Lada VAZ-2110 (2111, 2112). Brake system

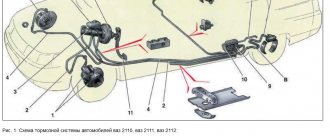

Diagram of the hydraulic brake drive: 1 - main cylinder of the hydraulic brake drive; 2 — pipeline of the “right front - left rear brake” circuit; 3 — flexible hose of the front brake; 4 — master cylinder reservoir; 5 - vacuum booster; 6 — pipeline of the “left front - right rear brake” circuit; 7 — rear wheel brake mechanism; 8 — elastic lever for the pressure regulator drive; 9 — flexible rear brake hose; 10 - pressure regulator; 11 — pressure regulator drive lever; 12 — brake pedal; 13 — front wheel brake mechanism.

The service brake system is hydraulic, dual-circuit (with diagonally separated circuits), with a pressure regulator 10, a vacuum booster 5 and an indicator of insufficient brake fluid level in the reservoir.

The brake mechanisms of the front wheels are 13 - disc (ventilated on VAZ-21103, -21113 and -2112), with a single-piston floating caliper and a brake lining wear indicator.

Vacuum booster 5 is located between the pedal assembly and the main brake cylinder 1 and is attached to the pedal assembly bracket with two studs. The amplifier is of a non-separable design; if it fails, it should be replaced. The simplest way to check the serviceability of the amplifier: on a car with the engine turned off, press the brake pedal several times and, holding the pedal down, start the engine. If the amplifier is working properly, when the engine starts running, the pedal should move forward. Failure to operate or insufficient efficiency of the vacuum booster can also be caused by a leak in the hose that takes vacuum from the intake manifold.

The rear brake pressure regulator 10 is attached with two bolts to a bracket in the left rear part of the body. One of these bolts (front) also secures the fork bracket of the pressure regulator drive lever 11. Due to the ovality of the holes for its fastening, the bracket together with the lever can be moved relative to the pressure regulator, changing the force with which the lever acts on the regulator piston (see “Checking and adjusting the rear brake pressure regulator drive"). As the load on the rear axle of the vehicle increases, the elastic lever is also loaded, transmitting force to the pressure regulator piston. When you press the brake pedal, the fluid pressure tends to push the piston outward, which is prevented by the force from the elastic lever. When the system comes into balance, a valve located in the regulator isolates the rear brake cylinders from the master cylinder, preventing further increases in braking force on the rear axle and preventing the rear wheels from locking up ahead of the front wheels. As the load on the rear axle increases, when the traction of the rear wheels with the road improves, the regulator provides more pressure in the wheel cylinders and vice versa - as the load decreases, the pressure drops. There is a hole in the regulator body that is closed with a plug. Leakage of brake fluid from this hole indicates leakage of the regulator O-rings.

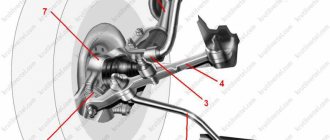

The floating front brake caliper includes a caliper and a wheel cylinder, which are held together by two bolts. The other two bolts secure the bracket to the pins installed in the holes in the pad guide. Lubricant is placed in these holes. Rubber protective covers are installed between the pins and the pad guide. The brake pads are pressed against the guide grooves by springs. The inner pad has a lining wear indicator. The cylinder contains a piston with a rectangular rubber sealing ring. Due to the elasticity of this ring, a constant optimal gap between the brake pads and the disc is maintained.

Brake discs are cast iron. The minimum permissible disc thickness during wear is 17.8 mm for ventilated discs and 10.8 mm for non-ventilated discs, the maximum runout along the outer radius is 0.15 mm.

The rear wheel brake cylinders are equipped with a device to automatically maintain the gap between the shoes and the drum. The main element of the device is a steel spring split ring mounted on the piston with an axial clearance of 1.25-1.65 mm. The thrust rings (two per cylinder) are inserted with an interference fit, providing a shear force along the cylinder surface of at least 35 kgf, which exceeds the force of the brake pad tension springs. When the brake linings wear, the thrust rings shift under the action of the pistons by the amount of wear. If the piston mirror is damaged by mechanical impurities that have entered the brake fluid or formed due to corrosion (the presence of water in the brake fluid), the rings may “sour” in the cylinder and one or even both pistons will lose mobility. In this case, the cylinders must be replaced.

Pumping the brakes

Now you can get started. On a VAZ 2112 we pump the brakes ourselves. The price at a service station for pumping is small, but you can save money, and by the time you get to the station, you can already have time to pump the brakes.

Master brake cylinder

After replacing the main brake or parts that are connected directly to it (pipes), it is necessary to bleed it. This is done differently than bleeding the brakes on wheels!

VAZ 2112 bleeding the brakes yourself

- After installing the new cylinder, fill the expansion tank of the VAZ 2112 brake system with brake fluid to the level. In general, fill the tank full.

- Then your partner should be seated behind the wheel, and you yourself should take a seat on the left side of the car to ensure maximum access to the master cylinder.

- All fittings that secure the brake pipes to the master cylinder must first be tightened.

- Now the procedure is as follows. The partner pumps up the pressure in the system with the pedal, then presses the brake pedal to the floor and holds it there.

Your partner presses and holds the pedal

- You should use a bleeder wrench or a regular 10 wrench to unscrew one of the fittings of the master brake cylinder.

- After unscrewing it, you will be able to observe how a small amount of brake fluid comes out from under the fitting along with air bubbles. So, there shouldn't be any bubbles.

- Tighten the fitting. After which the partner releases the pedal. And then he presses it again.

- At this time, you unscrew the SAME fitting and observe what is happening.

- This procedure must be performed until there is no air left.

- But that's not all. Next, you should do the same operation with each fitting.

There is another option for bleeding the main brake cylinder:

The essence of the process does not change. The steps are the same and the order is the same. In order to speed up the process, while your partner holds the pedal, you unscrew and tighten each fitting in turn

This is all done with ONE PRESS OF THE PEDAL, please note. But nevertheless, all the air will not come out with one press and the procedure will still have to be repeated.

Floating bracket device

The disc brake is equipped with a floating caliper, which, in turn, is equipped with a movement unit and a cylinder, they are secured using bolts. Installation or replacement of the bracket is carried out in the holes of the guide pads; this also contains liquid. Using springs, the pads are pressed against the connectors of the guides. This avoids spontaneous braking.

An electronic signaling device is installed in the inner block. It also monitors the condition of the pads. If replacement is required, the system will notify the owner. The design of the brake cylinder of the VAZ 2110 caliper has a piston. It is equipped with a sealing ring. This allows you to fix the location of the pads at the desired distance from the disc. The elasticity of the ring allows this to be achieved. If necessary, replace the sealing ring.

The brake system of the VAZ 2110 includes a parking brake. The operation of the mechanical drive is ensured by cables. The lever provides tension on the cable; it is located in the cabin. In turn, the cable is attached to the equalizer; each wheel on the rear suspension is equipped with it.

The wheels on the rear suspension are equipped with a lever that activates the pads. This device is necessary to rotate the spacer bar. It causes the brakes to lock. Knowing the structure of the VAZ 2110 brake system, you will be able to better understand its functions, monitor the serviceability of all components of the braking system, and ensure its high-quality and uninterrupted operation.

VAZ 2112 bleeding the brakes yourself

Everyone knows that brakes were invented by cowards, according to the famous saying, but their presence on a car is vital! Hence the conclusion - the brakes must always be in working order. To do this, it is necessary to bleed the brakes. Now we will do this. These are instructions on how to properly bleed the brakes, with which you can bleed the brakes on a VAZ 2112 with your own hands.

- Why do you need to bleed your brakes?

- When should you bleed your brakes?

- Tool

- Pumping the brakes

- Master brake cylinder

- Wheels

- Checking the brakes

System malfunctions

There are quite a lot of elements in the system, so it can be very difficult to determine the malfunction. The main malfunctions and their symptoms are described below:

- Braking is too slow.

A common problem that can be caused by grease or brake fluid getting into the friction area of the brakes. Also, a decrease in efficiency occurs due to wear or damage to the pads (only replacement will help). If the adjustment is made incorrectly, the system will overheat, and as a result, braking efficiency will noticeably decrease. Dismantling the amplifier - Increasing pedal stroke. Usually, with such a defect, the braking force decreases significantly, but sometimes it remains at the same level. The most common reason is a leak. First of all, you need to inspect the drums and calipers. If a damaged part is found through which the liquid escapes, it must be replaced. Air in the system hydraulic line can also cause an increase in stroke - to eliminate the problem, the brakes need to be properly bled (the process is described in detail below).

- After braking is completed, the “ten” wheels are partially released. The cause of the defect may be a violation of the protrusion of the adjusting nut on the vacuum booster rod. This malfunction can also be caused by jamming of one of the parts of the brake mechanism.

What does a hydraulic brake drive consist of?

1 – front wheel brake mechanism; 2 – pipeline contour “front left–rear right”; 3 – main cylinder; 4 – pipeline contour “front right – rear left”; 5 – tank; 6 – vacuum amplifier; 7 – rear wheel brake mechanism; 8 – drive lever (elastic); 9 – regulator; 10 – regulator drive (lever); 11 – brake (pedal); A – hose for the front brake; B – hose for the rear brake.

The VAZ 2110 car is equipped with a diagonally divided brake system. The first of the circuits is responsible for the front right and rear left (for their braking mechanism), the second - for the front left and rear right.

When one circuit fails, the second one comes into operation, which is also capable of stopping the car quite effectively.

The hydraulic drive includes:

- rear brake pressure regulator (9) - dual-circuit;

- vacuum booster (6).

The parking brake is activated by a lever that affects the rear brake mechanism.

Alarm Signals

The following symptoms are quite unsafe, please note:

- If the brakes are completely gone, then it’s clear that you can’t go any further, even to a service station! If independent repairs on site are beyond your capabilities, or simply impossible, you need to call a tow truck;

- When braking there is a strong vibration, especially felt in the steering column. You press the pedal, and it’s just hard to hold the steering wheel in your hands. There can be several reasons for vibration: • Many argue that vibration can occur due to the fact that there are non-ventilated disks. Their design is such that they really don’t like it when braking occurs in the rain, or even right in a puddle. No repair will help here - you need to replace the disks with ventilated ones; • Vibration may also occur if there is a problem with the rear drums. If upon inspection you find dark spots on the working surface, this indicates uneven wear. The vibration is usually very strong. Such drums need urgent repairs, and possibly replacement with disc brakes; • Check the front brake discs for deformation. At the same time, vibration is also observed.

- The brake pedal is too tight. There may also be several reasons for this: • A clogged air filter for the vacuum booster can cause the pedal to become stiff; • Check the vacuum booster itself. Its possible malfunctions are destruction of the diaphragm, tip, sticking of the check valve, damage to the hose connecting the intake manifold to the amplifier. In all these cases, a stiff pedal syndrome may occur, and repair of any of the indicated faults is necessary; • Also, the pedal may become stiffer as the pads wear, check them too.

- Hisses when you press the brake. If it hisses exactly when you press the pedal, you need to urgently check the vacuum booster, and then decide whether it needs repair or replacement. But if it hisses when you release the brake, then this is a normal phenomenon. Unless, of course, the hiss is too obvious.

Many, believing that the brakes are bad and repairs do not help them, decide on significant alterations and tuning. For example, tuning the brake system of a VAZ 2110 may include replacing the rear drum mechanisms with disc ones.

It is especially important to know here that braking of the rear wheels should be softer and occur a little later than the front wheels to prevent skidding. Another possible tuning idea is to replace the vacuum booster and the brake master cylinder

Instead of standard ones, they are installed from Lada Priora. This usually helps, first of all, in that vibration is not felt and the pedal works with optimal force.

Another possible tuning idea is to replace the vacuum booster and the brake master cylinder. Instead of standard ones, they are installed from Lada Priora. This usually helps, first of all, in that vibration is not felt and the pedal works with optimal force.

And do not forget - after each intervention in the brakes, they need to be pumped.

Amplifier (vacuum)

The vacuum amplifier consists of:

1 – amplifier housing; 2 – cups; 3 – rod; 4 – adjusting bolts; 5 – seal for the rod; 6 – sealing rings for the main cylinder flange; 7 – diaphragm springs (return); 8 – studs; 9 – flange for fastening the tip; 10 – valve; 11 – hose tip; 12 – diaphragm; 13 – amplifier covers; 14 – sealing cover; 15 – piston; 16 – protective cover of the valve body; 17 – air filter; 18 – pusher; 19 – pusher springs (return); 20 – springs on the valve; 21 – the valve itself; 22 – valve body bushings; 23 – buffers; 24 – valve body; Chambers: A – vacuum; B – atmospheric; Channels C and D.

Using the rubber diaphragm 12 and the valve body 24, the cavity of the vacuum amplifier is divided into chambers: atmospheric chamber B and vacuum chamber A.

Chamber A is connected to the engine inlet pipe using tip valve (return) 11 and a hose.

The housing 24 is made of plastic. The outlet from the cover is sealed with a protective cover 16 (corrugated). The valve body is equipped with: a master cylinder drive rod (3) with a support sleeve, a curtain buffer 23, a valve body piston 15, a valve 21, a pusher return spring 19, a valve spring 20, a valve, a pusher 18 and an air filter 17.

- Pressing the pedal.

- Moving the pusher 18.

- Piston movement 15.

- Following steps 2 and 3, valve 21 is moved all the way into the seat of the valve body.

- Chambers A and B are separated.

- The piston seat lags behind the valve and is connected to the atmosphere (through the formed gap in chamber B).

- Air enters through filter 17 and the gap between the valve and the piston, as well as through channel D.

- By performing step 7, pressure is created on the diaphragm.

- Since a pressure difference is created in chamber A and chamber B, the valve moves, followed by rod 3, which in turn acts on the piston of the master cylinder.

- When the brake pedal is released from the body seat, valve 21 moves away, creating a gap. Through this gap and channel C, chambers A and B communicate with each other.

GTZ malfunctions

The VAZ 2101 brake system has many parts that can fail due to wear, poor quality or untimely maintenance. The following characteristic symptoms of problems can be identified:

- slow stopping of the vehicle after pressing the brake pedal. One of the reasons is that the lip seals of the pistons have become unusable, which led to a loss of tightness;

- high pedal effort. This problem appears when the cuffs increase in size, for example, when installing a low-quality repair kit;

- The brake pedal has a short stroke. The working environment, i.e. the brake fluid, has nowhere to go due to the fact that the compensation hole is clogged. In addition, the canal may be blocked by swollen cuffs;

- The car only brakes when the pedal is pressed to the floor. This indicates a complete failure of the lip seals when the liquid goes into the tank and not into the system;

- Brake pads do not move away from the discs and drums, causing them to become hot while driving.

The reason lies in the jamming of one of the pistons or the formation of a blockage in the bypass hole. If the seal is lost, liquid begins to flow out of the cylinder

These symptoms may also occur if there are problems with other parts of the braking system. For example, the pedal may fail if there is no fluid in one of the wheel cylinders or if air gets into the system

Therefore, for a final diagnosis, it is necessary to pay attention to additional features of the car’s behavior. For example, there are certain signs that clearly indicate problems with other components of the brake system, and not with the GTZ:

- pulling the car to the side when braking;

- jamming of the brake mechanisms on one of the wheels;

- the appearance of sounds uncharacteristic of normal brake operation (creaking, squeaking, grinding);

- heating of brake pads or discs on one wheel.

Checking the brake master cylinder

The most common cause of GTZ problems is wear of the seals. When replacing cuffs, you need to take into account that repairs only make sense if the piston and cylinder walls do not have wear. Otherwise, replacing the rubber seals will not bring any results and soon you will still have to install a new part. Before you start checking the main hydraulic brake drive, you should make sure that there are no problems with other elements of the system:

- Inspect the wheels from the inner surface to identify any leaks of brake fluid from the brake fluid brake system.

- Check the integrity of the tank and hoses connecting it to the gas turbine engine, as well as the presence of fluid and its level.

Fluid leaks on the inside of the wheel indicate a leak in the brake system.

A clear sign that there is a problem with the master cylinder is the appearance of liquid on the unit body. A working mechanism should always be dry without a hint of leakage. If the hydraulic drive has lost its seal, it must be dismantled for further disassembly and repair. You can determine that the gas turbine engine bypasses fluid, i.e., it does not enter the system, but returns to the expansion tank when you press the pedal:

- Open the tank lid.

- An assistant is seated in the driver's seat. The engine does not start.

- Your partner presses the brake pedal, and you listen to the sounds coming from the reservoir.

- If gurgling is heard from the container, and the pedal is pressed lightly, it means that the liquid is entering the tank instead of the system. The malfunction lies in the wear of the seals, which are unable to create the necessary pressure in the cylinder circuits.

Leveling: detailed instructions

Bleeding is required to remove all air from the system.

In this work, it is important to remember that the circuit diagram is diagonal, so you need to bleed it as follows: first the rear wheel goes on the right side, then the front wheel on the left. In general, the work is done “diagonally”

To bleed, you will need a standard set of tools and materials: a jack, brake fluid, a set of wrenches and sockets, as well as screwdrivers.

First, consider working with a friend:

- The first step is to fill the reservoir with brake fluid to the “max” mark;

- Next you need to hang the rear wheelset. A screwdriver must be placed between the piston and the plate, thus blocking the brake mechanisms. The main thing is not to forget to take out the screwdriver after completing the work;

Now you need to insert a screwdriver between the plate and the piston

The cap must be removed from the air release valve. A clean hose must be placed on the valve head, the other end of which must be in a transparent container filled with brake fluid;

Place the hose in a container to drain the liquid

After this, the partner must press the corresponding pedal several times (the intervals between presses should be 1-2 seconds). When pressing the last time, the pedal must be pressed to the bottom and not released; The next step is to adjust the valve - it needs to be unscrewed 0.5-0.75 turns, after which liquid will begin to drip, along with it air bubbles will come out of the system. When everything comes out, the valve must be closed, while the partner must remove his foot from the pedal; Next, check the fluid level; if everything is in order, then reassemble in the reverse order.

To do the work yourself, you need to purchase a unit called “AERATOR”. Some people make the device with their own hands, but it is better to buy a ready-made unit for 70 rubles. Pumping is carried out as follows:

- The valve on the tank must be combined with the wheel valve using a new tool;

- The VAZ 2110 should be jacked up and the wheels should be hung;

- The bleeder fitting should be removed; the brake fluid will flow away due to the created compression;

- To do this, enough air from one tire.

Advice! Some motorists struggle with the air supply. The easiest way to do this work is with a pump that inflates tires. If there is a compressor in the garage, then it is better to use it.

Scheme and sequence of bleeding the brakes

The time has come to act.

In a VAZ-2112 car, you can pump the brakes in your garage, but it is advisable to involve another person. Prices at a car service center are decent, so it makes sense to save money and gain experience. Before starting work, it is worth remembering that in machines of the tenth family the system is designed so that the contours are not located horizontally, as on classic models, but diagonally.

- First you need to drive the VAZ-2112 into the inspection ditch. Now you should open the hood and find the brake fluid reservoir. Open the reservoir by unscrewing the cap, and then add new fluid to the max mark.

Problem in the operation of the central locking electrical circuit on VAZ cars

The first possible problem follows smoothly from those mentioned in the previous section. Overload in the operation of activators leads to an increase in the operating current in the supply circuit above the rated value. As a result, the fuse blows and the central locking of the VAZ 2110 simply “dies”.

It is by checking the fuse that the diagnosis of central locking malfunctions begins. By the way, it is located in a very specific place and it is not easy to find it right away even if you know where to look. In order to get to it, you will need to fold back the central panel with the fuses and dig into the entire wiring harness in the niche that opens behind it. The “comrade” you need is packaged in a special plastic cup and connected to the pink wire.

Central locking unit VAZ 2110

Another very common and obvious problem is the central locking connector. It is located in the most unfavorable place for this in the interior body, under the foot mat. A large amount of moisture and dirt inevitably gets there. Electrical contacts are intensively oxidized. As a result, the power supply circuit involuntarily breaks at the point where the plug connector is connected.

Leveling up

So, we come to the main question - how to properly bleed the brakes on a VAZ 2110. But the important point here is whether you are going to do the work yourself, or call a friend for help. Depending on this, pumping is performed in a slightly different way. Let's talk about each of them.

Self-leveling

If you couldn’t find an assistant, you can easily handle the task yourself.

Container with TJ

To get started, arm yourself with:

- Brake reservoir cap without sensors, regular black;

- Automotive nipple;

- Use a round file or a 14 mm drill.

- Make a hole in the lid, insert a nipple into it so that there are no gaps and the element fits tightly. This device replaces a ready-made aerator, which is sold in stores.

- Using the manufactured device, connect the valve of the spare tire or removed wheel with the valve of the reservoir.

- Jack up the car and remove all wheels.

- Unscrew the fitting intended for bleeding the brakes. The air will expel the brake fluid with air bubbles.

- If it is not possible to use a tire or you have a compressor, use it. Just make sure the pressure is no more than 1 atmosphere.

- Perform a similar sequence of procedures on each brake, following the sequence indicated above.

https://youtube.com/watch?v=jkYHTz9lNgM

With an assistant

If you still managed to find a partner to work with, that’s good. This way, pumping the brakes is not only more convenient, but also more fun. Plus, the quality of the operation is often higher.

Top up

The sequence of your actions in this case will be as follows.

- Check the car for brake fluid leaks.

- Add TJ into the tank to the maximum level. It is designated as MAX.

- Hang up the wheel on which you plan to bleed the brakes. You already know the sequence.

- The rear brakes have a pressure regulator that can be locked with a screwdriver. It is inserted between the plate and the piston.

- The brake device has an air release valve. Dry it thoroughly, remove the cap and place the rubber hose on the head.

- Prepare a transparent container with a volume of about 3 liters in advance and pour into it some of the brake fluid used in your car. The other end of the hose must be immersed in this brake fluid.

- Command your assistant to sharply press the brake pedal about 5 times in a row. During the last press, the pedal is held in the down position.

- While he holds the pedal, you open the valve about 50-75 percent and watch the brake fluid flow out through the hose.

- Initially, liquid with bubbles should come out. As soon as the leak stops, the valve closes.

- Is the valve closed? Then tell your friend to release the pedal.

- But this is not how the brakes on a VAZ 2110 are pumped in just one step. For a high-quality procedure, you will have to repeat it 3 more times. You need to achieve a result in which no air bubbles come out of the hose.

- Carry out a similar procedure with all brake mechanisms in the specified bleeding sequence. Don't forget to remove the screwdriver that is blocking the pressure regulator.

As you can see, bleeding the brake system is not as difficult as it might seem at first glance. The easiest way is to work together, since then the process is much easier and does not require the creation of any special devices.

The main thing in this matter is not to rush. Consistent operation, careful actions in a strict sequence of brakes. Doing all this yourself is not a problem if you competently tackle bleeding the brake system of your car.

Loading …

Pressure regulator (drive)

The pressure regulator drive consists of:

1 – pressure regulator; 2, 16 – bolts for fastening the pressure regulator; 3 – bracket for the pressure regulator drive lever; 4 – pins; 5 – pressure regulator drive lever; 6 – lever axis; 7 – lever springs; 8 – body bracket; 9 – pressure regulator mounting bracket; 10 – elastic lever; 11 – earrings; 12 – earring staples; 13 – washers; 14 – retaining ring; 15 – bracket pins; A, B, C – holes

How to bleed the brakes, aka the braking system on a VAZ 2110-VAZ 2112?

Note! Before you get to work, remember one thing for yourself, in cars of the tenth family the brake system is built in such a way that the contours do not go along one horizontal line like on the classics, but diagonally, for some these words mean little because not everyone will understand them, let's explain all these points in detail. To begin with, let's move a little away from the cars of the tenth family and talk about the classics, as many already know, the classics are the very first family of cars that appeared at the factory, later there were nines, tens, etc.

(Read the continuation in the “Important!” section at the very bottom of the article)

1) First, you will need to drive the car into the inspection hole and then open the hood and find the brake fluid reservoir there (shown with an arrow in the photo below), you open this reservoir by unscrewing the cap and then add it to the MAX mark new brake fluid.

Note! Do not under any circumstances add any other liquid, namely liquid from another manufacturer (Even if the composition is the same), and especially not underfill liquid of a different brand, because different additives are added to each liquid, and each manufacturer has their own, and therefore if you If you mix them, then the mixing will occur, thereby possibly ruining the brake system of your car, leading to corrosion, or the brakes will simply become ineffective! (If you don’t know what kind of fluid is in your reservoir, then replace the brake fluid; for information on how to replace it, see the article entitled: “Replacing brake fluid on a VAZ”)

2) After topping up, close the lid of the tank so that no air gets into it, or simply put it on top and after all this move under the so-called bottom of the car, and ask your assistant to sit behind the wheel of your car at this time and, by the way, give him some more hand brake fluid which he will periodically add to the system.

Note! If you have a question, why actually add liquid to the system, then we will now try to explain it. The whole point is that by pumping the brakes, we thereby remove air from the braking system, not many of you know, but still the air is very harmful to the operation of the brakes, or rather, nothing will happen to the system itself, the whole point is that when you press the brake pedal, the car stops your situation will be much worse than it should be, and all this will happen because of the air that accumulates in the system!

3) Next, explain to your assistant to monitor the level in the brake reservoir, namely, it should not drop below 15 mm during the entire pumping period, and it is better to generally add brake fluid to the reservoir more often, otherwise you never know.

Note! If it suddenly happens that the liquid in the tank completely leaves, then your system will depressurize again and then you will need to pump it again!

4) Next, ask your assistant to get into the car and tell him to press the brake pedal 5-10 times with smooth movements, and on the last press, tell him to squeeze it and hold it on the floor while you perform one operation at the same time.

5) So now to you, at this time (Depending on which wheel you are bleeding) remove the protective cap from the bleeder fitting, for example, on the rear wheel the bleeder fitting itself is located where shown by the arrow in the right photo, and on the front wheel this The part and its protective cap are located where indicated in the left photo:

6) So, you will need to remove this cap and put on the bleeder fitting the same hose that was mentioned at the very beginning of the article, and lower this hose with the other end into a small container which will be filled in advance with a little new brake fluid and after all the operations done, carefully loosen the fitting 2-3 turns and the waste liquid will begin to flow into the container, in which there will be air bubbles, so after the liquid stops flowing, tighten the fitting and then tell the assistant to remove his foot from the pedal and then do the same with the assistant operation but only until the liquid begins to come out without air bubbles. (The photo below shows an example on the front wheel; on the rear, everything is done identically)

Tool

What will you need to bleed the brakes on a VAZ 2112? Here is the list:

- Capacity (half liter bottle)

- Hose for bleeder fitting

- Wrenches for 8 and 10. You can have regular open-end wrenches, or you can have special bleeders. They look like regular caps, only with a slot. See photo.

Universal bleeder wrench 8 by 10 mm

- Brake fluid. This is not a tool, of course, but it will be useful. One bottle will be enough.

- Rust cleaner. WD-40 or cheaper equivalents.

- Metal brush

Checking the brakes

After bleeding the master cylinder as well as the wheel cylinders, you need to check the functionality of the brakes before you go on a trip. So:

- The first is the pedal. She must take it high. Pump the pedal a few times, then press and check if the pedal falls off when pressed for a long time. If it falls, we pump the brakes again or look for another reason (we diagnose the brake system).

- Before leaving the garage, press the pedal several times.

- Select a suitable, spacious area to test the brakes.

- Accelerate the car a little (first gear will be enough).

- Let go of the steering wheel and apply the brakes. If the brakes work correctly, then all wheels will brake (visible from the marks of braking) and the car will not pull to the side.

- If it pulls away, it means that one wheel is working weaker. The reason for this may be the presence of air in the brake circuit of the wheel or a malfunction of the brake elements (working cylinder, piston or pads).

Watch the video which clearly shows how to bleed your brakes. Take care of the condition of your car, and it will serve you for a long time and safely!

The main elements of the brake system of a modern car

Hydraulic drive

- this is the main type of design used to install a service brake system, which includes the following elements:

- pedal;

- amplifier (vacuum);

- network of pipelines and hoses;

- one main and several working cylinders.

Main task

– supply of liquid through pipes to the pistons located directly on the wheel. The force must be instantly transmitted from the pedal to the main mechanism, after which the pads, under the influence of hydraulic pressure, compress the brake mechanism. The main signs of a hydraulic line malfunction are a sinking or soft brake pedal and fluid leakage, which must be constantly topped up.

Replacing the brake cylinder on a VAZ 2110

may be necessary if liquid begins to leak from it - as a result, the tightness of the system will be compromised and its mechanisms will not work to stop the car. The wheel pistons push the pads apart, causing the disc to stop spinning. Failure of the listed elements is a direct threat to people's lives - the pedal will fail and in an extreme situation the car will not stop moving.

To replace it yourself, the car enthusiast will need to purchase the necessary parts and prepare the tools to carry out the “operation.”

Principle of operation

The driver presses the brake pedal; the rod coming from the pedal is connected to a vacuum booster, which further increases the pressure.

A rod also comes from the vacuum booster and is connected to the master cylinder piston.

The fluid in the lines of the front wheels presses on the piston of the working cylinder, which presses one pad to the disc, at the same time the caliper moves and presses the second pad.

At the same time, the fluid flows through the lines of the rear mechanisms to the regulator, where the pressure is adjusted and then to the mechanisms themselves.

There, the fluid presses on the pistons of the working cylinders, they come out of the cylinder and unclench the pads, pressing them against the brake drum.

The complete diagram is shown below.