is an antifreeze leak. Coolant usually ends up in the sump due to a damaged head gasket, which will have to be replaced to fix the problem.

But if there is no emulsion, but the level is higher than normal, and the oil itself is very liquid, fuel penetrates into the pan. The main reasons for this phenomenon are:

- Occurrence of rings;

- Misfires;

- CPG wear.

As a result of such malfunctions, the fuel supplied to the combustion chambers does not burn, but flows down the cylinder walls into the sump.

VAZ-2109 owners check the sensor in different ways:

First.

Remove the DDM located above the oil filter, turn the starter, the engine cannot be started during such a check. If all is well, oil should flow out. Then visually check the condition of the sensor. If there is no damage, then wash it with gasoline. They are installed in place. The light will go off. If it continues to burn, then it needs to be changed. Second. Check the oil level. If it’s low, add lubricant, then check again whether the light is on or not. Next, warm up the engine and then turn it off. Then connect to a pressure gauge. This adapter from the pressure gauge is screwed into place of the sensor and grounded through the ground of the car. Connect the signal LED to the battery positive and the sensor, start the engine and step on the gas. When the pressure gauge reads 1.2-1.6 bar, the LED goes out. If it lights up, then the DDM is broken.

The car owner must always monitor the condition of the DDM. After all, he also has problems. And these problems can affect the technical condition of the machine. You should not allow breakdowns, because if the engine jams, this will lead to large financial expenses.

Source

Third-party liquids in the pan

As for the increased oil level, it is not necessary to check the lubrication system, since the reason for the lamp to operate is the ingress of technical fluids into the pan. And here it is necessary to establish where they are leaking from and eliminate the damage.

If instead of oil an emulsion of asphalt or another color is found, this is an antifreeze leak. Coolant usually ends up in the sump due to a damaged head gasket, which will have to be replaced to fix the problem.

But if there is no emulsion, but the level is higher than normal, and the oil itself is very liquid, fuel penetrates into the pan. The main reasons for this phenomenon are:

- Occurrence of rings;

- Misfires;

- CPG wear.

As a result of such malfunctions, the fuel supplied to the combustion chambers does not burn, but flows down the cylinder walls into the sump.