The control system of a car engine contains a certain mathematical model, where output values are calculated based on measurements of input values. For example, how long the injectors open depends on the amount of air and many other variables. But besides them, there are also constants, that is, characteristics of the fuel system that are written in memory and cannot be controlled. One of them is the fuel pressure in the rail, or more precisely, its difference between the injector inlets and outlets.

The role of the fuel regulator in the car system

At different engine operating modes, it is necessary to create the appropriate fuel pressure in the fuel system.

To implement this task in practice, a special pressure regulator is used. It is used in injection engines, where the correct operation of the engine depends on the accuracy of the injection parameters. When the governor is faulty, the engine runs unevenly, acceleration times are increased, and in some cases power can be significantly reduced. So, for example, if the amount of air coming from the manifold remains unchanged, and there is more fuel than necessary, the air-fuel mixture will not ignite or will not burn completely.

Even if in this mode the electronic control unit shortens the injector opening interval, it will not be possible to completely compensate for the excess fuel pressure. This will lead to interruptions in engine operation and an increase in the amount of unburned fuel in the exhaust, which can prematurely damage the catalytic converter or particulate filter.

Design and operation of RTD

The fuel pressure regulator is a device designed to maintain pressure in the injectors at different operating intensities. Essentially, this regulator is a diaphragm valve, on which fuel presses on one side and the intake manifold spring on the other. This device consists of a fuel tank, a fuel drive with a pump, injectors, a fuel filter, a switch and an electronic control unit pump.

I think many car enthusiasts know what factors determine the amount of fuel injected. Absolutely right, it depends on its pressure inside the fuel rail, the vacuum process taking place in the manifold and on the duration of the injector operation.

To more accurately calculate the amount of fuel injected, taking these three factors into account, an appropriate regulator is used (only in systems with fuel recirculation).

The regulator is located on the fuel rail, and the principle of its operation includes the following points: at the initial stage of pump operation, the fuel mixture leaves the tank and is cleaned in the filter; then enters the regulator, where the system maintains its uniform pressure all the time.

If there is no recirculation in the system, then such a part must be placed directly in the tank, while the function of maintaining pressure remains the same. True, in this case the difference between the pressure in the intake manifold and the fuel pressure will not be constant, so it is taken into account based on the injection duration.

Let's now take a closer look at the principle of operation of the device in a system with fuel recirculation. In such conditions, the regulator looks like two chambers separated by a membrane: fuel and spring. The condition of the membrane is influenced by different types of pressure: from the top, the spring pressure and the pressure of the intake manifold, and from the bottom, the fuel pressure entering the chamber through the intake ports. If the fuel pressure exceeds the spring force, the valve opens slightly and allows fuel to flow into the return line.

In systems with unintended recirculation, where the pressure regulator is most often located directly in the fuel tank, there is no need for a return pipeline, so it is not provided for in the design. The calculated amount of fuel is immediately supplied to the injectors, and its excess is returned to the tank without entering the engine compartment, unlike the previous system. As a result, the fuel heats up less, which means the amount of evaporation is much less.

Also, at present, there is an automatic fuel control system that does not provide a mechanical fuel pressure regulator. Control of its parameters and the required amount of supply is regulated by a special module that measures the voltage on the electric pump.

This system allows you to reduce fuel heating to the optimal value, and the fuel pump supplies only the amount of combustible mixture that the engine needs in a specific time period, which significantly increases fuel economy. As an addition, a relief valve is installed in the automatic system to prevent pressure build-up.

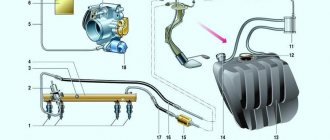

Installation locations

On cars, the injection system is equipped with a separate line for draining excess gasoline, which goes from the fuel rail to the gas tank (fuel recirculation). In such injectors, the regulator is installed directly on the fuel rail (or connected to it), so the unit quickly “reacts” to changes in engine operating conditions and adjusts the pressure in the rail. In this design of the power system, a mechanical type RTD is used.

There is another version of the injector - without gasoline recirculation. In this system there is no “return” at all, and regulation is carried out at the output of their fuel pump. A feature of such a system is the location of the regulator - in the tank or near it. An RTD is already used here, the operation of which is controlled by the ECU - the control unit, through a sensor installed in the ramp, monitors the necessary parameters and corrects them by sending signals to the regulator.

Power systems with electronic regulators are used less frequently than mechanical ones due to their complex design and, accordingly, lower reliability.

Location and purpose of the fuel pressure regulator

The pressure regulator is a structural part of the vehicle's power system. It is placed on the fuel frame and involves connection to three lines:

- inlet - through it fuel flows to the regulator;

- direct exhaust - directs the flow with adjusted pressure to the internal combustion engine;

- return exhaust - if excess pressure is detected, it returns part of the fuel to the tank.

The fuel pressure entering the regulator is created by a fuel pump, in front of which a filter element is installed. Thus, the task of the part is reduced to monitoring and, if necessary, flexible change in the pressure of pre-purified fuel in accordance with the needs of the engine.

Operating principle of RTD

The valve design and operating principle depend on the type of fuel system of a particular vehicle. There are 3 ways to supply gasoline from the tank to the injectors:

- The pump together with the regulator is installed inside the tank; fuel is supplied to the engine through one line.

- Gasoline is supplied through one tube and returned through another. The fuel system check valve is located on the distribution rail.

- The circuit without a mechanical regulator provides for electronic control of the fuel pump directly. The system contains a special sensor that registers pressure; the pump performance is regulated by the controller.

In the first case, the return flow is very short, since the valve and electric pump are interlocked into a single unit. The RTD, located immediately after the supercharger, dumps excess gasoline into the tank, and the required pressure is maintained throughout the supply line.

The second option is used in most foreign cars. A valve built into the fuel rail allows excess fuel to flow into the return line leading to the tank. That is, 2 gasoline pipes are laid to the power unit.

There is no point in considering the third circuit - instead of a regulator, there is a sensor whose functionality is checked using a computer connected to the diagnostic connector.

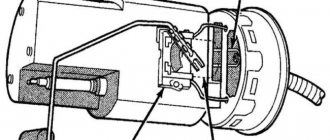

A simple fuel pressure valve installed in the fuel pump unit consists of the following elements:

- cylindrical body with pipes for connecting the supply and return lines;

- a membrane connected to a locking rod;

- valve seat;

- spring.

The amount of pressure in the supply line depends on the elasticity of the spring . While most of the fuel goes into the cylinders (high load on the engine), it keeps the membrane and valve stem closed. When the crankshaft speed and gasoline consumption decrease, the pressure in the network increases, the spring compresses and the membrane opens the valve. The fuel begins to be discharged into the return line, and from there into the gas tank.

The fuel pressure regulator installed in the rail operates on a similar principle, but reacts faster to changes in load and gasoline consumption. This is facilitated by connecting an additional pipe of the element to the intake manifold. The higher the crankshaft speed and the vacuum on the spring side, the stronger the membrane presses the rod and closes the passage of fuel into the return line. When the load decreases and the speed drops, the vacuum decreases and the rod releases - the return flow opens and excess gasoline begins to be discharged into the tank.

Location of the RTD in the fuel rail of the vehicle

The use of a special regulator for the fuel system is associated with the need to reduce or increase the pressure of fuel supply to the engine when it operates at different speeds. For example, idling requires a very small amount of fuel, while as the speed increases, the intensity of its injection should increase.

In order to equalize this difference on all injectors, the device is installed at the end of the fuel rail. As standard, it is mounted in the fuel rail. Very often, its location can be changed - for example, the RTD is placed in a return hose or even in a tank.

Placement in the gas tank makes it possible to avoid the need to install additional fuel lines, and the check valve blocks excess fuel from entering the system. Regardless of the location, the RTD performs the same function, which is to support the fuel pressure required and safe for the vehicle engine.

This is interesting: Description and purpose of the vehicle diagnostic card: 7 points required to be filled out

For systems without fuel recirculation, the RTD is located in the fuel tank and is designed to maintain the same fluid pressure relative to atmospheric pressure. The specificity of this arrangement is that the differences between the fuel pressures in the tank and in the intake manifold will not be constant, which is ultimately taken into account in the duration of injection of the working fluid.

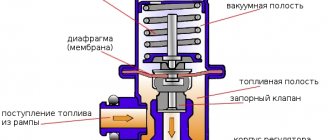

Regulator design

The design of the mechanical fuel pressure regulator is simple. It consists of a body, which is internally divided by a membrane into two chambers. One of them is called the fuel chamber, the second is called the vacuum chamber (or simply vacuum). Each of the chambers is connected to the system components by fittings and channels. The fuel chamber is connected through channels to the fuel rail, and a fitting for the line for draining excess gasoline (“return”) also comes from it. The vacuum chamber also has a fitting, which is designed to connect to the intake manifold.

A needle valve is fixed to the membrane, the seat for which is the channel of the drain line fitting. This valve is constantly in the closed position, and a spring installed in the vacuum chamber presses it to the seat.

How does the fuel pressure regulator work?

On the one hand, the pressure in the regulator is generated by a spring and this is combined with pressure from the intake manifold. In the opposite direction, the force is generated by the fuel pump. When the spring compression forces and the energy from the intake manifold are exceeded, the diaphragm valve opens. This cycle ensures the intake of fuel in the required volume. Next, the pressure from the supplied fuel decreases and the pressure regulator membrane closes.

Schematically, functionality is ensured due to design features. Fuel is pumped into one of the two chambers. The remaining one has a spring. The cavities are separated by a membrane that opens when there is a difference in pressure.

If there is no valve, its functions are assigned to an electronic special sensor. It measures the voltage in the electric pump that supplies gasoline to the system. Thanks to this solution, it is possible to fix the pressure at the optimal level, as well as remotely regulate the fuel supply. This makes it possible to directly control the pump.

The system, developed on an electrical basis, is very accurate when compared with its mechanical counterpart. However, practice shows that “mechanics” gives more reliability when used in domestic conditions. The block is less exposed to negative external influences.

Symptoms of element failure

During the operation of the car, a car owner may encounter two types of RTD failure:

- The pressure drop in the rail is below the permissible level - the regulator directs most of the fuel through the return line to the gas tank.

- Increase in pressure to maximum - the element does not allow fuel to flow into the return line.

Note. As a rule, the first malfunction is accompanied by a rapid drop in pressure in the system after the electric fuel pump is turned off.

It is quite simple to track the signs of the first malfunction - the power unit is sorely lacking fuel for normal operation in all modes. Symptoms appear as follows:

- cold starting is difficult, the engine runs extremely unstable until it warms up;

- “dips” during acceleration and jerks when moving uphill;

- the car often stalls at idle;

- Gasoline consumption per 100 km increases.

The increased fuel consumption is explained by the actions of the driver trying to compensate for the lack of fuel mixture by pressing the accelerator pedal. Driving in this mode is quite difficult - it is better to immediately check the fuel pressure regulator for functionality.

When the valve does not allow excess fuel to flow into the tank, the following consequences are observed:

- Due to too high pressure from the ramp side, the injectors begin to leak and fill the cylinders with pure gasoline, and not with the working air-fuel mixture.

- The engine is bad, it emits black smoke from the exhaust, and sometimes you can hear popping noises in the exhaust manifold. The reason is flashes of unburnt fuel.

- Consumption increases noticeably.

- Leaks may be observed at the joints of the fuel pipes, and a strong gasoline smell may be felt.

Practical experience shows that a lack of fuel mixture occurs more often than an excess. That is, the most common problem with an RTD is the draining of gasoline into the return pipe and tank.

Video

Problems with the RTD: it doesn’t drive well, it doesn’t accelerate, it jerks.

How to check the fuel pressure regulator. Example on a BMW E34 (BMW E34).

How to measure the pressure in the fuel system on a VAZ 2110 car.

Violation of the integrity of the body

Poor quality fuel, the presence of foreign impurities in it and other negative factors contribute to the destruction of the hull. The device stops working normally. Detecting a small fluid leak is quite difficult. This is due to the fact that gasoline evaporates quickly. Smudges and stains form at the installation site.

If a violation of the integrity of the housing is detected, the product should be replaced immediately. A leak may cause a fire.

Why is a control valve needed?

The fuel supply system of most passenger cars requires continuous operation of an electric fuel pump. It constantly pumps gasoline into the fuel line and ramp, raising the pressure to the maximum (5–7 Bar depending on the brand of car). But such performance is needed only under increased load on the engine, when it develops high speeds and consumes a lot of fuel mixture. In normal mode, a fuel pressure at the injectors of 3–3.5 bar is sufficient.

The fuel pressure diaphragm valve, installed in the engine power system after the fuel pump, performs 3 main functions:

- Limits the fuel pressure in the line at low engine loads, dumping excess fuel back into the tank through a separate tube.

- When the gasoline consumption of the power unit increases, the return flow is partially or completely blocked by the regulator. In this way, the valve maintains the minimum pressure required for normal operation of the motor.

- Maintaining pressure for a long time after stopping the power unit.

Without an RTD, the pump would “push through” the locking mechanisms of the injectors and gasoline would flow into the cylinders uncontrollably. In addition, the regulator protects the line from leaks at the connections, which will inevitably appear under the influence of strong pressure.

Failure options

The regulator is a simple device from a technical point of view, so there are few breakdowns that can happen to it. In almost all cases it is recommended to replace the RTD.

What can break:

- Spring. This is the main failure in the RDT. Due to the weakening of the spring, the engine becomes “starved”, there is not enough fuel at high speeds, when the clutch is pressed and during transient conditions.

- Pollution. When clogged, the ability to pass fuel is lost. The engine stops in any operating mode. If the RTD is heavily contaminated, the pressure in the vehicle rises sharply and fuel leaks through the sealing material. The problem is solved by pumping a large amount of fuel into the fuel pump.

- Jammed. The RTD in the ramp may periodically jam. The car twitches.

Causes of fuel pressure regulator malfunctions

RDT may fail for several reasons. For example, defective parts are found on Russian-made cars. There are significantly fewer defects on foreign models, but you can purchase a defective RTD by purchasing a non-original spare part.

Mostly the check valve breaks down due to natural aging. Let's say this can happen after a hundred thousand mileage or more. It should be noted that check valve failures are not common. Most often, in an RTD, the membrane dries out over time, less often the valve jams, and even less often the spring breaks or weakens.

Sensor failure may occur due to low-quality gasoline. For example, in winter, fuel was filled with water, and water got into the regulator. If the fuel filter is not replaced on time, dirt gets into the parts of the power system, including the regulator. In this case, the RTD valve most often jams. It’s hard to imagine what could happen to the spring, but apparently, it still breaks sometimes.

Preparatory work

- Take a tire pressure gauge and wrap flax or fum tape around the tip, this will prevent fuel spills and air leakage.

- Prepare a hose with a maximum internal diameter of 9 millimeters, and you will also need clamps for fastening. It is necessary to fix the hose on the pressure gauge and tighten everything with clamps.

- Place the prepared tool on the engine so that the hose and pressure gauge fixed on it do not roll off the surface. This will avoid fuel spilling on the engine.

- We unscrew the nipple spool on the ramp (fuel splashing is possible due to residual pressure).

- We put a hose with a pressure gauge on the ramp connections and secure everything with a clamp.

- Homemade pressure gauge for measuring pressure in the rail assembly.

Diagnostics

There are a number of methods to diagnose the condition. All of them are simple, even a novice car enthusiast can handle them.

Test methods:

- Visually. This is an option for carburetor engines. Pinch the valve or disconnect it. The fault can be determined by how intense the fuel flow is. The method is simple, but inaccurate.

- Pressure gauge. Install the device between the fitting and the hose, temporarily disconnecting the vacuum hose. The reading on the pressure gauge should rise to 0.7 bar.

- By pinching the hose. Check the RTD by clamping the return line. The pressure gauge should respond immediately. If the engine does not rev up, the governor is faulty. Start the engine by clamping the return line. Watch the speed and listen to his work. If its operation is uniform, the adjustment valve is faulty - it must be replaced.

The procedure for checking the performance of an RTD depends on its type - mechanical and electrical components are checked differently.

How to check a mechanical regulator:

- locate the fuel return hose under the hood;

- start the engine - let it run for a minute to warm up a little;

- using pliers - very carefully, pinch the return hose;

- if after clamping the engine begins to work well, then the problem is a broken RTD.

It is forbidden to pinch the hoses for a long time - this creates additional stress on the pump, which leads to its breakdown in the future.

In injection engines, fuel hoses are made of metal rather than rubber to increase reliability. Electrical sensors in such systems are made on the basis of strain gauges. To determine if the RTD on the injector is faulty, check the voltage at the sensor output.

In diesel engines, RTDs are checked by measuring the resistance of the sensor inductor. Usually the normal value is around 8 ohms. If the resistance is noticeably higher, or vice versa, much lower than stated, the regulator is broken. Detailed diagnostics are carried out only in the service center - at special stands where sensors and the entire fuel supply system are checked.

How to detect a malfunction?

There are a number of features in the operation of a vehicle that may indicate failure of the RTD. Consider these signs of a poor fuel pressure regulator:

- When starting the engine, you need to turn the starter for a long time and at the same time keep the gas pedal depressed.

- At idle or low speeds, extremely unstable operation of the engine is observed, to the point that it may stall. An attempt to apply more gas does not lead to the desired result - the power practically does not increase.

- Sharp changes in engine speed at idle are noticeable.

- Loss of acceleration after changing gears or sudden jerking of the car while driving.

- Significant increase in fuel consumption.

- Fuel leaks on the system hoses. However, replacing them and installing new clamps does not lead to a better result.

Repair and replacement of RTD

If your vehicle exhibits any number of symptoms of fuel regulator malfunction, diagnosing the fuel regulator is the only step toward returning it to proper operating parameters. In the event that a check indicates that the device is out of order, the following must be done.

Step 1. Remove the fitting plug to be able to control the pressure of the flammable liquid at its end.

Step 2. Using a special metal protective cap, carefully remove the spool from the inner cavity of the fitting.

Step 3. Reduce the pressure in the power system, and then carefully remove the vacuum hose from the device.

Step 4. Remove the nut used to secure the fuel supply tube.

Step 5. After the two bolts that secure the module to the fuel frame are unscrewed, you need to smoothly remove the fitting from their holes.

Step 6. Carefully remove the RTD.

As a rule, the removed device cannot be repaired, and it is replaced with a new, more functional one. You can purchase a module with delivery either in any specialized store or via the Internet.

Signs of device malfunction

The valve is operated at an intense rhythm. Long-term loads affect its performance. It is necessary to promptly identify the symptom of a malfunction of the fuel pressure regulator in order to replace it. Failures and malfunctions are determined in most cases by indirect signs. Such factors include the following phenomena:

- fuel consumption increases;

- the power characteristics of the internal combustion engine are deteriorating;

- the power plant loses stability at idle;

- dips occur or jerks appear when switching speed modes;

- the car responds inadequately to pressing the gas pedal.

Checking the fuel pressure regulator often begins with determining the quality of the springs. As the device is used, their hardness decreases. This phenomenon negatively affects performance, in particular, the valve opens earlier than the operating cycle requires.

The result of a drop in rigidity is that fuel is sent to the tank in larger quantities than intended by the designers. At the same time, the pressure in the system decreases, and the engine loses efficiency and power. If there is a design possibility, then the weak spring is replaced.

We recommend: Step-by-step instructions for checking the automatic transmission yourself when buying a used car

The low quality of domestic fuel also has a negative impact on the functioning. As a result, the membrane becomes clogged, after which it cannot close partially or completely. As a result, the fuel pressure in the system also drops, which leads to negative phenomena.

You can get rid of mechanical blockages by cleaning. This is carried out if the design of the device allows. It is worth considering that repairing the fuel pressure regulator does not always save users. This happens when there is significant wear or wear on the valve as a whole or its individual parts. It is not always possible to restore the element to full operation.

There are cases when the RTD becomes jammed. In this case, the engine simply stalls, and at the same time fuel begins to flow from poorly sealed joints. Here, repairs are unpromising; all that remains is a complete replacement of the unit with a new one. If this happens, then it is worth changing the gas station or not refueling at dubious gas stations in advance; it is also worth checking the functionality of the fuel filter, which has failed to be properly cleaned.

Partial loss of valve functionality often occurs. In such a situation, the engine operates jerkily, which the driver feels very well while operating the car. Sometimes passengers feel them too. Timely cleaning of passages will be relevant, restoring the product’s functionality .

An electronic device is less sensitive to the quality of gasoline. It is also little influenced by mechanical factors. However, it is not without its shortcomings, weaknesses and characteristic vulnerabilities. But if you avoid situations with low-quality fuel, you can largely avoid loss of regulator functionality.