The car’s braking system (English – brake system) refers to active safety systems and is designed to change the speed of the car until it comes to a complete stop, including an emergency stop, as well as to hold the car in place for a long period of time. To implement the listed functions, the following types of brake systems are used: service (or main), spare, parking, auxiliary and anti-lock braking systems (exchange stability system). The totality of all braking systems of a car is called brake control.

Working (main) brake system

The main purpose of the service brake system is to regulate the speed of the vehicle until it comes to a complete stop.

The main braking system consists of a brake drive and brake mechanisms. In passenger cars, a hydraulic drive is predominantly used.

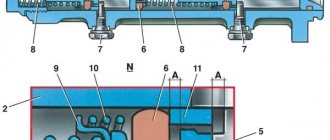

Car brake system diagram

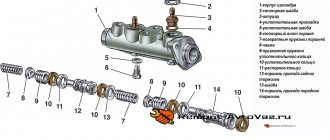

The hydraulic drive consists of:

- master brake cylinder (MBC);

- vacuum booster;

- pressure regulator in the rear brake mechanisms (in the absence of ABS);

- ABS unit (if equipped);

- working brake cylinders;

- working circuits.

The brake master cylinder converts the force applied by the driver to the brake pedal into the pressure of the working fluid in the system and distributes it among the operating circuits.

To increase the force creating pressure in the brake system, the hydraulic drive is equipped with a vacuum booster.

The pressure regulator is designed to reduce the pressure in the brake drive of the rear wheels, which contributes to more efficient braking.

Types of brake system circuits

The brake system circuits, which are a system of closed pipelines, connect the main brake cylinder and the wheel brakes.

Circuits can duplicate each other or perform only their functions. The most popular is the dual-circuit brake drive circuit, in which a pair of circuits operate diagonally.

Outlines

The disadvantage of the hydraulic system is the possibility of a breakdown of the line, as a result of which the fluid leaks out and the service brake stops working.

To eliminate the possibility of complete brake failure, the system is divided into two independent parts - circuits. To do this, it was only necessary to make the main cylinder two-piston. Each of the pistons pushes fluid into a line that connects only two brake mechanisms. One section of the master cylinder, two mechanisms and the pipelines connecting them form a circuit. On some cars, one circuit goes to the front wheels, and the second to the rear wheels. But more often a diagonal arrangement is used, in which the circuit includes one front and one rear wheel, located on different sides.

Types of contour systems

The use of independent circuits allows you to slow down traffic even with a broken highway. In this case, only two working mechanisms fail, while the rest continue to work.

The structure of the car brake system

Brake system

The basis of the braking system is the brake mechanisms and their drives.

The brake mechanism is used to create the braking torque necessary to brake and stop the vehicle. The mechanism is installed on the wheel hub, and its operating principle is based on the use of friction force. Brakes can be disc or drum.

Structurally, the brake mechanism consists of static and rotating parts. The static part of the drum mechanism is the brake drum, and the rotating part is the brake pads with linings. In a disc mechanism, the rotating part is represented by a brake disc, and the stationary part is a caliper with brake pads.

The drive controls the brake mechanisms.

The hydraulic drive is not the only one used in the braking system. Thus, the parking brake system uses a mechanical drive, which is a combination of rods, levers and cables. The device connects the rear wheel brakes to the parking brake lever. There is also an electromechanical parking brake, which uses an electric drive.

The hydraulically driven braking system can include a variety of electronic systems: anti-lock braking, stability control, emergency brake assist, and Brake Assist System.

There are other types of brake drive: pneumatic, electric and combined. The latter can be presented as pneumohydraulic or hydropneumatic.

Advantages of disc brakes

Compared to drum brakes, disc brakes have a number of advantages:

- The surface of the elements practically does not change when heated due to their high temperature stability. Therefore, even if the disc is at a sufficiently high temperature, the braking torque does not deteriorate.

- The holes on the disk contribute to high air cooling efficiency.

- When braking, the pads adhere to the disc with the entire surface of the lining, which increases the sensitivity of the system and reduces the braking distance.

- The disk mechanism is more compact and has less weight.

- Disc brakes respond faster when you press the pedal than drum brakes.

- Effective damping of inertia by front disc brakes (up to 70%).

In addition, replacing brake pads is easier and faster, since the linings of such strips do not need to be adjusted and ground.

In this material, we looked at how the braking system works, figured out its structure and types. To summarize, we recall that its serviceability must be constantly and carefully monitored, promptly replacing failed parts. A careless attitude can lead to serious consequences, since driving safety directly depends on the serviceability of the braking mechanism.

The principle of operation of the braking system

The brake system works as follows:

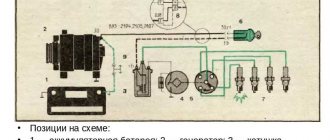

- When the driver presses the brake pedal, a force is transmitted to the vacuum booster.

- It is then increased in the vacuum booster and transferred to the main brake cylinder.

- The GTZ piston forces working fluid to the wheel cylinders through pipelines, due to which the pressure in the brake drive increases, and the pistons of the working cylinders move the brake pads to the discs.

- Further pressing of the pedal increases the fluid pressure even more, due to which the brake mechanisms are activated, leading to a slowdown in the rotation of the wheels. The pressure of the working fluid can approach 10-15 MPa. The larger it is, the more effective the braking occurs.

- Lowering the brake pedal causes it to return to its original position under the action of the return spring. The GTZ piston also returns to the neutral position. The working fluid also moves to the brake master cylinder. The pads release the discs or drums. The pressure in the system drops.

Important! The working fluid in the system must be changed periodically. How much brake fluid will be needed per change? No more than a liter and a half.

The science of stopping...

Here, friends, is a parachute brake that reduces speed and kinetic energy so that a pilot ejected from an airplane or from a simulator lands safely on the ground.

See also: Basic principles of operation of the car brake mechanism [Operation principle and elements of the brake system]

If you are moving, it means that you have energy, that is, kinetic energy to be precise. Kinetic energy is the energy that a certain object has because it has mass and velocity (speed in a certain direction). The more mass (that is, the heavier the object) and the faster you or the object moves, the more kinetic energy you or the object will have.

All this is of course good, but what if you suddenly need to stop? How do you go from moving quickly to not moving at all? To do this, you or the object need to get rid of its kinetic energy.

For example, if you are jumping from a high altitude from a flying airplane, then the best way for you to lose energy would be a parachute. Thanks to the giant “bag of fabric” that flies after you, the movement slows down, that is, the speed of the fall decreases, and therefore the parachute helps you get rid of your own kinetic energy.

As a result, the parachute allows you to land safely and smoothly on the ground unharmed.

By the way, powerful dragster cars, which are record holders for acceleration from a standstill and with them sports cars that can accelerate to record speeds, also use parachutes for stopping. But most ordinary cars, as you yourself know, use a traditional hydraulic braking system, which was invented at the beginning of the 20th century, to stop and reduce speed.

Basic malfunctions of the brake system

The table below shows the most common malfunctions of the car brake system and how to fix them.

| Symptoms | Probable Cause | Solutions |

| I hear a whistling or noise when braking | Wear of brake pads, their low quality or defects; deformation of the brake disc or contact with a foreign object | Replacing or cleaning pads and discs |

| Increased pedal travel | Leakage of working fluid from the wheel cylinders; air entering the brake system; wear or damage to rubber hoses and gaskets in the GTZ | Replacement of faulty parts; bleeding the brake system |

| Increased pedal force when braking | Vacuum booster failure; hose damage | Replacing the amplifier or hose |

| Braking of all wheels | Piston jamming in the GTZ; lack of pedal free play | Replacement of GTZ; setting the correct free play |

Pumping is the final stage of repair

Start-stop system: what is it and how does it work?

When the entire system has already been completely rebuilt and assembled, all that remains is to fill in the brake fluid and properly bleed the hydraulics. The system is pumped in order to expel air bubbles from all tubes and cylinders, which prevent the hydraulics from working correctly.

There are many ways to bleed the hydraulic brakes of a bicycle. Anyone can do this at home if they know how to use tools at least a little. Some people use syringes, while others use old and proven methods. Let's consider the simplest and time-tested option.

To bleed the brakes you will need the following components:

- a transparent tube matching the diameter of the bleeder bolt;

- brake fluid or oil, depending on the specific system;

- necessary keys;

- jar or bottle;

- a piece of clean cloth to keep clean.

First you need to put a transparent hose on the bleeder bolt, and lower its other end into a jar that should contain some brake fluid. Next, you need to open the brake fluid reservoir on the handle and make sure that it is at the maximum level. If necessary, liquid must be added.

After this, you can start bleeding the disc brakes on your bike. After pressing the brake handle several times, you need to lock it in the pressed state and at the same time unscrew the bleeder screw on the brake machine. In this case, you can observe how air bubbles come out of the tube. After this, you need to tighten the screw immediately, and only then you can release the handle and pump it again.

This procedure must be done several times until the entire system works as it should. This can be felt by the stiffness of the brake lever.

Video clearly showing the pumping procedure:

And one more way to pump a hydraulic line for the lazy: