Screw for the “amount” of fuel mixture in the Ozone carburetor

On carburetors of the Ozone family, a special screw is installed with which you can adjust the volume of the fuel mixture entering the cylinders of the car engine at idle.

This is a screw for adjusting the “amount” of the fuel mixture. Here is complete information on its design and location on the carburetor, as well as how it works, how many turns it needs to be turned in and out when adjusting the idle speed, and what malfunctions occur if the screw fails.

Screw for the “amount” of fuel mixture in the Ozone carburetor

— Purpose of the screw for adjusting the “quantity” of the fuel mixture of the Ozone carburetor

The screw is designed to regulate the volume of air, and accordingly, the fuel mixture entering the engine cylinders at idle.

— What does the Ozone “quantity” screw look like and how does it work?

On second-generation Ozone carburetors (2105, 2107) with the ACX system, the “quantity” screw is a needle screw that locks the exit of the fuel mixture from the annular nozzle and the outlet of the ACX. The screw has two cone-shaped working surfaces - the large one forms a kind of diffuser paired with a ring atomizer, the small one regulates the clearance of the CXX outlet hole. This design ensures improved mixture formation in XX mode. The “quantity” screw has its own housing, which is inserted into a hole in the throttle valve block of the Ozone carburetor.

Ring sprayer ASXX Ozone

On carburetors Ozone 2105-1107010, 2107-1107010, which have an EPH system, the “quantity” screw is one of its elements. These carburetors have a forced idle economizer, inside which the shut-off needle of the “quantity” screw is connected to the diaphragm. In this case, the opening and closing of the propeller is influenced by the vacuum that changes when the throttle valve is opened and closed and the operation of the EPH system, which cuts off the fuel supply in forced idle mode. The adjusting screw at the end of the economizer body only regulates the degree of movement of the diaphragm of the “quantity” screw.

— Turns of the screw “amount” of the fuel mixture of the carburetor Ozone

Before adjusting the idle speed, it is necessary to set the “quantity” screw to its original position. To do this, you need to screw it all the way and turn it out two turns. This will ensure that the engine receives enough fuel mixture to operate at minimum speed. During the adjustment process, this number of revolutions will change. See “How many revolutions should I tighten and unscrew the quantity and quality screws of the Ozone carburetor.”

Notes and additions

On Ozone carburetors of early years of production with throttle mixture formation, this is a screw with which the throttle valve of the first chamber of the carburetor was slightly opened to a certain angle. The larger the gap, the more fuel gets into the cylinders, the higher the engine idle speed.

— Malfunction of the “quantity” screw

The main problem is clogging of the CXX outlet. Damage to the propeller diaphragm and its gasket can also occur.

Source

Setting the transient mode of carburetor operation

At idle speed, the carburetor throttle valves close and a high vacuum area is created under them, which allows gasoline to be “sucked” out of the idle channel through the nozzle. If the damper is opened sharply, the vacuum decreases sharply, which disrupts the normal operation of the main dosing system of the first chamber and a failure appears.

To eliminate these symptoms, adjust the idle jet or accelerator pump nozzles. The adjustment must be made on a warm car engine.

The idle jets or accelerator pump are changed one by one to prevent dips and delays when you press the gas sharply.

You may need to adjust the idle speed a little. Over-enrichment is not transiently displayed as black smoke coming from the exhaust pipe.

Do-it-yourself interior tuning. How to do this and what is needed for this can be found on our unique website.

From here, you can learn how to do tuning a Chevrolet Niva with your own hands.

In this informative article, you will learn how to polish a windshield with your own hands.

It is recommended to install an accelerator pump with 40x40 nozzles, and an idle nozzle with parameters from 35 to 40. If there are dips from a lean mixture and it is not possible to adjust the idle speed due to the idle nozzle being too large, then both accelerator pump nozzles can be placed in the first camera as shown in the picture.

Adjusting the carburetor in simple language.

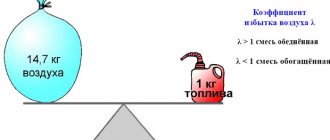

Let's start with what a carburetor is. A carburetor is a component of the internal combustion engine power system, designed to prepare a combustible mixture of the best composition by mixing liquid fuel with air and regulating the amount of its supply to the engine cylinders.

Carburetors are used on older cars, as well as trucks, motor boats, and small airplanes. Carburetors do not require any special care or maintenance, but they do require good adjustment and tuning to ensure that all carburetor parts perform optimally. The operation of the engine will depend on this. Carburetor problems

If you notice that gasoline is coming out from where it should not come out, then the reason for this usually lies in problems with the float chamber, float, or excessively high pressure. First of all, you need to check the fuel pressure, which should be within 4-7 atmospheres. If the pressure is normal, then the problem may be that the float is sinking or there are problems with the float chamber. In this case, you will have to replace the float chamber gasket.