Lada cars of the 2112 family were equipped with injection engines. 21102-1139009 is responsible for supplying fuel to these cars . We are talking about a plastic module containing a pump and a level sensor. Similar modules were produced by several companies, and the products varied in quality. If there is a suspicion that the fuel pump is not working, you need to turn on the ignition on the VAZ-2112 - the pump should pump fuel for the first 1.5 seconds. But the sound of a running motor may not be heard. It would be better to measure the voltage at the terminals.

The following video shows how to check why the fuel pump is not working.

Fuel pump relay

The fuel pump relay is often mounted next to the fuel pump ground, that is, under the dashboard. A normally operating relay after turning on the ignition for a couple of seconds allows the pump to create pressure in the system and immediately turns off.

When the ignition key is turned, the driver hears a characteristic click (the relay is turned on), then a similar click will indicate that the fuel pump relay is turned off. If such clicks are not heard, this indicates a malfunction of the relay or its contacts. The optimal solution would be to replace the fuel pump relay with a new or known-good device. Let us add that the cost of spare parts is quite affordable.

What is a relay for?

Above we talked about the microcontroller system. It is worth noting that the output of the ECU does not allow direct connection of a powerful load. And the fuel pump, which is based on a DC motor, has quite a lot of power. And when it is turned on, a significant current consumption occurs. But if you turn on the VAZ 2110 fuel pump relay coil from the control unit, the injector will continue to operate in the same mode, and no excess current consumption will be observed.

Therefore, we conclude: a relay is a buffer cascade between the electronic control unit and the current consumer. However, most relays have precisely this purpose - they allow a very weak current to flow in the control circuit. In this case, the entire electrical system of the car is divided into two parts:

- Low-current control circuits.

- Power cables (connecting optics, fluid and fuel pumps, power windows).

The VAZ 2110 fuel pump relay is located on the right side, opposite the front passenger seat. There is an additional block designed for installing some elements of electrical equipment. It is quite possible that such a simple solution was caused by the reluctance of the designers to use other fuse blocks that would be very different from those installed on carburetor engines.

Diagnosis and Troubleshooting

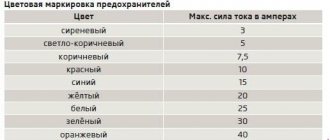

It is relatively simple to verify that the electrical network is faulty - this can be done without removing the fuel pump. When the sound of its operation is not heard when the ignition is turned on, you must immediately check the fuse responsible for this circuit. It is installed in a block mounted at the bottom in front of the front passenger seat. You need to remove the block cover, find the fuse marked F3, rated for 15 A, and replace it. This kind of work can be done on the road.

If the operation of the fuel pump has not resumed, you should switch your attention to relay K2, located in the same block. It closes the power circuit of the pumping device based on a signal from the controller. You can also check the serviceability of the relay in road conditions, for which you will need a piece of copper wire

Diagnostics are carried out in the following order:

You can also check the serviceability of the relay in road conditions, for which you will need a piece of copper wire. Diagnostics are carried out in the following order:

- Remove relay K2 from the connector.

- Turn on the ignition.

- Using a wire, connect the contacts marked “30” and “87”; the numbers are marked on the relay. Another option is to apply power to pin “11” located in the diagnostic connector. The +12 V voltage can be taken nearby, from the cigarette lighter.

- If you hear the pump humming, then you need to change relay K2.

If after the above manipulations the unit is still “silent”, it is necessary to check the integrity of the wiring and the reliability of the contact at the place of its connection. This will require a device, so it will not be possible to carry out such work in the middle of a field. Unless you can check the serviceability of the fuel pump itself by disconnecting the connectors from it and supplying 12 V directly from any convenient source. If the pump still does not hum, it should be replaced.

It will not be possible to diagnose insufficient fuel supply to the injectors under road conditions, unless you carry a pressure gauge with a corresponding hose for connection to the fuel rail. The amount of gasoline supplied is characterized by the pressure in the network, to measure which you will need a pressure gauge. The check is performed as follows:

- Twist off the plastic cap covering the diagnostic fitting. It is located at the end of the fuel rail and is a regular spool.

- Press the spool rod to release the pressure in the line. In case of gasoline leakage, place a small container under the spool. Perhaps the malfunction will make itself felt already at this stage if there is no pressure in the network and no fuel flows from the fitting.

- Unscrew the spool and put the hose from the pressure gauge onto the fitting. With the ignition off, apply 12 V directly to the pump. To clearly record the readings, it must work for at least 10 seconds.

If the pressure is below 3.6 bar, you must first change the coarse filter. If this does not help, then you will have to check the RTD and the tightness of the injectors. This is the only way to accurately determine the source of the problem.

Fuel pump electric motor

If checking the pressure in the fuel rail and the external wiring to the fuel pump gives positive results, then you should check the fuel pump motor. This electric motor is responsible for circulating gasoline inside the fuel pump.

When checking, you need to take into account that the terminals on the fuel pump themselves tend to oxidize, as a result of which power is not supplied and the pump does not pump. In this case, the motor is working, but the terminals need to be cleaned or re-soldered.

To check the fuel pump motor, you will need to attach the test lamp wires to a cleaned and serviceable terminal of the electric motor, after which you should turn on the ignition. If the light comes on, this will indicate that the fuel pump motor is not working.

Final check before replacing the starter

We turn the key to position II, and nothing happens... In this case, open the hood and remove the air filter by unscrewing the screw on the body and loosening the clamp on the pipe. The starter is located under the filter housing. In the photo we see the following: someone disconnected the solenoid relay cord.

What we found under the filter, we check with a needle probe that when you turn the key, “+12” appears. Then, after checking, we wrap the cord with electrical tape.

- The copper is polished to a shine;

- The wire (see photo) is supplied with “plus”;

- The starter doesn't even click.

The first thing you need to check is the battery contacts. We remove the terminals (key “10”) and look at what is under them. There is no point in measuring the voltage with a probe - it will show “12 Volts”.

Causes: fuse, relay, connector

The pump power circuit includes many elements: closed relay contacts 5, fuse 3 (15 A), “+” wire, “pump-to-ground” wire. The most “difficult” defect is a short circuit of the “+” wire to ground. By the way, the cord itself is laid on metal, so such a defect cannot be ruled out.

Mounting block for dashboard

Both the relay and the fuse are located in a block located under the dashboard on the right. A fuse can blow in two cases:

- The “+” cord makes contact with ground;

- The motor resistance decreases due to overheating.

The first defect may be “floating”, and then it will be difficult to identify. But before calling an electrician, try checking everything else:

- Relay 5 should click twice: when the ignition is turned on and after 1.5 s. If this does not happen, replace the relay;

- Check fuse 3. If it is blown, you need to look for the cause.

Consider the situation: the relay is working, but the fuse is blown. Then we do this: disconnect the pump connector, install a new fuse and measure the voltage at the terminals. Details are below.

Connectors under the hatch, disconnecting them

You need to remove the hatch under the rear seat: two screws are unscrewed with a Phillips screwdriver. Next you need to disconnect the connector on the module, and then move on to the block under the dashboard.

First, turn off the fuel pump!

Replace the fuse. Let's move on to the fuel pump: connect the probe (zero cord) to any of the mounting studs. Voltage should appear on the “gray” wire when the ignition is turned on. And also check the potential difference between the “gray” and “black” wires - it should be equal to 12 volts, and also at the moment the ignition is turned on. Wiring:

- The two outer cords are the FLS sensor;

- “Black” – minus power supply;

- "Grey" is a plus.

The "black wire" sometimes loses contact with ground. At the last step, we checked exactly this version.

There are reviews from owners that say: the fuel pump on a VAZ-2112 does not work if the electric motor is working properly and there is voltage in the connector. This happens when the contacts of the internal terminal block oxidize (see photo).

Internal connector - yellow

Getting to the connector on the motor is not easy - you need to remove the fuel pump module by unscrewing 8 nuts around the perimeter.

Diagnosing the fuel pump

Safety precautions

Before unscrewing the nuts, you need to disconnect the two hoses. But first try starting the engine. The power supply to the fuel pump is not connected.

Please note - the power is turned off here!

Everything is ready for dismantling if:

- External connector is disabled;

- It is impossible to start the engine, although the on-board network is not de-energized;

- It is better if the tank is filled less than 50%!

You need to unscrew two fittings from the module cover (top photo). Then use a socket wrench to unscrew the nuts from the studs and remove the retaining ring.

There is very little left to the internal connector

Having gained access to the internal connector, you need to clean its contacts. Assembly is carried out in reverse order. Good luck!

Common mistakes

You can use our instructions in one case: when the fuel pump does not work, but other systems are working properly. Sometimes the engine does not start for several reasons at once. And then you need to reduce the pressure like this: wait 5-6 hours, and do not turn on the ignition. Be careful!

Actually, the ramp is under pressure

You can find out about the presence of pressure in the standard way:

- Open the hood;

- There is a fitting on the fuel rail, closed with a plastic cap. It is turned away (photo 1);

- Using the nipple cap (photo 2) you can unscrew the fitting plug. This action is performed carefully: the residual pressure has not disappeared anywhere.

Even if gasoline starts to gush out, do not try to tighten the fitting right away. Let the pressure drop a little.

Diagnostic connection and plug

Trying to fix a fuel pump is commendable. It will be possible to change its mesh. But the cause of the problem may also be a clogged fine filter.

The replacement filter (“can” 2112-1117010) gradually fails. On all fuel-injected cars, including the VAZ-2112, the fuel pump will not stop working even if the filter is completely clogged. Fuel is not pumped, but the engine does not burn out.

The fuel pump sounds and pumps - does that mean everything is in order?

A radical test measure is to connect the battery to the connector. The module itself must be in the tank! A working pump operates quietly. If the motor is humming, it’s time to change the fuel pump; if it’s ringing, find the cause and fix it.

Replacing a mechanical fuel pump

Unscheduled replacement of a mechanical type device takes place in the following order:

- We dismantle the air purification filter.

- Remove the fuel supply line to the fuel pump.

- First loosen the tightening of the clamp.

- Remove the fuel supply line to the carburetor.

- Unscrew the fasteners of the product.

Installation is in the reverse order. At the same time, do not forget to look at the arrows on the products showing the direction of movement of fuel to the carburetor.

The question is often asked, how to check the VAZ 2110 unit in operation? To do this, it is necessary to tighten the screws on the cover with the pump lever depressed and test the carburetor accelerator pump.

Problems with the starter VAZ 2110 VAZ (2111, 2112)

+1″>When the starter is turned on, the armature does not rotate, the traction relay does not operate

The battery is faulty or completely discharged. Charge the battery or replace it.

The battery terminals and wire tips are heavily oxidized; lugs are loosely tightened Clean the pole terminals and wire lugs, tighten and lubricate with Vaseline

Interturn short circuit in the pull-in winding of the traction relay, its short circuit to ground or open circuit

Replace the traction relay Open circuit in the power supply circuit of the starter traction relay Check the wires and their connections in the circuit between plugs “50” of the starter and the ignition switch

The contact part of the ignition switch is faulty: contacts “30” and “50” do not close. Replace the contact part of the ignition switch.

The armature of the traction relay is stuck. Remove the relay, check the ease of movement of the armature.

+1″>When the starter is turned on, the armature does not rotate or rotates too slowly, the traction relay is activated

The battery is faulty or discharged. Charge the battery or replace it.

The battery terminals and wire tips are oxidized; lugs are loosely tightened Clean the pole terminals and wire lugs, tighten and lubricate with Vaseline

The lugs of the wire connecting the power unit to the body are loose. Tighten the lugs of the wire.

The contact bolts of the traction relay are oxidized or the nuts securing the wire tips on the contact bolts are loose. Clean the contact bolts, tighten the nuts securing the wires

The commutator is burning, the brushes are stuck or worn out. Clean the commutator, replace the brushes.

Break or short circuit in the armature winding Replace the armature

+1″>When the starter is turned on, the traction relay is activated and switched off repeatedly

Battery is low Charge the battery

Open circuit or short circuit in the holding winding of the traction relay Replace the traction relay

Large voltage drop in the power supply circuit of the traction relay due to severe oxidation of the wire tips. Check the wires and their connections in the circuit from the battery to the “50” plug of the starter.

+1″>When the starter is turned on, the armature rotates, the flywheel does not rotate

Freewheel slipping Check the starter on the stand, replace the clutch

Reducer gears are damaged Replace damaged gears

+1″>Unusual starter noise when rotating the armature

Excessive wear of the armature and drive shaft bearing shells. Replace the shells or covers and supports with shells.

The starter is loose or its cover on the drive side is broken. Tighten the fastening nuts or replace the starter.

The starter is attached incorrectly. Check the starter fastening.

Reducer gears are damaged Replace damaged gears

The teeth of the drive gear or flywheel ring are damaged. Replace the drive or flywheel.

The gear does not disengage from the flywheel: – the clutch is stuck on the splines of the drive shaft – the armature of the traction relay is stuck Do the following: – clean the splines and lubricate them with engine oil – replace the traction relay or eliminate the jam

Problems related to the fuel pump

So, you need to analyze several symptoms of the main breakdowns of the dozen injection systems. If the VAZ 2110 fuel pump activation relay is faulty, then when you turn the ignition key you will not hear the characteristic hum that comes from the rear of the car. It is quite possible that there has been a break in the power supply circuit of the winding of the electromagnetic device. Check if there is voltage on it. It is possible that the fuse may fail. Please note that if fuses burn one after another, you should not spend money on buying new ones, but look for the reason for this behavior.

If fuses constantly fail, then there is a short to ground in the connectors or wiring. Moreover, you need to look in that part of the circuit that is located after the protection device. It is also possible that everything is fine with the wiring, the relay works, but the VAZ 2110 fuel pump does not pump. The reason is a lack of power or a breakdown of the engine itself. Among the latter, we can highlight breaks in the rotor and stator windings and wear of graphite brushes. And one more thing I would like to highlight: monitor the condition of the filter (diaper), which is located at the bottom of the fuel pump. If it is in poor condition, then the injectors may become clogged and the motor may fail.

Final check before replacing the starter

We turn the key to position II, and nothing happens... In this case, open the hood and remove the air filter by unscrewing the screw on the body and loosening the clamp on the pipe. The starter is located under the filter housing. In the photo we see the following: someone disconnected the solenoid relay cord.

What we found under the filter

Using a needle probe, we check that when you turn the key, “+12” appears. Then, after checking, we wrap the cord with electrical tape.

- The copper is polished to a shine;

- The wire (see photo) is supplied with “plus”;

- The starter doesn't even click.

The first thing you need to check is the battery contacts. We remove the terminals (key “10”) and look at what is under them. There is no point in measuring the voltage with a probe - it will show “12 Volts”.

Starter malfunctions and reasons for their occurrence

The unit does not spin the flywheel due to many factors. Below we will discuss defects in the immobilizer, pull-out relay, injector, as well as in the car wiring. Sometimes repairs are not enough, in which case the device needs to be replaced.

Faulty injector

The standard version of the VAZ 2110 is not equipped with injectors, but they can be supplied separately. Drivers choose these devices for many reasons: reduced fuel consumption, no need to warm up the engine in cold weather, increased power characteristics.

Article on the topic: We eliminate damage to the front and rear side lights on a VAZ 2114

The arrow points to the starter relay

If the starter is not working well, then you need to check the injector, which may be acting up due to bad gasoline. This is the only drawback of the injector - it requires high-quality fuel. It is also worth checking whether the connection diagram is followed.

Overrunning clutch failure

If the overrunning clutch breaks, the engine starts and runs perfectly. But when the car stops, the engine cannot be restarted; it clicks but does not start. In this case, you need to wait until the power plant has cooled down, and only then try to start it.

Also in this case, it is worth inspecting the wiring that comes from the coupling. Sometimes replacing damaged wires can solve a problem where the engine clicks but won't start. Another sign of a faulty clutch is the radio turning on spontaneously.

Solenoid relay

Once behind the wheel, the driver inserts the key and turns it, the fuel pump starts working, the dashboard lights up, but when turning further, the pump and the panel turn off, and the starter does not turn. In such a situation, the solenoid relay is most likely to blame.

Removing the solenoid relayFirst of all, you need to check whether there is voltage going to it. If it does, then it’s worth checking the lock itself or the alarm system, which may close the circuit. If all the elements work separately and do not start together, then the starter does not turn due to the solenoid relay.

Article on the topic: Independent replacement of the front and rear crankshaft oil seals on a VAZ 2110

Poor contact

In this case, the starter starts after several attempts, but it still clicks. This problem occurs due to damaged contacts. The inspection should begin with the battery. If the terminals are oxidized, you need to clean them.

If this does not help, then you should check the starter contacts, because when they are oxidized, the device turns poorly or does not start the crankshaft at all. If the starter refuses to work, but the immobilizer is running, then there is a malfunction in it. Here you won’t be able to remove the defect yourself - you need to go to a car service center. Now readers know how much it costs and why the starter does not work; it is worth doing the work yourself only if you have experience working with wiring.

Other causes of fuel pump malfunctions

Quite often, unprofessional installation of additional electrical equipment or security anti-theft systems leads to the fact that the power to the fuel pump is lost due to mixed up contacts or other connection errors. Also, one should not exclude the possibility that a malfunction occurred in the car alarm or security system, after which the power supply to the fuel pump is blocked. In other words, the alarm blocks the engine from starting.

The gas pump in the gas tank is immersed in gasoline, in which it is actively cooled. The habit of driving with an empty tank can quickly damage the electric motor of the fuel pump, as it burns out.

Safety precautions

Before unscrewing the nuts, you need to disconnect the two hoses. But first try starting the engine. The power supply to the fuel pump is not connected.

Please note - the power is turned off here!

Everything is ready for dismantling if:

- External connector is disabled;

- It is impossible to start the engine, although the on-board network is not de-energized;

- It is better if the tank is filled less than 50%.

You need to unscrew two fittings from the module cover (top photo). Then use a socket wrench to unscrew the nuts from the studs and remove the retaining ring. There is very little left to the internal connector. Having gained access to the internal connector, you need to clean its contacts.

Oxidation of the terminals of the internal connector is a typical disease of the VAZ-2112 fuel pump, and only one of the contacts does not work. The “+” terminal is more often oxidized.

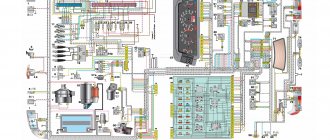

Electrical diagram of a VAZ 2112 car

Electrical diagram of VAZ 2112 - general diagram of connecting electrical equipment and instruments, engine control unit and fuses. When servicing and repairing the engine management system of this and other VAZ family vehicles, always turn off the ignition. When carrying out welding work, disconnect the controller from the wiring harness. The controller contains electronic components that can be damaged by static electricity, so do not touch its terminals with your hands. With the engine running, do not disconnect or adjust electrical connectors.

The Lada Kalina fuel pump does not pump and does not work. Reasons, signs

Sooner or later, any car enthusiast is faced with the fact that the gasoline pump of the Lada Kalina fails. Some people immediately go to a car service center, but there are also those who try to fix the problem with their own hands. This procedure cannot be called easy, but it is quite possible to do it yourself.

Lada Kalina fuel pump repair video

https://youtube.com/watch?v=7xPJSUReJKg

The video shows the process of repairing and diagnosing the Lada Kalina fuel pump, as well as some recommendations.

Main signs of fuel pump malfunction and diagnostics

Gasoline pump Lada Kalina

Before proceeding with repairs, it is necessary to determine whether the fuel pump is faulty. There are direct and indirect factors that indicate this. So, let's look at the main signs of a malfunctioning gasoline pump on Kalina:

- Poor engine start when cold.

- The car moves jerkily.

- The motor does not start.

- Insufficient pressure in pipelines.

All these reasons may mean that the fuel pump needs repair or replacement.

Removing the fuel pump

Before you begin removing the Kalina fuel pump, you need to assemble the tools. To carry out this operation you will need: pliers and a screwdriver. So, let's get straight to the process:

- Disconnect the “minus terminal” from the battery.

- Relieve the pressure in the system.

- We dismantle the rear seat sofa.

- Under the carpet we find a hatch from which you need to unscrew the 4 fastening bolts.

Under the rear seat and carpet there is a panel that covers the Kalina's fuel pump. - Disconnect the fuel pump wiring connector.

- Disconnect the fuel hoses.

By pressing the block you can disconnect the fuel hosesDisconnect the inlet and outlet fuel hoses of the Lada Kalina

- Unscrew the fuel pump mounting plate counterclockwise.

The place where the fastening ring should be so that the fuel pump can be pulled out - Once in a certain groove on the body, you can remove the gasoline pump from the fuel tank.

- Installation is carried out in reverse order.

Now the fuel pump has been dismantled and you can begin troubleshooting and repairs.

Repair operations

Before you begin repairing the fuel pump on Kalina, it is worth noting that you need to be 100% sure that this is where the problem lies. If you are not sure, then it is worth checking all other systems, since it is not recommended to disassemble it unless absolutely necessary.

It is also worth noting that repairing this unit should be done slowly and carefully, since the part is fragile and careless movement can only cause harm. So, let's consider the sequence of disassembly and repair processes:

- Use a screwdriver to pry up the drain module and disconnect it.

- Disconnect the ground wire from the pump.

- From the inside we disconnect the intermediate wire connector.

Clogged fuel pump screenThe working part of the Kalina fuel pump

Internal view of the fuel pump housing

Use a screwdriver to pry up the ring and turn it clockwise

- We dismantle the pressure regulator.

- We press the plastic retainer and remove the fuel pump module.

- We remove the filter mesh from the housing.

- We reassemble in reverse order.

Fuel pump mesh for Kalina fuel pump

If during disassembly we identified parts that need to be replaced, then we replace them.

Selecting a fuel pump

If the fuel pump stops showing signs of life, it must be replaced. To select, you need to know the catalog number.

The original article number of the Lada Kalina fuel pump is 1118-1139009. There is also an analogue from the manufacturers Master-sport (1118-1139009-PCS-MS) and Pekar (1118-1139009).

Replacing and repairing the Lada Kalina gasoline pump is quite easy compared to what it seems at first. You can carry out this operation yourself in your garage, if you have a screwdriver and pliers. If the fuel pump is completely out of order, you can easily find a new one. As practice shows, car enthusiasts install the original part.

Causes: fuse, relay, connector

The pump power circuit includes many elements: closed relay contacts 5, fuse 3 (15 A), “+” wire, “pump-to-ground” wire. The most difficult defect is a short circuit of the “+” wire to ground. By the way, the cord itself is laid on metal, so such a defect cannot be ruled out.

Both the relay and the fuse are located in a block located under the dashboard on the right. A fuse can blow in two cases:

- The “+” cord makes contact with ground;

- The motor resistance decreases due to overheating.

The first defect may be “floating”, and then it will be difficult to identify. But before calling an electrician, try checking everything else:

- Relay 5 should click twice: when the ignition is turned on and after 1.5 s. If this does not happen, replace the relay;

- Check fuse 3. If it is blown, you need to look for the cause.

Consider the situation: the relay is working, but the fuse is blown. Then we do this: disconnect the pump connector, install a new fuse and measure the voltage at the terminals. Details are below.

Fuel pump fuse

During diagnostics, be sure to check the fuel pump fuse. The specified 15 A fuse is usually located in the fuse box in the engine compartment and is marked FUEL PUMP, which means fuel pump.

The fuel pump fuse needs to be pulled out and its contact inspected. The integrity of the contact will indicate that the device is normal. A damaged contact will indicate that the fuel pump fuse has blown. In this case, you need to install a new fuse, which has a very low cost (as in the situation with the fuel pump relay).

How to check the fuel - air system of a VAZ 2110

Another reason why the VAZ 2110 will not start may be a faulty supply of the fuel-air mixture to the car’s engine. In the air supply system, malfunctions occur extremely rarely and boil down to either a tightly clogged air filter or a blockage of the air channel by a foreign object. Such malfunctions are unlikely to occur on a well-maintained personal vehicle. But if the car is, for example, a service car or recently purchased, it would be a good idea to make sure that the filter is intact and that there is no rag stuck in the channel after a recent repair.

The engine fuel supply system is controlled by an electronic control unit, which, in turn, regulates the fuel-to-air ratio based on readings from the mass air flow sensor (MAF) and the throttle position sensor. If both of them are faulty, it is not surprising that the VAZ 2110 does not start.

Diagram of the fuel air system of the VAZ 2110

Next, it’s worth checking the condition of the air filter, since this is the easiest thing to do. And, if none of the above steps help, you need to check the pressure in the system created when the fuel pump operates. Connect a pressure gauge to the diagnostic fitting of the fuel rail and measure the pressure. Its low level indicates a clogged pump filter, and its high level indicates a gearbox malfunction.

The normal pressure level directly depends on the type of engine installed in the VAZ 2110 car:

- the limit from 284 to 325 kPa is normal for engines of type 2111, 2112;

- the limit from 364 to 400 kPa is normal for engines type 21114, 21124.

By the way, the serviceability of the fuel pump can also be determined by disconnecting the main gas supply hose to the ramp and pumping gasoline through it into a clean container. A working pump will pump at least 1.5 liters in a minute. fuel.

Also listen to the starter. Does the main electromagnetic relay turn on with a characteristic click and does the electromechanical drive of the unit work at all? Despite the fact that the design of the starter is extremely simple, the electrical contact on it can easily be lost or the gearbox can fail. In the latter case, a characteristic creaking or whistling sound will be heard.

If the starter does not rotate, you should remove it from under the hood of the car. This process will not take much time, just like disassembling the block itself. It is worth checking the serviceability of the electrical part using a multimeter, “ringing” the windings, and disassembling the gearbox. A large amount of lubricant in it in the cold season does not allow the starter to rotate.

If everything has been checked, but the fuel pump does not work - article numbers

In general, the pump article number for VAZ-2112 engines looks like this: 21102-1139009-XX. Instead of the letters XX there are numbers, for example 02 or 03. They indicate the manufacturer. So, modules from different factories are not interchangeable! The resistance of the FLS resistor is different in them. However, when replacing the FLS sensor, you can borrow it from the “old” module. That's what they usually do.

Until April 2002, article numbers of the type 2112-1139009 were used.

Almost every module available for purchase contains a built-in pressure regulator. There are also exceptions - KSZC-A243, for example. The meaning is as follows:

- All internal combustion engines with a volume of 1.5 liters are equipped with a ramp with an “external” regulator (2112-1160010);

- The 21124 or 21114 motor requires a built-in regulator.

In conjunction with 1.5 liter engines, you can use any module – both with and without a built-in regulator.

Designations of analogues

- 21102-062213.0XX – instead of the letters XX there will be a plant designation (07, 13, etc.);

- KSZC-A233 or A243 – KSZC brand. No pressure regulator .

What to do Lada Kalina won't start

Stylish crossover Kalina

A lot of time has passed since AvtoVAZ announced the launch of a new project called Lada Kalina. Grandiose advertising and hope for a bright future did their job: millions of Russians, out of patriotic feelings, decided to choose the domestic Kalina, discarding numerous projects by Renault, Volkswagen and other factories positioning reliability and quality. But the joy was short-lived.

Already in the first months, Kalina did not show her best side, showing a capricious disposition. And it turned out that Kalina’s owners began to spend more time in the garage doing repair work than on trips. Engineers know their shortcomings and try in every possible way to get rid of them in each next generation of cars, to come up with something to increase the reliability of the car.

But for some reason the results are still little noticeable. As before, the car cannot please you with its endurance and wear resistance. The most unpleasant problem is that Kalina does not start from time to time. To return the machine to working order, it is necessary to find out the causes of the malfunction, and there are many of them. So, let's try to figure out why the Lada won't start.

Repair work

On a carburetor VAZ 2110 it is easier to replace the fuel pump if necessary. It is located under the hood and is not difficult to get to. It is enough to disconnect the pipelines, then unscrew the pump itself.

The electric fuel pump installed on an injection machine is located directly in the gas tank, so it is more difficult to get to it; this is done from the passenger compartment by removing the rear seat.

All fuel pumps are dismountable. After removing the cover, the mesh is removed and its condition is assessed. Of course, you can wash it, but it’s even better to replace it right away. Before starting repairs, you should purchase a repair kit, which must be equipped with a mesh.

What kind of fuel pumps are installed on VAZ 2110/2112 cars

The fuel pump is considered the most important element of the fuel system of any car. So, depending on what type of engine the VAZ 2110/2112 model is equipped with, the choice of fuel pump will also depend. An electric pump is installed on injection cars, and a mechanical one on carburetor cars.

The family is equipped with fuel pumps produced by AvtoVAZ. However, these units do not have a high service life and reliability, so often car owners do not wait until the fuel pump fails and replace it.

Installed at the factory on every VAZ 2110/2112 model

Most often, fuel pumps (Russia) and “Bosch” (Germany) are chosen for replacement. Their quality and durability have been known for a long time, although their cost is several times higher than the price of AvtoVAZ gasoline pumps.

The German manufacturer ensures the quality and durability of the products

It’s worth mentioning separately about the location of the fuel pump in the VAZ 2110/2112: the device is not located under the hood. To achieve maximum optimization of the fuel pump, manufacturers install it directly into the fuel tank. That is, to get to the pump, you will need to fold back the cushion in the back seat of the car and open the hatch hidden under the carpet.

The fuel tank and fuel pump are located under the seat cushion.