- Take a deep breath and don’t breathe. - Don't breathe. - Don't breathe. - Don't breathe. - You wear. - Next!

Let's start with a first understanding of what exactly we are setting up and why. Our interest here is the air to fuel ratio (AFR) supplied to the combustion chamber. This indicator affects the behavior of the combustion process and can serve both as safe indicators aimed at engine operation at medium loads and at operation at the limit, with maximum power output. Even a small change in the mixture ratio parameters will dramatically change the behavior of the machine. It is important to understand “how, why and for what” you change these parameters.

The gasoline/air ratio in which the entire mixture burns completely is considered stoichiometric (ideal). For gasoline/diesel, the ratio is approximately 14.7 parts air to 1 part fuel (14.7:1).

A mixture with a greater (than ideal) ratio of fuel to oxygen is called rich, respectively, a mixture with more air (more than ideal) is called lean.

In fact, in almost all cases, a rich mixture should be the goal; it is much safer and more reliable for the engine because... A lean mixture ignites faster and increases the load on the engine.

The table summarizes the basic influence of AFR on engine behavior and vehicle dynamics and should serve as a general guide in determining the air/fuel ratio on vehicle power at wide open throttle.

Lambda sensor reading

You noticed in the table that the lambda produces some numbers. Where do they come from? The lambda figure is the ratio of the current mixture to the ideal, i.e. (ideal, as we remember, 14.7:1) means for a mixture of 12.8:1, lambda will be equal to (12.8 divided by 14.7) - 0.87. We compare it with the table - and it’s true!

Having real-time lambda sensor readings, you can get any result based on your needs and the fuel poured in, because Each fuel requires its own fuel/air ratio.

There are two types of lambda sensor: Wideband and Narrowband.

The oxygen sensor traditionally used by most OEM manufacturers is a narrowband sensor. This sensor is used to measure AFR over a very narrow range (hence the name), and only accurate to that narrow range. The sensor typically has a 0-1 voltage output and will be most accurate at lambda-1 (stoichiometric).

Read also: Nissan heater motor repair

Such a sensor accurately displays lambda only in the range from 14.2 to 15.0. If the mixture parameters are above or below the range, then the sensor is simply ignored by the brains of the machine, because it absolutely does not accurately show data outside the range, which means its indicators cannot serve as a criterion for adjusting the mixture. The vehicle's fuel system simply does not "listen" to this sensor under extreme conditions, such as wide open throttle or heavy loads, where conditions are too rapidly changing and the fuel/air mixture ratio is outside the lambda sensor's range.

The purpose of these factory-installed sensors is to control the vehicle in moderate operating conditions, such as highway driving, and to monitor errors in the vehicle's fuel management system. These operations are essential to maintaining proper emissions levels and maximizing fuel economy and performance.

As we can see from table No. 1, for maximum power and torque you need a fuel/air ratio far beyond the operating range of a narrow-band lambda sensor. However, a narrow-band sensor works much more accurately in its range than a wide-band sensor works in its range, which is probably why they are placed together. Wide stripe is for meat, narrow stripe is for driving.

Wideband sensors have a much wider accuracy range from 7.35 to 22.39. This allows the sensor to increase its range to measure the air-fuel ratio under all engine operating conditions. This information is critical when tuning your engine.

So we tried to get a smooth understanding of the fuel mixture, and although it probably turned out crooked, we will try!

SUBARISTS FOR FREE KNOWLEDGE!

© Roman Grishin, there must certainly be a continuation

Engine power, and, consequently, the speed, acceleration and jerk of a car directly depend on the characteristics of the energy carrier - gasoline. But you can’t fool amateurs and professionals; they know very well that in the cylinders of the internal combustion engine hidden under the hood of their favorite car, it is not liquid gasoline or diesel that burns, but a fuel-air mixture. It is its composition, the ratio of the mass of atmospheric air to the mass of liquid fuel, that allows you to accelerate to maximum speed, make a breakthrough during an overtaking maneuver, or overcome a steep climb.

Fuel-air mixture - basic concepts

A finely dispersed mixture of atmospheric air and liquid fuel with a small inclusion of the vapor phase is called a fuel-air mixture or fuel assembly. It is this that, burning in the engine cylinders, gives translational motion to the pistons and ensures the movement of the car.

Read also: Rear view camera connecting to a computer

Depending on its structure, a fuel assembly can be homogeneous (uniform in composition) or have a layered structure. Depending on the type of load, the specified fuel economy parameters, and the required composition of the exhaust gases (the content of harmful substances and nitrogen oxides), the fuel injection system independently selects the most optimal structure of the fuel-air mixture.

Mixture formation in diesel engines

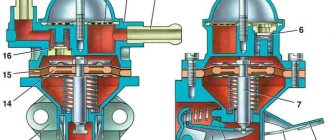

The mixture formation process is mainly determined by the interaction of the injected fuel jet with the air flow field in the combustion chamber.

The problem here is the rapid injection and preparation of relatively large masses of fuel, up to 200 mg per liter of displacement. Typical injection duration is about 1 ms. The term used to refer to the mass flow rate of fuel entering the combustion chamber is injection rate (unit: kg/s). Fuel injection is usually carried out using multi-hole injectors. Typically a combination of holes with a diameter of 120 to 150 µm is used. Fast fuel injection and mixture formation are facilitated by the small diameter of the holes and high injection pressure, reaching 2000 bar.

Initially, the diameter of the fuel jet is equal to the diameter of the hole. However, after traveling a few millimeters, the jet breaks up into individual droplets that interact with the flow field. The liquid phase of the fuel jet, depending on the density of the working medium, can penetrate several centimeters into the combustion chamber before it is completely atomized or evaporates (see Fig. “Propagation of the fuel jet and mixture formation in diesel engines”).

Turbulence promotes the formation of fuel droplets and evaporation. In modern diesel engines, more than 80% of the turbulence in the fuel jet region is generated by fuel injection. The development of turbulence is facilitated by the movement of the fuel charge, and on diesel engines with a flat cylinder head, horizontal turbulence predominates. Additional contributions may come from compression-induced air flows directed from the outer to the inner region of the combustion chamber (“compression flows”) or from a combustion chamber design that, for example, contacts the hot region of a recess in the piston to promote evaporation.

Over the past few decades, direct fuel injection systems have demonstrated their advantages over indirect injection systems such as swirl chamber or prechamber systems. In systems with indirect fuel injection, fuel preparation is mainly carried out through the formation of a local flow in the pre-chamber.

Lean and rich fuel assemblies, components and dosing systems

The empirical formula defines a “normal” fuel assembly as a mixture of 14.7 kilograms of atmospheric air and 1 kilogram of liquid fuel. A fuel mixture in which the amount of air is greater than that specified in the ratio is called lean, and, accordingly, rich, with less air.

- poor - air > 14.7

- rich - air » alt=»»>

Uniformity can be achieved by injecting a small amount of an enriched mixture into the ignition zone as a catalyst for the oxidation reaction. In carburetor engines, an additional intake valve is used to solve this problem, and injection systems are equipped with a dual-mode nozzle.

Reasons for the formation of a rich or lean mixture

Most often, a rich mixture is formed not because more fuel is supplied than necessary, but because less air is supplied than necessary. The most common and common reason is a clogged air filter. Unfortunately, many motorists forget that some components need to be changed regularly, even if they look like new. The air filter is one of these components; it needs to be changed at least every 30 thousand kilometers, and on powerful cars - even more often.

Also, the air supply can be “cut off” by a malfunctioning air pressure sensor - it needs to be adjusted. Paired with it is a fuel pressure sensor, which can also supply underestimated data to the engine's electronic control unit. Based on them, the block begins to pump more fuel into the cylinders, enriching the mixture. As we learned above, it worsens power and dynamics, the control unit doesn’t like it, and it supplies even more gasoline. Hence the greatly increasing fuel consumption.

The reason for the rich fuel mixture may also be hidden in the electronic engine control unit itself. These could be errors in his program, but also incorrect changes made to it. Self-taught craftsmen and simply unskilled craftsmen “tune” the control unit, deliberately increasing the proportion of fuel in the mixture. This way you can achieve a small increase in power, but it is much easier to upset the balance and achieve the opposite result.

The fuel pump can also disrupt the proportions of gasoline and air, pumping much more fuel into the system than necessary. And the most difficult reason to determine is malfunction of the injectors in the cylinders. They can become clogged or deformed, and then the balance of the air-fuel mixture can fluctuate in any direction.

Use of lean and enriched fuel assemblies

- An attempt to reduce fuel consumption by adjusting the fuel system often leads to unpleasant consequences. An increase in the amount of air in the fuel mixture increases the combustion temperature and leads to premature engine failure. Burnout of piston rings and erosion of cylinder walls is a common occurrence when driving on a lean fuel assembly. As the mixture becomes increasingly leaner, a decrease in engine power is observed, and as the load increases, “dips” appear. The car's movement becomes jerky, the slightest rise can become an insurmountable obstacle. When the ratio reaches 30 to 1, the engine begins to stall.

- Over-riching the mixture will not turn a standard model into a race car. As the air content in the fuel assembly decreases, the engine begins to operate intermittently, power drops, and fuel consumption increases catastrophically. Once a certain proportion is reached, the engine will no longer be able to start.

Every car owner who has an understanding of the operation of car components and assemblies understands how important the fuel-air mixture is for the smooth operation of the engine.

Signs and causes of lean mixture formation

However, it is very easy to diagnose:

- The simplest and most obvious is that the car stalls when moving. And not only when driving uphill, when this can be attributed to an incorrectly selected gear, but when driving on straight, level roads. However, this is only when the mixture is really lean.

- Another situation is when the car jerks while driving. Especially if you are driving not a fully loaded car, but an empty one, on a flat road. Although in this situation it cannot be said unequivocally that a poor air-fuel mixture is an indispensable reason. You may need to check other vehicle systems, such as the exhaust system.

- Another sign is that the car “shoots” when driving. Although more and more often in new cars this is not due to a lean mixture, but to problems in the exhaust system, this symptom is obvious. Especially when unstable exhaust appears not just once in a while, but constantly, since with single pops the situation is the opposite: the mixture is too rich, and the remaining gasoline that is not burned in the engine burns out in the muffler, ignited by a hot pipe.

- The color of the carbon deposits on the spark plugs can also tell a lot about the composition of the mixture. If he:

- brown, then everything is fine, there is an optimal amount of air-gasoline in the mixture;

- white, or alternatively light, then there is a lot of air in the mixture and it is poor;

- black candles - excess gasoline that does not burn completely;

If signs of a lean mixture are detected, this diagnosis can be confirmed in several ways:

- If the car is equipped with an on-board computer, the “Check Engine” indicator will light up on the dashboard, and P0171 will appear in the error list.

- By contacting a specialized service station, you can test the operation of the engine using a gas analyzer sensor, which is installed in the exhaust pipe.

- Finally, you can use a simple wired or Bluetooth OBD scanner, which costs only a few dollars on Aliexpress, a smartphone and the appropriate software.

You need to look for the cause of the formation of a lean mixture based on the diagnostic results and errors that appear along with P0171. The standard reasons are:

- Problems with sensors (mass air flow sensor, air pressure sensor, diaphragm pressure sensor, oxygen sensor). Incorrect sensor information usually results in an incorrect fuel/air mixture.

- Problems with the EGR valve. The valve may allow more exhaust gases into the engine than necessary.

- Timing problems. Incorrectly aligned marks or problems with tensioners can also lead to this problem.

- Problems with the fuel supply (faulty fuel pump, clogged fuel filter or injectors).

- Excess air supply through a crack in the hose or a loose connection in the air supply system.

What is the fuel-air mixture?

The fuel-air (fuel-air) mixture is a finely dispersed composition that includes atmospheric air, which is taken from the atmosphere, and fuel and lubricants previously poured into the car’s gas tank. The fuel can be used as gasoline, diesel fuel or liquefied gas. A working high-pressure fuel pump should provide an optimal air-fuel mixture with a fuel-air ratio of 1:14.7, that is, 14.7 parts of air are needed for one part of fuel.

Read also: Scheme gazelle 406 injector

Before being combined in the intake manifold of a car, these components first undergo mandatory filtration. Fuels and lubricants are cleaned in the fuel filter, and air is filtered through the air filter.

What happens to an engine with an enriched fuel assembly?

The mixture or fuel assembly should not be too rich or lean. Both mixing options can only lead to problems. The distribution of air and gasoline must be carried out strictly according to the instructions, otherwise high fuel consumption, loss of power and other malfunctions cannot be avoided.

Mixture quality chart

Read more about what happens to an engine if you feed it with an enriched fuel assembly.

- Thick black or gray smoke will pour out of the chimney, which will indicate that the fuel has not had time to burn completely.

- The engine will oscillate, and this indicates detonation moments inside it.

- Black soot will settle on the candles.

- Gasoline consumption will increase significantly.

- Slag will accumulate on the walls of engine elements, which will sooner or later lead to a major overhaul.

- The exhaust system will also not be left aside. The constant release of incompletely spent fuel into the pipe, its explosion, will ultimately lead to burnout of the muffler.

In a word, enriching the mixture does not lead to anything good. If measures are not taken in time, you will have to fork out money for engine repairs.

Therefore, it is so important to determine the presence of a rich mixture in time. For example, this is immediately noticeable by an increase in consumption and black candles

Article on the topic: Why engine cooling is needed and how it works

What causes the formation of rich fuel assemblies in the carb? The reasons are different, but the most important of them are: a dirty air filter and clogged jets. Therefore, before you start directly adjusting the carburetor, you need to check these parts. The air filter can be replaced and the jets can be purged.

It happens that the mixture is enriched due to a change in settings. In this case, you have to climb inside the carb.

The influence of the air-fuel mixture on power and fuel consumption

This fuel mixture, enriched with air, allows the car’s power unit to fully demonstrate its power characteristics, while it will not affect its efficiency. If a car uses a lean mixture of fuel and air, then not only its power performance will decrease, but also its efficiency.

A lean mixture greatly affects the fuel consumption of any car. As the car's power is lost, the driver will be forced to periodically shift to a lower gear in order to overcome even a minor road obstacle. Therefore, it is very important to have the correct ratio of fuel and atmospheric air for more efficient and smooth operation of the power unit.

Ratio - fuel - Great Encyclopedia of Oil and Gas, article, page 1

Ratio - fuel

The fuel to air ratio (F/A) is the reciprocal.

The fuel/oxygen ratio required to obtain maximum power is quite different from that required for maximum economy. It is advisable to identify the reasons for this difference and manage it as necessary.

The ratio of fuel and air is determined by eye by the length of the torch in the firebox and the color of the smoke in the chimney. If there is an automatic gas analyzer, then the amount of air is checked by the CO content behind the boiler. With proper air supply, the color of the flame should be light straw, and the smoke from the chimney should be slightly gray. As the slag cushion builds up on the grate, the opening of the dampers on the air ducts under the grate is gradually increased. Air must be supplied continuously under the grate.

Selecting the ratio of fuel and raw materials is not difficult if the composition of carbonate raw materials is constant.

The influence of the fuel-to-air ratio on the emissivity of the flame is also great. From Fig. 44 it can be seen that with an excess of natural gas, the emissivity is significantly greater than with an excess of air; It is also clear that the luminosity of the flame decreases rapidly if excess air is formed. In addition, the figure shows what the relationship is between the components of flame radiation: gas radiation and solid particle radiation.

Regulation of the fuel to air ratio must be automatic; The pilot should not fiddle with the throttles or check their position.

When the fuel to air ratio is less than 1:13, the combustion rate decreases, engine efficiency and power decrease. A mixture of this composition is called rich. If the ratio of fuel and air in the mixture is more than 1:18, its combustion rate is also sharply reduced, which also leads to a loss of efficiency and power. A mixture of this composition is called lean. When the air content in the mixture is less than 6 kg per 1 kg of fuel or more than 20 kg per 1 kg of fuel, the combustible mixture in the cylinders does not ignite.

It is difficult to regulate air flow and the fuel-to-air ratio to maintain combustion due to the relatively low pressures and high velocities in the combustion chamber. The issue of external motor resistance must be carefully considered in the same way as the issue of specific impulse. The specific impulse is usually less than 100 sec and reaches a maximum at the specific flight speed. The range of specific fuel consumption for the best operating conditions is 0 9 - 1 4 kg-hour per 1 g of thrust.

The composition of the working mixture depends on the ratio of fuel and air. Theoretically, 15 kg of air is needed for complete combustion of 1 kg of fuel. This mixture is called normal.

The analysis performed shows that the introduction of a fuel-to-air ratio regulator, while solving the problem of limiting the temperature rise and maintaining it at a maximum level, at the same time introduces elements of instability and increased overshoot. Therefore, the installation of such a regulator requires a very careful study of the dynamics of regulation and the selection of such dynamic constants and corrective devices, which will weaken the harmful influence of the second regulator on the regulation process.

The steam temperature behind the boiler is controlled by changing the ratio of fuel and water for each housing. Injection desuperheaters are installed in front of the screen superheater and the outlet stage of the convective package.

NO concentration increases to a maximum at that fuel to air ratio that produces the minimum amount of unburned hydrocarbons and carbon monoxide. A further increase in this ratio leads to a decrease in NO concentration, but increases the HC concentration. Thus, we can conclude that by changing only the air-fuel ratio it is impossible to achieve a simultaneous reduction in the amounts of HC, iNO and CO in the exhaust. Many other factors besides those already mentioned affect the emissions of a given spark ignition engine. Detailed discussion of these factors is contained in other sources, as well as in publications of the Society of Automotive Engineers.

Pages: 1 2 3 4 5

www.ngpedia.ru

Fuel to air ratio for fuel mixture

The most optimal ratio of fuel and air for the fuel mixture is 1:14.7. If you change this ratio, the resulting fuel mixture will be:

- power , during the creation of which the amount of air decreased from 15 to 12.5-13. This mixture, enriched with fuels and lubricants, exerts increased pressure on the engine pistons, thereby helping the power unit produce maximum power. The only drawback of this ratio of fuel composition components is an increase in fuel consumption by approximately 20%;

- economical , or lean , consisting of 1 part fuels and lubricants and 16 parts air. In this case, you can achieve a significant reduction in vehicle fuel consumption. But the result of this efficiency is a decrease in the car’s power performance, which is not very suitable for those who like to drive fast. If the lean mixture consists of 1 part fuel and 20 parts air or more, then ignition from a spark will become almost impossible;

- enriched , which contains fuel and air in a ratio of 1:11 or 1:12. If this composition continues to be enriched, this may lead to unpleasant consequences. Due to the fact that such a composition practically loses its ability to ignite, the power unit will not be able to perform its functions and will not be able to start.

Why is the mixture lean?

The mixture needs to be leaner in any case - this is efficiency and toxicity at the same power.

The fuel-air mixture is ignited by a spark in a certain range of concentrations. By directing the movement of air in the cylinder and the jet of injected fuel, it is possible to achieve a local “rich” mixture in the area of the spark plug in all operating modes, which will allow it to ignite reliably. In this case, the total mixture in the cylinder will be “lean”. In some modes (idle, low load) there is no need for a large dose of fuel. Accordingly, there is no need for a large amount of air. For such modes, they can reduce the amount of air, for example, by not opening one of the two intake valves or greatly distorting their opening/closing phases, creating additional resistance at the outlet. At high load conditions, everything that is possible is opened and the injected fuel is swirled with air in the cylinder so that the mixture at the spark plug will be locally rich and, most importantly, “smooth” ignition and combustion of portions of fuel in this vortex will be ensured. Those. the mixture becomes extremely lean, but only air vortices help to burn it normally.

Invite to tender

If you have a tender and need more participants:

Select from the list the type of work that interests youIndustrial safety auditIdentification and classification of hazardous production facilities, obtaining a license to operate hazardous production facilitiesDevelopment of plans, action plans, documentation related to the readiness of enterprises for civil emergency situations and fire safetyInspection and examination of the industrial safety of buildings and structuresWork on lifting structuresWork on boiler inspection and power equipment facilitiesWorks at gas supervision facilities Work at chemical and petrochemical facilities Work at facilities related to the transportation of hazardous substances Work at production facilities for the storage and processing of plant raw materials Work at metallurgical foundries Work at mining plants Conformity assessment of elevators, technical examination of elevators Development of a safety justification for a hazardous production facility Development of documentation for an industrial safety management system Development of industrial safety declarations securityWork at the facilities of the Ministry of Defense (special purpose production of military units) and the facilities of the Federal Penitentiary Service of Russia (special purpose organization of correctional institutions) Design Repair and installation work Electrical repair and electrical measuring work Development and production of safety devices for industrial facilities Development and production of non-standard metal products and equipment Non-state examination of design documentation (engineering surveys) Pre-certification training according to the rules and safety standardsVocational training (blue-collar professions)Training in labor protection, fire safety and electrical safety, heat and power engineeringSpecial assessment of working conditions (SOUT) (until 2014 certification of workplaces)Accreditation and certification in the industrial safety examination systemCertification of equipment, declaration of conformityEnergy auditDevelopment of heat supply and water supply schemesOther workAdvanced training, professional retrainingInspection of shelvingCopy the link to your tender into this field, to do this, go to the browser, open your site, highlight and copy the address line, then paste into this field. If it doesn’t work out, just write the tender number and the name of the site. personal data

Detonation and spontaneous combustion

Under normal conditions, combustion of the working mixture in the engine cylinders occurs at a speed of 25-30 m/sec and the pressure in the cylinder increases smoothly. The engine operates in normal thermal conditions, without knocking or failure.

When using lower quality fuel, overheating the engine, or setting a very early ignition point, the mixture begins to burn at a speed reaching up to 2000 m/sec. This explosive combustion of the mixture is called detonation. During detonation combustion, the pressure in individual parts of the cylinder increases sharply, metallic knocks appear, engine power drops, and black smoke appears from the muffler. The most harmful phenomenon of detonation affects the condition of the parts of the crank mechanism, where destruction of individual parts is possible.

The tendency of a fuel to detonate is conventionally assessed by its octane number. The higher the octane number, the less prone the fuel is to detonation. Gasoline with a higher octane number is used for engines with a higher compression ratio.

Detonation combustion of a mixture is sometimes mistakenly confused with self-ignition or glow ignition. Self-ignition can occur in the cylinders of an overheated engine at a time when the electric spark has not yet entered the cylinder, as well as during ignition from hot carbon particles or spark plug electrodes. In both cases, the mixture burns at normal speed. This phenomenon is usually observed when the ignition is turned off, while the engine continues to run for some time.

Automatic diagnostic system

If your vehicle's diagnostic system indicates that a "Compound Too Rich" error has occurred, certain actions must be taken. To do this, you need to understand the principles of the scanner.

Air is supplied to the fuel when diagnosing the MAP sensor and lambda probe. Maybe error P0172 is caused by deviations of these particular systems. However, in addition to them, problems may be associated with deviations in thermal clearances (engine with LPG), mechanical damage to sealing materials, insufficient compression or deviation during timing operation.

To understand why automatic diagnostics indicate such an error, the car owner can take several steps. First of all, you need to analyze the information that the scanner provides. Next, you can artificially simulate the conditions for the occurrence of such a malfunction.

The next step could be to check components and mechanisms, such as contacts, absence of suction, as well as the operability of systems related to the supply of fuel and oxygen to the combustion chamber.