Features of the VAZ 2110 gearbox

As you realized, if the unit breaks down, you have only two options - either drive the car at 100, or do everything yourself. To repair a VAZ 2110 without the help of others, you will need to dismantle and disassemble the unit in order to then replace the failed elements with new ones. Replacing the VAZ 2110 timing belt - vaz-remont.ru. Accordingly, it will be necessary to assemble in reverse order.

VAZ car 2110

tuning

One of the features VAZ 2110 gearbox

are common symptoms of defects.

In practice, many VAZ owners encounter such breakdowns. 2110:

- When switching speeds to “neutral”, third-party sounds appear. As a rule, this indicates poor quality of the lubricant or its complete absence. If you understand this and replace the transmission fluid, but the sounds remain, then most likely the issue may be a failure of the bearings .

- It is very difficult to switch the gearbox lever. The essence here may be a failure of the speed selection mechanism, a breakdown of the cardan joint, or incorrect disengagement of the clutch. In addition, difficult operation of the gearbox

is often caused by loosening of the fastening screw connections. - Speeds are turned off randomly. Such a defect in the VAZ 2110

may be associated with breakage or mechanical damage to the gear teeth.

This may also indicate a weakening of the secondary shaft , failure of the rods, damage to the forks, as well as excessive vibration of the engine when the vehicle is running. Knowledge of how to replace the fuel pump on a VAZ 2110, VAZ 2110 fuel pump injector. To eliminate this problem, it is necessary to replace the failed components and adjust the drive.

VAZ gearbox 2110

in filmed form

- Extraneous noise when turning on speeds. The main reason for this may be failure of the clutch mechanism itself. In addition, signs of a breakdown may include a lack of transmission fluid and increasing noise when driving the car. Fuel pump relay VAZ 2110 VAZ 2110 injector. VAZ engine replacement. First, you will need to check all oil-containing components for wear, change them, and then replace the lubricant itself. VAZ 2110 engines 8 and 16 valves replacement of the alternator belt VAZ 2110 alternator belt. It is also recommended to check the functionality of the secondary shaft bearings - very often they become the cause of extraneous noise.

Signs of failure

All bearings, of which there are quite a few in a car, have approximately the same signs of failure. But since you know the location of the input shaft bearing, it will not be so difficult to determine that the problem arose with it.

There are several characteristic signs of its breakdown.

Howling when the clutch is released in a parking lot

The element has failed and needs to be replaced. The howling is usually caused by the formation of chips, cracks, or the destruction of 1-2 rollers

Whistle when driving

The bearing is partially damaged or there is no lubrication. The problem in the absence of lubrication can only be determined by dismantling and visual inspection. To solve the problem, sometimes it is enough to simply lubricate the element and return it to its place

Clutch won't engage or disengage

Most likely the bearing is stuck. If the damage is serious, the input shaft may need to be replaced.

Knock in the area where the element is located

The bearing knocks only when the part is completely destroyed. If you do not replace it in time, the bearing will be welded to the shaft, so you will also have to replace the shaft itself

If you notice the first signs of a malfunction of the input shaft bearing on your gearbox, you should immediately check the condition of the element and, if necessary, replace it.

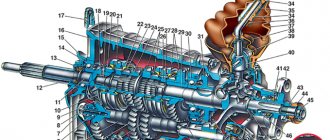

Stages of disassembling the gearbox

If you decide to disassemble the gearbox of your VAZ 2110

, you can wash it, but make sure that water does not get inside the unit.

Bearings for vaz boxes

The gearbox of a VAZ 2110 car contains several bearings. These parts are very reliable, but sometimes replacing the bearing in the VAZ 2110 gearbox becomes urgent. We have to repair it because it gets damaged. In order for the replacement of the gearbox bearing on a VAZ 2110 to be successful, you need to gain access to it, you need to understand the structure of the gearbox, etc. To ensure its serviceability, you should carefully check the clutch release mechanism and gear shifting.

Other signs of clutch failure

When the friction linings wear critically, the behavior of the car changes significantly. The following are signs of a burnt coupling:

- It is difficult to start moving. The car can remain stationary even when the clutch pedal is fully released. This means that the disc is not pressed enough to transmit torque to the transmission. Here you can judge the critical wear of the driven disk.

- Car jerking while driving. In this case, you can still start moving, but the start will create discomfort - the car jerks strongly. When the speed increases, the jerking disappears. However, the next time you try to drive from first gear, the jerking and vibration will appear again. In addition, the car may accelerate atypically when switching to higher speeds. Since the disk is not pressed tightly enough to the flywheel, the torque is transmitted intermittently. The car loses acceleration dynamics. If you disassemble the coupling, you can see the play of the diaphragm springs. They are responsible for compensating and smoothing the loads coming from the flywheel to the transmission. If such play is detected, the mechanism must be replaced.

- Free play of the clutch pedal.

Examination

VAZ 2110 replacement of box bearings

A possible malfunction can be considered a low oil level. At such moments, not only do the bearings stop functioning correctly, but every part of the gearbox begins to adhere poorly. If you do not fill in the required amount of oil or transmission fluid in time, the parts will quickly wear out. The car is installed above the inspection hole. A thorough inspection is carried out at the time of checking for oil leaks.

Note. Oil may leak through crankcase joints, wheel drive seals or gear selector rods.

- With the clutch depressed (see Repairing the VAZ 2110 clutch - we do it ourselves), you need to gradually shift all gears. Their accuracy of operation is checked at the time of switching on and off. If necessary, the gear shift mechanism is adjusted.

Replacing bearings in the box of a VAZ 2110 input shaft

- When the transmission lever is in neutral, the engine must be started. When you press the clutch pedal, you must try to hear the operation of the gearbox bearings. The characteristic sound of a breakdown appears the moment the pedal is released. As soon as you press, the sound disappears again. If the sound is loud, the bearings should be replaced.

- The operation of the gearbox is also checked while the vehicle is moving. It is necessary to accelerate the car, then slow braking. Gears shift up and then down. Here you should check the operation of the synchronizers and the clarity of the gear shift. There should be no extraneous sounds when the gearbox is operating. If the load increases, you must ensure that gears are not changed randomly.

Note: if there is a need to replace only one part of the mechanism, there is no need to completely disassemble the unit. It is enough to remove the part needed for replacement.

How to remove the transmission?

To remove the box you need an inspection hole or a lift. Also, for work you need a standard set of tools - a wrench, sockets, wrenches and a pry bar. The dismantling process is carried out in several stages:

- First of all, disconnect the terminal on the battery. Then the neutral gear is engaged and the parking brake is released. Raise and remove the rear axle. Next, unscrew the bolts holding the cardan and the gearbox flange. After this, you can disconnect the driveshaft.

- Then unscrew the bolts and dismantle the exhaust pipe of the exhaust manifold, disconnect the oxygen sensor, and remove the starter. Next, inside the car you need to dismantle the console and

- After this, remove the box protection and unscrew the clamps that connect the exhaust pipe to the catalyst. After this, you can dismantle the slave cylinder of the clutch system. Next, unscrew and remove the boot and reverse gear cable. Now you can remove the driveshaft. Then the traverses are unscrewed (you must hold the box so that it does not fall). Finally, you can unscrew and remove the gearbox assembly.

How to disassemble a checkpoint

Replacing bearings in a VAZ 2110 gearbox

To perform work on disassembling the gearbox, you must use:

- Impact screwdriver.

- Beard.

- Expanding pliers for removing retaining rings.

- Magnet.

- Mounting blades - it is better to have two copies of the tool.

- Two-jaw and three-jaw pullers.

- With a chisel.

- With a drift.

- Micrometer and dial indicator.

Note: This tool will be needed to replace the differential bearing adjusting ring.

- Locksmith's ruler.

- Glue-fixer.

- Sealant.

First of all, you need to remove the device from the car. The mechanism is cleaned from dirt, dust, and possible liquid residues. Each part is washed with detergent (outer part of the mechanism), diesel fuel or kerosene.

How to replace the bearing on the input shaft?

Often, descriptions of the steps for replacing a bearing indicate that this requires completely disassembling the gearbox, but in practice it is usually enough to remove the casing from the gearbox. Of course, before this you will have to dismantle the mechanical box:

- disconnect the battery terminals;

- remove all chips from the body;

- unscrew the speedometer drive;

- remove the “pants” of the exhaust removal system;

- remove the box from its place.

The case often turns out to be heavily contaminated with road dust - it is advisable to remove all this dirt and then remove the bell from the box.

The bearing is usually secured using a set of retaining rings, which can be removed by simply pressing a screwdriver. It is convenient to remove the rings from their place using tweezers. After this, insert the tip of a screwdriver into the annular groove of the bearing and move the input shaft forward.

During installation, the bearing is pressed onto the shaft, so to remove it you will have to use a hammer, turning the shaft in all directions to press it out. You should not rush to avoid damaging the shaft - this operation may take about 15-20 minutes. Experienced craftsmen use special tools - pullers, but in an ordinary garage, a simple tool set is enough.

The new bearing must be lubricated with engine oil, then put on the shaft and just as carefully pressed in, lightly hitting it with a hammer in a uniform rhythm in a circle. After pressing, make sure that the bearing is level, rotates freely, without runout. After this, you can reassemble the box by installing all the removed parts in the reverse order.

Bearings and their replacement

Accessing the input shaft bearing requires care and attention. To replace a bearing you must:

Note: The shaft must be secured in a vice before dismantling, as its stability will be required.

- Using mounting blades, the ball bearing is removed from the input shaft.

The bearing has been removed. It may need lubrication and preliminary repairs. If these procedures do not help restore its operation, the bearing must be replaced.

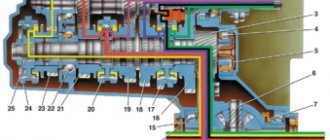

Bearing of the secondary shaft of the VAZ 2110 box

The second bearing of the VAZ 2110 gearbox is located on the secondary shaft. It must be disassembled to gain access to the broken part. It may be possible to restore the old bearing. Otherwise, it must be replaced. To gain access to the part, you must:

- Using mounting blades, the inner ring of the roller bearing is removed.

- The puller grips must be installed in the resulting connector.

- Using a gentle movement, remove the inner ring of the roller bearing from the shaft.

- It is necessary to release the locking ring.

- It is removed from the shaft.

- The main gear drive gear is removed from the mechanism.

- Together with the gear, it is necessary to remove the first gear synchronizer ring.

- The clutch retaining ring must be loosened and removed.

Note. This ring refers to the inclusion of first and second gear.

- Using mounting blades, the hub with the first-second gear clutch is removed from the shaft.

- The same procedure will be needed to remove the second gear synchronizer ring and gear.

- On the other side of the shaft, the ball bearing is disconnected.

Types and design features

In the design of a car clutch, two types of release bearings are used:

- Mechanical.

- Hydraulic.

The main elements of release bearings are closed ball or roller bearings. They are used on both mechanical and hydraulic types of products. Their design also includes a housing.

In mechanical elements, this housing is designed to interact with the clutch drive fork. Such units can have a very different design (the housing is presented in the form of a bushing inserted into the inner race, or it is installed on the outer ring), but all housings have special protrusions on which the fork acts. In general, in mechanical bearings, housings are designed for just this.

Clutch diagram of a VAZ car - 2107 1 - flywheel; 2 — clutch driven disc; 3 — clutch basket; 4 — release bearing with clutch; 5 — hydraulic clutch reservoir; 6 - hose; 7 — master cylinder of the hydraulic clutch release; 8 — servo spring of the clutch pedal; 9 — clutch pedal return spring; 10 — clutch pedal travel limit screw; 11 — clutch pedal; 12 — hydraulic clutch release pipeline; 13 — ball joint fork; 14 — clutch release fork; 15 — release spring for clutch release fork; 16 - hose; 17 — working cylinder of the hydraulic clutch release; 18 — clutch bleeder fitting

In hydraulic release bearings, the housing design is more complex because it acts as a hydraulic cylinder. The essence of his work is this: the driver, by pressing the pedal, creates fluid pressure in the clutch drive. This fluid enters the housing and squeezes out the hydraulic cylinder piston with the bearing attached to it. The housing itself in this design does not move along with the thrust element, which makes it possible to rigidly fix it with bolts to the clutch housing.

Gearbox assembly

Assembling a VAZ 2110 box

After replacing each bearing, the gearbox must be reassembled. In this case, the differential, input shaft and output shaft must be assembled in the opposite order to disassembly. Assembly must be carried out carefully to avoid any remaining parts. To complete the assembly process of the gearbox mechanism, you must:

- The surfaces of the crankcases must be cleaned of sealant residues.

- Each part is washed with diesel fuel or kerosene. After the washing process, it is necessary to wipe each part. After washing, lubricate each part with clean transmission oil.

- A new gear selector rod seal is installed.

- The gear selection mechanism rod and lever are installed.

- For stable fixation, adhesive fixative is applied to the cleaned surface of the lever fastening screw.

- The gear selection mechanism is installed.

- New bearing and differential outer races must be installed in the crankcase. Before mounting the bearings, it is necessary to install the adjusting rings.

- New drive seals are installed.

- The input shaft, secondary shaft, and reverse gear are mounted.

- A mandrel is installed to fix the gears.

Note: The subsequent assembly process is the opposite of the disassembly process. You should start from the last disassembly item and gradually move up the list. Before installing covers and crankcases, their surface must be degreased. Never install gaskets between the clutch housing and the gearbox. This setup can be quite frustrating when adjusting the bearings.

Detailed videos and photos on this topic can be viewed on the Internet. This must be done with full attention, since the work will be carried out with your own hands and mistakes cannot be avoided. But you shouldn’t despair, because the instructions give practical advice and recommendations. The price of bearings may vary depending on the place of sale. You should carefully select bearings, as there are many low-quality products and defective products on the market.

>