16.07.2019

| (No votes) |

Issues discussed in the material:

- How often to change the oil filter in a car

- How often to change the fuel filter in a car

- How often to change the air and cabin filters in a car

- Is it possible not to change filters in a car?

The operation of a car involves various mechanisms that require filters to function correctly. They are necessary in fuel supply systems, air, climate control, and lubrication systems. How often to change filters in a car, because by retaining excess working mixtures and waste materials, they become dirty. Let's talk about this today.

Types and functions of car filters

If earlier, when car production was just beginning to develop, their design did not include cleaning systems, which led to frequent breakdowns, then with the advent of filters the situation changed dramatically, as evidenced by a significant increase in the mileage between repairs.

Car filters differ not only in their specific purpose, but also in their level of cleaning. Conventionally, there are 3 classes:

- Completely trapping dust and other harmful particles;

- retaining contaminants from 1 micron;

- less sensitive, capable of capturing unwanted microparticles from 10 microns.

The quality of filters also depends on their manufacturers, and although they are all similar in appearance and design, the materials used and production technologies affect their performance. For example, DIFA filters, which are manufactured in Belarus - one of the largest filter production factories, at a relatively low cost, are not inferior in performance to foreign ones. The official distributor of the plant on the Russian market for many years has been DIFA-AVK LLC (official website).

DIFA FILTERS & FILTER ELEMENTS - DIFA FILTERS AND FILTER ELEMENTS

How does the replacement take place?

The fuel filter is replaced in the following order:

- On a car with carburetors, just unscrew the clamps and pull the hoses out of the fittings, then unscrew the consumable body and replace it with a new product.

- On machines with fuel supply from an injector, these actions must be carried out from the inspection hole or lying under the bottom.

- On the diesel version, you need to pull out the tubes, remove the cover and remove the littered paper insert.

The location of the filter and the replacement method may differ depending on the make and model of the vehicle.

For example, on a gasoline car, instead of a round barrel that cannot be disassembled, a housing with a filter paper insert can be installed. In this case, this core changes. When you need to clean or change the screen in the tank, then you need to remove the gasoline pump.

Air filters

In order to prevent dirt from entering the engine, each car is equipped with a consumable item such as an air filter. Thanks to its operation, all foreign particles are retained, and purified air enters the engine, the noise level is reduced and the fuel temperature is regulated. By design, the elements are ring-shaped, panel-shaped, frameless and cylindrical.

On average, after 15-30 thousand kilometers, and also by a number of signs, you can determine when it’s time to replace the filter:

- Fuel consumption has increased;

- engine power has decreased;

- startup problems;

- The “Check Engine” indicator is active on the instrument panel.

The presence of oil stains and general contamination of the filter indicate a decrease in its throughput.

How to choose the right car filter?

You need to select a filter from the catalog provided by each manufacturer. This is the only way you can be sure that the purchased filter will fully match the type and model of your vehicle. Many car enthusiasts choose filter products based only on external features, for example, thread diameter. This is fundamentally wrong. Identical threads can be used on filters with different functionality and characteristics. The differences are not in appearance, but in more significant parameters, for example, in throughput, in operating pressure and pressure at the limit, in the principles of opening and closing valves.

Oil filter

Each oil change is certainly accompanied by the replacement of the oil filter, the task of which is to clean it from dirt, dust, carbon deposits, and harmful particles. On average, after 10-15 thousand kilometers it is necessary to change this consumable element. The filter is installed on the engine block and consists of a cylinder with a metal body and a filtering internal part.

- The filter element is made of special paper, the quality of which determines the efficiency of the oil filter. It must meet a number of requirements, which is why reliable filter manufacturers only use certain brands.

- The design also includes a bypass valve that directs the flow of oil bypassing the filter element in some circumstances, for example, in winter, until the oil warms up to operating temperature.

- The anti-drainage valve prevents oil leakage into the engine crankcase when it is turned off.

Note! When purchasing an oil filter, you need to check the integrity of the housing and seal, as well as the manufacturer’s brand. Reliable companies provide complete information with address and contact details.

About filtering fuel before combustion

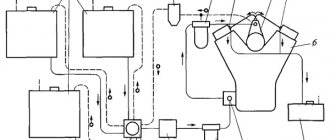

In vehicles with different fuel supply systems, cleaning is organized in two or three stages:

- Carburetor power system. The first stage is a mesh in the tank, then there is a fine filter, and at the end there is another fine mesh at the inlet to the carburetor.

- Nozzle injection from an injector. The same large mesh is in the fuel tank, then there is a mesh filter for the gasoline pump, followed by a fine cleaning element.

- Filtration for diesel power units is similar to the injection system, but an additional stage is added - separation. It consists of separating water particles from diesel fuel, since it can cause water hammer in the combustion chambers of the engine and destruction of the cylinder head.

Note. In gasoline versions of cars, there is a separate part at each cleaning stage. On diesel engines there are often two-in-one combined elements, which include a filter membrane and a separator (water separator). The entire filter of this design needs to be replaced.

Large and small meshes are designed to trap foreign solid impurities that have entered the fuel. The size of the retained particles is from 70 to 100 microns. Thanks to pre-filtration, relatively large debris does not get inside the fine filter element, therefore the fuel filter replacement interval increases.

The separation of the smallest particles is carried out using special paper with cells measuring 10 microns. The paper insert is placed in a metal case equipped with two fittings for connecting fuel line hoses.

The filter element has one feature: it is capable of retaining water to a certain extent. If too much of it is supplied, then this property is lost.

Fuel filters

The presence of foreign impurities in the fuel is unacceptable; this will inevitably lead to engine failure. To eliminate microparticles of rust, dust, water, fuel filters are installed. Their filter layer consists of special paper impregnated with acrylic resin.

Fuel filters differ in different ways:

- According to the degree of cleaning - coarse or fine;

- by design - collapsible and non-dismountable;

- by purpose - for carburetor, diesel, gasoline injection engines;

- at the installation location - inside or outside the tank.

To ensure optimal operation of the fuel filtration system, it is recommended to replace the fuel filter on average every 25-40 thousand km.

Signs of a blockage

Does a car enthusiast need to know when to change the filter? A number of features are known for this purpose. All symptoms are caused by poor fuel supply.

We provide the main signs of a fuel filter failure:

- Severely reduced power;

- Uneven engine operation - often detected by sneezing or jerking of the car;

- Increased fuel consumption. This sign is indirect, it is not always connected with this.

In the first stages of blockage, these signs of blockage are not clearly expressed, so drivers do not notice alarm bells.

Only after the fuel supply has completely stopped do the owners begin to think about the reason. There are cases when the car did not start due to the fact that gasoline could not squeeze through the filter.

Cabin filters

Before taking air from the street, cabin filters are installed, which not only provide comfort to passengers by preventing dust and dirt from entering the cabin, but also prevents clogging of the air conditioner and heater radiator.

There are 2 types of cabin filters, different in type of base:

- Filter paper is cheaper, effectively purifies the air from unwanted particles, but practically does not eliminate the incoming odor.

- Activated carbon - copes much better with unpleasant odors, but does not work well in humid weather and is more expensive than usual.

Which one to choose is up to the car owner to decide; like other filters, cabin filters must be replaced periodically.

Filter elements

Conventionally, the entire automotive filtration system can be divided into filters themselves and filter elements, but both the first and second are called filters. Each filter includes a main part - a filter element, which can be replaced or not. So, in addition to the oil and fuel filter assembly, there are also replaceable elements.

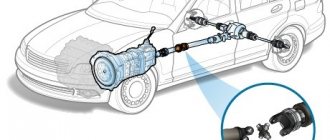

In addition to the main types of filtration elements that all modern cars are equipped with, depending on the design of the units, there are others:

- With an automatic transmission, there is an automatic transmission fluid filter in the gearbox;

- in the expansion tank there is an oil filter, which is a mesh with small cells when the suspension is hydraulically controlled;

- if you have power steering, use a power steering fluid filter;

- filters for gas equipment for cars running on gas;

- There are also fuel separators, pneumatic system dryers, breather filter, gas tank filter, particulate filter, and hydraulic filter.

All car filters are installed for one purpose - to remove unnecessary particles, which ensures the efficient operation of all components and systems of the car. Timely replacement and selection of high-quality filters will extend the repair-free life of the car.

Shift instructions

For most car brands, this procedure is not too difficult.

Basically, filters are installed in the following places:

- Under the bottom of the car - on the injection system;

- In the engine compartment in front of the high pressure pump - for diesel engines;

- In the engine compartment in front of the injection pump, there is a break in the gasoline line - on the carburetor;

- A coarse mesh is installed in the tank along with a gasoline pump.

To avoid dousing your hands and car parts with fuel, before the procedure it is advised to release the pressure in the lines, which is constantly present on injection models of cars. To do this, you will need to find the spool on the ramp, place a small container and press the valve.