As you know, for the VAZ-2114 engine to function normally, there must be normal compression in the cylinders. But not all motorists understand how to measure it and what should be the norm. This article will talk about the compression rate in the engine cylinders, as well as the reasons for the increase in the indicator and the measurement process.

Video about measuring compression on a VAZ-2114 with your own hands:

The video will tell you how to measure compression in a car.

Correct compression (norms) for VAZ-2114

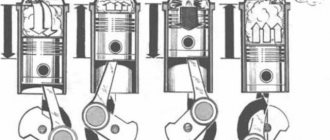

The process of measuring compression in engines

According to the regulatory and technical documentation, a limit value of compression in the cylinders of the VAZ-2114 engine has been established. Thus, an increase or decrease in the indicator is not considered normal, since excessive compression of the air-fuel mixture in the engine can lead to not very good consequences.

Also, it is worth noting that the compression in all cylinders should be relatively equal. Different indicators are not the norm and these are the first signs of a major engine overhaul.

Normal compression in the engine cylinder

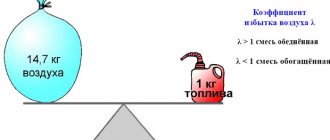

As practice and many years of experience of motorists show, the compression in the cylinders should be 14 bar, but the lower limit should not fall below 11 bar .

When measuring, the difference in compression between the cylinders should not exceed 1 bar .

Example of a bad and normal compress

Let's give a clear example: 12-13-12-13 is normal compression for the engine, but 12-11-12-8 is not normal and it is believed that the engine needs diagnostics and major repairs.

Reasons for increasing compression

Compression gauge for replacing compression

It becomes clear that a decrease in compression in the engine is associated with wear of key elements, such as pistons and compression rings, main and connecting rod bearings, as well as valves. But what are the reasons for the increased compression?

So, let's look at the main ones:

- When performing repair operations related to the gas distribution mechanism, an error was made in the adjustment work , which changed the order of operation of the unit, and, accordingly, the compression in the cylinders.

- Heat on the valves , as well as the accumulation of carbon deposits on the cylinder walls and throttle assembly, leads to an increase in the compression ratio due to a decrease in space in the nodes.

- Also, the reasons for increased compression in the cylinders include engine overheating.

- The last reason for increased compression is the “occlusion” of the valve stem seals. The malfunction is diagnosed quite simply - the spark plugs are unscrewed and the oil wells are examined. An oil film indicates that there is an excess of oil and the need to replace the valve seals.

Do-it-yourself compression test

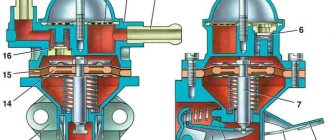

Compression in the cylinders must be measured using a special device - a compression meter. There are many types of them, but threaded ones are considered the best and most accurate.

- So, to measure the compression in the cylinder, you need to unscrew the spark plug and screw in the compression gauge fitting.

- Then, turn the ignition key until the engine begins to turn the crankshaft.

- The engine should start and the car enthusiast adds gas so that the engine runs a little.

- So, the compression meter measures the most accurate value.

The compression should not be lower than 11 bar, otherwise it is necessary to understand the causes of the malfunction.

Engine Lada Vesta

Products from the assortment of Dustershop77 on the topic of the article: Image[/td]

| vendor code | Name | Manufacturer | Price | Availability | Add to cart |

| DC1822-8200291355 | Crankcase gas recirculation valve Renault 8200291355 | Original | 6900 / 5500 rub. Discount: 4900 rub. | 2 | |

| DC1644-140328698R | Intake manifold gasket H4M original 140328698R | Original | 700 / 600 rub. Discount: 400 rub. | 4 | |

| DC380-ASAM-30376 | Lower radiator support cushion 7700430992 / 215081131R ASAM-SA 30376 analogue | Analogue | 150 / 100 rub. Discount: 80 rub. | 4 | |

| DC919-226A41772R | Oxygen sensor lambda probe upper Duster, Vesta and other engines. H4M 1.6 226A41772R / 226901841R / 226906393R | Original | 4500 / 4200 rub. Discount: 3900 rub. | 1 | |

| DC1211-8200132254 | Fuel injector for K4M engine original 8200132254 | Original | 2900 / 2200 rub. Discount: 1900 rub. | 4 | |

| DC1321-161757436R | Throttle valve gasket H4M/F4R original 161757436R | Original | 1000 / 900 rub. Discount: 700 rub. | 2 | |

| DC1738 | Fuel pump fuel filter mesh Renault Duster, Captur, Terrano, Vesta, etc. 2.0 / 1.6 (Masuma) | Analogue | 800 / 500 rub. Discount: 350 rub. | 1 | |

| DC619-8200048024 | Expansion tank cover original Renault 8200048024 | Original | 700 / 500 rub. Discount: 350 rub. | 2 | |

| DC1398-30777 | Gasket for fuel pump ring ASAM 30777 | ASAM | 300 / 250 rub. Discount: 200 rub. | 2 | |

| DC1746 | Membrane of the crankcase gas recirculation valve Renault Duster, Captur, Terrano, etc. (KVKG membrane F4R 2.0) | Analogue | 2200 / 1900 rub. Discount: 1600 rub. | 1 | |

| DC981-FCR210114 | Electric fuel pump FRANCECAR FCR210114 | Analogue | 1500 / 1200 rub. Discount: 1100 rub. | 1 | |

| DC1322-224332428R | Ignition coil 1.6 H4m original 224332428R | Original | 3500 / 3000 rub. Discount: 2600 rub. | 9 | |

| DC1682-6001549070 | Fuel vapor absorber original 6001549070 | Original | 4000 / 3200 rub. Discount: 2800 rub. | 1 | |

| DC1643-140323253R | Intake manifold gasket H4M original 140323253R | Original | 2000 / 1800 rub. Discount: 1600 rub. | 2 | |

| LRT-002/6001548140 | Washer reservoir is not original, ANALOGUE 6001548140 | LOGEM | 1000 / 900 rub. Discount: 500 rub. | 1 | |

| DC382-ASAM-30494 | Expansion tank ASAM-SA 30494 (7701470460) | Analogue | 1000 / 700 rub. Discount: 600 rub. | 1 | |

| DC918-226A44171R | Oxygen sensor lower lambda probe H4M 1.6 Lambda probe Renault 226A44171R | Original | 32000 / 6500 rub. Discount: 5300 rub. | 1 | |

| DC955-150100565R | Oil pump for F4R original 150100565R | Original | 7500 / 6900 rub. Discount: 6600 rub. | 1 | |

| DC1314-135101KT0A | Front crankshaft oil seal H4M original 135101KT0A | Original | 900 / 700 rub. Discount: 550 rub. | 2 | |

| DC1320-161191KA1B | Throttle valve H4M original 161191KA1B | Original | 35000 / 29900 rub. Discount: 28300 rub. | 1 | |

| DC1664-21179113201000 | Fuel injector VAZ 1.8l 21179 original 21179113201000 | Original | 1800 / 1500 rub. Discount: 1300 rub. | 4 | |

| DC2457-8200291355 | Crankcase gas recirculation valve - analogue 8200291355 | Analogue | 4000 / 2400 rub. Discount: 1900 rub. | >10 | |

| 6001548140 | Washer reservoir Renault 6001548140 original | Original | 2000 / 1700 rub. Discount: 1500 rub. | 1 | |

| DC957-8200665520 | Starter K4M 1.6 original 8200665520 | Original | 13000 / 11500 rub. Discount: 10500 rub. | 1 | |

| DC1302-166008992R | Fuel injector for H4M engine original 166008992R | Original | 3500 / 2600 rub. Discount: 2400 rub. | 4 | |

| DC1315-122791HC0A | Rear crankshaft oil seal H4M original 122791HC0A | Original | 2000 / 1700 rub. Discount: 1400 rub. | 1 | |

| DC1889 | Upper radiator support cushion 215060007R analog | Analogue | 340 / 250 rub. Discount: 200 rub. | 1 | |

| DC1663-21120370501015 | Ignition coil VAZ 1.6/1.8 21129/21179 original 21120370501015 | Original | 1900 / 1200 rub. Discount: 900 rub. | 4 | |

| DC1836 | Lower thin injector sealing ring Vesta, Largus, X-ray, Granta, Kalina 21127-1139045R (1 pc.) | Original | 25 / 15 rub. Discount: 10 rub. | 4 | |

| DC1837 | Valve cover bushing Vesta, Granta, 2108 (1 piece) | Original | 25 / 15 rub. Discount: 10 rub. | 4 | |

| DC1838 | Upper thick injector sealing ring Vesta, Largus, X-ray, Granta, Kalina (1 pc.) | Original | 25 / 15 rub. Discount: 10 rub. | 4 | |

| DC1839 | Rings for injectors Vesta, Largus, X-ray, Granta, Kalina (set of 8 pcs.) Rosteco | Analogue | 340 / 250 rub. Discount: 200 rub. | 1 | |

| DC1878-21080130704204 | Gasket for pump Largus, Vesta, X-Ray, VAZ-2108-2112 21080130704204 | Original | 50 / 30 rub. Discount: 20 rub. | 1 | |

| DC1740 | Fuel filter for submersible fuel pump Renault Duster, Captur, Terrano, Vesta, etc. 2.0 / 1.6 (LYNX) | Analogue | 2100 / 1800 rub. Discount: 1500 rub. | 0 | |

| DC1766 | Throttle valve gasket repair kit K4M/F4R (large+small) Balakovo PTP64 | Analogue | 300 / 200 rub. Discount: 150 rub. | 0 | |

| DC1200-BK64105/30598 | Fuel pump ring with gasket | Analogue | 1000 / 700 rub. Discount: 500 rub. | 0 | |

| DC522-233009370R | Starter for F4R engine original art. 233009370R | Original | 14000 / 10600 rub. Discount: 9900 rub. | 0 | |

| DC1002-B208A03276 | Fuel injector for K4M DEKO engine B208A03276 (analogue 8200132254) | Analogue | 2000 / 1500 rub. Discount: 1300 rub. | 0 |

conclusions

It was found that normal compression for a VAZ-2114 engine is 11-14 bar . An increase or decrease in this indicator, as well as a gap of more than 1 bar between the cylinders, is not considered normal and is subject to diagnosis. Engine compression is measured using a compression gauge.

There are several inaccuracies. Firstly, compression is traditionally measured with the engine not running at the starting speed generated by the starter! This is important: the pressure at the end of the compression stroke depends on the crankshaft speed, so if the engine is running, the compression will be much higher than the specified range - up to several times! Secondly, compression is measured on a warm engine (although there are some “former” ones who measure it on a cold engine, but the result is no more than a “funny letter”!). Third, the throttle must be fully open. Otherwise, the required amount of air will not be supplied, so the readings will be underestimated (there is nothing to compress!). On an injection engine, when the throttle valve is fully opened, the fuel supply and sparking stop (so-called cylinder purging). So there is no need to additionally turn off the ignition system (unlike carburetor engines). Fourthly, not only the absolute value of the pressure itself is important, but also how quickly it builds up. This indicator characterizes the condition no less accurately than the pressure itself. Ideally, a fixed value should be achieved in 2-3 “pumps”. And fifthly, the compression level is also affected by the condition of the starter and the flywheel ring gear: if the teeth are worn out and jammed, the compression value will also be underestimated. In general, for a more accurate assessment of the condition, the leak method is now much more often used.

Compression measurement of gasoline and diesel engines

The list of general requirements in order to accurately measure compression includes:

- The engine must be warmed up to 80-90 degrees;

- The fuel supply must be turned off;

- All candles without exception must be unscrewed;

- The starter must be absolutely in good working order;

- The battery must be fully charged;

- In the case of a manual gearbox, you can engage the upper (over) gear and also prevent the vehicle from moving. To do this, use the parking brake and/or wheel chocks. It is also possible to measure compression in the “neutral” position of the manual transmission lever. In cars with an automatic transmission, the selector is set to parking mode (P).

- The next step is to check the condition of the air filter. Before measuring compression, a dirty filter is replaced with a new one. The second method is to temporarily disconnect the air supply line from the inlet.

- In gasoline internal combustion engines, the ignition system will need to be turned off. To do this, it is necessary to disconnect the wiring from the breaker to supply low voltage, which is supplied to the ignition coil. Motors equipped with an ignition distributor will require removal of the main high-voltage wire from the coil. The specified wire is then connected to ground.

- To effectively shut off the fuel supply in designs that include a mechanical fuel pump, the fuel line will need to be disconnected. Next, the pipe is turned off. For an electric fuel pump, it will be enough to remove the contact from its relay.

- Afterwards, the places for installing the spark plugs are cleaned of dirt and the tips of the high-voltage wires are removed from the spark plugs. Then the candles are unscrewed.

- With the spark plugs removed, you will need to turn the engine over several times with the starter. The procedure is necessary to clean the cylinders from possible carbon deposits and other deposits.

- The last step is to connect the compression gauge to the spark plug well of the cylinder. It is better to measure compression with a partner who will press the accelerator pedal all the way. The gas pedal is depressed so that the compression measurement is carried out with the throttle valve open, and due to this, the intake resistance is reduced. With the pedal depressed, the engine is turned with the starter for about 5 seconds. It is necessary to monitor when the highest value appears on the scale. The indicated value is noted and further measurements are taken in other engine cylinders.

As for the features of measuring compression on a diesel engine, then:

- Turning off the fuel supply in a diesel engine is achieved by pressing down the cut-off lever. This lever is located on the injection pump. The second way is to turn off the solenoid valve, which will also block the fuel supply to the diesel internal combustion engine. This valve is located on the fuel line, which is responsible for supplying fuel.

- The compression gauge in a diesel engine is connected through the holes of the injectors or glow plugs. This depends on which elements are more convenient to reach, as well as according to the recommendations for a particular type of diesel engine.

- To measure compression on a diesel engine, you will need a special compression meter, which will have an appropriate tip for secure fastening in the hole of the injector or glow plug. The maximum measurement threshold for such a compression meter for a diesel engine should be higher compared to its gasoline counterpart. A diesel compressometer should be able to record a pressure of about 60 atmospheres.

- When measuring diesel compression, there is no need to press the gas pedal. The fact is that most diesel engines do not have a throttle valve. Only diesel engines that have a special valve in the intake stand separately. The valve is necessary to create vacuum. The vacuum will ensure the functionality of the vacuum regulator and brake booster.

The fuel supply must be turned off so that the fuel does not wash away the so-called oil wedge. To stop the fuel supply, you can use one of the listed methods to turn off the fuel pump, fuel injection pump or injectors. The spark plugs must be unscrewed.

If you take measurements by unscrewing only the spark plug in one cylinder, then there is a noticeable increase in the resistance to crankshaft rotation. When the starter cranks, this resistance leads to a decrease in speed. If the battery is faulty or has a weak battery, you can use a jump starter, although this method is not recommended.

Signs of low compression and how to measure it on a VAZ engine

Compression on a VAZ 2114 should be measured every 30 thousand kilometers. This is usually done in conjunction with adjusting the valves. However, signs of low compression may not only appear with a routine check. As you use your car, signs of poor compression are easy to spot; you just need to keep a close eye on your engine. These are phenomena such as:

- ICE strength drops sharply;

- the engine fires, this can happen when low compression occurs in one cylinder;

- significantly increases oil and gasoline consumption.

Reasons for low pressure in the cylinders of the VAZ-2109 engine

Air compression will show why the pressure is low. To determine the compression stroke in a specific cylindrical device, place a thin and long screwdriver in the spark plug hole; you can replace it with a regular stick or a piece of wire. Hold the screwdriver with your hand and lower it directly onto the piston bottom. Next, rotate the crankshaft while holding the flywheel teeth in the clutch housing hatch.

When the air is compressed, the screwdriver comes out of the spark plug hole, following the direction from bottom to top. Your task is to determine the moment when the upward movement stops and changes into a downward movement following the piston; this is the intake stroke - the starting point of the piston movement and the end of the compression stroke.

Next, insert the hose coming from the compressor into the recess of the spark plug and transfer the air flow into the cylindrical structure, pumping up pressure from 2 to 3 atmospheres. The malfunction of the unit is determined by where the air comes from:

- If air leaks through the adjacent recess into the spark plugs or appears in the expansion tank, it means the head gasket has burned out.

- If the air flow comes out of the carburetor, the intake valve may be burnt out, and there is also the possibility of poor valve adjustment.

- Air coming out of the muffler also indicates a burnt out exhaust valve or poor regulation.

- If the air flow is directed from the breather, it can be assumed that the rings and pistons are worn.

WHAT THE COMPRESSION SHOULD NOT BE IN AN ENGINE

At first glance, it may seem that the higher the compression parameters of the air-combustible mixture, the better. But actually it is not. Compression has an upper threshold that cannot be crossed, as this will lead to overheating of the engine, and, as a result, deposits of carbon deposits, excessive load on the pistons and rings, as a result of which engine parts may fail.

Low pressure in the engine leads to excessive consumption of fuel and oil. It is not permissible that in individual cylinders it differs sharply from neighboring ones. Different compression in the cylinders indicates serious problems in the engine - wear and defects that have appeared that require replacement or repair of parts.

Thus, bad compression is:

All of these signs of poor compression are a sign that the heart of the car needs repair.

Why measure compression?

It makes sense to measure compression when you notice one of the following symptoms:

- reduction in engine power (reduced traction, increased acceleration time);

- increased oil consumption;

- interruptions in engine operation (if replacing spark plugs and checking the coils did not yield anything);

- increased fuel consumption.

The nominal compression value in a particular engine design is influenced by a variety of factors, so check the exact value and permissible deviations in the repair manual for your car.

Measuring the compression in the cylinders will help to identify the malfunction in a timely manner.

CORRECT COMPRESSION

How much compression should be in the engine for its long-term and trouble-free operation? Long-term practice of operating cars shows that ideally it should be 14 barrels in each cylinder. But a reduction to 11 barrels is allowed, provided that the difference in compression in the cylinders should be no more than 1 barrel. For example, a compression pattern of 11-12-11-12 is considered acceptable, but if the pressure in different cylinders is 11-12-11-9, or another combination of indicators that differs from normal, then the engine already needs repair.

What compression should be on a VAZ 2114 8 valve also depends on how long and under what conditions the car is operated. Ideal pressure, as a rule, occurs with a new engine, or one that has just come out of a major overhaul. During vehicle operation, compression may drop by 1-2 barrels. And this will also be within the normal range.

Pressure measurements

We have already answered what the normal compression for a VAZ 2114 should be. Now let's look at how to actually measure it? First we need a special device called a compression meter.

Compressometer

All measurements using it are performed in the following order:

- Fully charge the battery.

- Warm up the engine to 75-90 degrees. WITH.

- After the engine warms up, remove all spark plugs.

- Disconnect the fuel supply hose.

- Insert the measuring device into the first spark plug hole.

- Press the gas pedal and hold it (to do this, two people need to take measurements).

- Start the starter and turn the crankshaft with it.

- Wait until the readings on the dial (monitor) of the device reach the maximum - this will be the compression value in a particular cylinder.

- Move the compression gauge to another spark plug hole and continue measurements.

After the pressure is measured in all cylinders, conclusions can be drawn about the general condition of the engine and the need for its repair/restoration.

If the compression is not normal, then you should stop driving the car and try to solve this problem first. Otherwise (especially if the pressure is very high), the engine may completely fail, after which it will need to be completely restored.

REASONS FOR INCREASED COMPRESSION IN THE ENGINE

Let's look at the main reasons:

- Incorrect adjustment of the timing belt leads not only to increased compression, but also to decreased compression, depending on the direction of regulation.

- The appearance of scale on the valves, which appears due to the use of low-quality gasoline, oil or other automotive chemicals. Carbon deposits on the throttle assemblies and in the combustion chamber also appear due to engine overheating. Thus, overheating of the internal combustion engine is not only a consequence, but also a cause of high pressure of the air-combustible mixture. The operating temperature of the VAZ 2114 8 valve engine should not exceed 85-90 o C.

- High compression can be caused by stuck oil seals. This reason is not difficult to detect. You just need to unscrew the spark plugs and inspect the cylinders. The appearance of an oil film on their walls will indicate an excess of oil in them, and the need to change the caps.

Compression is also affected by the level of oil pressure in the engine. If it is too high, then this leads to increased pressure of the air-combustible mixture.

Low pressure occurs if the rings are worn out or the valves are burnt out. The operating temperature of the engine also affects. If it is below normal, this will also affect the pressure of the air-combustible mixture.

The reasons for the lack of compression in the engine lie in improper operation and untimely preventive repairs. Sometimes air breaks through from several sides at once - for example, through valves, and at the same time through pistons with rings. Then the pressure disappears completely. It's simply not acceptable to let the car get into this state.

How to get rid of inaccurate compression measurements

The compression meter may show inaccurate values if at least one of the following factors exists:

- VVAZ-2109 battery is practically not charged;

- a starter malfunction has been detected;

- the engine is cold;

- valve clearances do not correspond to normal values;

- gasoline got into the cylinders;

- The measurements were initially taken incorrectly.

In the absence of an assistant, the procedure was carried out without pressing the gas pedal, which in itself is considered a significant violation of pressure measurement.

Experts note that the compression meter gives increased readings when there is excess oil in the cylinders, this is due to wear of the oil scraper caps built to guide the VAZ-2109 or CPG valve bushings.

Regardless of which mechanism is installed in the VAZ-2109 - a carburetor or an injector - the maximum pressure value is calculated based on the product of the compression ratio and a constant coefficient equal to 1.2.

PREPARATION FOR MEASUREMENTS

Engine compression is measured with a fully charged battery. After charging and installing the power source in place, check the starter. It shouldn't create any problems either. Then warm up the engine. Its temperature during measurements should be 70-90 O C.

It is necessary to unscrew all spark plugs from all holes. Also unscrew the fuel hose to stop the fuel supply. Prepare the compression gauge for use.

Compressometer

How is compression measured?

To obtain reliable results, when measuring compression, you must adhere to the following rules:

- warm up the engine to 70-90 degrees;

- shut off the fuel supply: disconnect the fuel pump power wire or disconnect the fuel hose (so that a lot of fuel does not get into the cylinders);

- remove all spark plugs to reduce rotational resistance;

- make sure that the starter is in working order and the battery is charged (it is recommended to use a starter charger - then the shaft will be guaranteed to rotate at the same speed when measuring compression in different cylinders).

Methods for measuring compression on a hot engine

There are a couple of main ways to measure pressure in internal combustion engine cylinders: with an open or closed throttle. Here we mean carrying out the procedure with the accelerator pedal depressed or in the absence of influence on it. Each of these methods allows you to obtain different results that help you more accurately determine the cause of the lack of compression.

Measurements with the damper open

In this situation, a lot of air is supplied to the cylinders, and the average pressure will be in the range of 11-13 kg/sq.m. cm (true for AI95 gasoline). In this case, measurements of air mass leakage are comparable to the amount entering the cylinder of an internal combustion engine. That is, if the pressure is below normal, this means that leaks occur by an “alternative method.” This may be a loose fit of the valve to the seat, a flaw in the camshaft cam profile (in engines with hydraulic lifters) or its wear, as well as a lack of tightness of the cylinder head gasket or a through crack in the combustion chamber.

How to check compression in an engine with the throttle closed

Here the picture is different. There is little air entering the cylinders, causing the cylinder pressure to increase, increasing leaks. But their volume will still be less than the amount of supplied air. Compression should be 12-14 kgf/sq.m. see. This method can determine the most severe defects:

- coking of rings (or their occurrence);

- burnout of a valve (one or more) or pistons (the latter may break);

- wear of the cylinder walls.

Measurements with oil added to cylinders

Both of the above methods do not allow taking into account the increase in pressure when the crankshaft rotates. For example, if it is low during the first steps - 4-5 kg/sq.m. cm, and then increases sharply, this may indicate wear or breakage of the piston rings. However, it makes sense to conduct additional testing. How to check compression taking into account the increase in pressure? To do this, pour a little (4-5 ml) of engine oil into the cylinder. This will increase compression, raise pressure on the first stroke and prevent gases from breaking through the rings into the crankcase. If the measured parameters have not changed, then it can be said with a high degree of probability that the cylinder head gasket is broken or the piston is burned out. When the pressure changes upward, we can talk about the occurrence, deformation or coking of the rings.

Checking compression on a cold engine

This method is usually used in case of difficult starting. The pressure in the cylinders of a cold engine is sometimes 2 times (6-7 kg/sq. cm) less than normal when the parts of the cylinder-piston group are seriously worn out. After starting and subsequent warming up of the power unit, the compression rises by 3-5 units. If this is not the case, a major engine overhaul is needed. That is, it is obvious that a comprehensive check (both “cold” and “hot”) is more effective.

Checking compression with compressed air

This method allows you to more accurately understand the reason for the decrease in pressure in the problem cylinder. Adjust the piston to TDC on the compression stroke (all spark plugs must be removed and at the same time remove the plug from the oil filler neck). Next, you will need a compressor, with which you need to supply air under a pressure of 2 to 3 atmospheres into the “suspected” cylinder. If air comes out of the spark plug hole located nearby, it means the cylinder head gasket is damaged. A hissing sound from under the lowest carburetor gasket indicates a loose fit (or burnout) of the intake valve. Air flow from the neck indicates a violation of the integrity of the piston body or its burnout. And if hissing comes from the muffler pipe, it means the exhaust valve is faulty. The last trouble is the most common.

Below is a table of normal compression for the most popular cars:

COMPRESSION MEASUREMENTS IN THE ENGINE. COMPRESSOMETER

A device consisting of a pressure gauge and a rubberized tube that measures compression in the engine is called a compression gauge. The following devices are used:

Experts believe that of all types of compression gauges, it is better to use threaded ones. They provide more accurate information. It is necessary to measure the compression in the engine in each cylinder separately. The measuring instrument hose is inserted into the spark plug socket.

Now that everything is ready for measurements, start the engine and squeeze the gas all the way, let the engine run for a while. Check the pressure gauge readings and record them. Move the compression tester hose to the next spark plug hole, and take measurements in the second and subsequent cylinders in the same way. Write down all the results and compare them.

Instructions for checking compression of VAZ-2109

To measure compression, you need to prepare special tools:

- a compression gauge consisting of a soft bendable hose, a pressure release key and a tip with a measurement panel;

- spark plug key.

When diagnosing yourself, you cannot do without an assistant. Instructions for measuring compression of a VAZ-2109 injector and carburetor look like this:

- Turn on the car engine and heat it to a temperature of 80 to 90 degrees.

- Remove the hose from the fuel pump that drains gasoline.

- Carefully unscrew the spark plugs, first clearing the wells of any build-up of dirt and debris.

- Remove the armor wire located in the center from the toggle switch cover, fix the spark plug in it and place it on top of the engine.

- Place the compressor tip in the recess of the first cylinder; the device does not have to be screwed in; it can be pressed against the hole with your hands.

- Proceed to measure pressure. The assistant must take the driver's seat and press the gas pedal all the way, then turn the key in the ignition and start the starter for at least 3-5 seconds.

- Watch how the compression meter values change at this time, the dynamics of increasing readings should be recorded, and also write down the maximum position of the arrow. Once locking is complete, release the pressure by pressing the release button.

- These actions must be performed for each engine cylinder separately, so as not to forget the indicators, record them on a piece of paper.

INJECTION ENGINE PRESSURE

Below you will learn how to correctly measure compression in a VAZ 2114 engine with injection type power.

If in at least one cylinder the pressure gauge shows a pressure below 10 barrels, then we need to look for the reason for such a low indicator. Otherwise, very soon it will fall in other cylinders.

Fill a medical syringe with about 10 milligrams of oil and spray it into the cylinder. Take the measurement again. If the pressure gauge readings increase, it means the piston rings are worn out and require replacement. If it remains at the same low level, then it is necessary to adjust the clamped valves or replace the burnt valves.

Diagnosing faults

After taking measurements in all cylinders, you should pay attention to two points. The first is whether the measured compression corresponds to the minimum permissible value

The first is whether the measured compression corresponds to the minimum permissible value.

It is determined by the engine developers and is indicated in the repair manual.

The second is the difference in compression values in different cylinders of the same engine.

As a rule, it should not exceed 20% of the nominal value.

If you find that the pressure in any of the cylinders is below normal, inject three portions of oil into it from a manual oil can.

Do not inject more than three portions of oil, as excess oil can lead to the formation of a hydrostatic plug, which can cause breakage of the rings, piston, or even lead to a crack in the cylinder head.

The oil will seal the gap between the rings and the cylinder, and if the reason for the low compression was in this gap, then with such a “wet” test the compression should increase significantly.

Then check the condition of the rings, and if one of them is damaged or stuck, replace it.

If compression behaves this way in all cylinders, then it’s probably time for a serious repair with boring the cylinders and installing rings of the next repair size.

The effect of additives that increase compression is based on the effect of sealing gaps, similar to an oil wedge.

This is the easiest way to restore to some extent the former agility of the engine.

Only in this case you need to remember that their effect is quite short-lived, and repeated use no longer has such an effect.

Therefore, this method is often used before selling a car, so as not to spend money on expensive engine repairs.

If, after injecting oil into the cylinder, the compression changes slightly, then most likely the reason for its drop is a malfunction of the valve group or a broken cylinder head gasket.

From all that has been said, another conclusion follows: low, but approximately equal in all cylinders, compression indicates natural wear of engine parts, but a sharply different drop in one or more cylinders indicates a malfunction.

Sometimes damage or wear to the oil ring can cause compression to rise above the values set for a new engine.

This occurs because the worn ring does not remove excess oil from the cylinder walls, and it seals the gap between the cylinder and the compression rings, and then, during the power stroke of the piston, the oil burns out, forming carbon deposits on the cylinder head.

If this process continues for a long time, then the carbon layer becomes so significant that it leads to a decrease in the volume of the combustion chamber, and therefore to an increase in compression.

This phenomenon is dangerous due to engine detonation. It also leads to increased oil consumption.

Video: measuring compression correctly

Compression is an important indicator of engine health. If it is normal, then we can speak with confidence about the serviceability of its main parts: the cylinder head, cylinders, pistons, piston rings and valve group.

If the measured compression values differ from the values permissible by the engine manufacturer, then this is a reason to quickly determine and eliminate the cause of the malfunction.

WHAT TO DO IF YOU DO NOT HAVE A COMPRESSOMETER AT HAND?

Is it possible to measure compression without a device? Practice shows that yes, it is possible. But this method will give relative and approximate readings. To measure the compression indicator without instruments, remove the spark plugs from all cylinders except the one being tested. Manually rotate the crankshaft until the compression stroke ends (watch the marks - they should match). Perform this operation on all cylinders one by one. Where the pressure is low, it will take less effort to turn the crankshaft. In this way, of course, you will not get accurate compression readings in the engine. But it is possible to understand the presence of problems.

It is recommended to measure compression every 20-30 thousand kilometers, so every car enthusiast is recommended to have his own compression gauge. Its price is not so high that it is worth saving on it.

The approximate price of a device for measuring engine compression in online stores in the capital is from 600 rubles to 2 thousand. Branded models from Western manufacturers are more expensive – up to 8 thousand. In the regions, a device for measuring compression costs no more than in the capital. Its price varies depending on the manufacturer.

What affects engine compression

- Throttle position . When the throttle is closed or covered, the pressure decreases

- Air filter dirty.

- Incorrect valve timing when the valve closes and opens at the wrong times. This happens when the belt or chain is installed incorrectly.

- The valves do not close on time due to gaps in their drive.

- Motor temperature . The higher its temperature, the higher the temperature of the mixture. Therefore, the pressure is lower.

- Air leak . Air leaks reduce compression. They are caused by damage or natural wear of the combustion chamber seals.

- Oil entering the combustion chamber increases compression.

- If fuel enters in the form of droplets , then compression is reduced - the oil, which plays the role of a sealant, is washed off.

- Lack of tightness in the compression gauge or check valve.

- Crankshaft rotation speed . The higher it is, the higher the compression; there will be no leaks due to depressurization.

The above describes how to measure compression in an internal combustion engine running on gasoline. In the case of a diesel engine, measurements are made differently.

How often should I check my blood pressure?

For preventive purposes, diagnostics should be carried out along with replacing the spark plugs of a gasoline engine. Depending on the brand of car, technical condition and quality of products, such an operation is carried out at intervals of 25–50 thousand km.

The following symptoms are the reason for an emergency compression check:

- the power unit began to “eat” oil in the amount of 150 ml per 1 thousand km or more;

- blue smoke from the exhaust tract is noticeable;

- the car became bad;

- At idle the engine stalls and shakes.

The last sign may indicate a malfunction of the ignition system or failure of 1-2 spark plugs. Before measuring pressure, it is advisable to eliminate such problems. On diesel engines, wear of the piston group and valves manifests itself in similar symptoms; cold starts are especially difficult - if there is insufficient pressure, the diesel fuel simply does not flare up.

Since there are many reasons for the appearance of such symptoms, it is first recommended to carry out computer diagnostics of the car. The easiest way to do this without visiting a service station is to use an inexpensive scanner, for example Rokodil ScanX Pro.

If a malfunction is detected, the scanner will accurately indicate the cause of their occurrence, and in the case of malfunctions of the ignition system or failure of the spark plugs, it will indicate a specific cylinder. This car scanner is universal and is suitable for almost all cars with an OBD2 connector.

The concept of compression, its measurement

This specification is not included in the technical data provided in the vehicle's owner's manual. There is a slightly different concept. compression ratio. There is no direct connection between these two parameters; they combine only one. In both cases we are talking about pressure.

- The compression ratio is a calculated constant; it has no units. For the VAZ 2106

and its modification 8.5. This figure is the result of dividing the total displacement of the cylinder by the volume of the combustion chamber. Simply put, the air-fuel mixture entering the cylinder space is compressed by the piston 8.5 times. - Compression is a variable value, its value depends on the technical condition of the engine. This parameter shows what pressure is

in each cylinder when the crankshaft rotates using the starter. Measure this with a pressure gauge that screws in instead of the spark plug, the device is 1 kgf/cm2 or 1 bar, which is almost identical (1 kgf/cm2 - 0.98 bar).

Compression is measured to determine the degree of wear of the cylinder-piston group. Its values were obtained experimentally in practice.

The measurements are made as follows: all 4 spark plugs are unscrewed and a pressure gauge with a check valve is screwed into each cylinder and as it rotates the starter determines the maximum pressure that each piston can pass.

In a VAZ engine 2106

the ideal figure is 13 kgf / cm 2, but this is a rare phenomenon -

there is pressure on new, just running engines.

Compression measurement of VAZ 2106

How to measure compression in cylinders. How to use a compressor. Compressor VAZ

stylish

How to use measurement results?

If the measured value is from 11 to 12.5 kgf / cm 2, then this is a normally operating VAZ engine 2106

. It is important that the compression in all 4 cylinders is the same; a difference of more than 0.5 kgf / cm 2 indicates a malfunction in one of them. As a rule, this is a purge valve; this problem occurs when driving on low-quality fuel and heavy loads.

The measurement results, which showed a pressure of 10 to 11 kgf/cm2, indicate rapid engine repair. These results may not be completely accurate when the engine is running.

This is the name for the phenomenon when engine oil begins to flow through the hose to release the crankcase fan into the carburetor along with the blow-by gases.

The reason is simple: due to wear on the piston rings, excess pressure builds up in the engine crankcase, which pushes oil droplets through the breathing tube into the carburetor.

The fat enters the combustion chamber along with the fuel and after combustion forms a deposit on the walls and a spark plug. When the oil gets very high, it begins to fill the gap between the worn rings and the cylinder surface, then the compression readings will be higher and will not be maintained. That is, if the engine is blowing, it’s time to replace the piston rings.

A compression ratio of 9-10 kgf/cm2 indicates wear of the cylinder-piston group or valves. In both cases, engine disassembly is required. Such an engine usually consumes oil and fuel, it is unstable, and part of its energy is lost.

However, it can continue to be used for some time, the main condition is. compression in all cylinders should be the same.

If in some of them the valve is fully engaged, the pressure in it drops sharply and the cylinder fails altogether.

A device that compresses less than 9 kgf/cm2 awaits the same fate. This pressure indicates the need for a major overhaul. In such cases, if possible, all devices are removed from the engine, unscrewed from the gearbox and completely removed from their posts for dismantling and repair in more convenient conditions.

At the same time, check the condition of the rubber parts of these supports; The cushions may need to be replaced. Many motorists disassemble the engine directly on the car; this option also has a right to life, especially if you only need to replace the piston rings.

Source: https://autointerline.ru/kakaja-kompressija-dolzhna-byt-na-vaz-2106/

What compression should be on a VAZ 2106

Considering that more than 4 million units of VAZ 2106 cars were produced, there are many more of them on our roads. Accordingly, the issue of repairing the famous “classic” still remains relevant. For example, the question of what compression should support six good engines.

The technical data specified in the vehicle's operating manual does not contain such a function. There is a slightly different concept - compression ratio. There is no direct connection between these two parameters; they have only one thing in common - in both cases we are talking about pressure.

- The compression ratio is a calculated constant and has no dimensional units. For the VAZ 2106 engine and its modifications it is 8.5. This figure is the result of dividing the total displacement of the cylinder by the volume of the combustion chamber. Simply put, the air-fuel mixture entering the cylinder is compressed 8.5 times, moving the piston upward.

- Compression is variable; its value depends on the technical condition in which the engine is located. This parameter indicates how much pressure appears in each cylinder when the crankshaft rotates with the starter. This is determined by a pressure gauge that is screwed in instead of spark plugs; the unit of measurement is 1 kgf/cm2 or 1 bar, which is almost identical (1 kgf/cm2 - 0.98 bar).

Compression is measured to determine the degree of wear of the cylinder-piston group. Its values were obtained experimentally in practice.

Extinguishing occurs as follows: All 4 spark plugs are unscrewed and the check valve is turned in place in each cylinder, and by rotating the starter, the maximum pressure that can be supplied by each piston is determined.

In the VAZ 2106 engine, the ideal figure is 13 kgf/cm2, but this is a rare case; such pressure is found on new, running-only engines.

Determination of compression in a cylinder without a compressor

If the measurement range is from 11 to 12.5 kgf / cm 2, this is a normally working VAZ 2106 engine. In addition, it is important that the compression in all 4 cylinders is the same, a difference of more than 0.5 kgf / cm 2 indicates a malfunction of one of them . This is usually a burnt valve, this is a problem when driving on poor fuel and heavy loads.

The measurement results, which showed pressure from 10 to 11 kgf / cm2, indicate early engine repair. These results may not be entirely accurate when the engine is breathing.

This is the name for the phenomenon when engine oil begins to flow through the crankcase ventilation hose from the fan to the carburetor along with crankcase gases.