A possible sign of the need to replace the fuel supply hose to the fuel rail is the smell of gasoline in the cabin. This hose begins to flow at the junction with the fuel supply line from the fuel tank (plastic tube). The location of this connection is below the battery near the partition of the engine compartment. Moreover, for many people the hose starts to leak in cold weather.

I started to leak when my Kalina was 4 years old, in frosts of -25, and heavily, in copious drops. When the engine warms up, the leak in many Kalinovods disappears. So it was with me. Since in such frost there is no point in getting under the hood yourself if there is no warm garage, and in such weather there are enough customers in the services, so I went. To be honest, it was scary, because I saw how quickly the cars were burning. Luckily there was a fire extinguisher in the trunk. When the temperature warmed up to -20, the leak disappeared when warming up.

This happens because in such frost the rubber rings in the seal become stiff, losing elasticity. When the engine warms up, they heat up, become elastic, expand, and stop leaking. This can also be caused by increased pressure in the engine power supply system - the pressure limiting valve (located in the gas tank) freezes. Since at -25 outside, the pressure in the fuel rail was somehow not ready to be measured, I couldn’t determine the reason for sure. Without waiting for the next frost, when it warms up, I decided to change the fuel hose.

The length of the original hose is 26 cm. After a long search, I found a hose of acceptable quality, but it turned out to be Chinese, and besides, it is 3 cm longer than the original - its length is 29 cm. The price is 350 rubles. For lack of anything better, I put it in. These extra 3 cm did not play a role. I was alarmed by the inscription on the hose - instead of GOST - TOAST. But I still didn’t “wash” the hose).

And I’ll immediately give you an example of what you shouldn’t put. The sealing rings of this hose are worse than those of the Chinese one. In addition, it is longer and thinner in diameter, which can lead to bending, etc. The braid of this hose is made of synthetic woven fiber

The fuel supply hose to the fuel rail from the Chevrolet Niva is also suitable, but it is almost 2 times longer. In my opinion, it’s better to just pull out the two O-rings from it and insert them into your original one if you can’t find the original one. This should only be done if it is not possible to buy an original one for Kalina. Since it is easier to change the entire hose.

When replacing the hose, it is necessary to replace the O-ring on the fuel rail, which must also be purchased. It is highlighted in red in the photo. The other two rings are precisely the cause of gasoline leakage.

To remove the hose from the plastic high-pressure fuel supply line, it is necessary to relieve the pressure in the system. To do this, remove the plastic plug near the cigarette lighter (the one under which the ECU diagnostic connector is located) and pull out the fuel pump fuse (in the middle between the outermost ones).

Next, we start the engine and wait until it stalls (for the fuel to be completely exhausted). After this, turn the starter for about 3 seconds. Remove the air supply hose to the throttle assembly. Using a 10mm socket, unscrew the nut securing the clamping plate of the fuel supply tube holder and the canister purge solenoid valve tube and remove it. This holder is located under the battery tray. Next, remove the fuel supply hose to the fuel rail. To do this, first place a rag under it so that residual gasoline does not flow through the engine compartment. In the very top first photo you can see the metal locking bracket. We press it from ourselves (if you look at the photo) and remove the hose from the fuel line. Use a previously prepared rag to remove any remaining dripping gasoline. We unscrew the hose itself from the fuel rail, holding the tip of the hose with a 17 key. An O-ring should remain on the fuel rail when the hose is removed. We replace it immediately with a new one.

We put the new hose on the plastic tube of the fuel line until it is fixed with a metal bracket and screw it to the fuel rail. We screw the bracket back, insert the fuse, turn on the ground and check for leaks. If there is no leak, you can start the engine.

If someone decides to change only two o-rings in the hose, this must be done at a positive temperature so that the plastic is not fragile (there is a risk of breaking 2 plastic clips). Outer and inner diameter of 2 o-rings

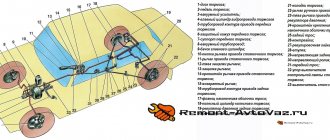

The device of the VAZ 2110 gas tank

There is nothing complicated about the design of the “tens” gas tank. In fact, this is an ordinary metal fuel tank with a capacity of 43 liters. Inside this tank there is a fuel level sensor and a fuel inlet pipe with a strainer.

Diagram of the gas tank and fuel system of the VAZ 2110

An electric fuel pump is attached to this pipe externally, which pumps gasoline out of the tank and delivers it through the fuel line to the fine filter. Next, the gasoline goes to the pressure regulator and enters the fuel rail to the injectors, which spray it into the combustion chambers.

Disassembly

13. Using a slotted screwdriver, release the two brackets securing the wiring harness.

14. Disconnect the four wiring harness connectors from the injectors.

15. Remove the wiring harness from the fuel rail.

16. Move the spring clamp along the fuel rail and remove the injector.

17. Remove the spring clamp of the injector from the fuel rail.

18. 24 mm

unscrew the nut of the fuel drain pipe...

...and remove the end of the tube from the pressure regulator.

5mm hex wrench

unscrew the two bolts securing the fuel pressure regulator (1) and move the clamping bar (2) of the fuel supply tube along the fuel rail. Remove the fuel pressure regulator (3)…

...and remove the tube from the ramp hole.

Warning! Damaged O-rings of fuel pipes and injectors must be replaced.

Reasons for replacing the gas tank on a VAZ 2110

There are two main reasons why a car owner will have to remove the gas tank on a VAZ 2110:

- mechanical damage to the gas tank. The tank can simply be pierced by catching it on a ledge, a stone, or some other obstacle on the road. This happens quite often. And the reason for this is the location of the tank on the “ten”. On earlier VAZ models (up to and including VAZ 2108), the gas tank was actually located in the trunk. Because of this, the trunk of these cars could not boast of spaciousness, but the gas tank was intact. Starting from the VAZ 2110, the tank is located lower, under the bottom of the car. On the one hand, the trunk capacity has increased. On the other hand, the risk of damage to the tank has increased manifold;

The tank on the VAZ 2110 is located low and is easily broken through

A completely rusted tank of a VAZ 2110

Whatever the reason, the car owner has no choice: if the tank leaks, it will have to be removed and welded (in the case when the tank is new and the damage is mechanical). If the tank is seriously damaged by chemical corrosion, then there is only one way out - replacement. Such spare parts cannot be restored.

Replacing the gas tank on a VAZ 2110

To successfully replace the tank on a VAZ 2110, we will need the following tools and materials:

- new gas tank for VAZ 2110;

- open-end wrenches - set;

- flat screwdriver.

Sequence of operations when replacing a tank

The success of the event lies in the scrupulous implementation of the following actions:

- The VAZ 2110 is installed on an overpass or on an inspection hole. The handbrake is applied.

- In the cabin, the floor covering moves back, under which there is a fuel pump hatch. The power wires are disconnected from this pump and a pair of fuel pipes are unscrewed. This is done using a 17mm open-end wrench.

Power wires and fuel pipes are removed from the VAZ 2110 fuel pump

The clamp holding the VAZ 2110 filler tube is loosened and the tube is removed

The hose on the neck of the VAZ 2110 is loosened with a socket head by 8 and then moved to the side

Two mounting bolts holding the bars on which the tank of the VAZ 2110 hangs

The slats on which the VAZ 2110 tank hangs bend down

The VAZ 2110 gas tank needs to be tilted down a little to get to the last hose

The thinnest hose is removed from the VAZ 2110 gas tank manually

The VAZ 2110 gas tank was dismantled and removed from under the car

Replacing the fuel line of a VAZ 2110 with your own hands

Here's the fuel system for the VAZ 2110 to help you get an idea of what you'll have to work with.

First, let's buy a fuel pump. Catalog number of the fuel pump is 2112-1139009-03.

We buy fuel pump gaskets. Buy good gaskets for the fuel pump, because poor quality ones will have to be replaced very quickly. Gasket catalog number 21103-1101138.

We purchase a fuel line using catalog number 21121104032.

Of course, we also need a high-quality fuel tank. Catalog number 21103-1101011.

We remove the old fuel line.

Remove all fuel pipes.

Disconnect the tank mount to remove it. And we take it off.

We are laying a new fuel line.

This is what a new fuel line and a fresh tank look like, the fuel pump is already installed and everything is assembled.

Here is a useful video on replacing the fuel line:

Flushing the gas tank of a VAZ 2110

Flushing the gas tank is an operation that must be performed at least once every two years, regardless of whether the tank is in good condition or not. Over time, contaminants accumulate in the tank, which can subsequently impair the performance of both the fuel pump and other components of the fuel system.

Tank flushing sequence

To clean the gas tank, you must perform the following manipulations:

- The gas tank is removed from the VAZ 2110 as described above. After this, you need to drain all remaining gasoline from the gas tank.

- Now you need to rinse the tank. To do this, any detergent is poured into it. Even household dishwashing liquid diluted in water will do.

- After filling the liquid, the tank must be allowed to stand for at least half an hour.

- After this time, the washing liquid is drained and the tank is rinsed with clean water.

After draining the washing liquid, the VAZ 2110 tank is washed with clean water

Repair of studs on the gas tank of a VAZ 2110

The fuel pump is attached to the gas tank using studs. They, like any other part, wear out and break over time. As a result, the driver is forced to repair them. For repairs you need the following:

- bolts for 8, 25 mm long (8 pieces);

- file;

- hacksaw for metal;

- M5 tap;

- electric drill with a 4.5 mm drill bit.

Stud repair sequence:

- Use a hacksaw to cut off all the old studs. The surface of the gas tank underneath is processed with a file.

The surface of the VAZ 2110 gas tank, carefully processed with a file

The VAZ 2110 fuel pump is held in place by a ring with eight holes

In the new holes on the VAZ 2110 tank, threads are cut with a tap

New bolts are screwed into the VAZ 2110 tank so that their heads are inside the tank

The fuel pump is one of the most important components of the fuel system. The following material will help you carry out independent diagnostics of this mechanism: https://vazweb.ru/desyatka/pitanie/toplivnyj-nasos.html

Important nuances

When replacing the gas tank and the studs on it, we must not forget about several important points:

- Fire safety. Work on the gas tank, as well as on any part of the vehicle’s fuel system, should only be carried out in a well-ventilated area or in the open air. There should be no sources of open fire or flammable materials nearby. And, of course, you should always have a fire extinguisher at hand;

During any work on the VAZ 2110 fuel system, a fire extinguisher must be nearby

When screwing new studs into a VAZ 2110 tank, it is recommended to treat them with THREADLOCKER sealant

Replacing the tank is not a very complicated procedure. Even a novice car enthusiast can do it. To successfully complete this operation, he will need not so much repair skills as physical strength: removing a large tank with remaining gasoline from under the car is quite difficult. And if the car owner cannot boast of a strong physique, then at this stage he cannot do without an assistant.

A possible sign of the need to replace the fuel supply hose to the fuel rail is the smell of gasoline in the cabin. This hose begins to flow at the junction with the fuel supply line from the fuel tank (plastic tube). The location of this connection is below the battery near the partition of the engine compartment. Moreover, for many people the hose starts to leak in cold weather.

I started to leak when my Kalina was 4 years old, in frosts of -25, and heavily, in copious drops. When the engine warms up, the leak in many Kalinovods disappears. So it was with me. Since in such frost there is no point in getting under the hood yourself if there is no warm garage, and in such weather there are enough customers in the services, so I went. To be honest, it was scary, because I saw how quickly the cars were burning. Luckily there was a fire extinguisher in the trunk. When the temperature warmed up to -20, the leak disappeared when warming up.

This happens because in such frost the rubber rings in the seal become stiff, losing elasticity. When the engine warms up, they heat up, become elastic, expand, and stop leaking. This can also be caused by increased pressure in the engine power supply system - the pressure limiting valve (located in the gas tank) freezes. Since at -25 outside, the pressure in the fuel rail was somehow not ready to be measured, I couldn’t determine the reason for sure. Without waiting for the next frost, when it warms up, I decided to change the fuel hose.

Features of the VAZ 2112 (1.5i) engine power system

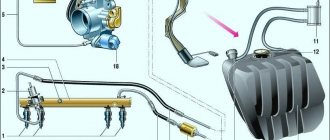

Diagram of the VAZ 2112 (l.5i) engine power supply system

: 1 - injectors; 2 - fuel rail; 3 — diagnostic fitting of the fuel rail (for checking the fuel pressure, closed with a threaded cap); 4 - adsorber; 5 - check valve; 6 — throttle assembly; 7 - gravity valve; 8 - safety valve; 9 - separator; 10 - filler pipe; 11 — fuel filter; 12 — fuel supply line; 13 — fuel line hose connecting the outlet pipe of the fuel module to the fuel filter; 14 — fuel module; 15 — fuel tank; 16 — fuel drain line; 17 - fuel pressure regulator

Location of elements of the engine power system* VAZ 2112 (l,5i) in the engine compartment

: 1 - receiver;

2 — throttle assembly; 3 — air supply hose to the throttle valve; 4 — air filter; 5 — fuel pressure regulator; 6 — throttle valve drive cable; 7 — fuel rail; 8 — diagnostic fitting; 9 — adsorber check valve; 10 — adsorber * VAZ 2112 (1.5i) engine with the decorative trim removed.

Purpose and place of fuel hoses in VAZ cars

The fuel system of any car consists of a relatively small number of components - a tank, filters, a pump, a carburetor (in classic carburetor engines) or a fuel rail with injectors (in injection engines), etc. All these components are connected by a network of pipelines through which fuel circulates. In this case, pipelines consist of two parts - metal tubes and rubber hoses.

The combined design of pipelines is used for a reason. The fact is that individual parts of the car and components of the fuel system, although they are fixed in strictly defined places, still do not have an absolutely rigid fixation. While the car is moving, parts, especially those located on the engine (carburetor or ramp with injectors), move relative to each other, so they cannot be rigidly connected with metal tubes. Elastic rubber hoses come to the rescue, ensuring uninterrupted fuel supply regardless of the position of the fuel system components.

If we talk about fuel hoses in general, they perform several main functions:

- Communication of vehicle fuel system components;

- Compensation for longitudinal and transverse displacements of fuel system components during vehicle operation;

- Compensates for movement of fuel system components when performing various adjustments, maintenance or repairs.

Thus, they play an important role in the operation of the vehicle. This fully applies to all cars of the Volzhsky Automobile Plant, the hoses of which will be discussed in more detail.

Features of the VAZ 21124 (l,6i) engine power system

Location of elements of the engine power system* VAZ 21124 (l,6i) in the engine compartment

: 1 — intake module;

2 — throttle assembly; 3 — air supply hose to the throttle valve; 4 — air intake; 5 — air filter; 6 — fuel rail; 7 — throttle valve drive cable; 8 — fuel rail fitting; 9 — adsorber check valve; 10 — adsorber * VAZ 21124 (l.6i) engine with the plastic cover removed.

VAZ 21124 (1.6i) engine power supply system diagram

: 1 - nozzles; 2 - fuel rail; 3 — diagnostic fitting of the fuel rail (for checking the fuel pressure, closed with a threaded cap); 4 - adsorber; 5 - check valve; 6 — throttle assembly; 7 - gravity valve; 8 - separator; 9 — fuel line tube connecting the fuel filter to the tee; 10 — fuel line tube connecting the fuel filter to the outlet pipe of the fuel module; 11 — fuel module; 12 — fuel filter; 13 - filler pipe; 14 — fuel tank; 15 — hose connecting the fuel filter and the fuel module with the fuel line; 16, 18 — metal fuel pipes; 17 — connecting hose; 19 - fitting for connecting the fuel rail to the fuel line

useful tips for motorists

Types and design of VAZ fuel hoses

All fuel hoses used on VAZ cars can be divided into two groups according to applicability:

- For models with carburetor engines;

- For models with engines with a fuel injection system (injectors).

Hoses of the first type are used in all VAZ Classic cars (2101 - 2107), as well as on some later ones (2108, 2109, early modifications of the Lada-110 family). These are ordinary reinforced rubber hoses that do not have special fasteners; they are fixed to the fittings using clamps. All hoses used in these cars are the same, differing only in length (from 400 to 1000 mm).

Hoses of the second type are installed on some early (21099, 2113 - 2115) and all current VAZ models, starting with Lada Kalina. These hoses come in a variety of designs, applicability and mounting types.

According to their purpose, fuel hoses for injection engines are divided into the following types:

- Fuel supply hose to the ramp;

- Hoses for draining fuel from the ramp (return hoses) - usually there are two of them, one is located on the ramp side, the other is on the tank side;

- Hoses for connecting the fuel filter - one from the tank to the filter, the second from the filter to the ramp;

- Filler hose;

- Hoses for connecting the adsorber (separator), in fact these are air hoses, but they belong to the fuel system.

Structurally, hoses are divided into three large categories:

- Hoses without fasteners;

- Hoses with connectors at both ends;

- Hoses with a connector at one end and a metal tube at the other.

As already mentioned, hoses of the first type are a traditional solution used on classic VAZ models. They are attached to fuel system parts and pipelines using clamps (or wire loops).

Hoses of the second type have a connector of one design or another at both ends. There are two main types of fasteners currently in use:

- “Nut” type fastener - at the end of the hose there is a metal tip with a union nut, which is screwed onto the mating threaded fitting;

- Quick-release fastener - at the end of the hose there is a fitting (female type) with a locking mechanism that allows you to quickly install or remove the hose from the mating fitting (male type).

Today, in VAZ cars, hoses with “Nut” type fasteners at both ends are used, as well as with “Nut” type fasteners at one end and with quick-release fasteners at the other end.

Quick-release fittings, in turn, come in two types:

- With a plastic latch - such fittings are usually square in shape, and to remove the hose you need to press the button on the side of the fitting;

- With a steel spring bracket - such fittings are usually round in shape; to remove the hose you need to press on the bracket.

A hose with a metal tube differs from the others in that on one side, instead of a fitting, a metal pipeline of one or another length and shape is fixed. Such hoses are most often used to connect the filter and in the drain line on the fuel tank side.

Questions regarding maintenance and replacement of fuel hoses

Fuel hoses are constantly exposed to aggressive environments (gasoline from the inside, oils, exhaust gases and high temperatures outside), so over time they lose their strength characteristics. In order not to miss the moment to replace the hoses, they should be periodically inspected, monitored for the appearance of cracks or kinks, as well as leaks at the attachment points. Particular attention should be paid to the places where the hose comes into contact with other parts, at bends and at the places where the fittings are attached. If any problems arise - be it cracks or small leaks - the hose must be replaced as soon as possible.

The procedure for replacing hoses depends on the engine model and the types of mounting used. But in any case, you first need to remove the fuel and relieve pressure in the fuel system; this is generally done like this:

- Disconnect the fuel pump (disconnect the electrical connector from it; access to the pump may require removing the rear seats of the car);

- Start the engine;

- Wait until the engine has exhausted the remaining fuel from the system and stalls;

- Crank the engine with the starter for a few seconds.

Now you can begin replacing hoses and other parts of the fuel system. If we are talking about the classic VAZ family, then you should simply loosen the clamps and remove the hose from the fittings (or tubes); installing a new hose is done in the reverse order and preferably using new clamps.

To replace hoses with “Nut” type fasteners, use a “10” wrench to loosen and unscrew the nuts, install a new hose and tighten its nuts with the torque recommended by the manufacturer. When replacing hoses, the rubber O-rings should also be replaced; old O-rings should not be used. This work should be performed at positive air temperatures, since in cold weather the ring loses its elasticity and the connection will not be airtight.

The easiest way to replace hoses is with a quick-release connection - to remove the hose, you need to press a button or bracket. The new hose is simply installed on the fitting until it clicks. However, before installing a new hose, the mating fitting should be inspected and if it is damaged or worn, it should be replaced. Otherwise, when you first start the engine, the hose may simply be torn off by fuel pressure.

With timely and correct replacement of hoses, the fuel system of a VAZ vehicle will serve reliably, ensuring uninterrupted operation of the power unit in any conditions.

If such malfunctions occur in the operation of the carburetor engine of VAZ 2108, 2109, 21099 cars, such as unstable idling, failure when pressing the gas pedal, drop in power and throttle response, difficulty starting the engine, etc., you should pay attention to the fuel supply system to the carburetor, namely on the cleanliness of fuel lines and the cleanliness of the vehicle’s fuel tank. The presence of blockages and contaminants in them often leads to disruption of the fuel supply to the carburetor and further to the engine, followed by the occurrence of the above-mentioned malfunctions. Let's consider cleaning fuel lines on VAZ 2108, 2109, 21099 cars.

— Raise the back seat in the car.

Under it in the body there is a hatch for access to the fuel intake of the fuel tank. Remove the hatch by unscrewing the screws securing it.

— Remove the fuel hoses (main line and) from the fuel intake.

To do this, loosen the clamps and move them from the fittings on the fuel intake. The fit of the tubes on the fittings is very tight, so when moving, you can help yourself with a 10 mm open-end wrench.

— Place a cloth under the fuel pipes to prevent splashing.

— We disconnect, in the engine compartment, the fuel pipes from the fine fuel filter (if there is none from the inlet pipe of the fuel pump) and the non-return valve fitting. To do this, you need to loosen the clamps securing them.

Cleaning fuel lines of VAZ 2108, 2109, 21099

— We blow compressed air from a compressor or a conventional pump into the fuel pipes in the direction from the engine to the tank.

First to the main highway, then to the return line. The duration of the purge is arbitrary.

— We check the ease of air passage through the fuel lines.

To do this, we blow them through again, but this time with our mouth and evaluate them. If necessary, repeat blowing with compressed air.

We assemble everything in reverse order.

Notes and additions

— You shouldn’t limit yourself to cleaning only the fuel lines. You should also clean the entire fuel supply system, namely the fuel tank, mesh filters in the carburetor, in the fuel pump and on the fuel intake, and replace the fine fuel filter.

— On VAZ 2108, 2109, 21099 cars a check valve is installed. When cleaning the fuel lines, it is worth removing it completely and rinsing it with gasoline. Blow with compressed air. You can check its performance by blowing it with your mouth. Air should flow freely in one direction and not at all in the other. In case of malfunction, replace the check valve.

— You can quickly clean the fuel lines on a VAZ 2108, 2109, 21099 car. To do this, we disconnect the pipes only in the engine compartment from the check valve and the fine fuel filter. Remove the cap from the gas tank. We blow with compressed air for a short time until active seething of the fuel appears in the tank. We check by blowing through the lines with our mouth.

Check fuel pipes, hoses and their connections as follows.

Metal fuel pipes are laid under the bottom of the car and secured with clamps and self-tapping screws. Inspect them periodically for leaks and damage.

If, when replacing the fuel filter, there is dirt in it and the fuel lines, be sure to disconnect the lines and blow them out with compressed air. Also check the condition of the strainer on the fuel pump assembly.

Never use copper or aluminum tubing to replace the steel tubing installed on the vehicle, as it may not withstand the vibration of the vehicle.

Because fuel pipes are under high pressure, they require special maintenance.

Some fuel lines have O-ring threaded connections that must be loosened before servicing or replacing components. In such connections, cone nuts are used, which, when tightening the nut, additionally compresses the connection. Check the O-rings for cracks and damage and replace if necessary. If steel tubes are being replaced, install only original tubes.

Flexible fuel hoses must be located at least 100 mm from the exhaust system components and 250 mm from the catalytic converter.

Some models have nylon fuel hoses with quick-release connectors. In this case, if you need to replace one hose, replace the hoses complete with quick-release connectors.

Replace fuel pipes/hoses as follows.

Relieve pressure in the fuel system.

Release all clamps securing the tube/hose to the vehicle body.

On normal steel fuel pipe and hose connections, loosen the clamp, then pull out the hose tube. Turning the tube and hose in different directions makes the disconnection process easier.

If the hoses are connected using a quick-release connector, open and remove the clamp, then press the latches on both sides with one hand and remove the tube from the connector with the other hand ( , ).

A fuel filter is an essential element of a vehicle's fuel supply system. The main purpose of the unit is to mechanically clean fuel from solid impurities that can clog the system. It can also harm the engine or impair its performance.

Fuel supply diagram for an engine with a fuel injection system

1 – nozzles; 2 – fitting plug for monitoring fuel pressure; 3 – injector ramp; 4 – bracket for fastening fuel pipes; 5 – fuel pressure regulator; 6 – adsorber with solenoid valve; 7 – hose for suction of gasoline vapors from the adsorber; 8 – throttle assembly; 9 – two-way valve; 10 – gravity valve; 11 – safety valve; 12 – separator; 13 – separator hose; 14 – fuel tank plug; 15 – filling pipe; 16 – filling pipe hose; 17 – fuel filter; 18 – fuel tank; 19 – electric fuel pump; 20 – fuel drain line; 21 – fuel supply line.

Fuel is supplied from a tank installed under the bottom in the rear seat area. The fuel tank is made of steel and consists of two stamped halves welded together. The filler neck is connected to the tank with a gas-resistant rubber hose secured with clamps. The plug is sealed.

The fuel pump is electric, submersible, rotary, installed in the fuel tank. The developed pressure is at least 3 bar (300 kPa).

The fuel pump is turned on at the command of the injection system controller (with the ignition on) through a relay. To access the electrical connector of the pump, there is a hatch under the rear seat in the bottom of the car. From the pump, fuel under pressure is supplied through a flexible hose to the fine filter and then through steel fuel lines and rubber hoses to the fuel rail.

The fine fuel filter is non-separable, in a steel housing, with a paper filter element. There is an arrow on the filter housing that must coincide with the direction of fuel movement.

The fuel rail serves to supply fuel to the injectors and is mounted on the intake manifold. On one side there is a fitting for monitoring the fuel pressure, on the other there is a pressure regulator. The latter changes the pressure in the fuel rail - from 2.8 to 3.2 bar (280-320 kPa) - depending on the vacuum in the receiver, maintaining a constant difference between them. This is necessary for accurate dosing of fuel by injectors.

The fuel pressure regulator is a fuel valve connected to a spring-loaded diaphragm. The valve is closed under the action of the spring. The diaphragm divides the regulator cavity into two isolated chambers - “fuel” and “air”. The “air” is connected by a vacuum hose to the receiver, and the “fuel” is connected directly to the ramp cavity. When the engine is running, the vacuum, overcoming the resistance of the spring, tends to retract the diaphragm, opening the valve. On the other hand, fuel presses on the diaphragm, also compressing the spring. As a result, the valve opens and part of the fuel is released through the drain pipe back into the tank. When you press the gas pedal, the vacuum behind the throttle valve decreases, the diaphragm, under the action of a spring, closes the valve - the fuel pressure increases. If the throttle valve is closed, the vacuum behind it is maximum, the diaphragm pulls the valve harder - the fuel pressure decreases. The pressure drop is determined by the spring stiffness and the size of the valve opening; cannot be adjusted. The pressure regulator is non-separable; if it fails, it is replaced.

The injectors are attached to the ramp through rubber sealing rings. The injector is an electromagnetic valve that allows fuel to pass through when voltage is applied to it and closes under the action of a return spring when there is no power. At the injector outlet there is a nozzle through which fuel is injected into the intake manifold. The injection system controller controls the injectors. If there is a break or short circuit in the injector winding, it should be replaced. If the injectors become clogged, they can be washed without dismantling at a special service station.

The closed-loop injection system uses a fuel vapor recovery system. It consists of an adsorber installed in the engine compartment, a separator, valves and connecting hoses. Fuel vapor from the tank partially condenses in the separator, and the condensate is drained back into the tank. The remaining vapor passes through gravity and two-way valves. The gravity valve prevents fuel from leaking out of the tank when the vehicle rolls over, and the two-way valve prevents excessive increase or decrease in pressure in the fuel tank.

Then the fuel vapor enters the adsorber, where it is absorbed by activated carbon. The second fitting of the adsorber is connected by a hose to the throttle assembly, and the third is connected to the atmosphere. However, when the engine is turned off, the third fitting is closed by an electromagnetic valve, so that in this case the adsorber does not communicate with the atmosphere. When the engine starts, the injection system controller begins to send control pulses to the valve with a frequency of 16 Hz. The valve communicates the adsorber cavity with the atmosphere and the sorbent is purged: gasoline vapors are sucked through the hose into the receiver. The greater the engine's air consumption, the longer the duration of the control pulses and the more intense the purging.

In an open-loop injection system, the fuel vapor recovery system consists of a separator with a two-way check valve. The tube connecting the tank to the atmosphere is led into the cavity of the rear right wing.

The air filter is installed in the front left part of the engine compartment on three rubber holders (supports). The filter element is paper.

After the filter, the air passes through the mass air flow sensor and enters the intake hose leading to the throttle body.

The throttle assembly is fixed to the receiver. By pressing the gas pedal, the driver slightly opens the throttle valve, changing the amount of air entering the engine, and therefore the combustible mixture, because the fuel supply is calculated by the controller depending on the air flow. When the engine is idling and the throttle valve is closed, air flows through the idle air control valve, a valve controlled by the controller. By changing the amount of supplied air, the controller maintains the idle speed specified (in the computer program). The idle speed regulator is non-separable; if it fails, it is replaced.

The vehicle's power system is designed to store fuel reserves, purify fuel and air from foreign impurities, and supply air and fuel to the engine cylinders. The power system consists of a fuel tank, a fuel module, a fuel filter, a fuel rail with injectors, an air filter, fuel lines, air ducts, a throttle assembly, a receiver, and a gasoline vapor recovery system.

The air entering the engine cylinders is cleaned of dust by an air filter. Air filter

installed in the engine compartment on three rubber supports. The filter element is replaceable and made of special paper. To prevent contaminated air from leaking into the intake tract, there is a sealing edging at the top of the element. To replace the filter element, the filter cover is removable. The purified air passes through the mass air flow sensor (for more details, see “Engine Management System”) through the air duct to the throttle valve.

Operating principle of the fuel filter

Depending on the make of the car, the design of the fuel filter may differ. But the basic principle of operation and operation scheme is the same for all models.

The principle of operation of the fuel filter: 1 - filter element for injection cars, 2 - its housing.

The gasoline filter is located in the fuel line and looks like a metal or plastic bulb with two terminals. To which the main pipelines are connected. Inside the housing there is a filter element, which is usually made of special paper.

The device works like this:

- The fuel moves along the line and enters the housing through the inlet pipe;

- During the passage of fuel through the bowels of the unit, mechanical impurities (dirt, sand, rust, etc.) are retained on it. The purification fraction depends on the type of model used.

- Purified gasoline leaves the flask through the outlet pipe and moves to the engine.

Which fuel pump to choose for replacement

BOSCH fuel pump 580454138 is installed from the factory . Its service life depends on the quality of the fuel used, as well as on operating conditions. It is also worth noting that this pump is suitable for most other cars, including imported ones. The cost of a BOSCH fuel pump at the moment is from 1,700 rubles. Cheaper analogues are also offered on the market:

- WEBER FP 453-453 from 600 RUR

- ATS 2112-1139010 from 550 RUR

- PEKAR 2112-1139010 from 600 RUR

- FENOX EFP35005O7 from 700 RUR

- HOFER HF 830 301 from 550 RUR

- StartVOLT SFP 0153 from 750 RUR

- VOLTON VLT2112-1139010 from 650 RUR

Any of the above fuel pumps will be suitable as a replacement for the original one, however, not all of them are of the same quality as the original. In addition to the pump itself, you may need a corrugation to replace it, and if the fuel pump mounting ring is damaged, you can order it or purchase it using the following article number:

- Electric fuel pump ring /2110/ metal price from 120 rub.

- Fuel pump corrugation /2110/ 1.5 white from 50 rubles per piece

- Fuel pump corrugation /21101/ 1.6 long from 60 rubles per piece

Frequency of replacing the fuel filter

According to the technical passport, this element must be replaced on a VAZ 2110 car every 30,000 km. This recommendation must be followed provided that high-quality fuel is used. If dirt, water or low-quality gasoline may get into the gas tank, the unit should be replaced more often. And due to the low quality of gasoline at domestic gas stations. In practice, experts recommend reducing the interval between device replacements to 20–25 thousand km.

Also, reasons for premature replacement of a part may be:

- Increased fuel consumption;

- Violation of engine stability;

- Decrease in power of the power unit;

- Deterioration of dynamic performance;

- Water or foreign objects getting into the gas tank;

Fuel filter location

For different types of engines installed in VAZ 2110 cars. The installation location and the process of replacing the element differ.

Location of the fuel filter on the injection VAZ 2110

On injection "tens" the fuel filter is located under the bottom of the car. Specifically, behind the gas tank and attached to the beam using a metal bracket. During inspection it is quite easy to detect. The unit looks like a metal flask with two hoses connected to it. To facilitate access and change the unit, the machine must be placed on an overpass or a special lift.

Location of the fuel filter on a carburetor VAZ 2110

On the carburetor model of the VAZ 2110 car, the fuel filter is located in the engine compartment. And the procedure is much easier. Specifically, the element is located near the brake fluid reservoir. The unit looks like a transparent plastic flask with a special element inside. Fuel lines are connected to the device body using metal clamps.

Tools to get the job done

Injector

To replace the fuel filter on an injection VAZ 2110 car with an 8 valve system.

The following tools are required:

| Wrenches for 10, 17 and 19 |

| crosshead screwdriver |

| Flat head screwdriver |

| Containers for gasoline |

| Lint-free rag |

Carburetor

With a carburetor system everything is a little simpler. To perform the operation you will need:

| crosshead screwdriver |

| Fuel drain container |

| Rags |

Recommendations

Every car enthusiast can do a lot to extend the life cycle of all elements of the unit in question. To ensure that your car's power system works flawlessly, use the following recommendations:

- Refuel only at approved gas stations.

- Replace fuel and air filters in a timely manner.

- Use cleaning additives with caution.

- Try not to drive on a half-empty gas tank, especially in winter.

Replacing the fuel filter on a VAZ 2110 8 valves - step by step

Relieving excess pressure in lines

Initially, you should reduce the pressure in the fuel supply system. This is necessary so that when dismantling the part, gasoline does not escape out under pressure. Some car enthusiasts do not know about the existence of such an opportunity or ignore it. However, it allows you to perform the procedure more accurately. There are two ways to relieve pressure in the system.

- According to the first method, you need to remove the fuse from the fuse box, which is responsible for the operation of the fuel pump. To do this, remove the cover of the additional fuse panel, which is located under the glove compartment (at the passenger's feet, on the right). Next you need to remove the fuse itself. It looks like a black box measuring 2x3 cm. There are three of them in the panel; you need to take out the central one.

- The second method is to turn off the power to the fuel pump. To do this, you need to disconnect the terminal from the battery. Then fold down the rear seat to reveal a square cover underneath. Using a flat-head screwdriver, you need to unscrew the screws and the hatch can be removed. Below it is the fuel pump itself. Next, you need to disconnect the voltage supply cables to the device.

After the power to the fuel pump is turned off. You need to start the engine and let it run until the fuel is completely exhausted (until it stalls). To be on the safe side, you can try to start the engine again. Now that the pressure has been released, you can begin replacing the filter.

Replacing the fuel filter on a VAZ 2110 8 valve injector

The procedure for replacing the fuel filter on VAZ 2110 vehicles with an 8-valve injection engine is performed only on a lift or inspection pit and in several stages.

- Using a brush, you need to clean the body parts located close to the unit. This is necessary to prevent dirt or debris from accidentally getting into the fuel line.

- A container for draining gasoline is placed under the work site. Despite the pressure release, there is still fuel left in the line.

- Lubricate all threaded connections with oil or WD 40. This is necessary to make it easier to unscrew all the nodes.

- The key at “19” holds the body of the unit, and the key at “17” unscrews the lines.

- Using a key set to “10”, loosen the fastening clamp and remove the filter.

The procedure for installing a new element is performed in reverse order. Particular attention should be paid to the direction indicators located on the housing of the new filter. The arrow should “look” in the direction from the gas tank to the engine.

Important! When installing a new part, do not use old seals on the fuel pipes (they look like rubber rings). Used seals can cause gasoline to leak and cause a car fire.

It is worth mentioning that on injection VAZ 2110 cars fuel filters are also installed on latches (clips). In this case, the work progress looks the same as for threaded fasteners. The only difference is that the highways are disconnected. On one side you need to press the lock and remove the pipe. On the other side there is a spring retainer. You need to bend it with a screwdriver and remove the line.

If you still have questions about replacing the fuel filter on a VAZ 2110 with an injection engine, I recommend watching this video:

Replacing the fuel filter on a VAZ 2110 carburetor

On the carburetor model VAZ 2110, replacing the filter is much easier. Due to the fact that for this you do not need to drive the car onto an overpass or lift. After all preparatory procedures (pressure relief, etc.)

You need to do the following:

- Open the hood;

- Find the fuel filter (it is located near the brake fluid reservoir);

- Using a screwdriver, disconnect the fuel hoses;

- Remove the unit from the car;

- Install a new element;

- Reconnect the lines in the reverse order and tighten the clamps securely;

After replacing the filter, you need to apply voltage to the fuel pump. Then turn the key in the ignition and let the pump pump up fuel. After this, you need to start the engine and let it run. In the meantime, you should inspect the junction of the lines and the filter for gasoline leaks. If necessary, connections must be tightened.

If you still have questions about replacing the fuel filter on a VAZ 2110 with a carburetor engine, I recommend watching this video:

Types of filters used

On VAZ 2110 cars with an injection engine. The factory configuration usually uses domestically produced products with the name “Salyut”. Despite this, many car owners choose imported components of higher quality when replacing them. But such parts have one significant drawback - their price.

Of the Russian-made filters, the following models are in particular demand:

- Fuel filter VAZ 2110 8 valves carburetor – UT-00002606;

- Fuel filter VAZ 2110 8 valves injector (on clips) – 00000011756;

- Fuel filter VAZ 2110 8 valves injector (nuts) – 00000009674;

Conclusion

You can replace the fuel filter on an injection VAZ 2110 with 8 valves yourself. This will require a little knowledge and a primitive set of tools, which is available to every car enthusiast.