The design of modern diesel and gasoline power units may vary depending on the fuel system that the manufacturer uses in its cars. One of the most progressive developments of this system is the Common Rail fuel rail.

In short, its operating principle is as follows: a high-pressure fuel pump (read about its design here ) supplies diesel fuel to the rack line. In this element, the portion is distributed among the nozzles. Details about the operation of the system have already been described in a separate review , but the process is regulated by the ECU and the fuel pressure regulator.

Today we’ll talk in more detail about this part, as well as its diagnostics and operating principle.

Functions of the fuel pressure regulator

The function of the RTD is to maintain optimal fuel pressure in the engine injectors. This element, regardless of the intensity of the load on the unit, maintains the required pressure.

When engine speed increases or decreases, the amount of fuel consumed can either increase or decrease. To prevent a lean mixture from forming at high speeds and a too rich mixture at low speeds, the system is equipped with a vacuum regulator.

Another benefit of the regulator is compensation of excess pressure in the rack. If the vehicle were not equipped with this part, the following would happen. When less than the required amount of air enters through the intake manifold, but the pressure remains the same, the control unit would simply change the time of spraying the fuel (or the finished VTS).

However, in this case it is not possible to completely compensate for the excessive pressure. Excess fuel still has to go somewhere. In a gasoline engine, excess gasoline will flood the spark plugs. In other cases, the mixture will not burn completely, causing particles of unburned fuel to be removed into the exhaust system. This significantly increases the “gluttony” of the unit and reduces the environmental friendliness of automobile exhaust. The consequences of this can be very different - from heavy soot while driving to breakdown of the catalyst or particulate filter.

Checking the technical condition of the regulator

On models equipped with a standard pressure gauge, it is enough to simply read the readings of the device and compare them with standard data. For simpler models, you will need to connect an external pressure gauge to the system. In this case, the following sequence of work is performed:

- Unscrewing the spool from the inner surface of the fitting.

- Attaching the pressure gauge hose to the fitting.

- Starting the internal combustion engine and reading the instrument readings.

- Removing the vacuum hose from the pressure regulator.

- Repeated readings at short intervals.

An increase in pressure by 20...80 kPa during repeated measurements will indicate the serviceability of the regulator. If the readings remain the same, the part should be considered faulty.

Operating principle of the fuel pressure regulator

The fuel pressure regulator operates according to the following principle. The injection pump creates pressure, the fuel flows through the line into the ramp in which the regulator is located (depending on the type of vehicle).

When the volume of pumped fuel exceeds its consumption, the pressure in the system increases. If it is not reset, sooner or later the circuit will break at its weakest link. To prevent such a breakdown, a regulator is installed in the rail (it can also be located in the gas tank), which reacts to excessive pressure and opens an outlet to the return circuit.

Fuel leaks into the fuel system hose and flows back into the tank. In addition to relieving excess pressure, the RTD reacts to the vacuum that is created in the intake manifold. The higher this indicator is, the less pressure the regulator will withstand.

This function is necessary so that the engine consumes less fuel while operating at minimum load. But as soon as the throttle valve opens further, the vacuum decreases, causing the spring to become stiffer and the pressure to increase.

Choosing a new regulator

Finding a new fuel pressure regulator for your car is easy. It is best to search by car parameters, however, in the secondary market of automotive components you can find universal regulators and even tuning (sports) models with wide applicability. If you are afraid of making a mistake, then search by:

- Catalog number of the existing RTD;

- Vehicle parameters: make and model, year of manufacture, engine.

Searching by VIN code gives the exact result. Taking into account the fact that the car enthusiast usually does not know the catalog numbers of the necessary spare parts, it is worth selecting them according to the VIN code or vehicle parameters. In the second case, you should turn to the Avto.pro spare parts catalog - here it is easy to select any spare parts, and interchangeable analogues will be offered to the car enthusiast by the marketplace search engine. This saves time and nerves.

If you decide to take a spare part from the secondary market, then you should pay attention to the name of the manufacturer . Companies included in the lists of suppliers to the conveyors of automobile concerns, in the vast majority of cases, offer spare parts of excellent quality under the names of their own brands. When choosing a fuel pressure regulator, we advise you to take a closer look at the products of the following companies:

- VDO (Germany);

- Denso (Japan);

- INZI (South Korea);

- Bosch (Germany).

RTDs are also offered by many packaging companies, such as Kemp and Avtofit. Quality varies from company to company, but the general rule applies here: the cheaper the spare part, the worse its quality. However, we note that this rule also has exceptions. However, in the case of pressure regulators, it is better not to skimp. A good analogue or original is not very expensive and lasts for a long time, so you will forget about the breakdown of the part for a long time.

Device

The design of classic regulators consists of the following parts:

- Durable metal housing (must have perfect tightness, as it is subject to changes in fuel pressure);

- The interior of the body is divided into two cavities by a diaphragm;

- To ensure that the fuel pumped into the ramp is retained there, a check valve is installed in the housing;

- A rigid spring is installed under the diaphragm (in the part where there is no fuel). This element is selected by the manufacturer in accordance with the modification of the fuel system;

- There are three fittings on the body: two for connecting the supply (input to the regulator and output to the injectors), and the other for return;

- Sealing elements for sealing the high pressure fuel system.

The general operating principle of the RTD was described a little higher. In more detail, it functions like this:

- The injection pump pumps fuel into the ramp;

- The injectors open in accordance with the signal from the control unit;

- At lower speeds, the cylinders do not need a lot of fuel, so the ECU does not initiate strong opening of the injector nozzles;

- The fuel pump does not change its mode, so excess pressure is created in the system;

- The pressure drives a spring-loaded diaphragm;

- The circuit opens to dump fuel back into the tank;

- The driver presses the gas pedal;

- The throttle opens more;

- The vacuum in the intake manifold decreases;

- Additional resistance is created to the spring;

- It is more difficult for the diaphragm to maintain this resistance, so the circuit is blocked to some extent (depending on how hard the pedal is pressed).

In some modifications of fuel systems with the supply of a combustible mixture under pressure, instead of this regulator, an electronic valve is used, the operation of which is controlled by the ECU. An example of such a system is the Common Rail fuel rail.

Here is a short video about how this element works:

We disassemble the BOSCH fuel pressure regulator. Principle of operation.

Location in the vehicle structure

A modern car in which such a device will be installed can use one of two regulator layouts:

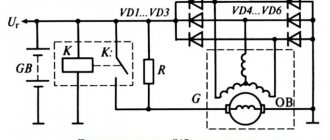

- The fuel supply system line is equipped with a return line. In this case, the regulator, or valve, will be installed on the fuel rail. A supply hose will be attached to the valve inlet (input from the pump at one end, and output to the nozzles at the other), and a return hose is connected at the outlet;

- Main line without recirculation. In this case, the regulator is installed next to the fuel pump in the gas tank (often included in its design). Its operation is regulated either by the ECU or by the mechanism of the pump itself. Fuel is dumped in the tank itself.

The first scheme has several disadvantages. Firstly, if the unit depressurizes, gasoline or diesel fuel will spill into the engine compartment. Secondly, unused fuel is unnecessarily heated and returned to the gas tank.

For each engine model, its own modification of the regulator is created. In some cars you can use universal RTDs. Such models can have manual adjustment and be equipped with a pressure gauge. They can be used as an alternative to the standard regulator, which is installed on the ramp.

Diagnostics and malfunctions of the fuel regulator

All modifications of regulators have a non-separable design, so they cannot be repaired. In some cases, the part can be cleaned, but its service life does not increase much. When a part breaks, it is simply replaced with a new one.

Here are the main reasons for failure:

- The spring is broken;

- Formation of a fistula in the body (often due to exceeding the pressure threshold or mechanical damage);

- Natural wear and tear of moving elements;

- Corrosion formation;

- Clogged channels.

When diagnosing the device, you should remember that some symptoms are similar to fuel injection pump failures. It is also not uncommon for the fuel system to malfunction, the symptoms of which are very similar to a regulator failure. An example of this is clogged filter elements.

In order for this element to work out its intended life, it is very important to pay attention to the quality of the fuel used.

What are the consequences of malfunctions in the operation of RDTs?

Over time, the engine starts more and more poorly. Fuel begins to come out of the cracks, which leads to a strong increase in its consumption. When the pressure changes unevenly, the dynamics of movement are disrupted, surges occur, and the car jerks during acceleration.

Is it possible to repair a failed part? In most cases, no, you have to completely change it. Repair units are almost always non-separable. Some experts suggest repairing the component, but this is dangerous. It is better to buy a new regulator - fortunately, it is inexpensive.

Determining violations in the operation of RTDs is not a very difficult task, which can be handled independently. Remember that this part of the machine needs to be checked periodically. By detecting the problem in time, you will protect important car components from rapid wear.

How to check the fuel pressure regulator?

There are several simple methods for checking the fuel regulator. But before we consider them, let’s pay attention to the symptoms that may directly or indirectly indicate a malfunction of the RTD.

When should you check your pressure regulator?

Difficulty starting the engine may indicate a malfunction of the regulator. Moreover, in some car models this happens after the engine is idle (cold start), while in others, on the contrary, during a hot start.

Sometimes situations occur when, if a part malfunctions, a message about engine emergency mode is displayed on the instrument panel. However, this is not the only failure that activates this mode.

On some cars, a signal with a filament coil periodically appears on the dashboard during a trip. But even in this case, before replacing the part, it will be necessary to diagnose it.

Indirect signs include:

- Uneven operation of the unit;

- The car stalls at idle;

- The crankshaft rotation speed sharply increases or decreases;

- A noticeable decrease in the power characteristics of the motor;

- There is no response to the gas pedal or has significantly deteriorated;

- When shifting to a higher gear, the car loses a lot of dynamics;

- Sometimes the operation of the internal combustion engine is accompanied by jerks;

- The “gluttony” of the car has noticeably increased.

Checking the pressure regulator on the stand

The easiest diagnostic method is to take the car to a service center that uses diagnostic stands. To check you will need:

- Remove the fuel rail along with the RTD;

- All contacts and hoses are connected to the module on the stand;

- The device simulates the operation of a motor in different modes, while measuring all parameters.

The stand program contains different algorithms that determine the serviceability of the regulator. Such programs are used only by service centers, so it is impossible to carry out this diagnostic procedure without visiting a service station.

Checking the regulator without removing it from the car

It must be remembered that this is not possible in all cases, but if the vehicle structure allows you to get to the regulator without major dismantling work, then the procedure can be performed as follows:

- First, a visual inspection is carried out. It will be difficult not to notice the depressurization of the case. The same procedure will help identify any mechanical damage, as well as the formation of rust;

- Disconnect the vacuum hose, and install a pressure gauge between the supply fitting and the fuel hose. We start the engine. If the device shows stable pressure, then the regulator is faulty. The arrow indicator should vary from 0.3 to 0.7 and src=»https://www.avtotachki.com/wp-content/uploads/2020/10/uqaaaggpaoa-1920-scaled.jpg» class=»aligncenter » width=»800″ height=»600″[/img]

- Another method is to clamp the return hose. The pressure gauge is installed according to the previous scheme. The device reading should immediately jump. The same procedure can be carried out without a pressure gauge. We just start the engine, clamp the return line and listen to how the unit works. If its operation has stabilized, then the regulator needs to be replaced.

Checking the regulator using the substitution method

This is the surest way to verify that a part is faulty. In this case, we remove the element being diagnosed and install a known-good analogue in its place.

If you do not undergo diagnostics in a timely manner, the engine may suffer serious damage. If not the unit, then some important element of the fuel supply system will definitely fail. And this is unjustified waste.

Signs of RTD malfunction

The mechanical regulator is a reliable element due to its simplicity of design. But it also breaks. A malfunction of the RTD is manifested by a number of symptoms:

- Difficulty starting the engine.

- Instability and “swimming” of revolutions.

- Reduced power and dynamic performance of the car.

- Spontaneous stop of the unit at idle.

- Jerks and jerking of the car when changing the engine operating mode.

Malfunctions of other components of the injection system also give the same symptoms, which makes it difficult to identify the cause of incorrect operation of the power unit. At the same time, when searching for a problem, car owners do not even pay attention to the RTD, believing that there is nothing to break in it.

- reduction in spring stiffness;

- valve jamming (RDT functions spontaneously and haphazardly);

- valve jamming;

- clogged channels;

The pressure regulator is considered maintenance-free, and if a malfunction is detected, it is replaced.

Something else useful for you:

Possible causes of failure

Possible causes of failure of the fuel pressure regulator include:

- The car was idle for a long time, and the fuel system was not used;

- Water has gotten into the fuel (condensation is natural under some operating conditions);

- The spring has weakened;

- The membrane is damaged;

- The check valve is stuck or worn;

- The car owner does not change the fuel filters on time;

- The driver fills in low-quality fuel (the valve becomes clogged).

If there is any suspicion of a malfunction of the fuel regulator, it must be checked. As we have already said, for this you can use a simple pressure gauge (even the one used to measure the pressure in tires will do).

How to replace the regulator?

The procedure for replacing the fuel pressure regulator is simple. The main thing is to adhere to the following scheme:

- The fitting plug is unscrewed at the end part. An O-ring is installed in it. In a working regulator, this element is elastic and without damage. If inconsistencies are identified during the inspection, the part or the entire plug is replaced;

- The umbrella is turned out of the fitting. To do this, you will need a cap from the tire (the metal version has clamps that will help with this);

- Next, the regulator is checked in operation. A hose with a pressure gauge at the other end is connected to the regulator. It is fixed with a clamp. The internal combustion engine is started and the pressure in the system is checked. At this moment, the indicator should be in the range from 284 to 325 kPa. Next, the hose is disconnected from the device and the readings on the pressure gauge are checked. In this case, the pressure should increase by approximately 20-70 kPa. If this parameter has not changed, it means that the regulator is faulty, and then it must be replaced;

- To replace the regulator, you must first reduce the fuel pressure in the system. This is done by unscrewing the nut securing the fuel pipe. It is also necessary to unscrew the two bolts that secure the regulator itself to the ramp;

- Carefully remove the regulator fitting from the fuel rail;

- The fuel tube is disconnected (if the system has not yet released the pressure, you need to prepare an empty container into which the freed end of the tube is quickly placed);

- Now you can remove the regulator.

When installing a new fuel pressure regulator, the seating areas of the tubes and sealing elements must first be moistened with gasoline so that the elastic parts do not receive mechanical damage.

Diagnostics

The serviceability of the fuel pressure regulator is checked by measuring the pressure in the fuel rail. Let's consider the algorithm for checking the pressure regulator using the example of a VAZ-2110 car with an injection power system. This car uses an injector with fuel recirculation, so the RTD is located on the fuel rail. To do this, you will need a pressure gauge, as well as a piece of oil-resistant rubber tube and two clamps. The algorithm of actions is as follows:

- We produce fuel from the ramp (we remove the fuse responsible for powering the electric fuel pump, start the engine and wait for it to stop voluntarily).

- On the ramp we find a fitting designed to relieve pressure and remove the cap on it.

- We unscrew the spool valve from the fitting (carefully and slowly, since fuel may remain in the ramp).

- We pull the tube onto the fitting and secure it with a clamp.

- We connect a pressure gauge to the tube and also fix it.

- We put the fuse back and start the engine.

- We install it on the XX motor.

- We check the pressure gauge readings (on the VAZ-2110 this parameter is 2.8-3.2 Atm.).

- We find the pipe coming from the manifold on the regulator and disconnect it from the RTD. If the device is working properly, this action will lead to an increase in pressure by 0.3-0.7 Atm.

Inconsistencies in pressure gauge readings will indicate a problem with the regulator or other system components. To accurately identify the cause of the malfunction, you need to diagnose the operation of other components.

Video: Fuel pressure regulator. It doesn't drive well, it doesn't start well.

The fuel line and the injector ramp that supplies the engine injectors operate under a pressure of about 3 bar. Since gasoline is supplied by an electric pump, the system uses a special valve that limits the fuel pressure. Otherwise, the nozzles will leak and the engine will choke on the over-enriched mixture. To avoid problems with fuel supply, you need to promptly diagnose the signs of a malfunction of the fuel pressure regulator (abbreviated as RTD) and know how to eliminate it.