How does a mechanic diagnose a P0342 code?

First, the mechanic reads all stored error codes using an OBD-II scanner. He will then check and, if necessary, repair or replace all damaged wires, connectors and other electrical components of the system. The mechanic will then clear the error codes from the PCM memory and recheck the system. If the error code appears again, the mechanic will check the battery charge and also inspect the starter motor. It will then clear the error codes from the PCM memory again and check the system to see if P0342 appears again. This procedure must be performed every time after repair work is performed. This will help determine if the problem is resolved.

Motor Master Club

- ANNOUNCEMENTS, INFORMATION

- ↳ RULES

- ↳ Announcements

- ↳ Articles

- TECHNICAL SUPPORT

- ↳ Installation and update of “Motor-master” software

- ↳Motor-scan (scanner)

- ↳ Archive (questions about the scanner)

- ↳ Motor-Loader (loader)

- ↳ DiSco, DiSco-Express, Motor Tester, Test Master

- ↳ History of changes

- ↳ Other devices and sensors

- ↳ Alphameter ALC

- ↳ Archive (Questions to the manufacturer)

- MOTOR-MASTER

- ↳ Disco (oscilloscope, recorder, etc.)

- ↳ Motor-Tester (ignition systems)

- ↳ DiSco-Express (express diagnostics)

- ↳ Test Master (testing sensors and MI)

- ↳ Motor-Loader (loader)

- ↳ General questions

- ↳ Chip tuning VAZ, GAZ, UAZ

- ↳ Chip tuning of foreign cars

- ↳ Odometers (odometer programmer)

- ↳ General questions

- ↳ Removal and disassembly of instrument panels

- ↳ Help for newbies

- DIAGNOSTICS

- ↳ Diagnostics VAZ, GAZ, UAZ, ZAZ

- ↳ VAZ

- ↳ GAS

- ↳ UAZ

- ↳ ZAZ

- ↳ Diagnostics of foreign cars

- ↳ Europe

- ↳Japan

- ↳ Asia

- ↳America

- ↳ Diagnostics of diesel engines

- ↳ “Iron” questions

- ↳ Engines

- ↳ Power systems (hardware)

- ↳ Chassis

- ↳ Transmissions

- ↳ Body

- ↳ Exhaust system

- ↳ Lubricants

- ↳ Tools and consumables

- ↳ Selection of spare parts and components

- ↳ Diagnostic devices

- ↳ Electrical and electronics

- ↳ Autoelectrics

- ↳ Alarm and music

- ↳ Repair of ECU and other units

- ↳ Miscellaneous

- ↳ Section for beginners and car owners

- AUTHOR'S MATERIALS and PROGRAMS

- ↳ Section information

- ↳ Vijar

- ↳ kdv

- ↳SAW

- ↳ DataLook (program for configuring firmware)

- ↳ sts1968

- COMMERCIAL FIRMWARE

- ↳ About the Motor-Master Chip firmware store

- ↳ Articles and materials for beginners and more…

- ↳ Chip tuning

- ↳ Diagnostics

- ↳ Devices and accessories

- ↳ Information materials

- ↳ Representatives of Motor Master

- ↳ VAZ

- ↳ UAZ

- ↳ KOREA

- ↳Kefico 797

- ↳ Kefico M(G)798 Kia-Hyundai

- ↳ Bosch ME17911(12) Kia-Hyundai

- ↳Bosch ME17921

- ↳ RENAULT

- ↳EMS3132

- ↳ Valeo 40/42

- ↳EMS3120

- ↳EMS3125

- ↳CHEVROLET

- ↳ Simtec 7.6

- ↳ Announcements

- GENERAL ISSUES

- ↳ General questions

- ↳ Site operation

- ↳ Communication

- ↳ Flea market

- ↳ Car services (offer of services)

- ↳ All about our work

- ↳ Computers, laptops, etc.

- Moved topics

Additional comments for troubleshooting P0342

The camshaft position sensor is an integral part of the system that allows the vehicle to operate reliably, smoothly and quietly. If the sensor does not operate properly, symptoms will occur indicating a problem. If the problem is not solved for a long time, it can lead to more serious problems. Therefore, if a P0342 error is detected, it is recommended that you contact a qualified technician as soon as possible to diagnose and resolve the error.

It should also be noted that if this error code is stored in the PCM and the Check Engine Light illuminates, the vehicle will most likely fail an emissions test.

Bringing the Chevrolet Lacetti to Mind

18.11.2020 . . I decided to remember from the very beginning how this problem began with the camshaft position sensor, with its Error P0342 - weak signal. Maybe it will be useful to someone. After I installed the new original sensor GM# 96253544, several problems disappeared. Now we can say with confidence that the culprit was the camshaft sensor itself. It all started after 4 years of operation, at which time the mileage was about 50,000 kilometers. Usually I came to the garage in the morning, and the car started with half a turn. But as soon as I left the garage, turned off the engine, went to lock the locks on the gate, got back into the car and started the engine, the first time it wouldn’t start, and the second time again with half a kick. It used to happen when it’s hot - you go into the store for cigarettes, you come out, and the engine starts the second time. Naturally, there were no errors, and the thought began to appear that the injectors were not holding well. And at the moment of starting, a rich mixture is obtained in the cylinders. Then the engine turns over, and the incoming air expels the rich mixture, and the second time everything starts. The same thing happens on carburetor cars when the carburetor overflows. But all this happened very rarely, maybe twice a month, so it didn’t cause me much trouble, but it was still unpleasant. Over time, this problem began to appear more often - perhaps a couple of times a week. There were no mistakes.

And just at this time I started working on firmware. And just in the same summer, Error P0342 popped up for the first time - a weak signal from the camshaft sensor. Based on the logs and old videos, I was able to figure out that the error occurred on the same day that I installed the firmware from Icebreaker . Pay attention to this, since we will return to the Icebreaker later. The firmware is playful, economical, 850 rpm at idle, which seems to be all the engine needs. Many people like this firmware, and everything is fine with them, but it turned out that not everyone did. Personally, when washing my car, when the engine braking mode is turned on, it’s as if someone sharply tugs the tail once. And I know several other comrades who have the same problem on the Icebreaker firmware. At that time I thought, but I still didn’t understand why this was happening. Then I installed other firmware, looking for something that the engine, and therefore me, would like. A whole year passed like this. On other firmwares, no one pulled the tail, but I had already forgotten about Error P0342. But it turned out that she had not forgotten about me, and this summer she began to come out almost every month. Then I decided not to eliminate all possible problems at once, because then you won’t understand what was causing it, but I checked one thing, drove it, looked, then another. In general, this is the sixth video about the camshaft sensor. You probably remember that in the fourth video I tried to change the position of the DPRV itself, moving it to the right side. And then I noticed that in this position the sensor stands a little further from the camshaft pulley. And if something happens, I have the last option - to press it closer with the help of a construction pencil, it was just the right thickness. And then we got ready to go to our relatives in Sharya. Usually this trip takes me about 800-odd kilometers. And in order to save gasoline for this trip, I decided to re-upload the firmware from Icebreaker EURO 2 , since it is the most economical for my engine. And on the highway, engine braking is activated very rarely. I went to the garage, started it half a turn, drove up to the house, went to get my laptop and uploaded the firmware. I started to start it, but it wouldn’t start. The second time I didn’t let go of the key - first I grabbed it, then it stalled, but it started. And immediately Error P0342 popped up. But I had one last option - to insert a construction pencil and press the sensor closer to the camshaft pulley. I tried it on, broke off a pencil to size and inserted it. The sensor moved almost close. I cleared the error and started it again - it started with half a kick and even somehow softly. I decided to take a ride and - OH A MIRACLE! The Icebreaker's firmware stopped pulling the car's tail when braking with the engine. It appears that this firmware does not like a faulty camshaft sensor. In short, we went to Sharya, came back 4 days later, drove around the city for a couple of days - there were no errors, it started with half a kick, no one pulled the tail. And then I receive an SMS saying that your order is ready, come and pick it up. This is a new original camshaft sensor GM# 96253544 MADE IN CHINA for 2,600 rubles.

I went to the store and felt that somewhere in the middle of the journey the tail tugging started again when braking the engine. Then I started turning on neutral, I looked, and the speed began to freeze. The tachometer needle drops to 1,800, then rises to 2,000, and so on a couple of times. Then it drops to 1,000, then to 1,200, again to 1,000 rpm. And so he walks until the car comes to a complete stop. Apparently the old sensor realized that he was going to be fired and decided to die right on the job. I went to the store, picked up a new sensor and drove back. I’m driving and thinking, shouldn’t I check the DPRV again as a last resort, so that I can install a new one with peace of mind. I pulled into the parking lot, disconnected the chip from the crankshaft sensor and started running it on one camshaft sensor. The engine started reluctantly, but ran fine. Then my wife called, and I talked to her for about three minutes. I started putting the phone in my pocket, and my engine stopped. I launched it again and waited about five minutes - it worked as if nothing had happened. I drove about a kilometer and stopped at a traffic light. Everything is fine - everything works. But as soon as the light turned green, it died out again. I'm about to start, but the engine doesn't want to start at all. I had to turn on the emergency lights, run out of the car and reconnect the crankshaft sensor chip. The engine started immediately. Here my assumptions were 100% confirmed that the sensor sometimes works, sometimes it doesn’t, and the error simply does not have time to pop up. Even with the chip removed from the camshaft sensor, it only pops up the third time the engine is started.

The next day I replaced the sensor, but placed it offset to the right side; if anything, I’ll return it to the vertical factory position. It started with half a kick, and even the engine began to run somehow softer. I didn’t go anywhere that day, but went to the garden the next day. But the Icebreaker’s firmware also jerked when braking with the engine, and the revs in neutral also floated to a complete stop, as on the old sensor. The first thought is that the sensor is defective. In the garden I checked the entire throttle assembly and found nothing suspicious. I reset the adaptations with a smartphone with ELM 327 and went home. The revolutions began to drop normally, then float again. The next day I moved the new camshaft sensor to the factory vertical position. And immediately everything settled down - the speed does not fluctuate, and the Icebreaker’s firmware does not pull the tail when braking the engine. And the question immediately arose - why does the sensor work better for some when shifted all the way to the right, while for others it works better in the factory vertical position? I won’t throw out the old sensor, but I’ll try to revive it. Throwing away 2,600 rubles every time is a bit expensive, and many people complain about non-originals that they don’t work and begin to believe in the proverb that the miser pays twice. Using a tester, I found poor contact between the signal and negative contacts of the sensor when it was bent. Either there is contact or there is no contact. And it does not leak inside the sensor itself. Most likely at the junction of the external contacts that we see and on which the chip is placed - with the internal contacts. Now I realized that when I inserted a construction pencil to bring the sensor closer to the pulley, what played more was that the sensor simply bent, the contacts were restored and the sensor worked without interruption for almost a whole week. To make it clearer, I inserted a piece from the following video about resuscitation of the DPRV. It shows how the instrument needle twitches when the sensor is bent, and the sensor is on the engine, and there is always vibration when the engine is running. What kind of signal can the ECU receive from the sensor, when there is contact, then there is none. It’s good if the sensor dies immediately, but in this situation the error may not appear at all. So one of these days I’m going to dig out the old sensor, get to the junction of these contacts and solder it. At least the people on Drive2 write that they managed to restore the sensor in this way. So we will dare.

. . 11/25/2020 Already wrote an article and made a video Repairing the Camshaft Sensor .

Go to Main page

Self-diagnosis

The easiest and most common way to diagnose error codes on a VAZ Kalina is to search using the on-board network. The procedure looks like this.

Insert the key into the lock cylinder. Next, hold down the RESET key and, without releasing it, turn on the ignition. In this case, the device will automatically switch to diagnostic mode. At the same time, all the indications will light up, and the instrument arrows will make a full circle.

You should pay attention to the arrows and indicators - if any diode does not light up, you need to check the device for which the element is responsible. On the right steering column lever there is a button for scrolling through the options - you need to scroll to the required position (error codes). Next, the display will show the general error number; to reset the index, you need to hold RES for three seconds.

Note! The indicated sequence is relevant for Lada Kalina of the first and second modifications.

The position of the error codes will show one of the indices on the display:

- “2” – there is a surge in the BS power supply – a possible short circuit in the wiring;

- “3” – rupture of lines, or failure of the float inside the gas tank;

- error 4 Lada Kalina says that the coolant temperature sensor is broken or malfunctioning;

- “5” – the thermometer has gone astray, the element may be damaged or the circuit may be broken;

- “6” – exceeding the maximum permissible temperature of the internal combustion engine block, while the acoustic alarm is working;

- “7” – exceeding the permissible pressure thresholds inside the oil line;

- “8” - on a Lada Kalina car, error 8 appears when there is a malfunction of the calipers or a breakdown in the hydraulic drive line;

- “9” – critical voltage drop in the battery;

- “E” – incorrect reading or display of the EEPROM information module.

To return to the original part, it is enough to hold RES for 30 s. The disadvantage of this method is minimal accuracy - the procedure shows in which direction to look for a breakdown, but not a specific node. So, it is possible to understand exactly where the failure occurred only by the following method.

DESIGN FEATURES AND OPERATING PRINCIPLE

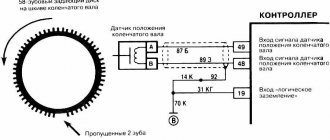

The VAZ 2114 FAZ sensor is an integrated device, the main function of which is to receive information about the current operating cycle of the power unit and transmit it to the ECU via pulse signals.

Structurally, the DF consists of two parts - a sensitive element and a pulse signal converter, which in turn consists of an operational amplifier, a bridge circuit and an open-collector type output stage.

The DF sensitive element operates according to the Hall principle; it is a microcircuit that responds to fluctuations in the magnetic field, which gains the ability to transmit an electrical signal only when there is a magnetically conductive material next to it, which is the steel head of the valve.

The location of the VAZ 2114 camshaft position sensor is as follows: it is located on the end of the cylinder block, not far from the air filter.

There is a lot of discussion on the Internet about which phase sensor is best to buy from which manufacturer. We recommend giving preference to devices from the German company Bosch. It is she who has the license to manufacture sensors operating on the Hall principle, so, in essence, you get a reliable and durable device produced by the direct owner of the technology by which it is made.

Deciphering codes, checking devices

Mistake No. 2. Overvoltage. Error No. 3. An error has been detected in the fuel sensor level; it occurs if the circuit is broken.

Error No. 4. Coolant temperature sensor error. Error No. 5. The outside temperature sensor has failed. Error No. 6. The motor has overheated. This happens if the engine overheating alarm is triggered. Mistake No. 7. Oil pressure is in poor condition. Happens if the alert bell is triggered. Mistake No. 8. Problems with the brakes. Happens if the alert bell is triggered. Mistake #9: The battery is dead. Happens when the alert bell is triggered.

To reset all types of errors, press and hold the reset button until all data on the display is cleared. Testing of devices and their combinations is carried out in accordance with technical specifications using special equipment (pulse generator, from a stable power source, etc.). If a short circuit suddenly occurs in existing devices (less than 40-50 Ohms), the maximum temperature indication must prevail.

Before buying a car, I recommend checking the errors of the on-board computer to be sure of the iron horse. If you have identified any problems, we give you the opportunity to familiarize yourself with the error code of the on-board computer.

First of all, you need to watch the video.

The process of launching the instrument panel diagnostic mode, I think, became clear from the video, and below we will now look at the main error codes that may appear on your on-board computer display: Lada Kalina on-board computer error codes

2

- increased voltage of the vehicle's on-board network

3

- error in the fuel level sensor (if an open circuit of the sensor is detected within 20 seconds)

4

- error in the coolant temperature sensor

5

- error in the external temperature sensor

6

- engine overheating (the criterion for triggering the acoustic signal is met)

7

- emergency oil pressure

8

- brake system defect

9

- battery discharged

In the video above, it was clear that I was displaying errors 4, 6 and 8. With four, everything is clear, as I read many reviews, this error always appears on a cold engine. As for number 6, here most likely there is data in the memory of the on-board computer about the engine overheating alarm that once tripped. If my memory serves me correctly, this happened when I had to trail behind a scraper at a speed of 10 km/h for a couple of kilometers in 40 degree heat. But fortunately, immediately after the signal went off, I was able to drive onto a repaired section of the road and quickly cool down. Regarding the defect in the brake system, I can say the following: the warning lamp for insufficient brake fluid level came on quite often at the same time, and I wrote about this problem here: the brake fluid level lamp is constantly blinking.

Fortunately, my Kalina did not have the rest of the errors listed above. Resetting the readings is very simple, again by pressing the daily mileage button.

Attention! If you decide to buy a used Kalina, then be sure to go through the diagnostic procedure and look at the errors that the computer shows. Surely not every owner knows about this and will reset them

And the information may be very useful for you. For example, the car’s engine has already overheated or the engine pressure warning light has tripped, and this is already a serious reason to refuse to buy such a car.

If you decide to carry out maintenance on your car, I advise you to read the article about replacing the fuel filter on a Lada Kalina with your own hands.