The steering mechanism of a car consists of a steering wheel, a shaft, a gearbox, rods, a trapezoid, a pendulum and steering knuckles.

Due to the steering gear, which transmits forces from the steering wheel to the rods, the front wheels of the car rotate at a given angle.

Transmission oil poured into the steering system helps ensure stable operation of the gearbox and reduce wear on its parts. If it leaks, which occurs regardless of the condition of the gearbox, and untimely replacement occurs, the problem of dry friction in the unit arises. As a result, the quality of driving deteriorates, the rotation of the steering wheel becomes difficult, and its play increases.

Let's take a closer look at what oil is used for the VAZ 2107 steering gear, how to check its level and replace it.

Operating principle of the steering gear

The VAZ 2107 is equipped with a worm-type steering gear. The principle of its operation is as follows.

The driver turns the steering wheel. The worm shaft is driven by cardan joints. It rotates, moving the double-ridge roller. Then the secondary shaft rotates, on which the bipod is fixed, driving the steering rods.

The trapezoid moves the steering knuckles, turning the wheels in the desired direction.

To reduce friction of the internal elements of the steering gear, transmission oil with a viscosity grade of SAE 75W-90, 80W-90 or 85W-90 is poured into the mechanism. The filling volume of the VAZ 2107 gearbox is 0.215 liters.

STEERING COLUMN REPAIR

Due to constant friction in the steering mechanism, elements wear out, which indicates the need not only for adjustment of the unit, but also for possible repairs.

HOW TO REMOVE THE GEARBOX

To dismantle the steering column on the “seven”, you will need the following tools:

- a set of keys;

- knob;

- heads;

- steering rod puller.

After preparing everything you need, perform the following step-by-step actions:

- The car is placed on a lift or inspection hole.

- Clean the steering rod fingers from dirt.

- The rods are disconnected from the gearbox bipod, for which the cotter pins are removed, the nuts are unscrewed and the pin is squeezed out of the steering gear bipod using a puller.

After unscrewing the nuts, disconnect the steering rods from the bipod of the steering gear.

- The steering column is connected to the steering wheel using an intermediate shaft. Unscrew the fastener of the latter from the gearbox shaft.

To remove the steering column, you will need to unscrew the fastening of the mechanism shaft to the intermediate shaft

- The gearbox is fastened to the body with three bolts. Unscrew the 3 fastening nuts, remove the fasteners and dismantle the steering mechanism from the car. To make it easier to remove the assembly, it is better to turn the bipod all the way into the column body.

The steering gear is attached to the vehicle side member using three bolts

VIDEO: REPLACING A STEERING COLUMN USING THE EXAMPLE OF A VAZ 2106

HOW TO DISASSEMBLE THE GEARBOX

When the mechanism is removed from the vehicle, you can begin to disassemble it.

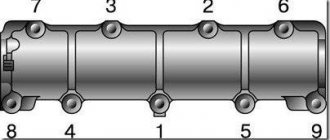

Parts of the steering gear housing: 1 - housing; 2 - bipod; 3 — lower crankcase cover; 4 — adjusting shims; 5 — outer ring of the worm shaft bearing; 6 — separator with balls; 7 — bipod shaft; 8 - adjusting screw; 9 — adjusting plate; 10 — lock washer; 11 - worm shaft; 12 — upper crankcase cover; 13 - sealing gasket; 14 — bipod shaft sleeve; 15 — worm shaft seal; 16 — bipod shaft seal

Tools you need to prepare:

- standard set of keys;

- head at 30;

- bipod puller;

- vice.

The work is carried out in the following order:

- Unscrew the bipod nut and use a puller to press the rod off the shaft.

To remove the bipod, unscrew the nut and compress the rod with a puller

- Unscrew the oil filler plug, drain the lubricant from the crankcase, then unscrew the adjusting nut and remove the lock washer.

- The top cover is secured with 4 bolts - unscrew them.

To remove the top cover, unscrew 4 bolts

- Remove the adjustment screw from the engagement of the bipod shaft, then remove the cover.

To remove the cover, you will need to disengage the adjustment screw from the bipod shaft

- Remove the thrust shaft with the roller from the gearbox.

From the gearbox housing we remove the bipod shaft with the roller

- Unscrew the fasteners of the worm mechanism cover and dismantle it along with the adjusting shims.

To remove the worm shaft cover, unscrew the corresponding fasteners and remove the part along with the gaskets

- Use a hammer to lightly strike the worm shaft and knock it and the bearing out of the steering column housing. The end surface of the worm shaft has special grooves for the bearing.

The worm shaft is pressed out using a hammer, after which it is removed from the housing along with the bearings

- Remove the worm shaft oil seal by prying it off with a screwdriver. In the same way, remove the bipod shaft seal.

The gearbox seal is removed by prying it with a screwdriver

- Using the adapter, knock out the outer race of the second bearing.

To remove the outer bearing race, you will need a suitable tool.

After disassembling the steering gear, it is troubleshooting. All elements are pre-cleaned by washing in diesel fuel. Each part is carefully inspected for damage, scuffing, and wear. Particular attention is paid to the rubbing surfaces of the worm shaft and roller. The bearings must rotate without jamming. There should be no damage or signs of wear on the outer races, separators and balls. The gearbox housing itself should not have cracks. All parts that show visible wear must be replaced.

Oil seals, regardless of their condition, are replaced with new ones.

ASSEMBLY AND INSTALLATION OF THE GEARBOX

When the faulty elements have been replaced, you can begin assembling the unit. The parts that are installed inside the crankcase are lubricated with transmission oil. Assembly is performed in the following order:

- Using a hammer and a socket or other suitable device, press the inner bearing race into the steering assembly housing.

The inner bearing race is pressed in using a hammer and a tool.

- A separator with balls, as well as a worm shaft, are placed in the cage. The outer bearing separator is placed on it and the outer race is pressed into place.

After installing the worm shaft and outer bearing, the outer race is pressed in

- Mount the cover with gaskets and press in the oil seals of the worm shaft and bipod. A small amount of lubricant is first applied to the working edges of the cuffs.

- Place the worm shaft in the mechanism body. Using adjusting shims, the rotation torque is set from 2 to 5 kgf*cm.

- Install the short rod shaft.

- At the end of the work, lubricant is poured into the steering column and the plug is screwed in.

Installation of the unit on the machine is carried out in the reverse order.

VIDEO: HOW TO DISASSEMBLE AND ASSEMBLE A VAZ STEERING MECHANISM

How to check the oil level in the gearbox?

To avoid premature failure of the steering gear, the oil level in it must be periodically checked, topped up or completely replaced with lubricant.

The VAZ 2107 gearbox is located in the engine compartment on the left side, under the vacuum brake booster. Checking the oil level is done as follows: Using a 8 wrench, unscrew the filler plug. A screwdriver or similar tool is lowered into the crankcase. Normally, the lubricant should reach the bottom edge of the filler hole.

If the oil level is lower, top it up (using a syringe). The crankcase is filled until lubricant begins to flow out of the filler hole.

At the end of the work, tighten the plug and remove any leaks from the gearbox.

see also

Comments 25

If you solve the problem, please write back. And so the advice is to lift the front of the car with jacks and try to turn the steering wheel

I also heard that the steering rack from the VAZ 2110 is put on high quality.

I poured an engine additive into the column and the steering became a little lighter.

Check the pendulum on the right side, they sometimes jam. When I changed mine, I couldn’t turn it by hand, which couldn’t be said about the new one.

Oil is not the reason, the main thing is the level, and what kind is not important, even engine oil, as long as there is some kind of oil.

Level at the top filler plug

Strengthen your arm muscles. Seriously. Nothing else can be fundamentally changed. I drove different cars, including various Zhigulis and PP Vases. Well, you can’t do anything with a system like a globoidal worm. This steering mechanism is reliable, but generally tight. The most effective tuning method is installing an EUR. But it's difficult and expensive. Good pressure in the tires of the front wheels will make driving a little easier, oddly enough. Well, replacing the pendulum, of course.

Oil change process

The oil in the VAZ 2107 steering gear should be changed once every one and a half years or every 50-60 thousand kilometers.

All work is carried out in a viewing hole or overpass, wearing special clothing and rubber gloves.

Before you start changing the fluid, warm up the engine to improve the fluidity of the lubricant.

Prepare a metal brush to clean the surface of the gearbox, two large-volume syringes and a small piece of washer hose (or a dropper tube).

Clean the hood and the surface of the gearbox from dirt (especially in the area of the filler hole). Find the filler plug - it is located near the adjusting screw in the middle of the top cover. Remove the plastic plug from it, unscrew the plug itself using a 8mm wrench.

Place a piece of tubing on the syringe and pull out the old oil.

Using a second clean syringe, fill the gearbox with new lubricant to the required level. In this case, it is recommended to rotate the steering wheel, so it is better to carry out the replacement with an assistant.

At the end of the procedure, tighten the filler plug and wipe off any traces of oil.

The steering mechanism of a car consists of a steering wheel, a shaft, a gearbox, rods, a trapezoid, a pendulum and steering knuckles.

Due to the steering gear, which transmits forces from the steering wheel to the rods, the front wheels of the car rotate at a given angle.

Transmission oil poured into the steering system helps ensure stable operation of the gearbox and reduce wear on its parts. If it leaks, which occurs regardless of the condition of the gearbox, and untimely replacement occurs, the problem of dry friction in the unit arises. As a result, the quality of driving deteriorates, the rotation of the steering wheel becomes difficult, and its play increases.

Let's take a closer look at what oil is used for the VAZ 2107 steering gear, how to check its level and replace it.

Operating principle of the steering gear

The VAZ 2107 is equipped with a worm-type steering gear. The principle of its operation is as follows.

The driver turns the steering wheel. The worm shaft is driven by cardan joints. It rotates, moving the double-ridge roller. Then the secondary shaft rotates, on which the bipod is fixed, driving the steering rods.

The trapezoid moves the steering knuckles, turning the wheels in the desired direction.

To reduce friction of the internal elements of the steering gear, transmission oil with a viscosity grade of SAE 75W-90, 80W-90 or 85W-90 is poured into the mechanism. The filling volume of the VAZ 2107 gearbox is 0.215 liters.

How to check the oil level in the gearbox?

To avoid premature failure of the steering gear, the oil level in it must be periodically checked, topped up or completely replaced with lubricant.

The VAZ 2107 gearbox is located in the engine compartment on the left side, under the vacuum brake booster. Checking the oil level is done as follows: Using a 8 wrench, unscrew the filler plug. A screwdriver or similar tool is lowered into the crankcase. Normally, the lubricant should reach the bottom edge of the filler hole.

If the oil level is lower, top it up (using a syringe). The crankcase is filled until lubricant begins to flow out of the filler hole.

At the end of the work, tighten the plug and remove any leaks from the gearbox.

Lubricant selection

When choosing oil for a VAZ 2107 gearbox, you should take into account the compatibility of the fresh product with the used one - especially when filling in new fluid without flushing the crankcase.

The manufacturer recommends using transmission fluids of the GL-4 or GL-5 group. The former contain a high concentration of additives, the latter are used to lubricate rubbing gears.

Oil change process

The oil in the VAZ 2107 steering gear should be changed once every one and a half years or every 50-60 thousand kilometers.

All work is carried out in a viewing hole or overpass, wearing special clothing and rubber gloves.

Before you start changing the fluid, warm up the engine to improve the fluidity of the lubricant.

Prepare a metal brush to clean the surface of the gearbox, two large-volume syringes and a small piece of washer hose (or a dropper tube).

Clean the hood and the surface of the gearbox from dirt (especially in the area of the filler hole). Find the filler plug - it is located near the adjusting screw in the middle of the top cover. Remove the plastic plug from it, unscrew the plug itself using a 8mm wrench.

Place a piece of tubing on the syringe and pull out the old oil.

Using a second clean syringe, fill the gearbox with new lubricant to the required level. In this case, it is recommended to rotate the steering wheel, so it is better to carry out the replacement with an assistant.

At the end of the procedure, tighten the filler plug and wipe off any traces of oil.

Flushing the gearbox

When switching to another transmission oil, after purchasing a used car, or when undergoing scheduled repairs, it is recommended to flush the steering gear.

To do this, mix transmission or motor oil with diesel fuel in a 3:1 ratio.

The mixture is poured into the system after removing the old oil, then jack up one wheel, start the engine and leave it running at first speed for a few minutes. After this, the washing is drained.

Flushing the gearbox

When switching to another transmission oil, after purchasing a used car, or when undergoing scheduled repairs, it is recommended to flush the steering gear.

To do this, mix transmission or motor oil with diesel fuel in a 3:1 ratio.

The mixture is poured into the system after removing the old oil, then jack up one wheel, start the engine and leave it running at first speed for a few minutes. After this, the washing is drained.

Peculiarities

If extraneous sounds and knocking noises appear in the steering gear, which are felt through the steering wheel, you should think about changing the oil, because this is the first sign of a malfunction of the mechanism. You should also be careful and hurry up with repairs in cases where turning the steering wheel becomes difficult, various sounds and noises occur constantly or periodically. If there is obvious play in the steering gearbox, you may notice an oil leak. If you identify at least one of these signs, you should not waste time, you need to urgently repair the mechanism or seek help. Neglect of this kind of malfunction will not lead to anything good, because the loss of the ability to control a car can have unpredictable consequences, not only for the driver, but also for other road users.

Why is it needed in a car?

In the modern automotive world, manufacturers are striving to improve driving comfort. This did not bypass the “brutal” Russian SUV UAZ Patriot. While taxiing, the owner turns the steering wheel, but does it with ease, since the specified amplifier comes to his aid. All this happens when the engine is running, since the amplifier is driven by a rotating crankshaft pulley. Try turning the steering wheel with the Patriot engine not running. Yes, this is a gym! Off-road driving will turn into a test that not every owner can withstand.

Thanks to the amplifier, the driver can turn the steering wheel with one finger. How did this become possible? The main “person” in the amplification mechanism is the pump. It receives rotational torque from the crankshaft. For such transmission, the designers used a belt. The pump generates fluid pressure, which in turn is sent directly to the steering mechanism. It is due to the “work” of the oil that the driver receives such invaluable “relief” in turning the steering wheel.

To ensure circulation, there is a special main hose in the system, which we will discuss in more detail. It has its own resource, so the owner should be more careful and monitor its condition and frequency of replacement.

Since we touched on this “repair” point, we note that in the list of such procedures regarding the Patriot’s power steering, experts also include replacement:

- hose;

- working fluid (oil);

- pumping unit.

We examined the main areas of repair, without which the normal functioning of the amplification mechanism can only be a dream for a carefree owner.

Influence of viscosity grade

If the VAZ-2107 will be operated in temperate climate areas, where summers are constantly hot and winters are quite cold, then it is recommended to fill the manual transmission with all-season transmission fluid - SAE75W90. It can operate in a wide temperature range (-40/+45). Moreover, the performance qualities of the oil always remain unchanged.

When purchasing lubricant for manual transmission, you must take into account your place of residence. Each region has its own climatic conditions.

For example, SAE 80W85 can be operated in the range from +35 to -26 Celsius. Some regions require a wider range, so it is important to consider these values when purchasing.

What kind of oil and how much liquid to fill in UAZ-2206 Bukhanka

UAZ Bukhanka is a car with a long history. Almost every domestic driver knows about it. Many still buy today. This is not surprising. It’s hard to argue with the advantages of the car:

- Good maneuverability, both on city roads and off-road;

- Excellent maneuverability;

- Maintainability;

- Low price.

A new version of the minibus was presented last year. It has been significantly transformed and improved. The car embodies the latest technical innovations that were developed at the Ulyanovsk plant. It features excellent performance characteristics. The installed units are reliable and durable.

Drivers who properly maintain it will not have any problems with the minibus.

The first thing that is most important in this process is the timely replacement of oil in the components and assemblies of the machine. For the engine it is provided every 10 thousand km

It is necessary to fill in no more than 7 liters of semi-synthetic liquid.

In the gearbox, the lubricant is changed every 45 thousand km. The amount of oil is 1 liter. The table below will help you figure out how much liquid to pour into other systems.

Device

The working pair of the steering gear is a globoidal worm and a double-ridge roller. A worm pressed onto a hollow shaft is installed in the steering gear housing on two tapered roller bearings.

To ensure the reliability of the connection between the shaft and the worm, a keyway is made and splines are cut on the worm shaft. A double-ridge roller is in constant engagement with the worm.

Its annular grooves located inside provide a working surface for a double-row ball bearing. It is mounted on an axis, which is mounted in the head of the bipod shaft.

This shaft rotates in two bearings at once: a bronze bushing pressed into the crankcase and a cylindrical roller bearing. This element is installed in the crankcase cover on the side of the steering gearbox.

The shaft head shank fits into the groove of the adjustment screw. It is screwed into the crankcase cover on the side. The adjustment screw is secured with a pin and a lock washer, which are pressed into the cover. The mechanism is closed with a nut and cap.

With its upper end, the steering shaft enters the bearing, rotating on it. The bearing is pressed into the column housing. The bearing spacer is prevented from moving by a special spring.

Why is it needed in a car?

In the modern automotive world, manufacturers are striving to improve driving comfort. This did not bypass the “brutal” Russian SUV UAZ Patriot. While taxiing, the owner turns the steering wheel, but does it with ease, since the specified amplifier comes to his aid. All this happens when the engine is running, since the amplifier is driven by a rotating crankshaft pulley. Try turning the steering wheel with the Patriot engine not running. Yes, this is a gym! Off-road driving will turn into a test that not every owner can withstand.

Thanks to the amplifier, the driver can turn the steering wheel with one finger. How did this become possible? The main “person” in the amplification mechanism is the pump. It receives rotational torque from the crankshaft. For such transmission, the designers used a belt. The pump generates fluid pressure, which in turn is sent directly to the steering mechanism. It is due to the “work” of the oil that the driver receives such invaluable “relief” in turning the steering wheel.

To ensure circulation, there is a special main hose in the system, which we will discuss in more detail. It has its own resource, so the owner should be more careful and monitor its condition and frequency of replacement.

Since we touched on this “repair” point, we note that in the list of such procedures regarding the Patriot’s power steering, experts also include replacement:

- hose;

- working fluid (oil);

- pumping unit.

We examined the main areas of repair, without which the normal functioning of the amplification mechanism can only be a dream for a carefree owner.

Which lubricant to choose

Many drivers have a reasonable question: what kind of oil to fill? Oil

Mechanics recommend filling the rear axle gearbox of a VAZ-2107 with a viscosity of 75W90, 80W90 or another suitable one with API classification GL-4/GL-5.

For example, Castrol 75W90, Lukoil 80W90. In winter, it is better to fill the rear axle of the VAZ- 2107

with synthetics. In summer, mineral water.

How much to fill (volume)

You won’t believe it, but there are also owners who don’t even know that the rear axle of a car also needs regular lubrication, although not as often as the engine. Also, there are drivers who believe that if the oil does not expel or ooze, there is no need to change it at all. This is all wrong and it is also necessary to perform this procedure, as in the internal combustion engine and in the gearbox.

The lubricant volume should be 1.3 liters. To fill the required level, you need to wait until the oil flows from the filler hole; this will be considered the optimal volume.

Steering mechanism VAZ 2107 - brief description

The steering mechanism of the VAZ “Seven” has a rather complex design that ensures reliable vehicle control in different driving situations. The steering wheel is endowed with good information content, which eliminates driver fatigue when traveling long distances. When turning the steering wheel while the car is stationary, some difficulties arise. However, as soon as the car starts to move, the steering becomes less stiff and handling improves.

The steering mechanism has a nuance - a slight play, which is normal. This is explained by the considerable number of parts in the gearbox and the presence of rods. After modernization, a safety pillar with a composite bridge was installed on the VAZ 2107. Its design consists of two cardan-type joints, allowing the shaft to be folded in the event of an accident. Thus, driver injuries are excluded.

The steering box is designed to transmit force from the steering wheel to the tie rods to turn the front wheels to a certain angle