Why the speedometer on the Lada Priora may not work

The stable operation of injection power units depends on the synchronous functionality of all electronic components.

One of these important components is the electronic speedometer. The article will answer the question why the speedometer on a Lada Priora car does not work. Symptoms, causes of failure, and methods for checking damaged elements of the entire system will also be described.

Layout and operating principle

The Lada Priora model is equipped with a fully electronic speed calculation system. It consists of the following elements:

- Speed sensor (EMF). Its function is to create electrical impulses.

- Electrical wiring. Powers the speedometer system with electric current.

- Fuse. Protects the system from voltage surges.

- On-board computer. Monitors work and analyzes incoming data.

- The speedometer itself. Necessary for visual speed control.

There are not many components in the system. The system works as follows:

- The speed sensor produces electrical impulses. It is installed on the gearbox housing. On power units with 16 valves, the EMF is located on the side of the expansion tank. The EMF is installed opposite the flywheel. This gear has teeth along its entire diameter. There is only one tooth missing in one place. It is to this place that the magnetic speedometer sensor reacts. During the passage of an empty space, the EMF opens, thereby creating an electrical impulse.

- The pulses generated by the opening are sent through wires to the ECU. The computer calculates the speed at which the signals arrive and converts them into an electrical voltage of a certain strength.

- Voltage is supplied to the instrument panel, activating the speedometer drive motor.

- The electric motor deflects the speedometer needle by a certain degree.

In addition to needle deflection, electrical impulses from the speed sensor are necessary to calculate the fuel supply to the engine. Based on the data received, the on-board computer determines the required amount of combustible mixture and its filling with air. In this way, the required, stable engine speed is maintained for the current speed limit.

The speedometer on the Priora does not work for several reasons. But this is always preceded by the appearance of a number of symptoms of a malfunction. They will be described below.

Symptoms

Drivers accustomed to carburetor engines often do not react to the appearance of symptoms of speedometer failure. On injection engines, you need to pay attention to the behavior of this device. Symptoms of failure are as follows:

- The instrument needle does not work completely or partially. It can periodically turn on, tremble, freeze at a certain level.

- Complete failure of the instrument panel.

- The speedometer determines the speed limit with a large error.

- The engine is losing power.

- Fuel consumption increases noticeably.

- The stability of the power unit at idle speed is lost.

All these signs are the result of a breakdown or malfunction of the components of the speed calculation system. A detailed analysis of the reasons will be given below.

Checking the condition of the wires

When operating the car on not very good roads, one of the wires that goes to the dashboard from the speed sensor may break, which leads to damage to the speedometer. A special tester will help determine the integrity of the wires; if the wires are not damaged, the device will notify you of this with a signal, but if the signal does not arrive, the wire must be replaced with a new one.

Experts recommend not only checking the integrity of the wires, but also analyzing the functionality of the following elements:

- Check whether the contact goes to the column that connects the wires to the speed sensor. Quite often, contact is lost due to oxidation, and it will be possible to resume the operation of this element after the plaque has been thoroughly removed.

- Check the functionality of the motion sensor using a special scanner. If during the test the device reveals interruptions in operation, the element will need to be replaced with a new one.

- Check the functionality of the dashboard. To do this, you need to remove the printed circuit board from the dashboard and visually inspect its condition. If traces of oxidation are noticed at the connection point or a so-called “track break” is detected, the board must be replaced.

Malfunctions

If the speedometer on a Priora stops working, then you need to check each of its components step by step. It's better to start with the device itself.

Drive unit

The drive is checked by simply disconnecting the negative terminal of the battery. After reconnecting the terminal, the on-board computer reboots the system. Next, you need to reset the odometer, hold down the reset button and turn on the ignition. The tachometer and speedometer needles should deflect to the maximum. If this does not happen, then electrical voltage is not passing through these devices.

You can conduct an additional test of the speedometer's performance. On a Priora, the speedometer may not work due to a failure of the signal receiver drive. To check you need:

- From the “+” terminal of the battery, run a wire to terminal “26” of the red connector.

- With short touches you need to simulate the arrival of signals from the EMF.

- The arrow should deflect each time terminal “26” is touched.

If there is no response to the incoming voltage, you will have to dismantle the panel and remove the instrument printed circuit board. It needs to be inspected for breaks or oxidation of soldering and tracks. The oxidation needs to be cleaned, and the broken tracks need to be soldered with jumpers. Next, perform the following test:

- Set the tester to resistance measurement mode.

- Connect the red measuring probe to terminal “26”.

- Apply the black test lead to ground.

- The pulse input should show an operating resistance of up to 3 ohms.

If these readings are not present, then the fault lies in the radio components of the drive or its motor has burned out. Without special knowledge, such breakdowns cannot be repaired on your own. You'll have to change the drive.

Fuse

The speedometer is protected by fuse “F1”. It is located in the safety block under the dashboard, on the driver's side. It is necessary to remove the element and check the condition of the internal jumper.

If it is broken, you need to replace the element with a 10 Ampere analogue. Before replacing, it is important to clean the fuse contacts from oxidation and possible carbon deposits.

After replacement, you need to check the operation of the speedometer again.

Wiring

It's just that fuses don't blow. This was preceded by a short circuit or high voltage.

It is necessary to carefully check the wiring for breaks, deformation, and lack of insulation. All defects found must be eliminated.

If the Priora's speedometer does not work, the cause may be the speed sensor. Its verification is carried out sequentially. First you need to check the condition of the connecting plug. It is necessary to open it and inspect the contacts of both parts of the socket. If dirt, moisture, or oxidation is detected, clean with a solvent. Next, you need to check whether the electrical voltage reaches the sensor itself. Necessary:

- Set the multimeter to voltmeter mode to measure DC voltage.

- Connect the red test probe to terminal “1” of the wiring cable.

- Connect the black probe to terminal “3”.

- Turn on the ignition.

The voltmeter should show a result equal to the battery voltage. If voltage is supplied, then the sensor’s ability to generate electrical impulses is checked. This test requires:

- Raise the drive wheel of the vehicle on a jack.

- Connect one end of the control wire to terminal “2” of the sensor.

- Connect the red probe of the multimeter to the second end of the control wire.

- Connect the black test lead to ground.

- Insert the plug into the EMF socket.

- Turn on the ignition.

- Rotate the drive wheel of the machine.

As electrical voltage is applied to the sensor, it must produce electrical signals. The tester defines them as a pulse voltage from 0.6 to 12 volts. If there is no response from the tester, then you will have to dismantle the EMF to check.

Private situations

General signs do not always indicate specific breakdowns. There may be exceptions.

If individual devices refuse to work, it is quite possible that this is their personal problem. You'll have to parse the specific pointer. It may have a cracked gear that needs to be replaced.

Also, why doesn’t the instrument panel of the VAZ 2114 work? If the fuel gauge and tachometer are capricious (either they function, or they don’t react at all), the contacts and the mounting block are normal - you need to do a small check.

Reset is pressed and held, and the ignition is turned on at the same time. Raised arrows indicate the need for further searches. Lifeless - that microcracks have appeared in the shield itself. You will have to remove it and examine all soldering and traces under a magnifying glass. In principle, these are all the main options. If calling all the listed components and parts did not lead to the revival of the instrument panel, your case is individual, and you will have to determine the situation in the company of an experienced auto mechanic.

No power supply to Priora speed sensor

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

1 brown, 2 gray, 3 pink with black stripe

I don’t have a Priora, but in all schemes, including e-gas, it’s the other way around: 1 - pink (+12V) 2 - gray (signal) 3 - brown (ground)

Change pink with brown, you have confused the sensor's power supply with ground. How can you randomly connect wires in the engine control system on a new car? Do you want to kill the ECU?

I don’t have a Priora, but in all schemes, including e-gas, it’s the other way around: 1 - pink (+12V) 2 - gray (signal) 3 - brown (ground)

Change pink with brown, you have confused the sensor's power supply with ground. How can you randomly connect wires in the engine control system on a new car? Do you want to kill the ECU?

IMHO Genady you are wrong, but thanks for your participation. Today I reviewed the diagram again, I assembled everything correctly. Why didn't it work? I guess I just didn't tighten something up. I would also like to note that mainly sensors 2170-3843010-04 are available for sale. I have 2170-3843010-02 and it turned out to be very difficult to find one in the rather large Chelyabinsk. which 04 stupidly does not reach the end 3-4mm, it is a little thicker and has a slightly different shape. It’s hard to say why they did such crap at VAZ, but I didn’t think that I would experience problems with the spare part with the Priora.

Why is the old guy fucked up, he ordered me to live long.

No, it works, but every trip it cuts out for 5-10 minutes, this is very annoying, because... The EUR is cut off, the engine becomes very jerky without any speed readings, you drive in some jerks. Apparently water gets into the sensor through the gap and the board in it oxidizes. On the new one, I covered this gap with super glue. This is the kind of laboratory work I did, although I could have just rolled it out under warranty

Source

Speed sensor on Priora: purpose and principle of operation

A speed sensor or DSA is needed to measure the speed of a vehicle. Such devices are also called speed detectors, which on Priora and other modern cars are presented in the form of electrical devices operating through a control unit.

Many drivers know that it is through the speed sensor that the speedometer on a car functions, but how the readings are recorded, few even think about it. If your DS fails, replacing it will eliminate the problem. However, knowing the operating principle of such a device will be useful for all car owners in order to be able to determine the reasons why the device failed and how to prevent such consequences in the future.

It’s worth noting right away that there are two types of speed sensors: contact and non-contact. The Prioras use non-contact speed detectors (and the VAZ-2110 uses contact speed detectors), the operating principle of which we will consider in detail.

The operation of the speed sensor on the Priora is based on the Hall effect. The sensor itself is a semiconductor Hall element (located inside the working part of the “bevel”), which is designed to record pulses. These impulses are created by a rotating disk with teeth. This disc is also called the master disc, which is installed on the differential box, and it rotates at the same speed of the car wheels. When the car moves, the plates induce pulses in the semiconductor element (pulse magnitude from 1 to 5V), which are transmitted to the ECU. The rate of change of these pulses per unit time allows us to obtain information about the frequency of rotation of the disk. Below is a diagram of the design of the speed sensor on a Priora car.

The main reasons for speedometer failure

First, you need to make sure that the source of the trouble is not bugs in the chip itself, on which the vehicle operates. While the machine is in use, the so-called cache in these chips is filled with information. This is why failures occur, including temporary ones. The “mass” from the battery is simply reset in this case. Otherwise, you will not be able to reset your data. In this case, the on-board network in the vehicle is completely de-energized.

What should you do if your car smells like burnt oil? You will find the answer in our material.

How to remove the bumper on a Priora and how difficult it is to replace it - find out here.

If resetting does not help get rid of the problems, conduct a full system check:

- Check the fuse plate installed on the board in the power circuit. The required part will have the designation “IGMETER”.

- After this, it is necessary to diagnose the serviceability of the wiring located in the area, starting with the speed registration sensor and ending with the instrument panel. It is in this section that the wires begin to break. Clinching may occur and other types of defects may appear. This usually occurs due to heavy use of the vehicle.

- The contacts located in the connectors require special attention. And they can become unsuitable for use due to the formation of rust and high acidity. In this case, the contacts of the sensor and connectors can be easily cleaned to get rid of defects.

- The next step is to check the monitoring sensor based on the distance traveled by the vehicle. If you contact a service center, special equipment is used to check this part. If it is missing, then the check is performed when the car drives several kilometers. As the countdown continues, we can say for sure that the system is working properly.

What to do if the speedometer on a Priora does not work due to the dashboard

If this is where the malfunction lies, then you will need to get to the mechanism that rotates the arrows. And conduct a thorough inspection. It is recommended to drive the car into a garage box and set the vehicle's parking brake. After this, open the hood of the car and disconnect the terminal marked with a minus from the battery. Thanks to this action, you will not be afraid of a short circuit in the on-board network.

Almost anyone can remove the dashboard on a Lada Priora. Photo: tuningtaza.ru

The next stage is careful dismantling of the torpedo. And here we need to perform several actions.

- First, remove all the pads completely.

- Then carefully unscrew the steering wheel.

- Remove the switches located under the steering wheel.

The next stage is detection and unscrewing of self-tapping bolts. They allow the torpedo to gain a foothold in its place. Only when all these steps have been completed can you begin dismantling the torpedo itself. To do this, just grab the part, pulling it slightly towards you. Then the wires are disconnected. But before that they are marked so as not to be confused later. The torpedo is pulled out and carried through the passenger door.

Other causes of malfunction

It is not yet known how problems with the speedometer will persist in the new generation of Priora. Photo: smolmotor.ru

Deflection of the arrow axis is another reason why the device may fail ahead of time.

In this case, several recommendations are also given:

- First, remove the arrow itself, very carefully.

- To do this, place a small fork made of plastic under the arrow.

- The device must be lifted up, carefully, without haste.

- If the arrow was indeed bent, then it is enough to simply replace it.

The rotation of the speedometer is ensured by special gears located on the back of the dashboard, at the rear. Each gear requires inspection if there are any problems with the speedometer. If necessary, parts are replaced, there should be no problems with this.

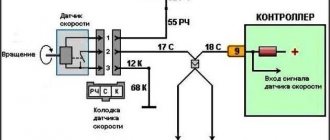

Diagram and pinout of DS Priora

Three wires are connected to the DS Priora plug. One of them is positive 12V, the second or central one is the signal wire that supplies impulses to the control unit, and the third is ground.

The speed sensor power supply circuit is shown in the photo below.

The DS pinout diagram on a Priora may be needed when replacing a plug or checking the incoming power.

What is the effect of a DS malfunction on a Priora?

All Priora car owners are familiar with the situation when the speedometer begins to act up. The arrow either shows the wrong speed value, freezes at some position or shows no signs of life at all. The reasons for this behavior are often related to the speed sensor. Such a device affects not only the operation of the speedometer, but also the engine.

If the speed sensor on the Priora is faulty, the engine will function, but the possibility of it going into emergency mode is possible when the fuel-air mixture is prepared at average values. Even on a Priora with electric power steering, if the speed sensor malfunctions, the power will not work (or work intermittently).

Let's immediately look at how the speed sensor affects engine operation. When the vehicle speed increases, the ECU understands that frequent fuel supply through the injectors is required. Naturally, the rapid movement of the car is also recorded by the level of throttle opening, for which the throttle position sensor is responsible.

If the car is coasting (downhill), then approximately the following picture occurs:

- the speed of the car increases, as evidenced by the DS readings;

- however, intensive fuel supply to the manifold is not necessary, since the ECU records the closed position of the throttle valve;

- Thus, the ECU understands that the car is coasting, which means that fuel consumption at such a moment is minimal.

In modern cars, DS play a very important role, and if you could drive a carburetor car with a broken cable as much as you like, then on injection cars, where the DS is presented in the form of an electrical element, such a breakdown will entail an increase in fuel consumption, as well as interrupted operation of the engine . That is why it is very important, if such a malfunction occurs, to eliminate it as quickly as possible.

VAZ-2114 - searching for the cause of tachometer failure

To find out why the device in question does not work, diagnostics should be carried out. For this you will need a multimeter. With its help, first of all, ring the wire that supplies power to the VAZ-2114 tachometer, and then ground. This way you can easily detect a break in the electrical network. The tester should be set to ohms.

Before testing the circuit, make sure the multimeter is operating at up to 20 volts direct current.

Please note that the minus is always present in the circuit, but the plus appears only when the ignition is started. In this case, the tester will show pulses (regular voltage surges) if the crankshaft is spinning

During this process, be sure to inspect all connectors and make sure that the wires attached to them are held properly.

A blown fuse is the most obvious reason when the tachometer suddenly fails, and along with it they “die”:

- odometer;

- speedometer;

- sensor that monitors coolant temperature;

- fuel level indicator.

In this case, they function normally:

- panel lighting;

- indicators;

- multimedia center;

- optics;

- ignition.

With such symptoms, you should first look at the fuse, indicated in the diagram as F3. Its location is the mounting block. Keep in mind that installing a new one without finding out the reason for the burnout of its predecessor is pointless. Most often the culprit is a short circuit. Experts have noticed that old VAZ model 2114 very often puzzles its owners with this breakdown after washing.

Even if you do not find a short circuit, do not rush to forget about the fuse. Check the condition of its connector. It may burn, oxidize, or become dirty. All this creates a high contact resistance, which overheats the fuse-link and contributes to its destruction.

Reasons for failure of the speed sensor on a Priora

As mentioned above, on a Priora the speed sensor is a pain. Moreover, its malfunctions do not appear after 100 thousand kilometers, but literally from the first days of operation of the new car. The reason for this is various factors:

- Oxidation of contacts - this phenomenon occurs due to a violation of the seal of the plug.

- Liquids getting inside - and although the sensor’s power supply chip (plug) is sealed, the possibility of oil and other aggressive substances (antifreeze, water) getting inside the connection cannot be ruled out.

- Damage to contacts - oxidized contacts simply fall off over time, breaking the electrical connection. Moreover, this happens even if the chip was not disconnected from the sensor.

- Violation of the integrity of the plastic housing - if the sensor housing is damaged, the product will not function.

- Damage to power cords. On Prioras, this phenomenon is very common, and if you determine that the sensor is working, then you should check the quality of the wires in the area where they enter the chip.

- The presence of dirt on the sensor body, which is a common cause of interruptions in the speed indicator. Small metal particles act as contaminants (production of gearbox gears). The particles are magnetized to the DS body.

Although the speed sensor on the Priora is relatively inexpensive (500-800 rubles), you should not rush to buy a new element. After all, the reason can only be contamination of this device or damage to the supply wires. That is why you first need to identify the cause of the breakdown, and only after that resort to eliminating it.

Checking fuses

Often the cause of a speedometer malfunction is a blown fuse. Most often, a fuse fails due to water getting on it, which flows onto the contacts, which leads to an interruption in the operation of the electrical circuit. If the check reveals that the fuse responsible for the operation of the dashboard has blown, then the car owner will simply need to replace it with a new one. Finding the right fuse is quite simple by marking “IG/METER”, but if the replacement process does not help solve the problem, then you will have to check the integrity of the wires that go to the dashboard from the speed sensor.

Signs of a malfunctioning speed sensor on a Priora

The main consequence of problems with the DSA is interruptions with the speed indicator, or more precisely, with the arrow. It can not only be motionless, but also “act up”, namely:

- indicate an incorrect speed value;

- “freeze” at one value (not just zero);

- twitch periodically.

The following types of manifestations may indicate a malfunction of the DS on the Priora:

- The electric power steering does not work (on Priors with electric power steering);

- The fuel level indicator in the tank does not work;

- unstable engine operation, which is especially evident at idle;

- loss of engine power and increase in consumption;

- jerks when changing gears;

- when coasting, the car may stall;

- motor vibrations.

If the speed sensor is faulty, the Check Engine light may light up on the dash. However, the indicator lights up only when the pulses (signal) completely stop arriving at the ECU. This is why the indicator often does not light up, although there is a sensor malfunction. The following error codes may indicate that the DS on the Priora has failed:

- 0500 - no speed sensor signal. When such an error occurs, the “CHECK” light comes on.

- 0501 - DS error.

- 0503 - if the signal from the DS is interrupted.

Private situations

General signs do not always indicate specific breakdowns. There may be exceptions.

If individual devices refuse to work, it is quite possible that this is their personal problem. You'll have to parse the specific pointer. It may have a cracked gear that needs to be replaced.

Also, why doesn’t the instrument panel of the VAZ 2114 work? If the fuel gauge and tachometer are capricious (either they function, or they don’t react at all), the contacts and the mounting block are normal - you need to do a small check.

Reset is pressed and held, and the ignition is turned on at the same time. Raised arrows indicate the need for further searches. Lifeless - that microcracks have appeared in the shield itself. You will have to remove it and examine all soldering and traces under a magnifying glass. In principle, these are all the main options. If calling all the listed components and parts did not lead to the revival of the instrument panel, your case is individual, and you will have to determine the situation in the company of an experienced auto mechanic.

Where is the speed sensor on Priora?

An element such as a speed sensor is located on the gearbox housing, or more precisely, on the clutch housing under the housing of the internal joint of the right wheel drive. It is installed in this place on almost all car models. The photo below shows the place on the gearbox where the DSA is located on a Priora.

The photo below shows the place where the speed sensor is located on a Priora in the engine compartment.

No previous dismantling is required to access it for removal, inspection or replacement. It is better to get to it from the engine compartment (not from the pit), although this is not entirely convenient.

Characteristics of the control and measuring device

The Lada Priora has an electronic speed sensor (DS). Its design consists of a plastic housing, inside of which there is a sensitive element.

Location

In order to perform diagnostics, you need to know where the speed sensor is located. On the Lada Priora it is located in the upper part of the gearbox to the right of the exhaust manifold.

Functions and principle of operation

The main function of the DS is to determine the speed of rotation of the front wheels and transmit this data to the controller. Based on the information received, the controller regulates the quantity and quality of the fuel-air mixture that enters the cylinders. This data is reflected on the speedometer and odometer, which are located on the dashboard.

The operating principle of the device is based on the Hall effect. The DS transmits pulse signals of a certain frequency to the controller.

Errors and symptoms

You should know the main signs of malfunctions:

- increased fuel consumption;

- incorrect readings on the speedometer and odometer or their absence;

- the engine is unstable at idle;

- power decreases.

If the Priora speed sensor is faulty, it must be replaced immediately.

Which speed sensor to buy on Priora: types of products

Priora is equipped with three types of speed sensors from the factory. This is important to consider before purchasing a new product. To avoid mistakes, you should first remove the product and, having copied the serial number (you can take a photo), buy a similar option. This approach will ensure that you do not make a mistake with your purchase and buy the right type of sensor.

The second note when buying a DSA for Priora is to choose only original products. Chinese devices may cost 100-200 rubles cheaper, but they may not only not be suitable for installation, as evidenced by the photo below, but also not work correctly (or not work at all).

If you bought a DS, but during installation it fits tightly into the hole, it means that the product was chosen incorrectly. Compare the diameters of the standard and new products, and only then install the part.

In order not to make a mistake with your choice and buy an original DSA for Priora, you should pay attention to the presence of the serial number:

- 2170-3843010-04;

- 2170-3843010-02;

- 2170-3843010.

The main difference between them is in the calibration (the type of signal perceived by the controller) and the shape of the working part where the semiconductor element is located. Choose the products correctly, as the correctness of their operation depends on this.